Patents

Literature

36results about How to "Effect separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

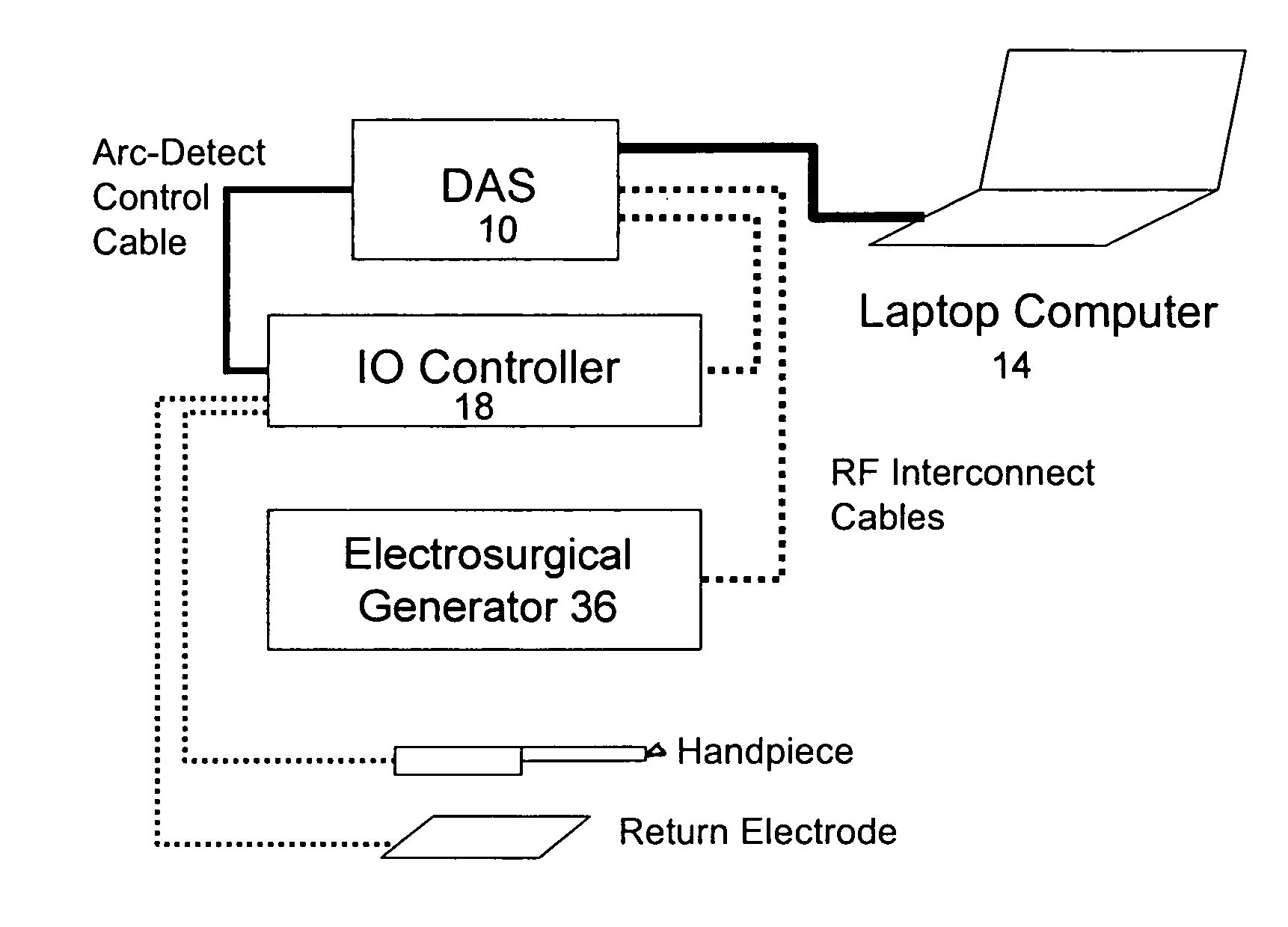

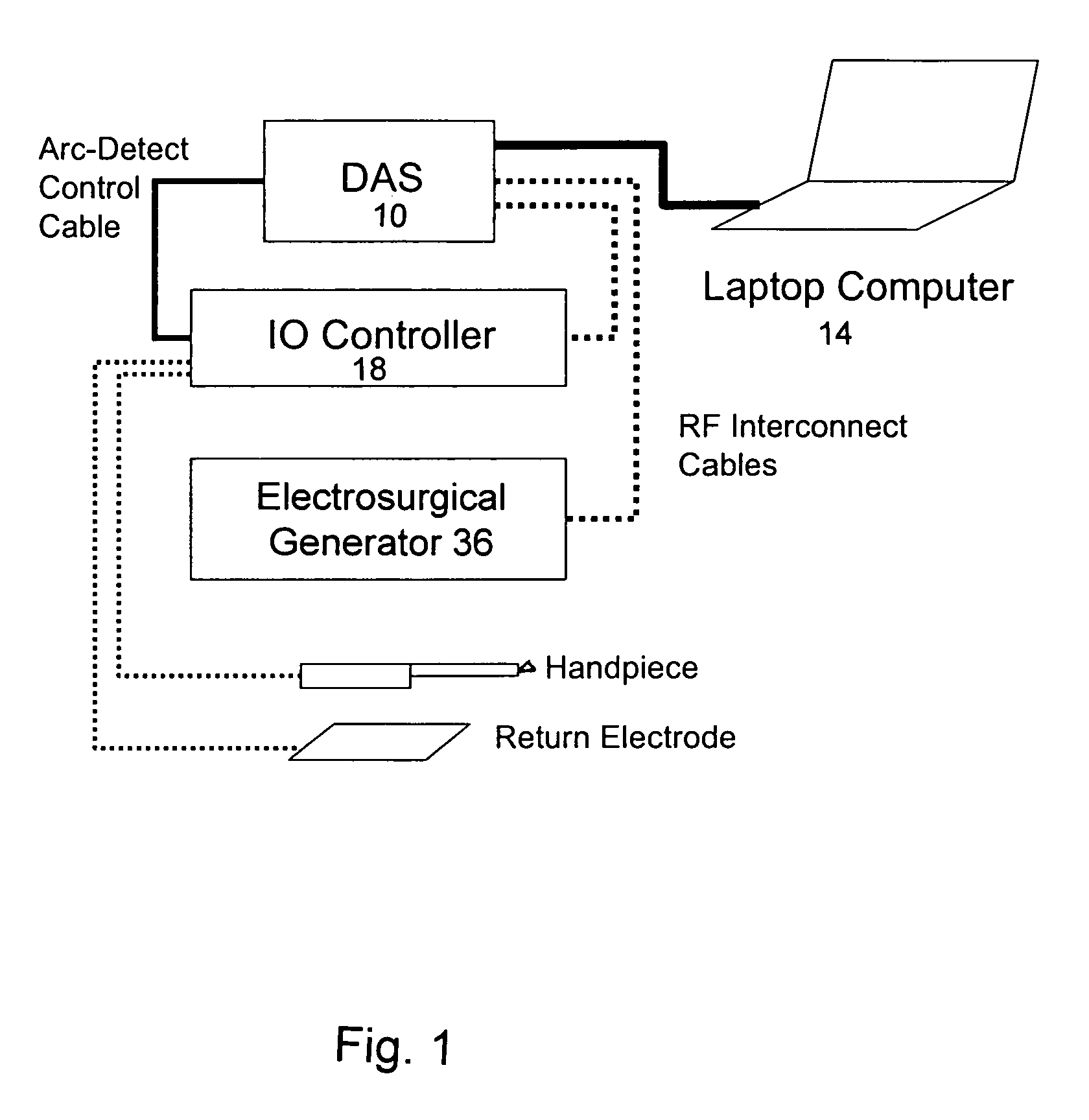

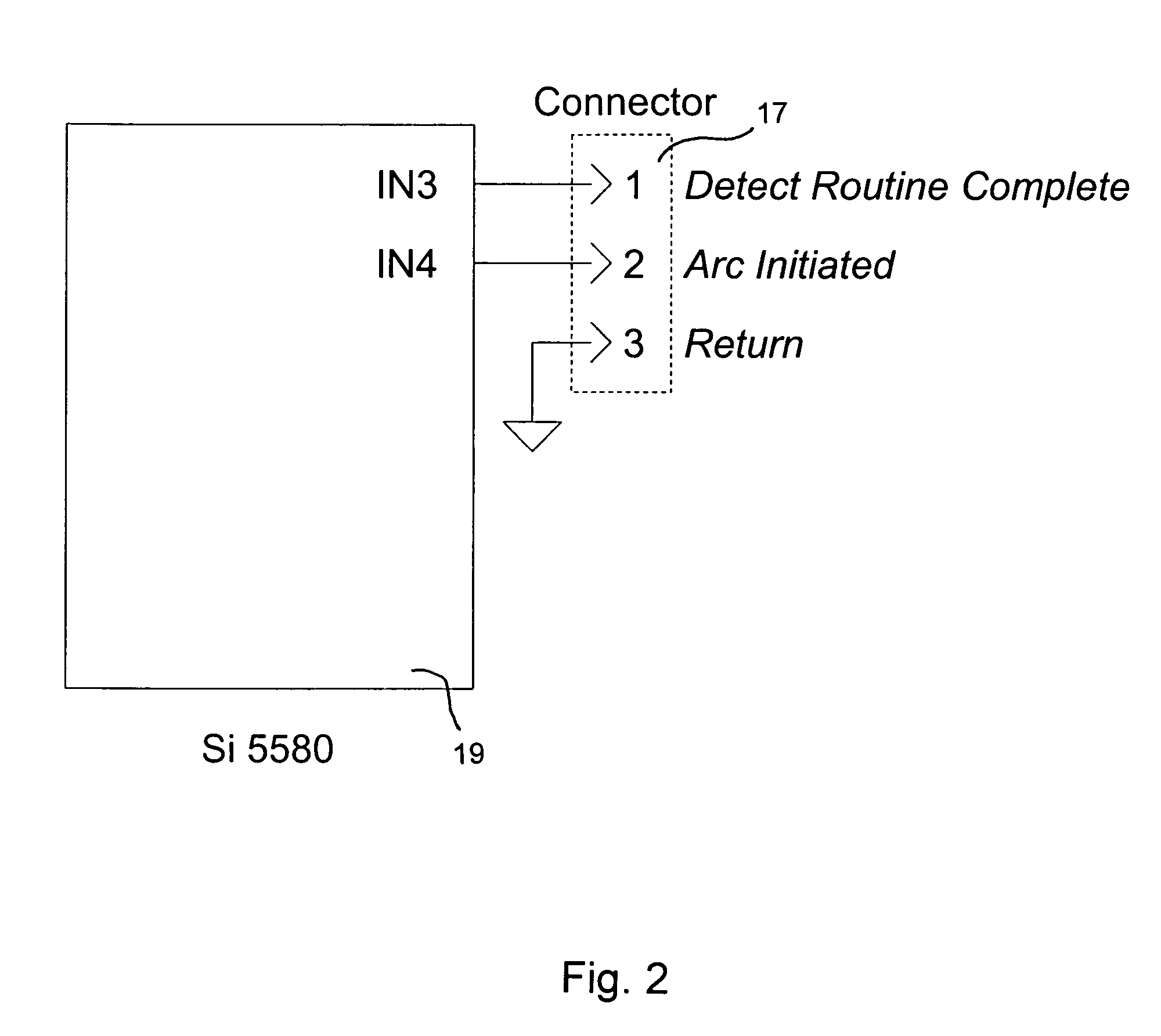

Devices and methods for controlling initial movement of an electrosurgical electrode

ActiveUS7060063B2Effect separationCatheterSurgical instruments for heatingData acquisitionBiomedical engineering

An electrosurgical electrode assembly having a cutting device including a catheter with a proximal and distal end, and an electrode carried on the distal end of the catheter. A controller is connected to the cutting device. A data acquisition system is connected to the controller and is capable of monitoring voltage and current output. A microprocessor may also be connected to the data acquisition system for processing voltage and current data from the data acquisition system. A generator is also connected to the data acquisition system. The controller initiates movement of the electrode upon arc initiation at the electrode. Methods of using the devices herein are also disclosed.

Owner:CILAG GMBH INT

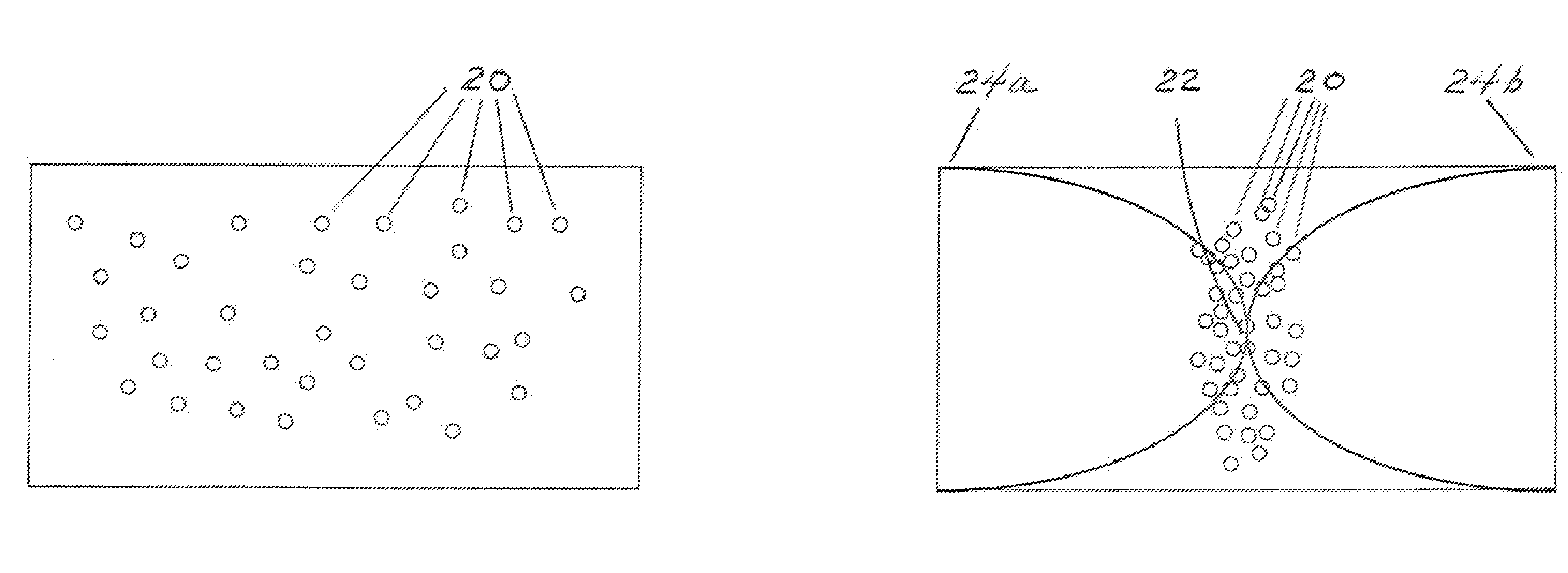

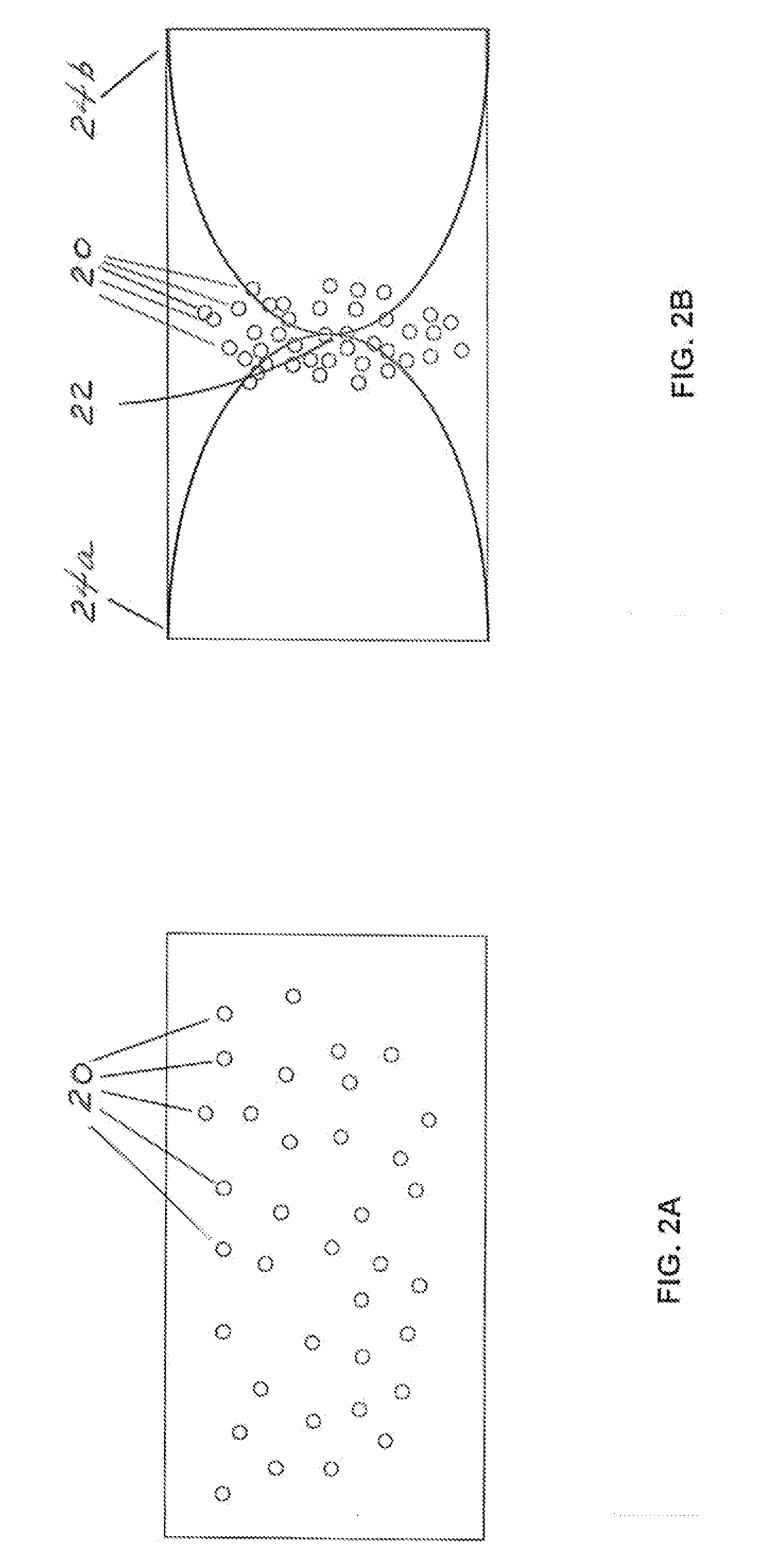

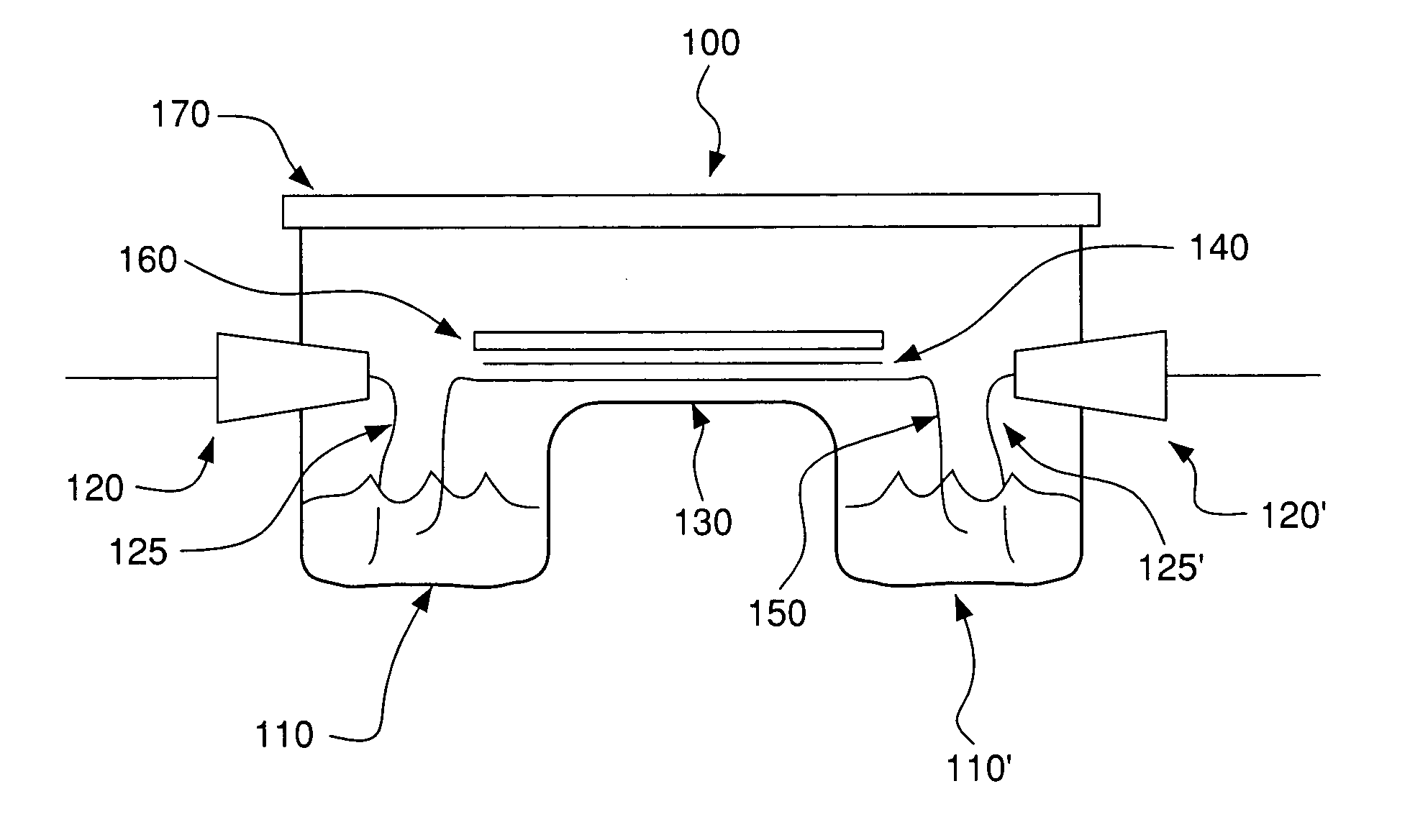

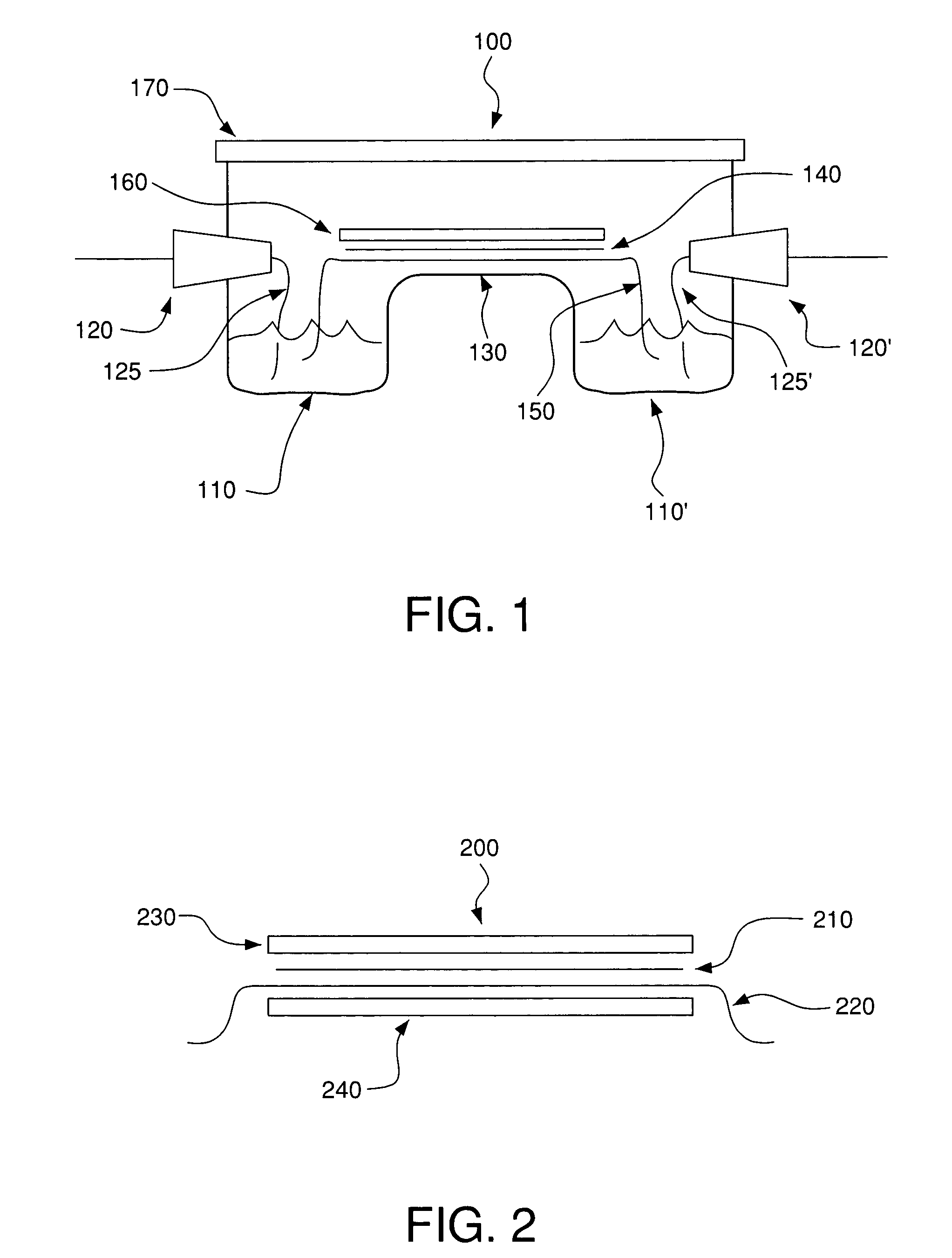

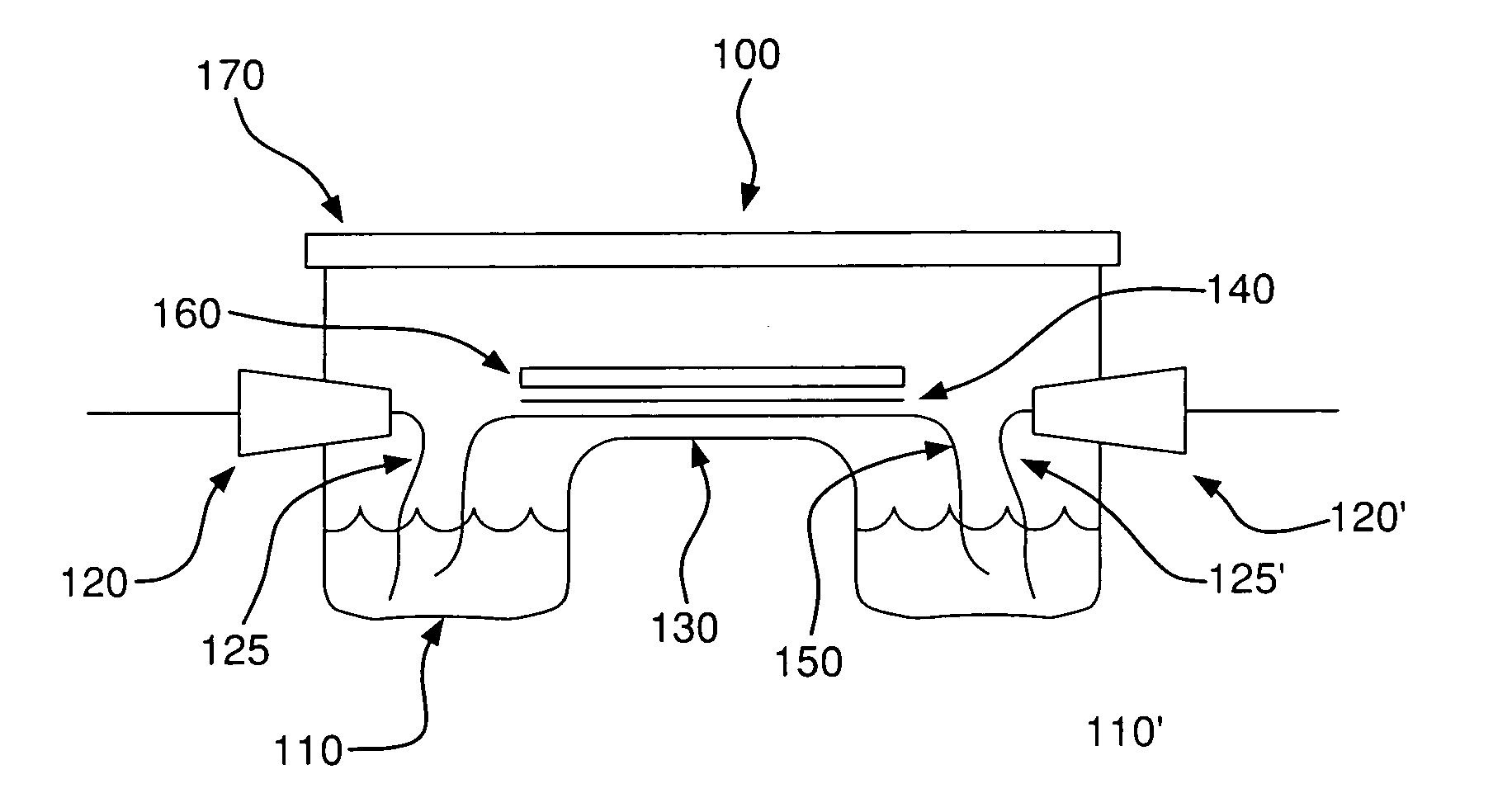

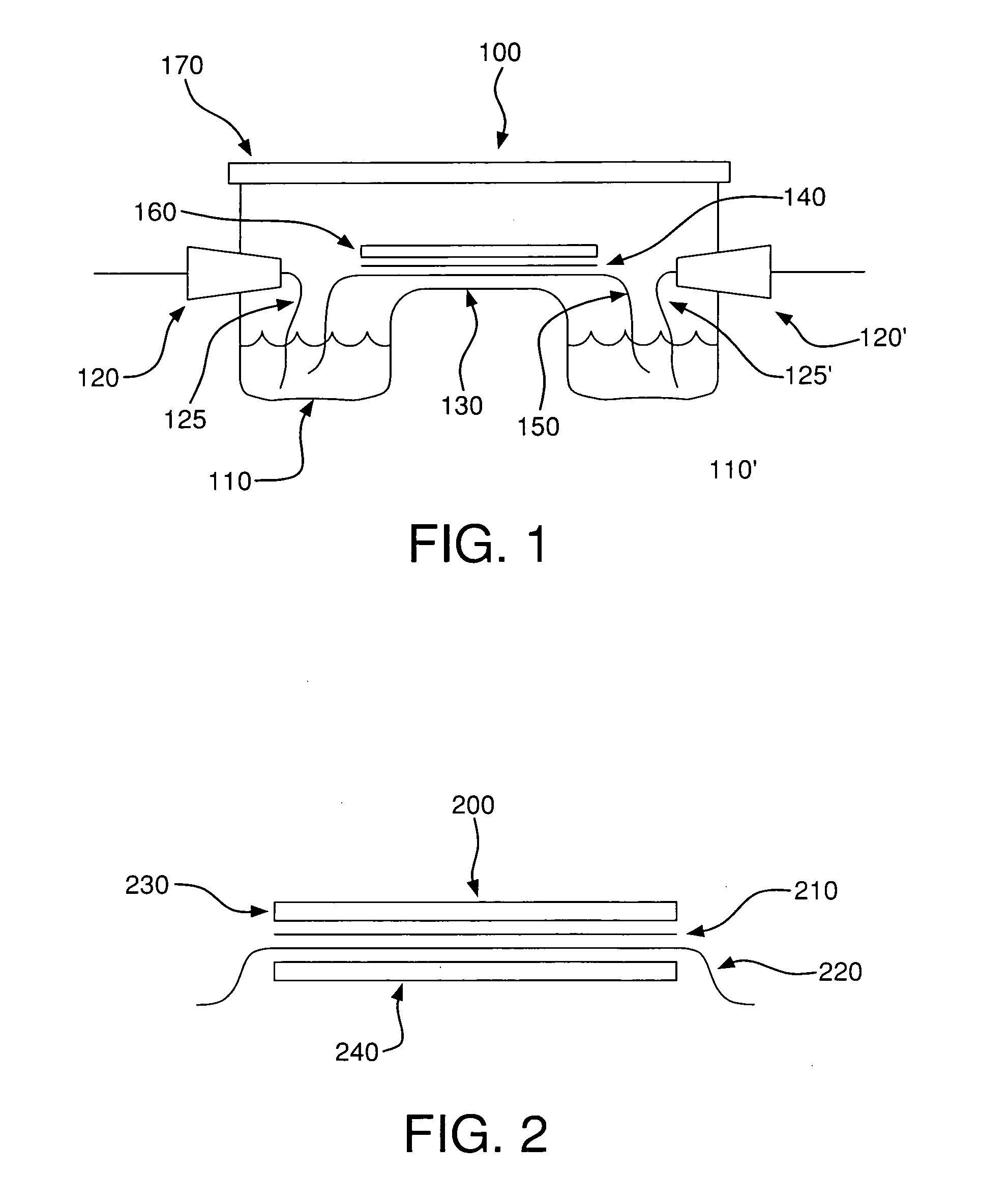

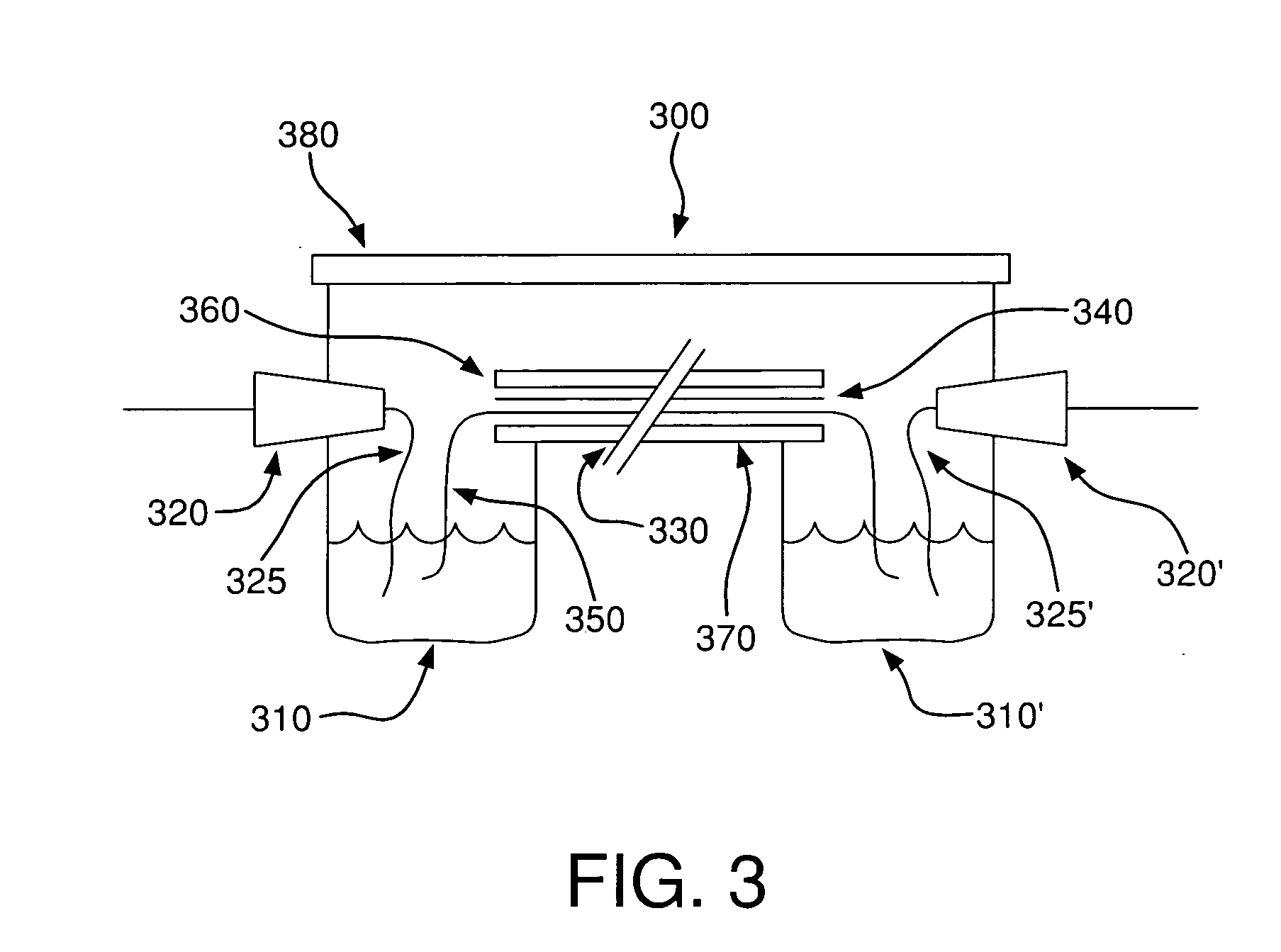

Apparatus and method for separation of particles suspended in a liquid from the liquid in which they are suspended

InactiveUS20100078384A1Improve concentrationAvoid turbulenceSemi-permeable membranesLiquid separation by electricityUltrasonic sensorCompressibility

A method for separating, or removing, particulate material, e.g., blood cells, from a sample of fluid, e.g., whole blood of a patient, in which the particulate material is suspended. In the case of separating blood cells from blood plasma or blood serum, the resulting samples of blood plasma or blood serum can be used for in vitro diagnostic applications. In normal practice, a whole blood sample of a patient are provided and then introduced into an apparatus that contains a flow channel. An acoustic field, which contains acoustic standing waves from external ultrasonic transducers, is located within the flow channel. Laminar flow is maintained in the flow channel. Blood cells and platelets are separated from blood plasma or blood serum at the end of the flow channel and collected. The method described herein allows fluid components to differentially migrate to areas of preferred acoustic interaction. The parameters that affect separation of particles are size, density, compressibility of the particles, and the fluid surrounding the particles.

Owner:ABBOTT LAB INC

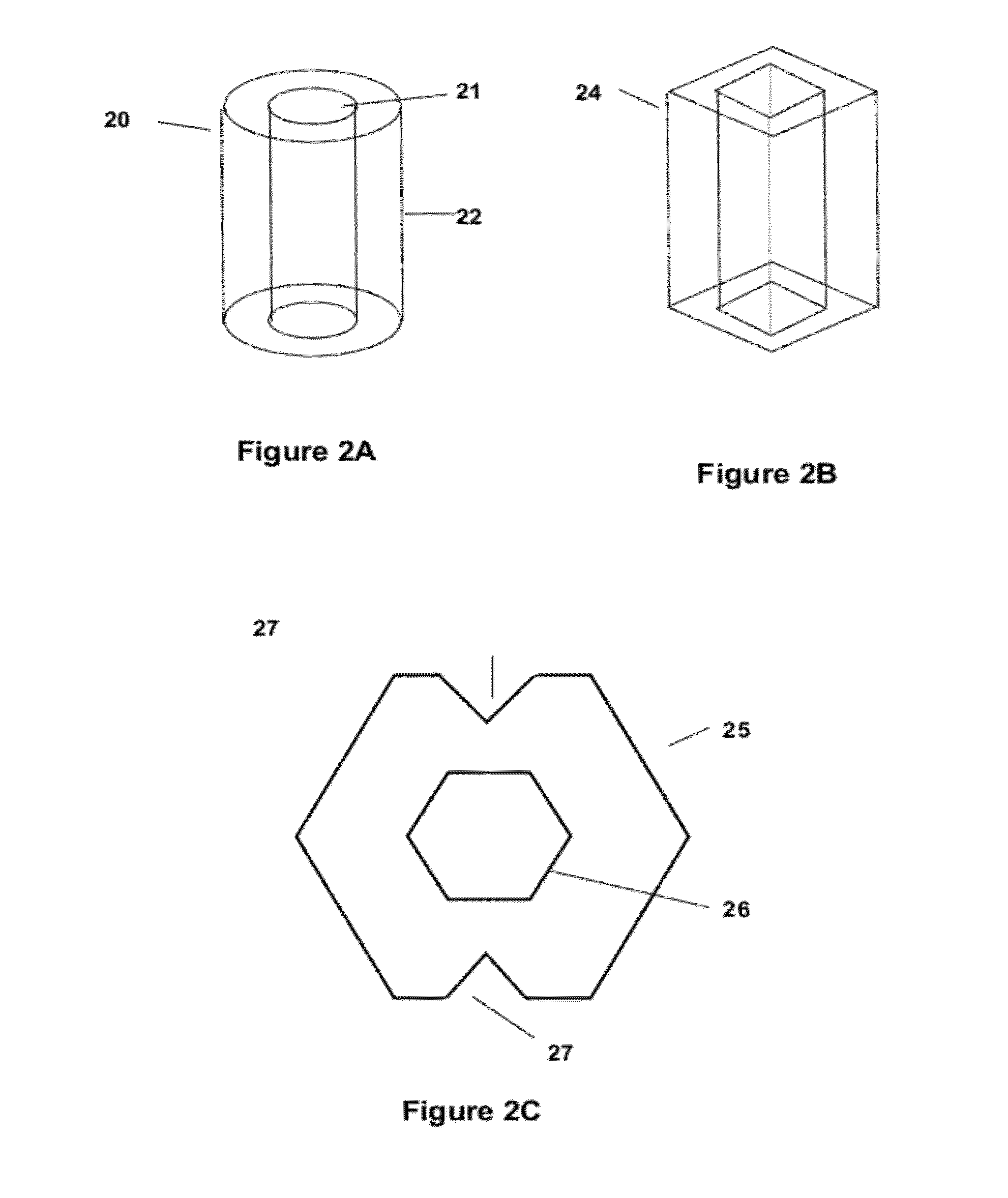

Gas Purification Process Utilizing Engineered Small Particle Adsorbents

ActiveUS20120222555A1Great diffusion rateLower Level RequirementsCarbon compoundsSulfur compoundsParticulatesSorbent

A gas separation process uses a structured particulate bed of adsorbent coated shapes / particles laid down in the bed in an ordered manner to simulate a monolith by providing longitudinally extensive gas passages by which the gas mixture to be separated can access the adsorbent material along the length of the particles. The particles can be laid down either directly in the bed or in locally structured packages / bundles which themselves are similarly oriented such that the bed particles behave similarly to a monolith but without at least some disadvantages. The adsorbent particles can be formed with a solid, non-porous core with the adsorbent formed as a thin, adherent coating on the exposed exterior surface. Particles may be formed as cylinders / hollow shapes to provide ready access to the adsorbent. The separation may be operated as a kinetic or equilibrium controlled process.

Owner:EXXON RES & ENG CO

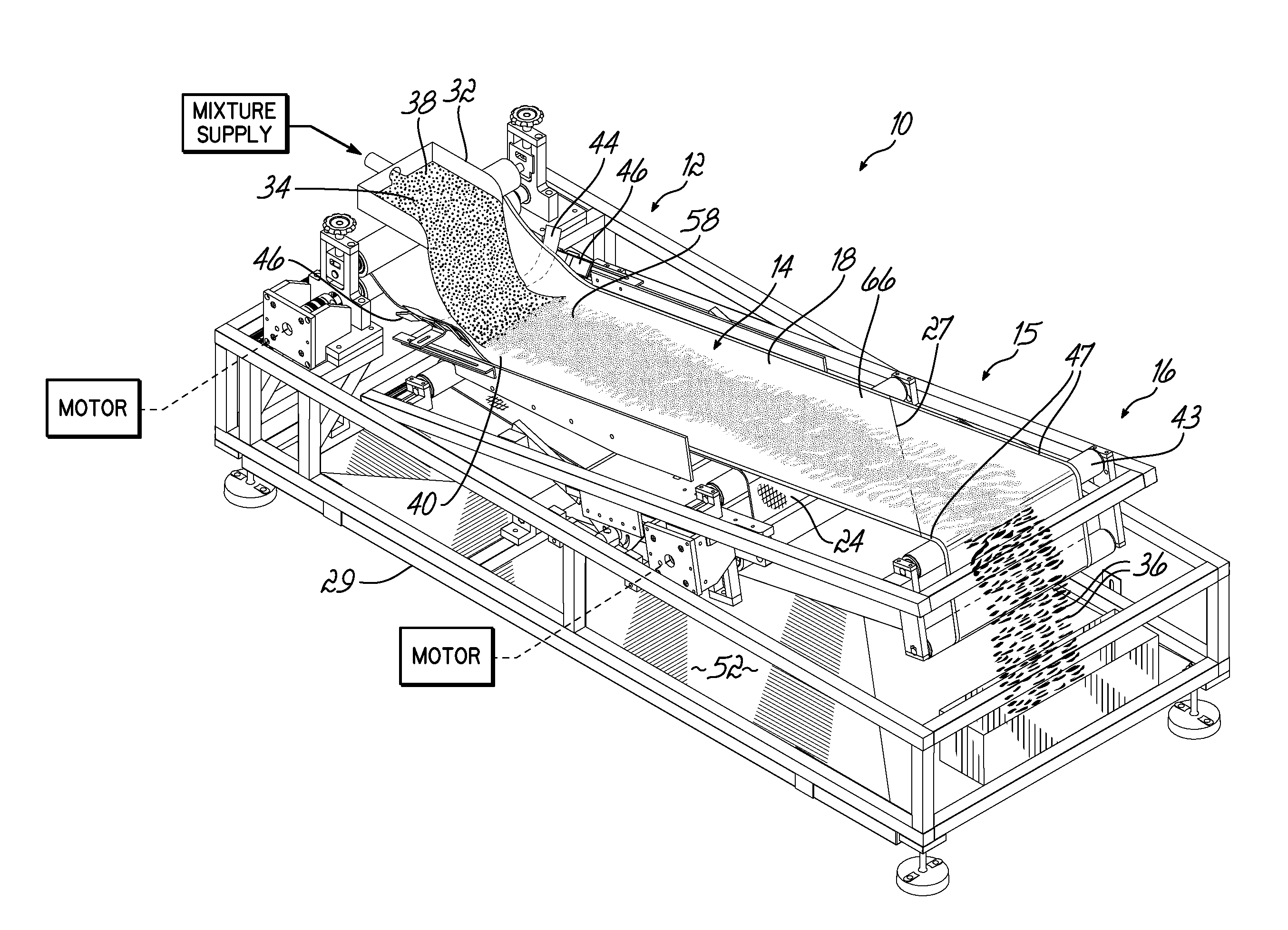

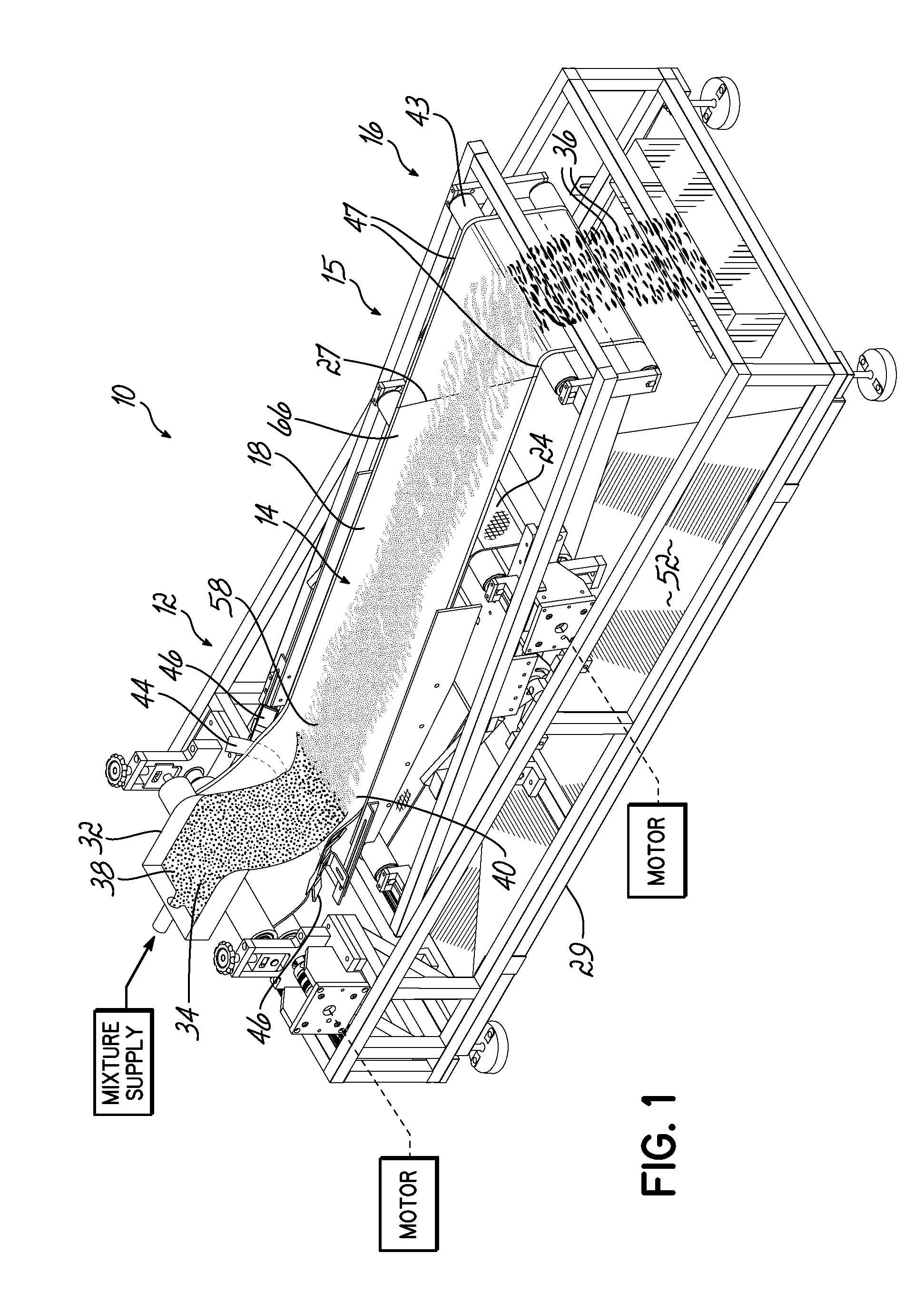

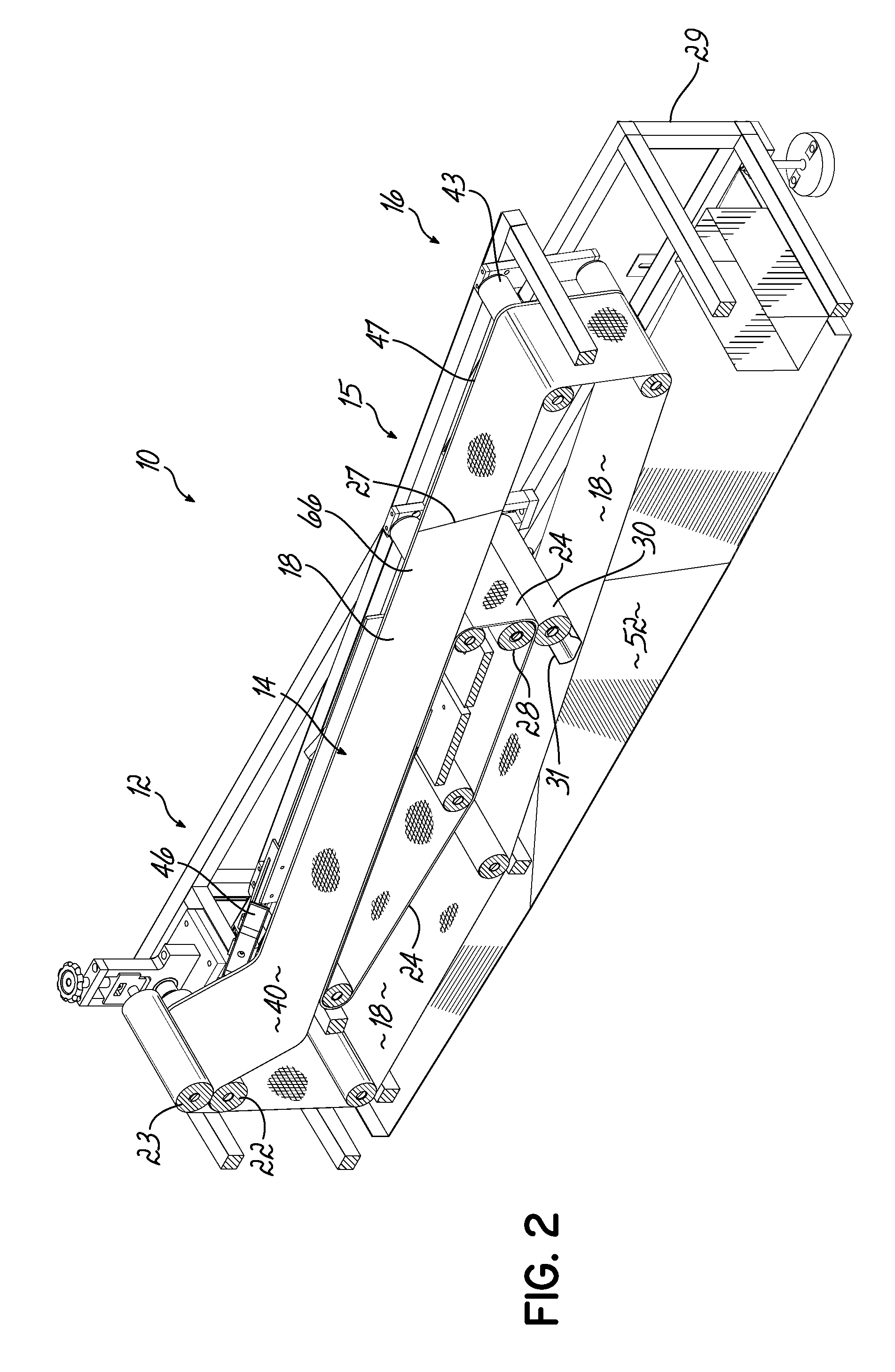

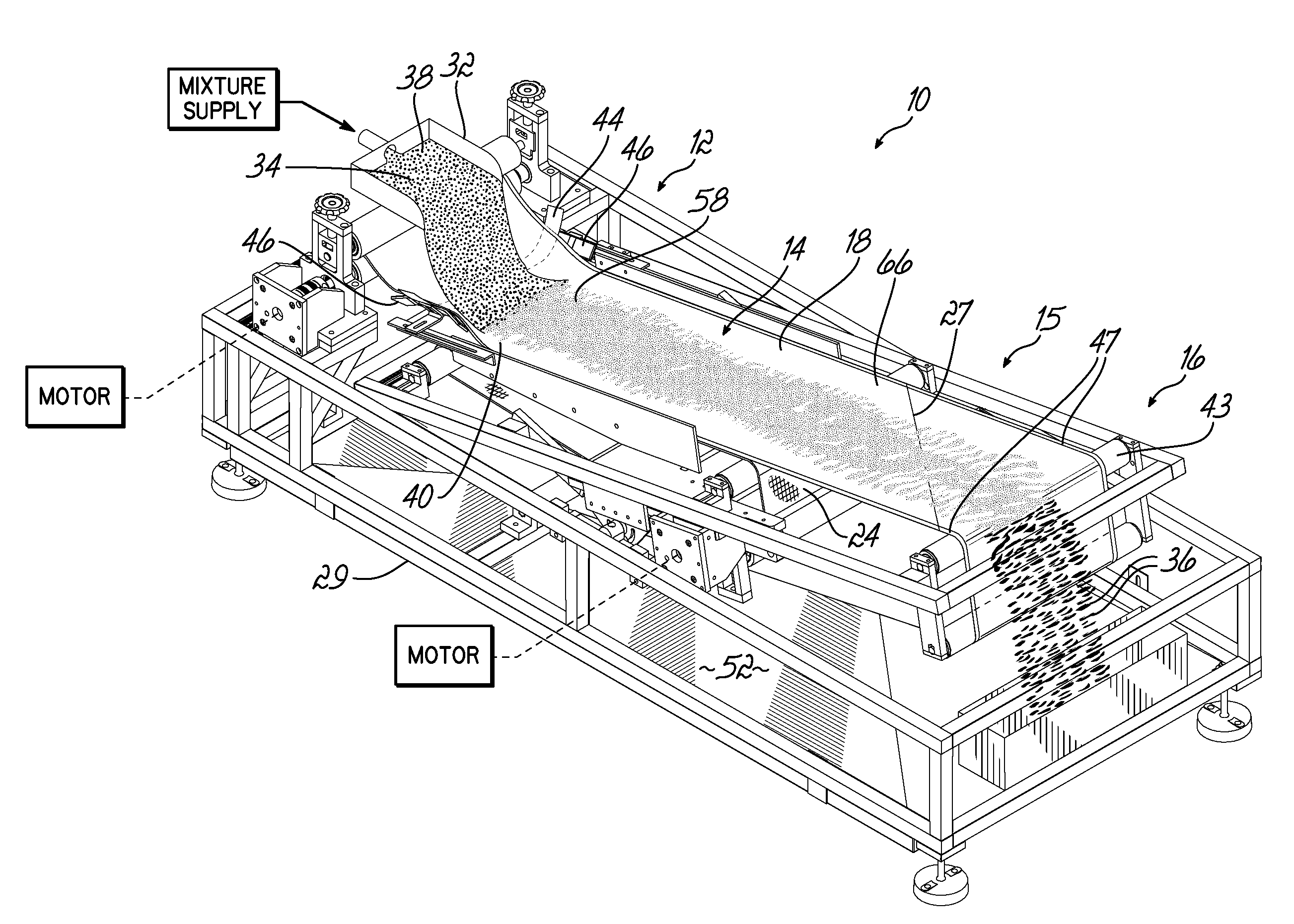

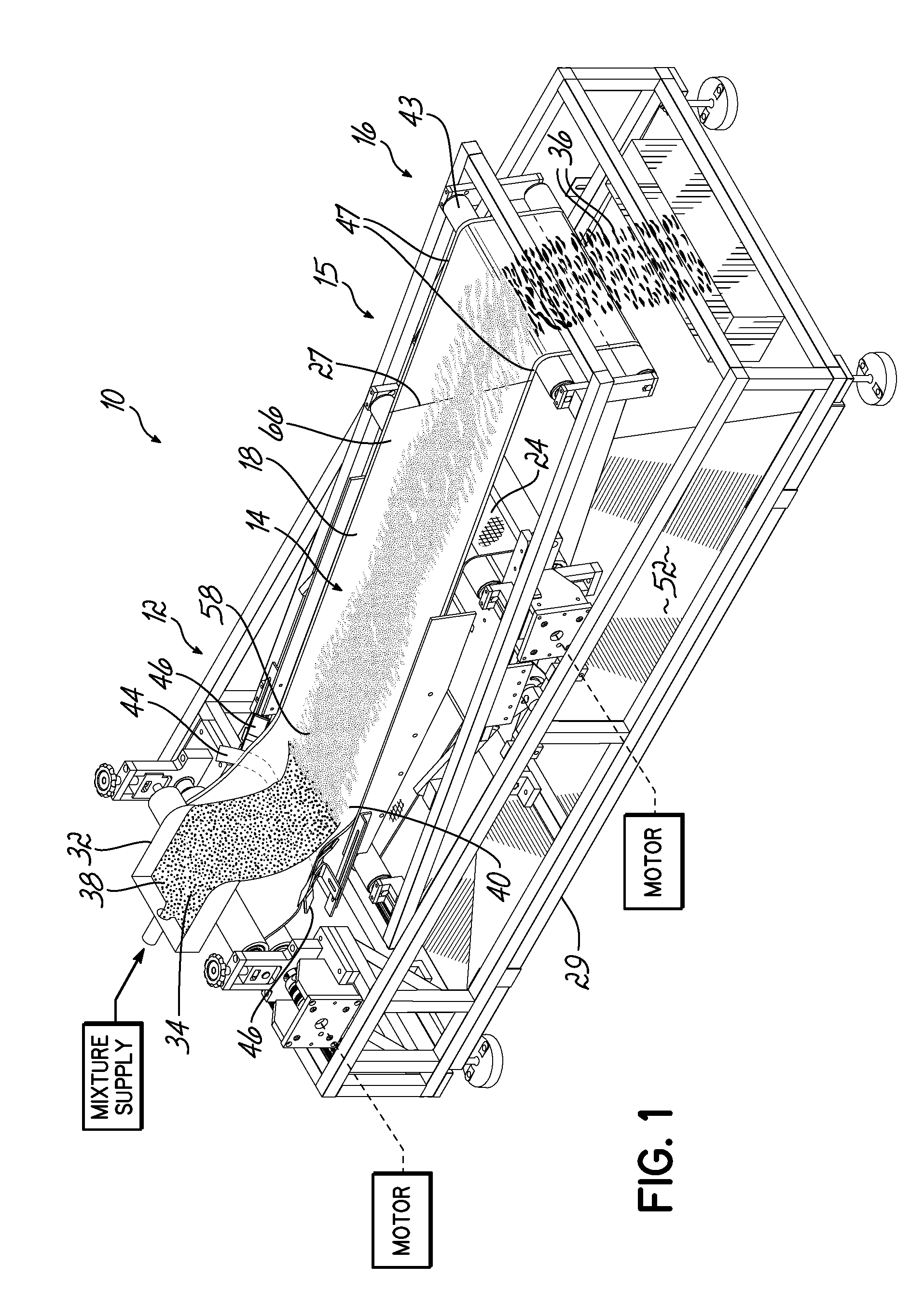

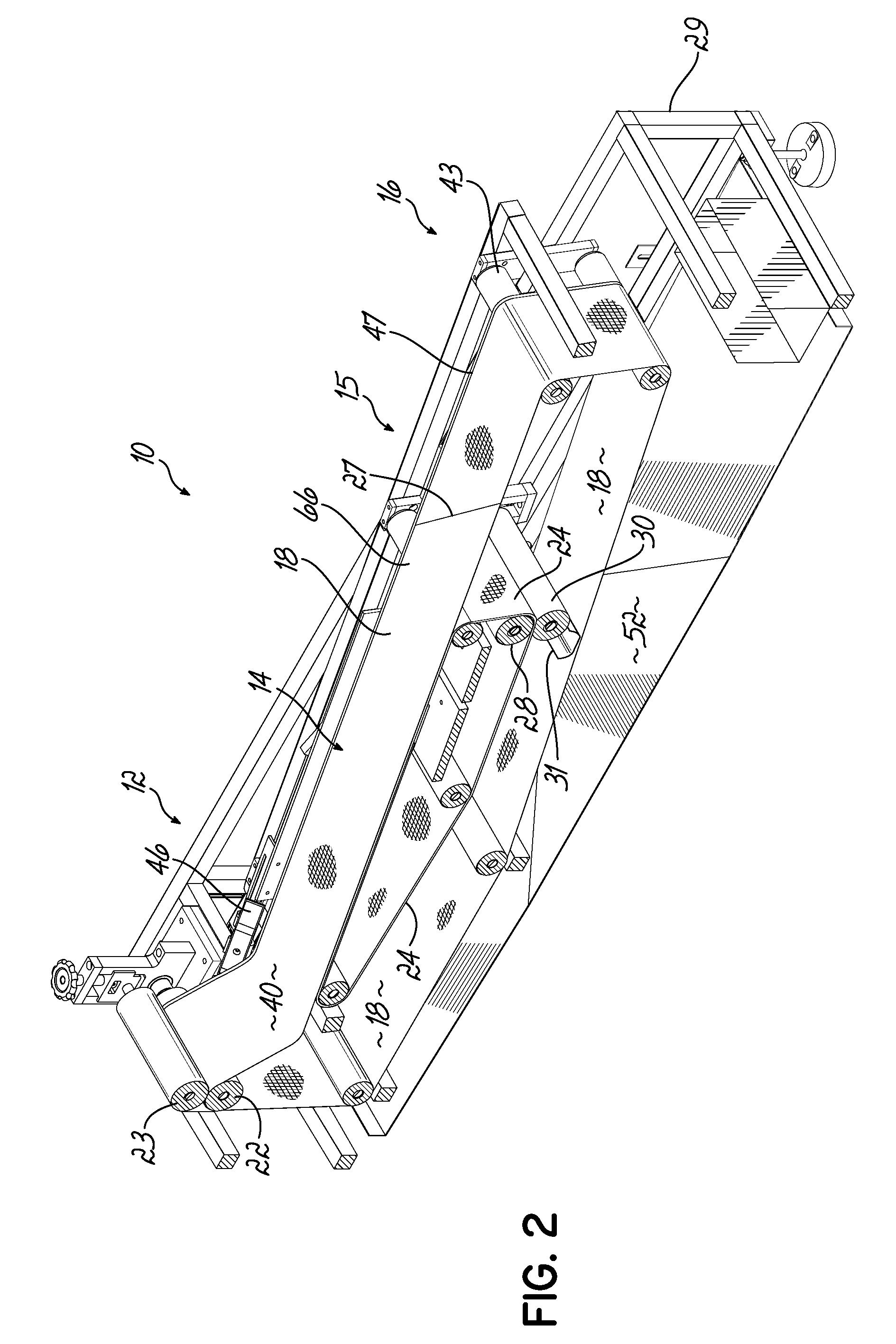

Method and apparatus for separating particles from a liquid

ActiveUS20100224574A1Easy to separateReduce differential pressureUnicellular algaeSolid sorbent liquid separationEngineering

Owner:UNIVENTURE

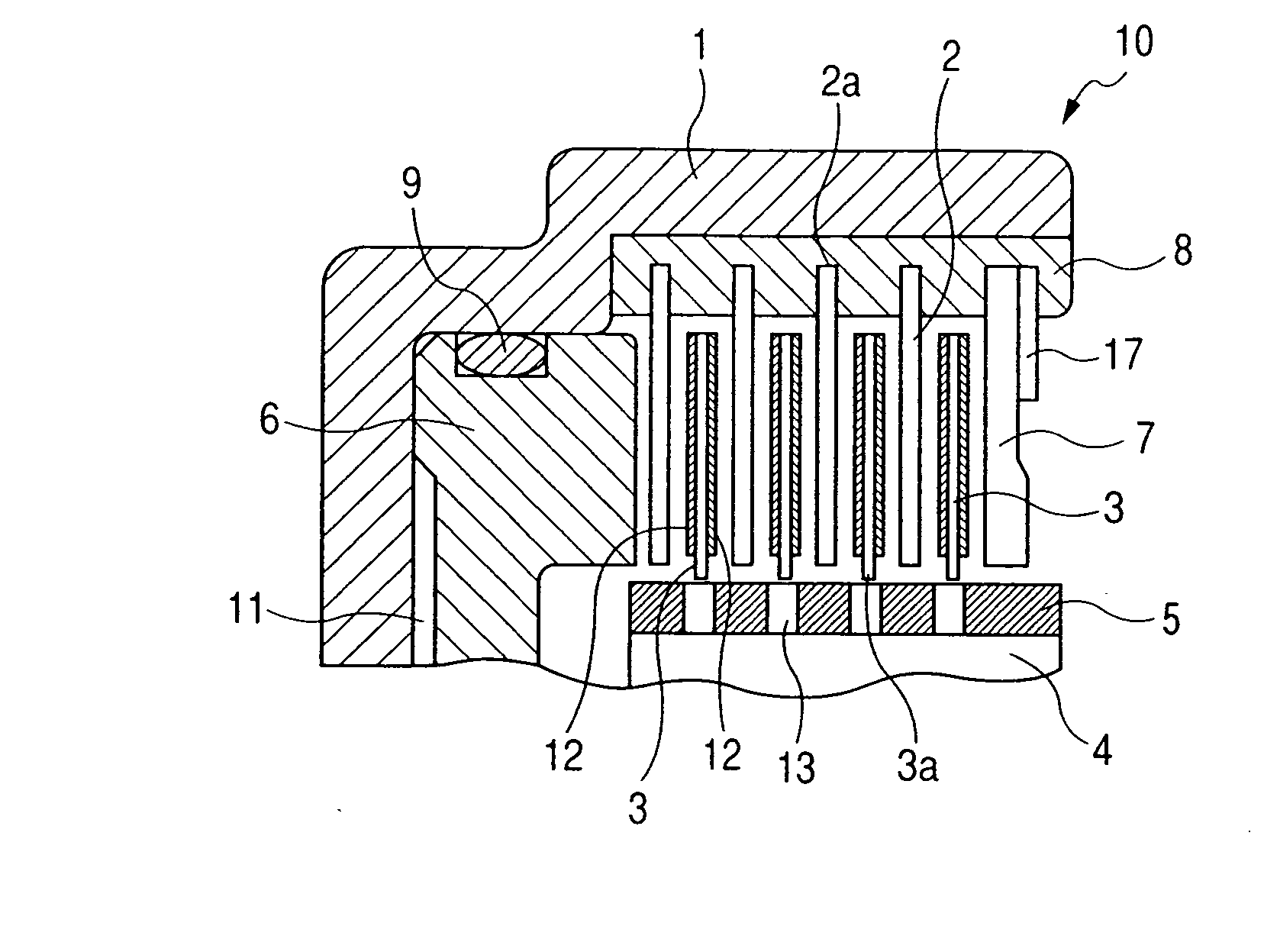

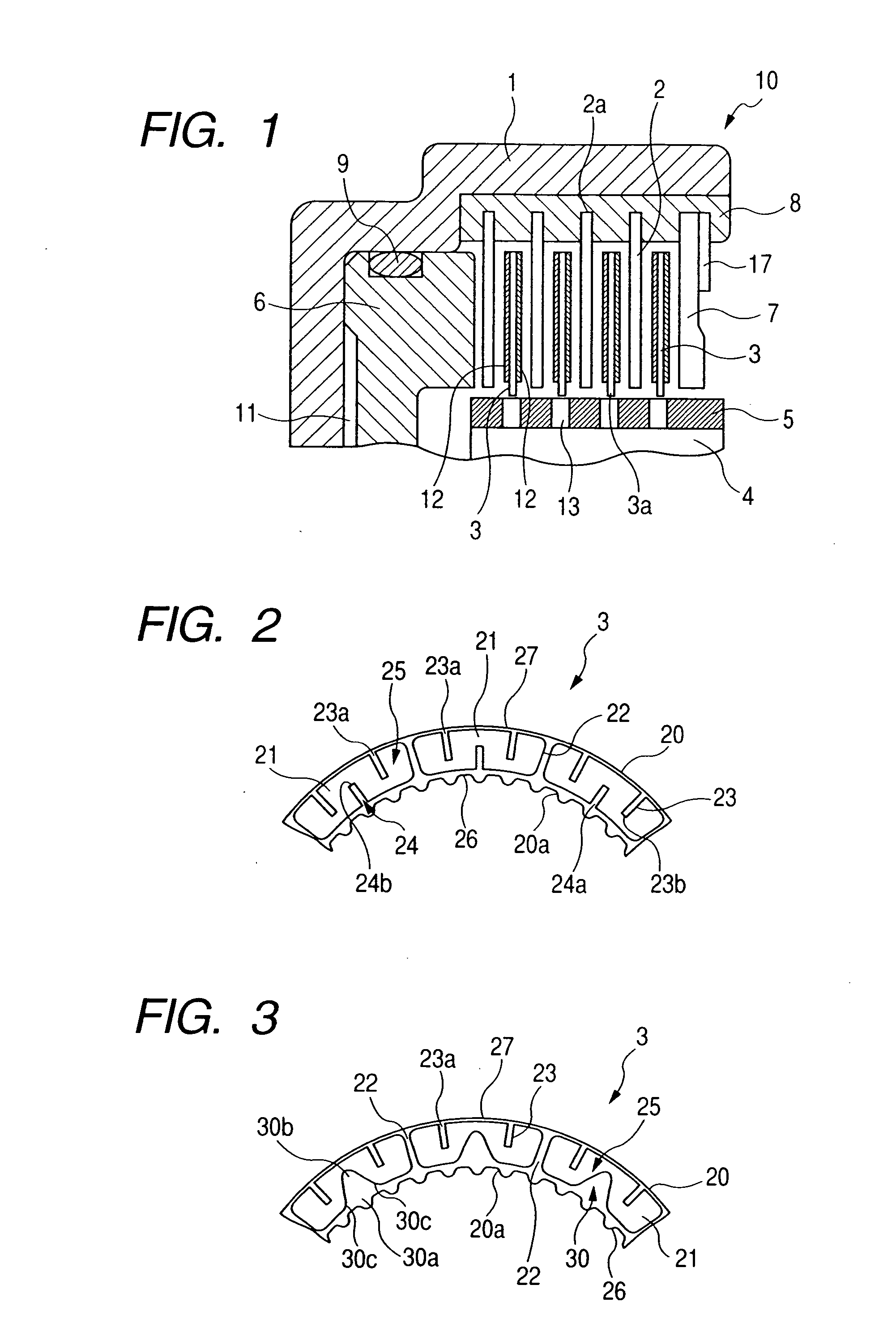

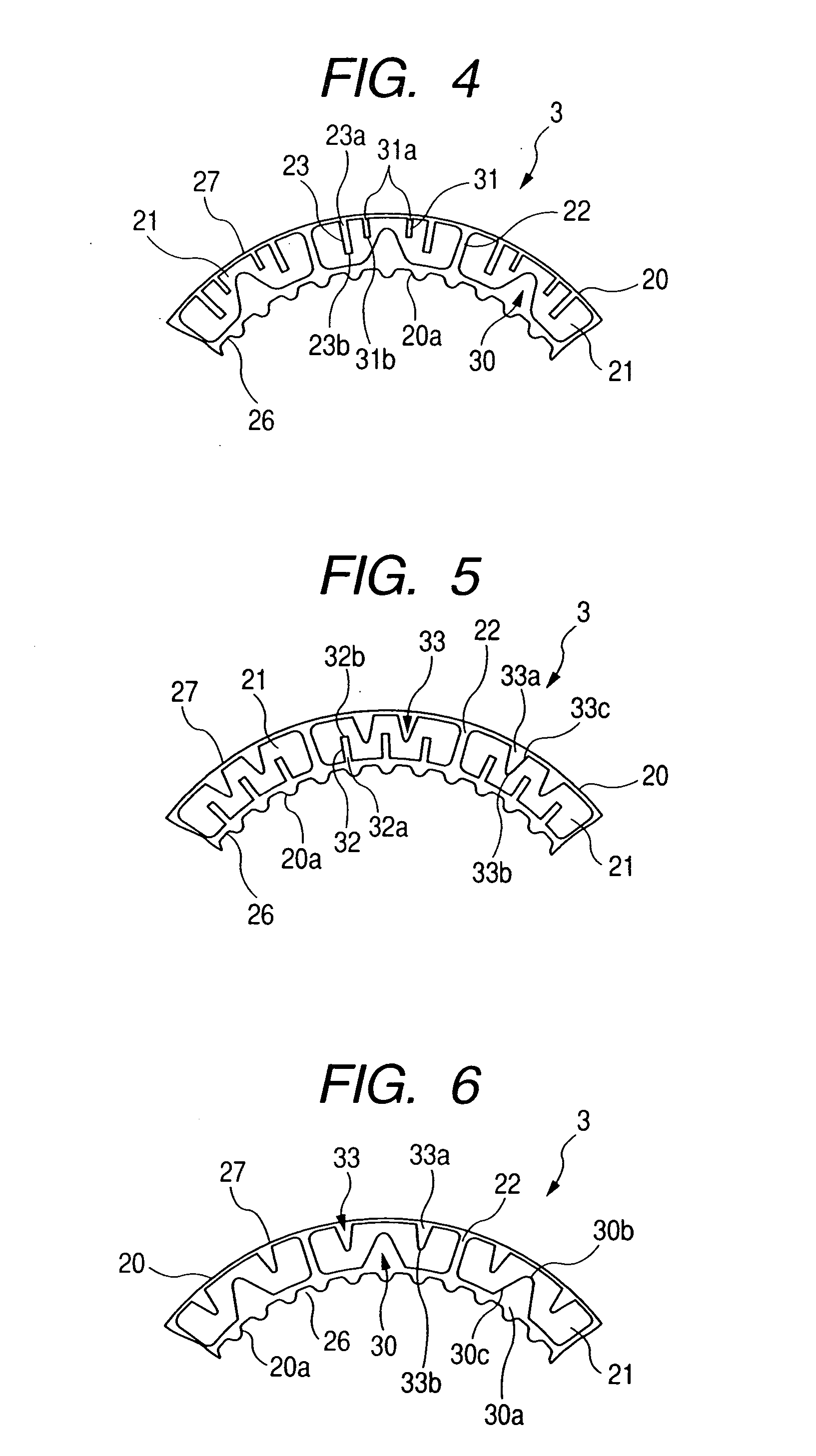

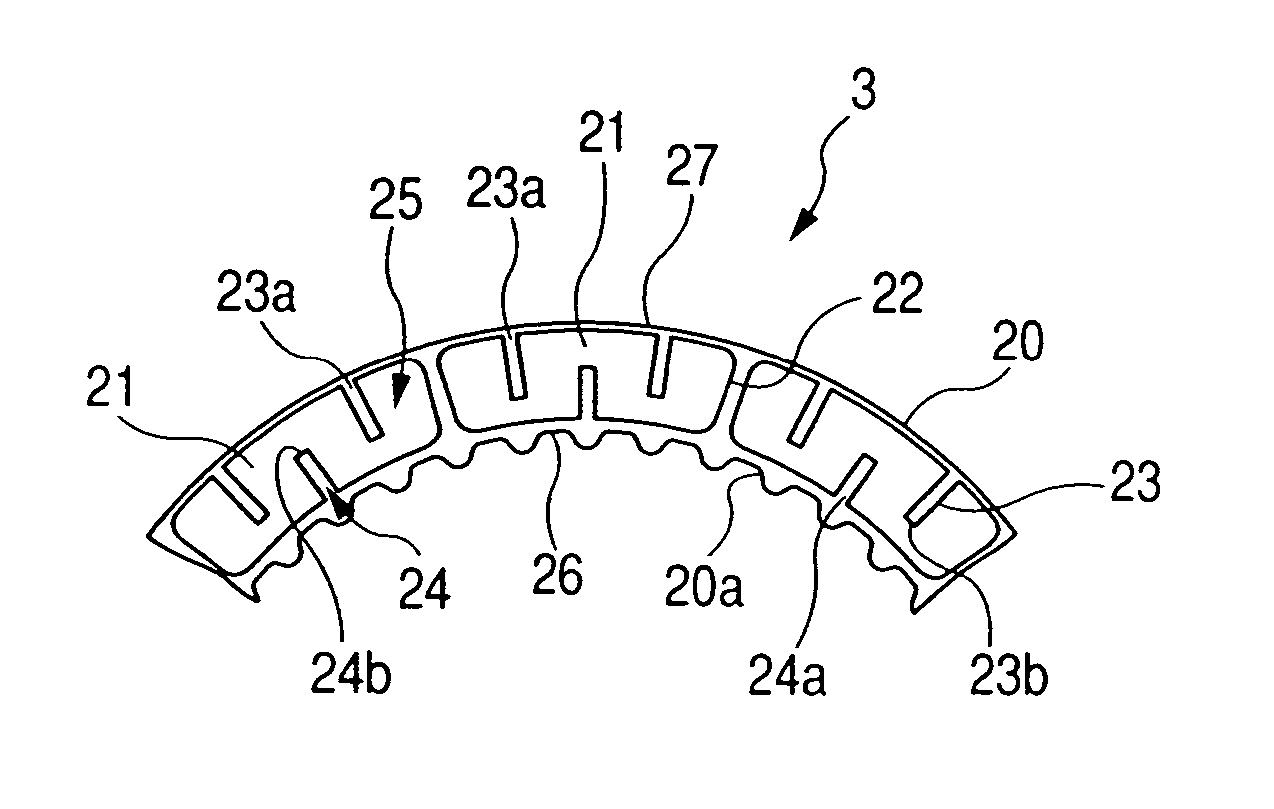

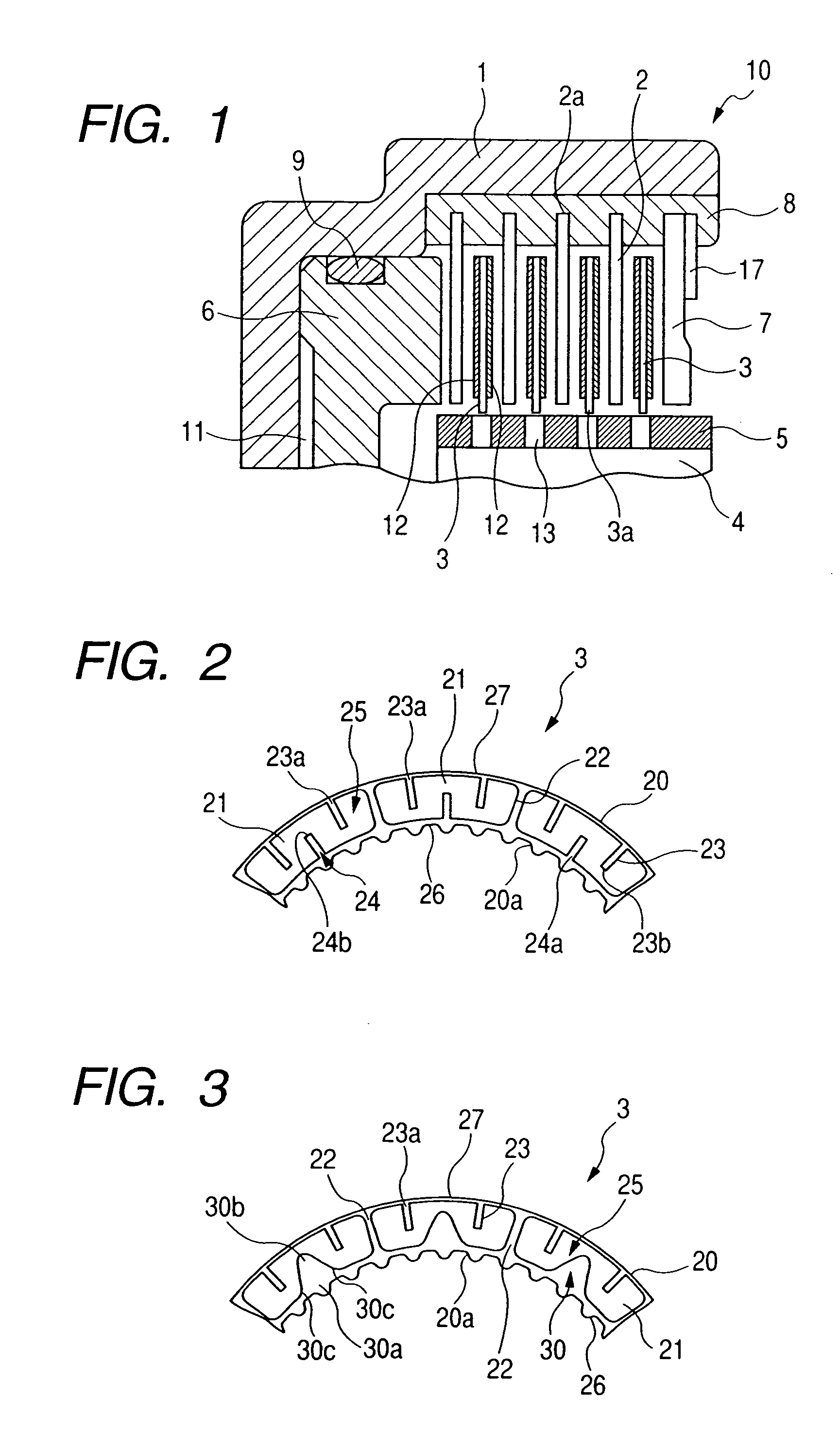

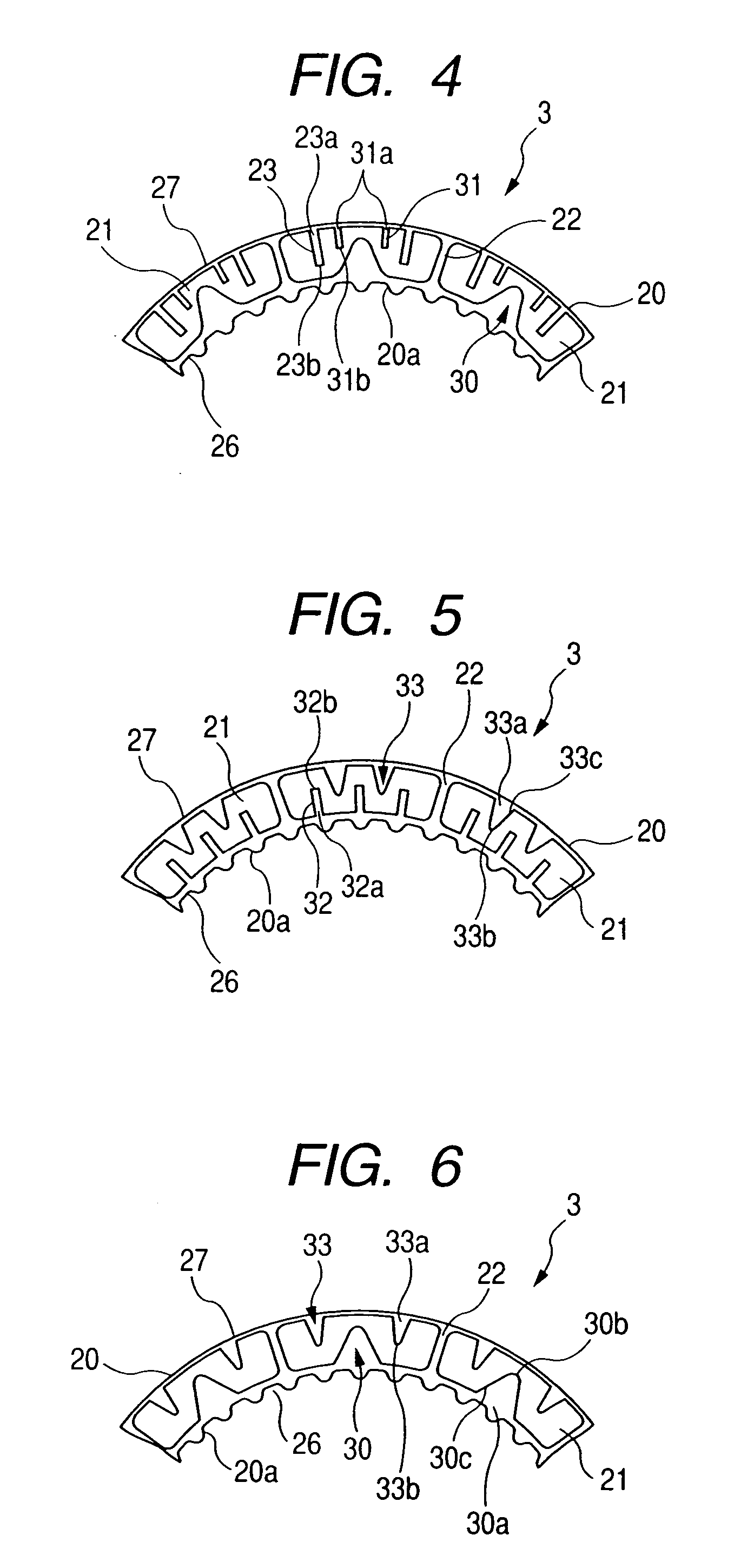

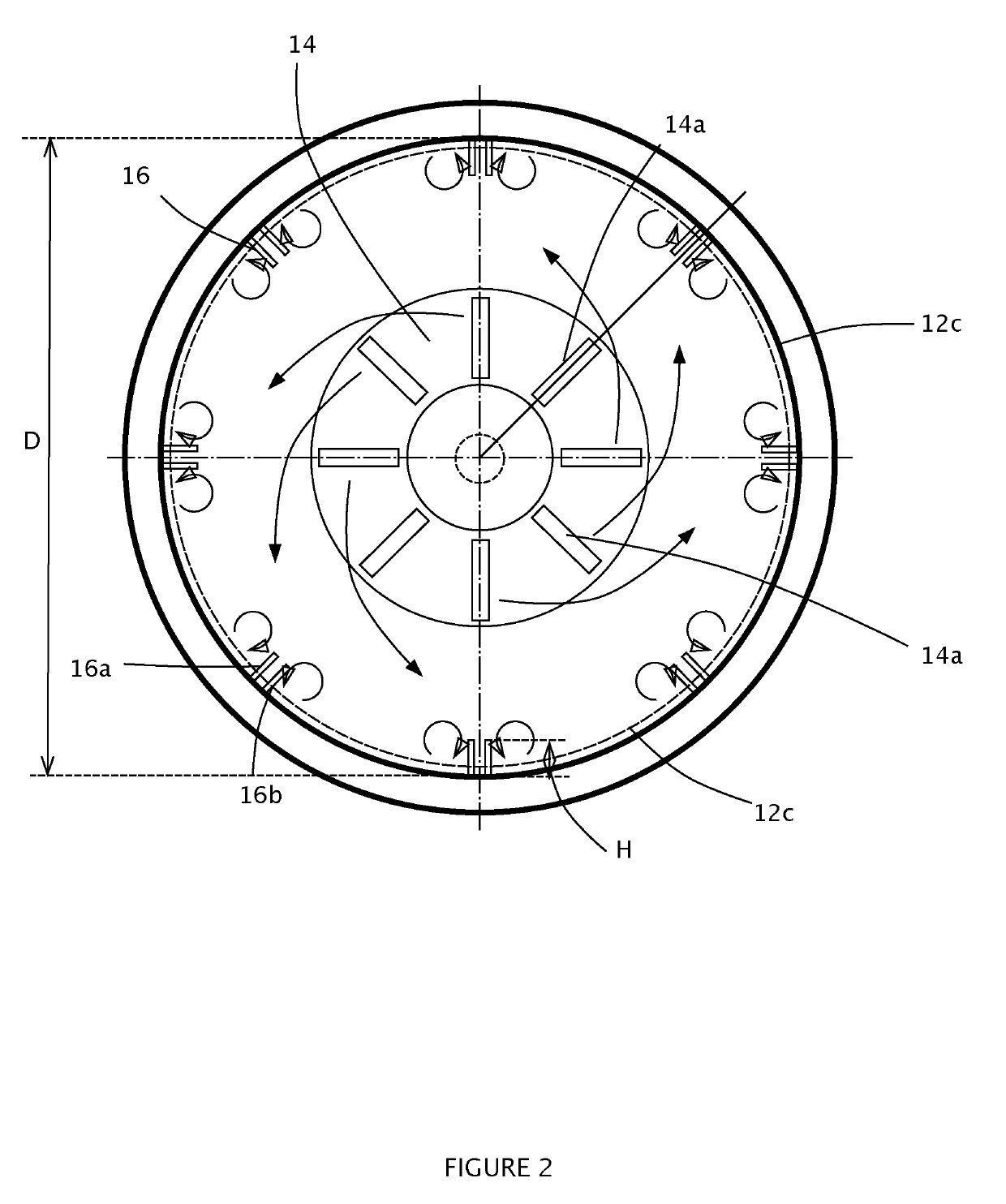

Friction plate and wet-type multi-plate clutch

InactiveUS20070102258A1Improve heat resistanceReduce participationFluid actuated clutchesFriction clutchesEngineeringClutch

The present invention provides a friction plate having a friction surface formed by adhering a friction material to a substantially annular core plate and wherein the friction surface is provided with an oil passage communicated with inner and outer peripheral edges of the friction plate, a first oil groove having an opening portion opened to the inner peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges, and a second first oil groove having an opening portion opened to the outer peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges.

Owner:NSK WARNER

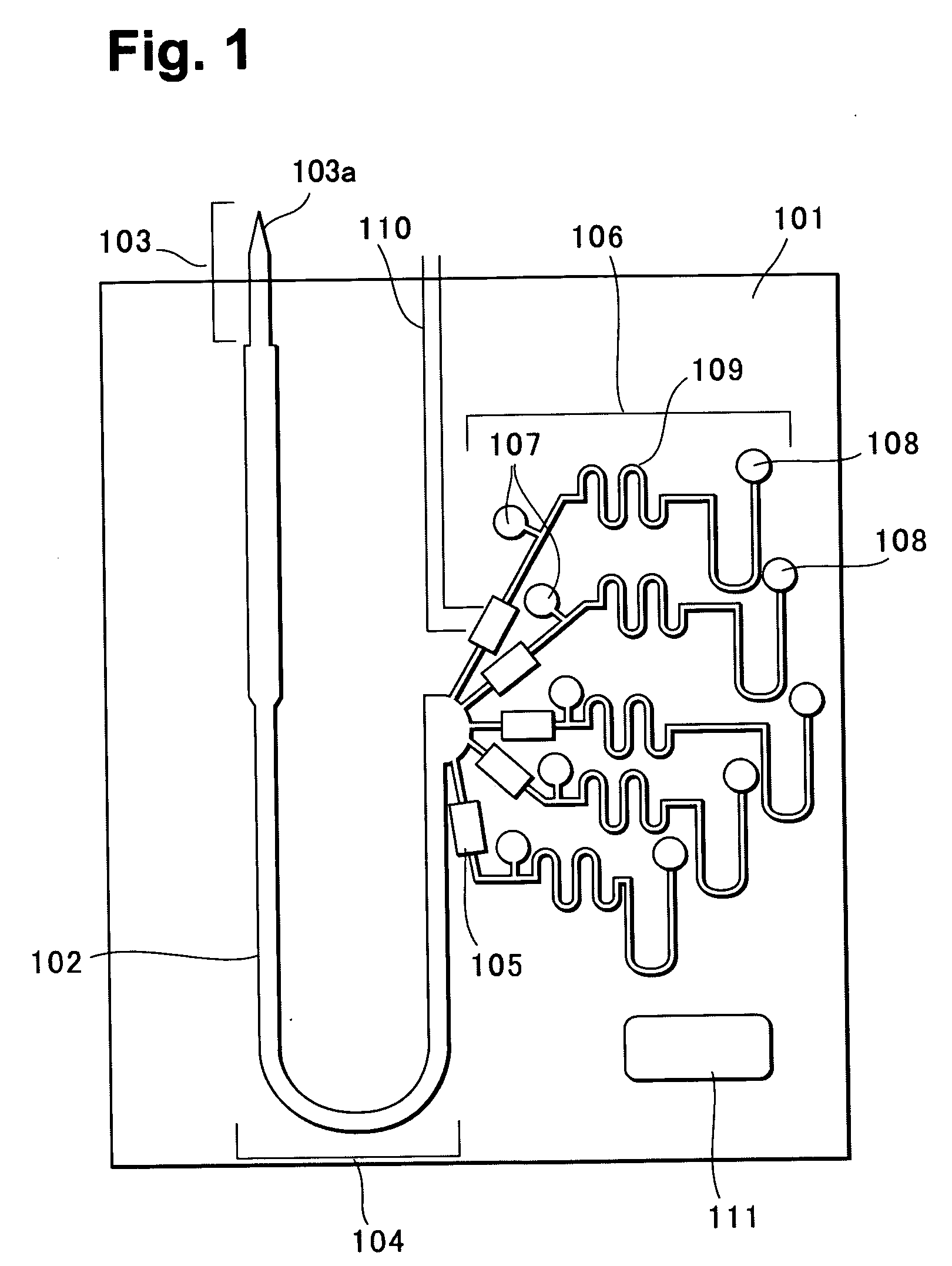

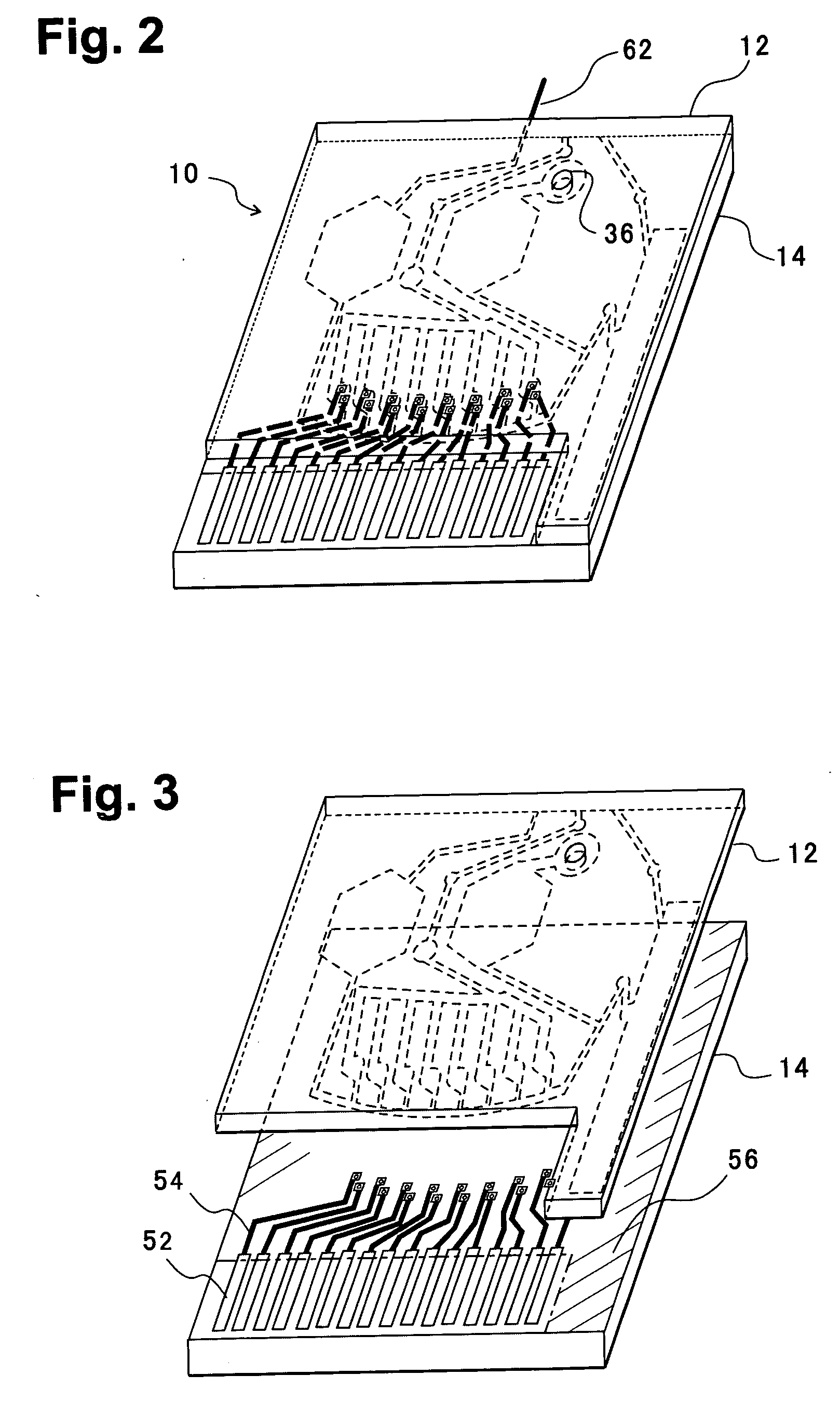

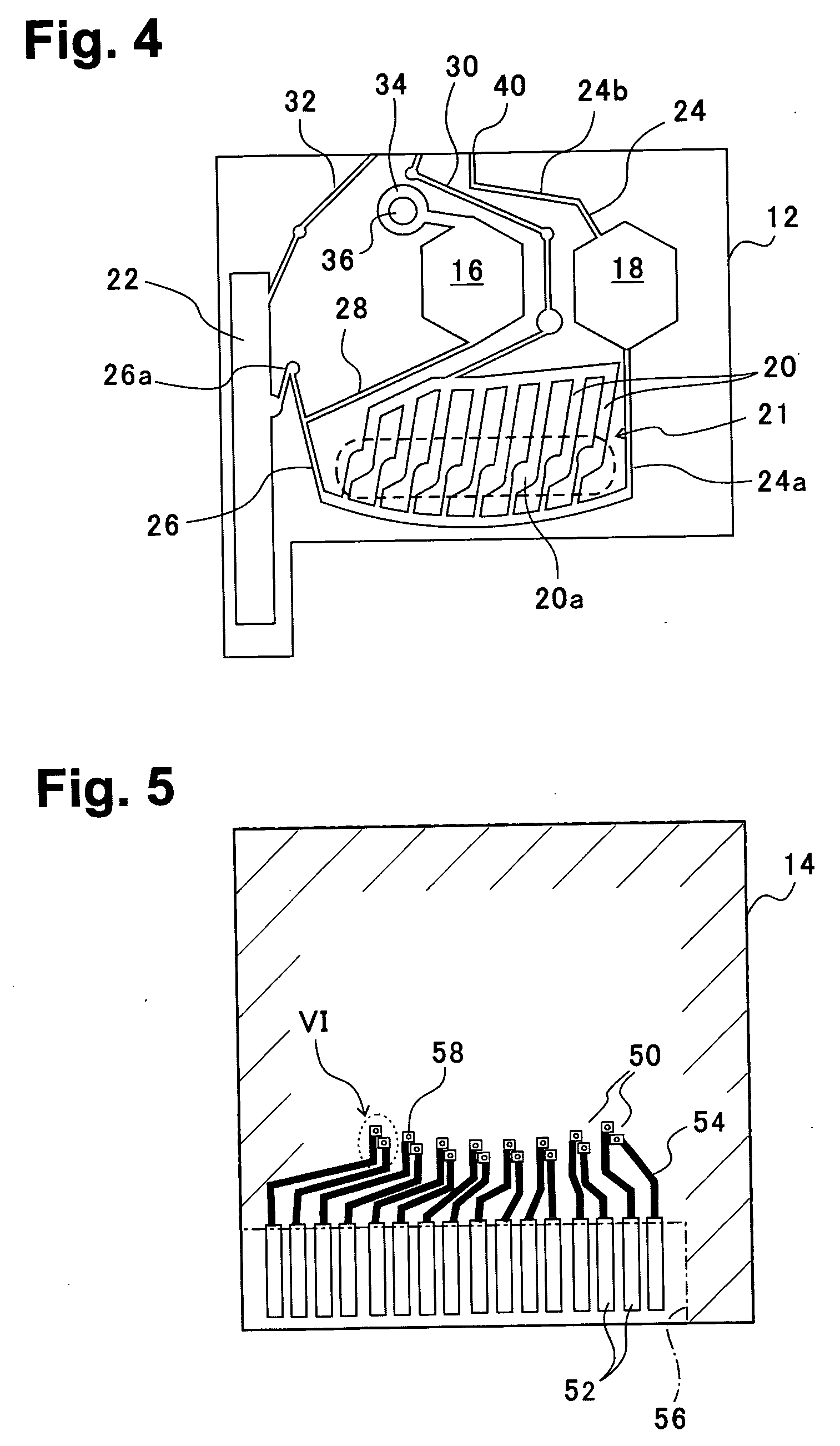

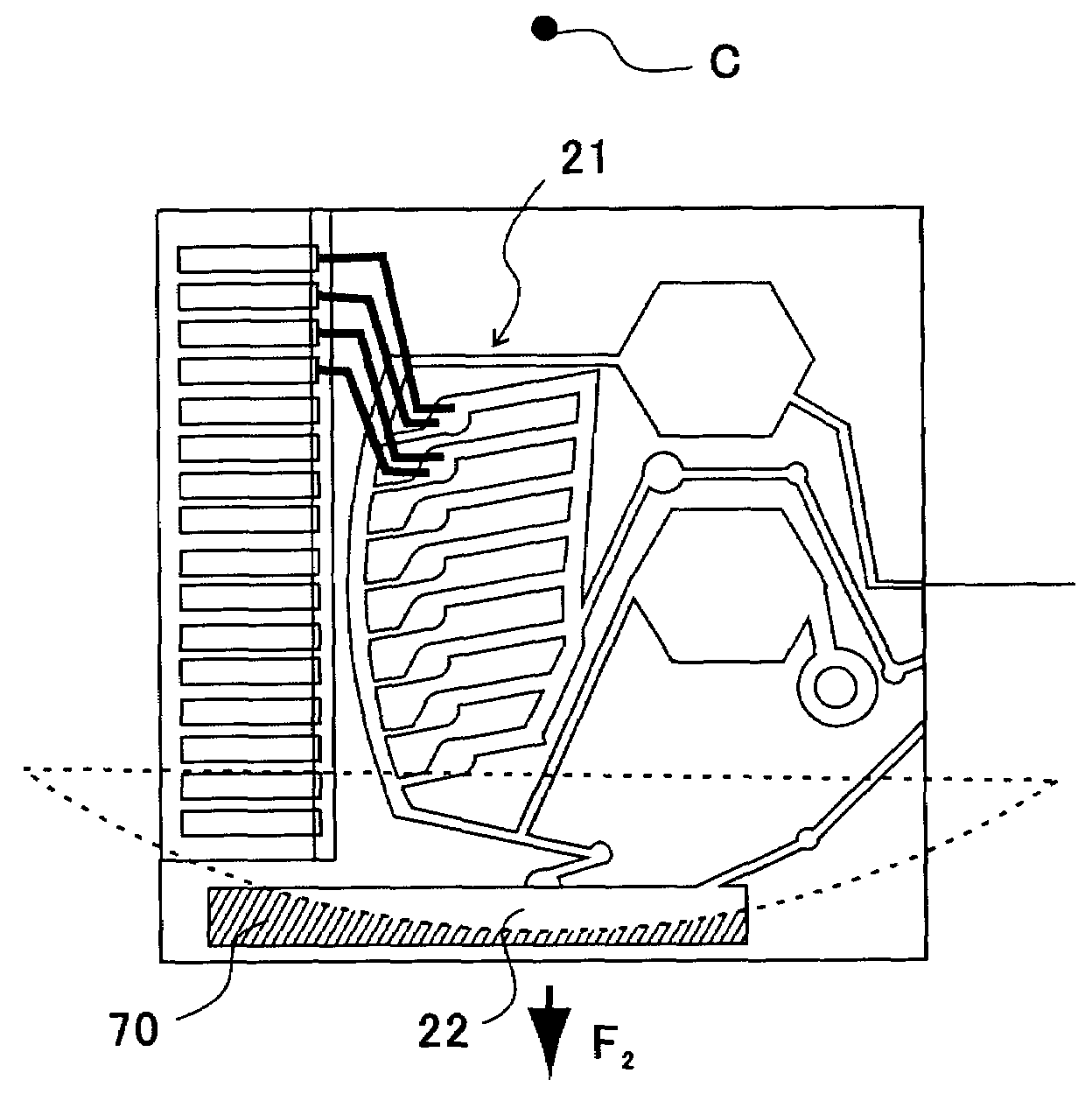

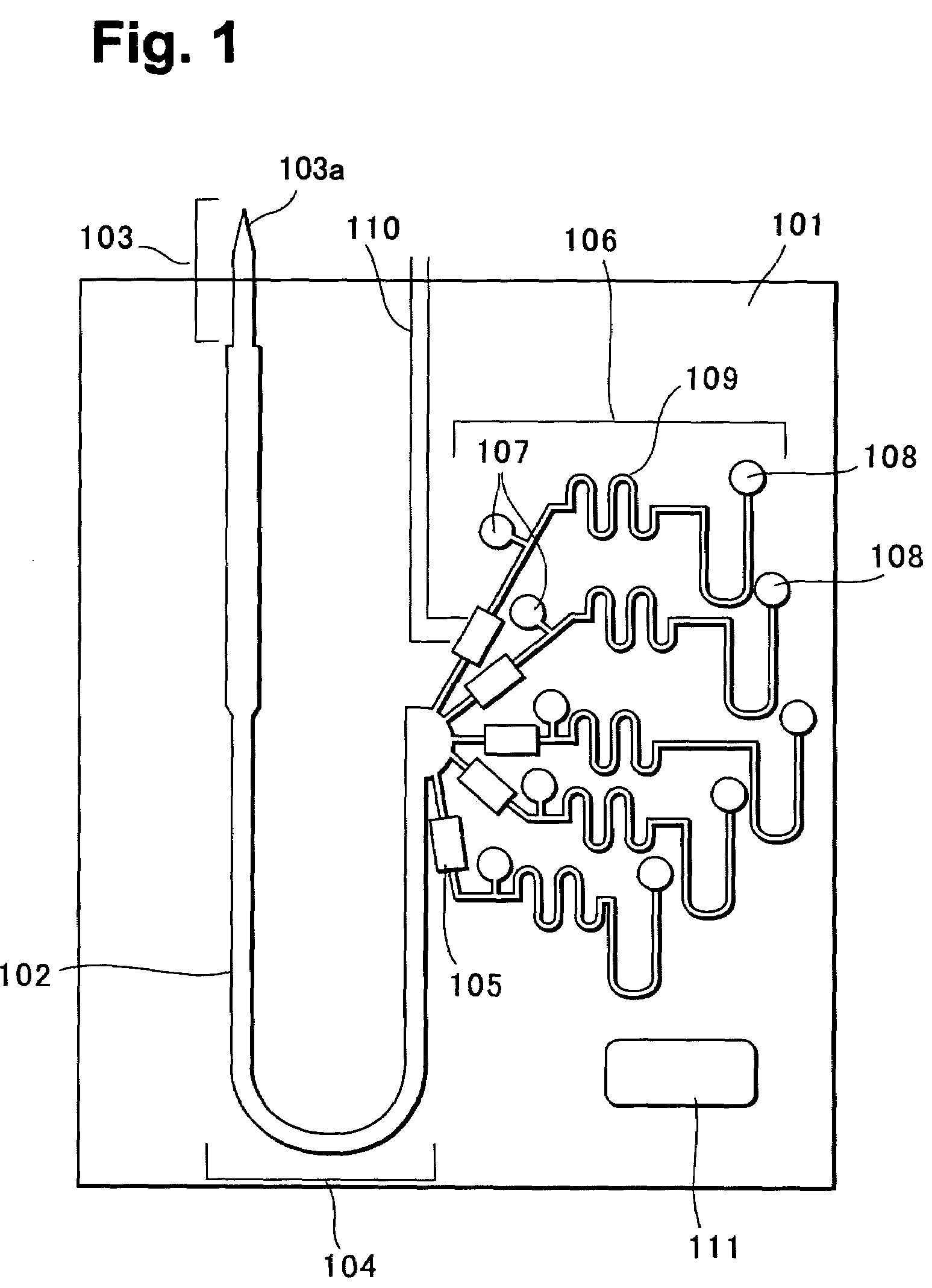

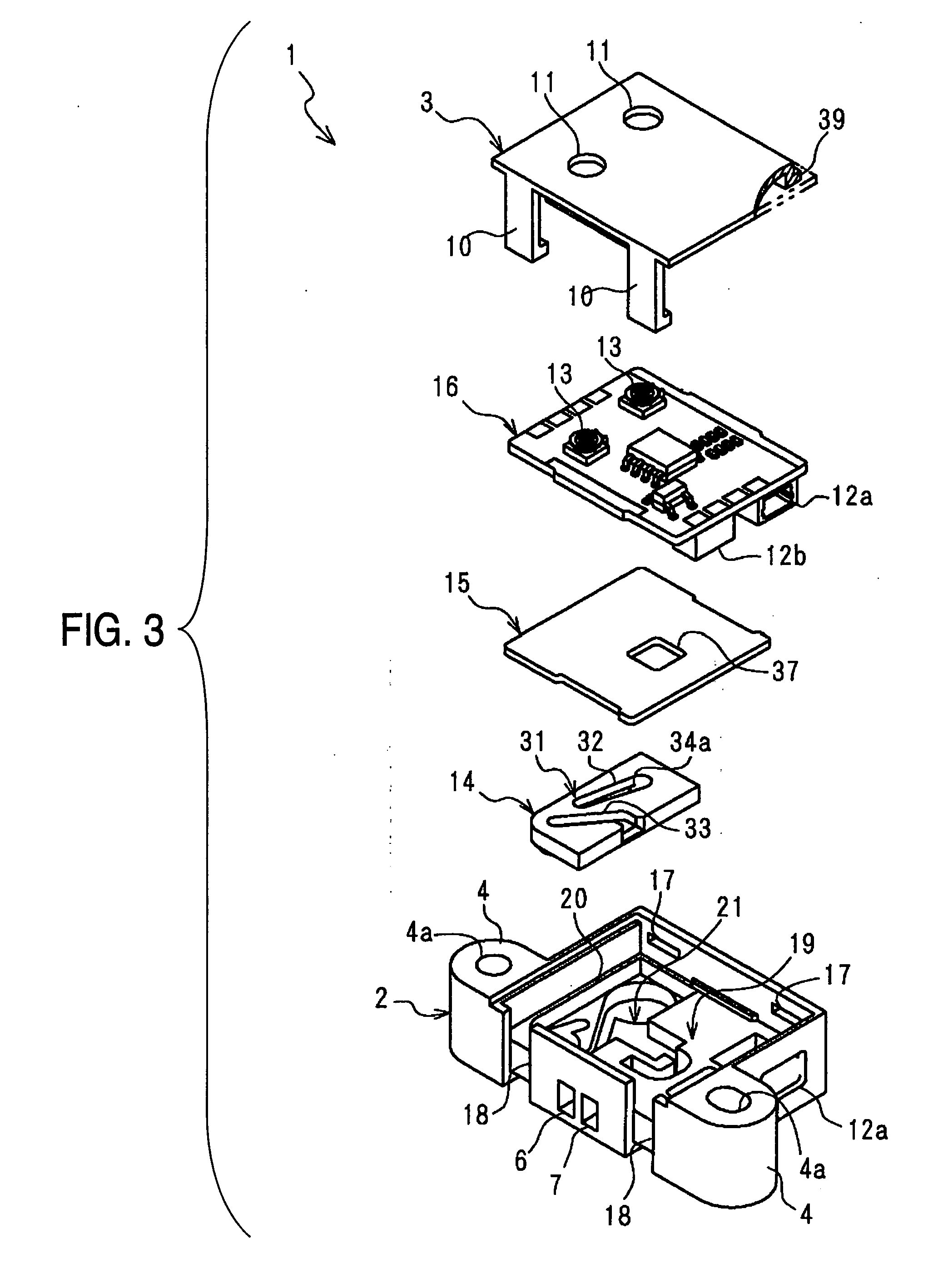

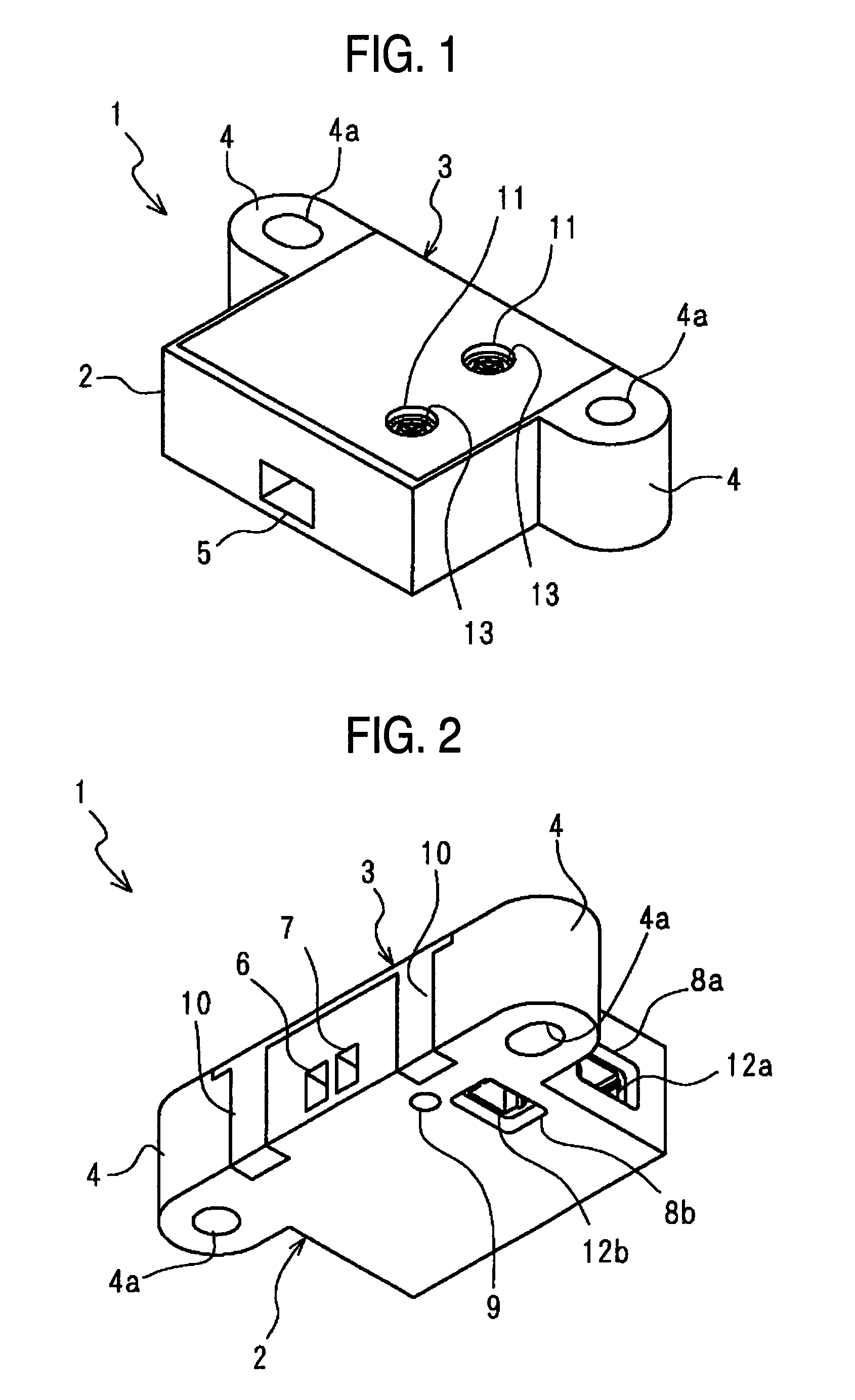

Blood analysis device and blood analysis method

InactiveUS20060078873A1Smoothly introduceReliable dischargeBioreactor/fermenter combinationsBiological substance pretreatmentsTransducer calibrationBlood plasma

A blood analysis device for centrifugally separating plasma in a channel, wherein conveyance of blood, plasma and calibration liquid is effected within the device without using a pump or the like. The calibrator solution is reliably discharged from a sensor portion so as to make high precision analysis possible. A sensor section is provided in a plasma separating section and disposed on the side associated with a first centrifugal pressing direction as seen from a blood reservoir and a calibrator solution reservoir, while a calibrator solution waste reservoir is disposed in a second centrifugal pressing direction as seen from the plasma separating section (sensor section). The calibrator solution is conveyed to the sensor section by centrifugal operation in the first centrifugal direction. After sensor calibration, the calibrator solution can be reliably discharged from the sensor section by effecting centrifuging in the second centrifugal direction. After the calibrator solution discharge, centrifuging is effected again in the first centrifugal direction, thereby conveying the blood in the blood reservoir to the sensor section and effecting separation of blood cells and plasma. In the case of providing a plurality of sensors, a blood introducing channel from the blood reservoir is branched downwardly of a sensor groove for communication, with the blood cells being fractionated in the branch section. The individual sensors can be isolated from each other by blood cell fraction, making higher precision analysis possible.

Owner:JAPAN SCI & TECH CORP

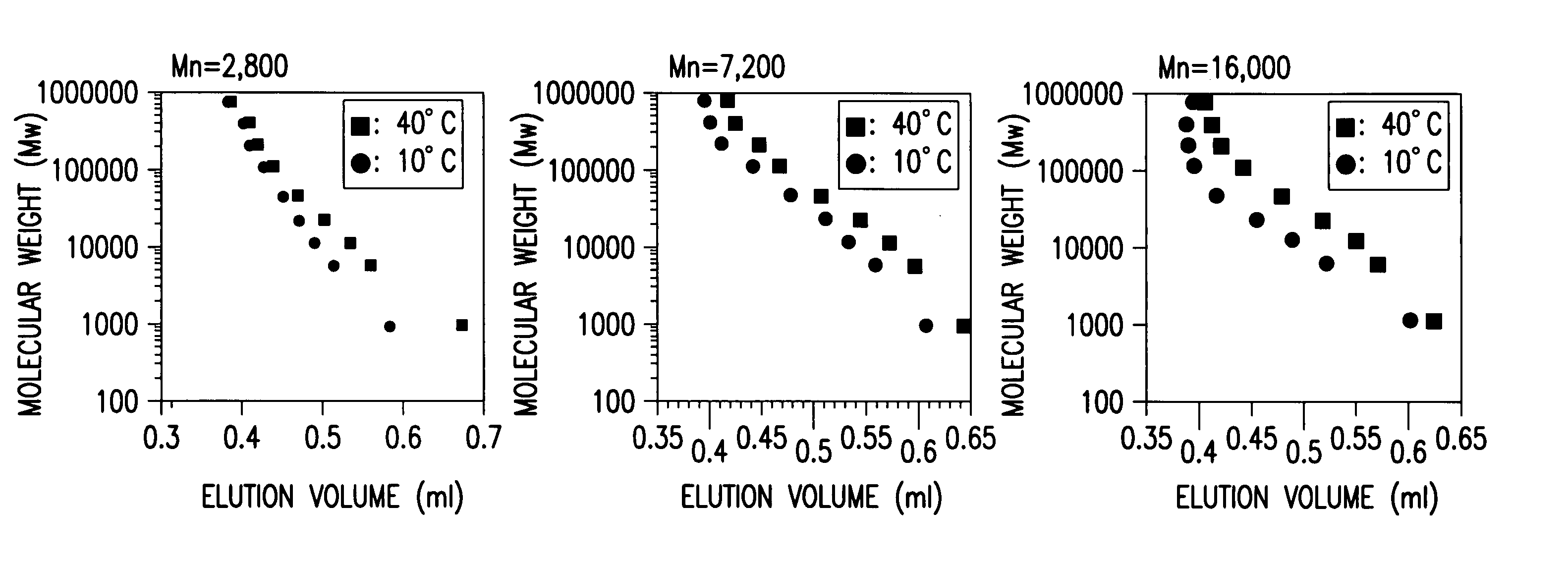

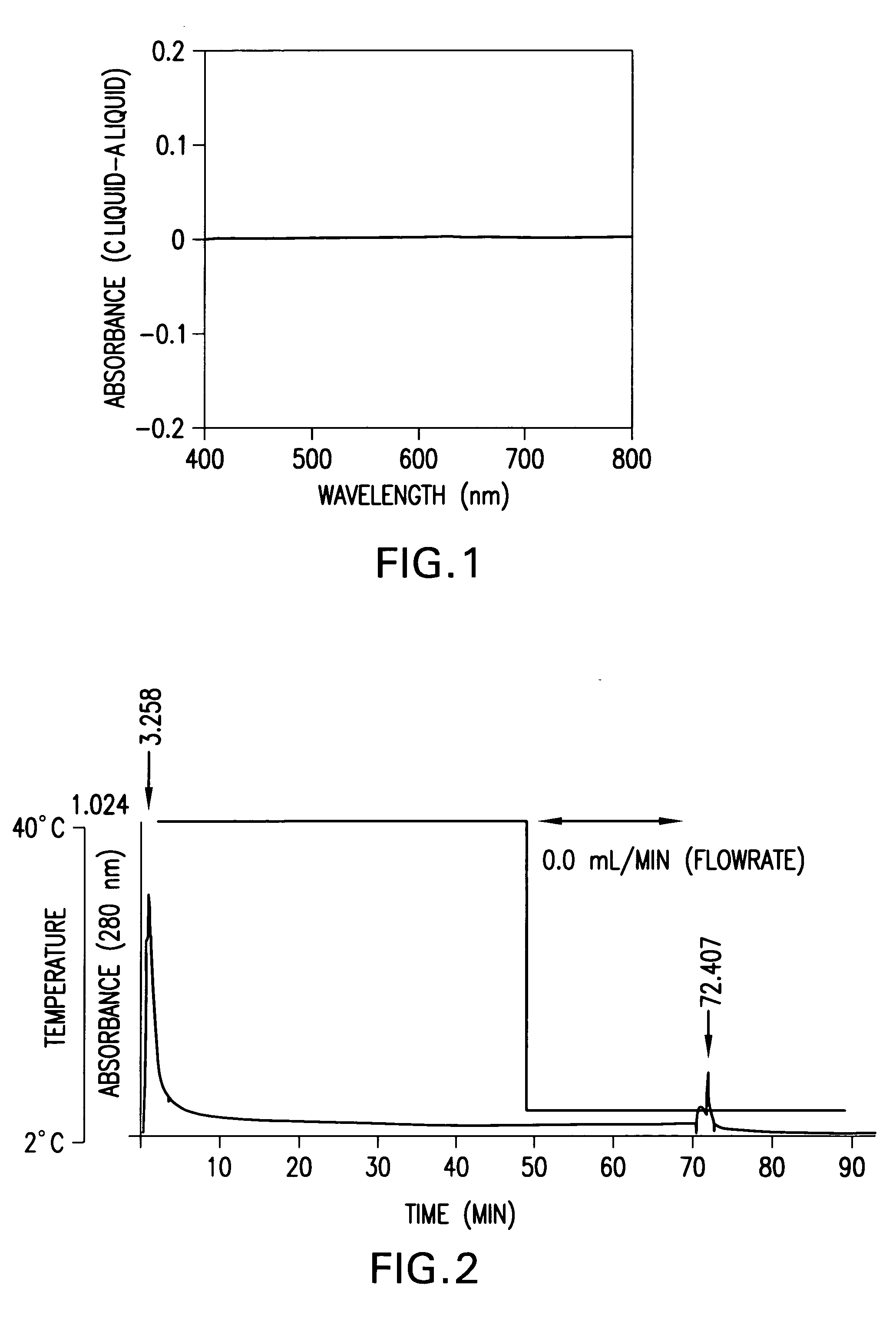

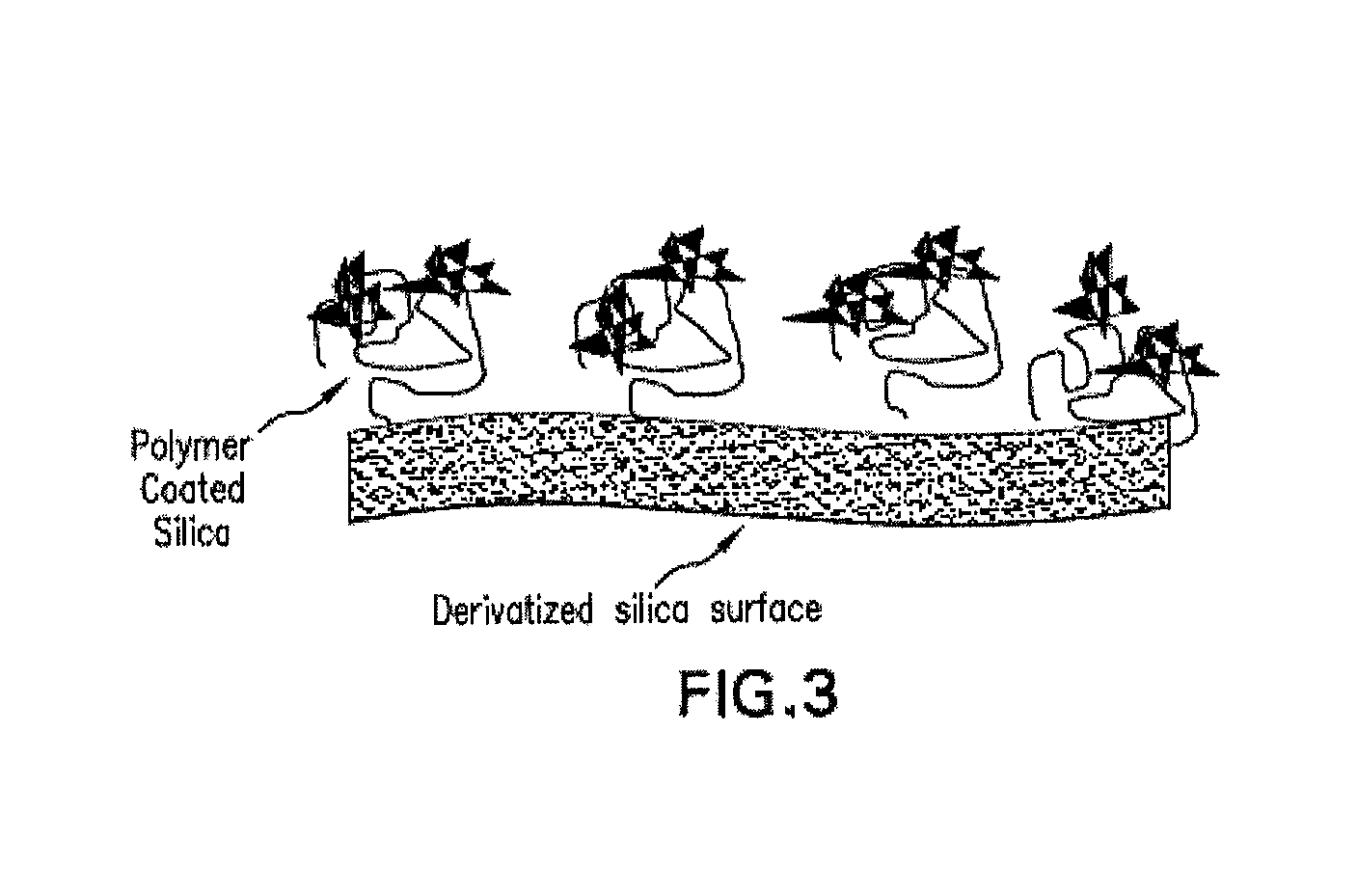

Novel material for use in separation and separating method using the same

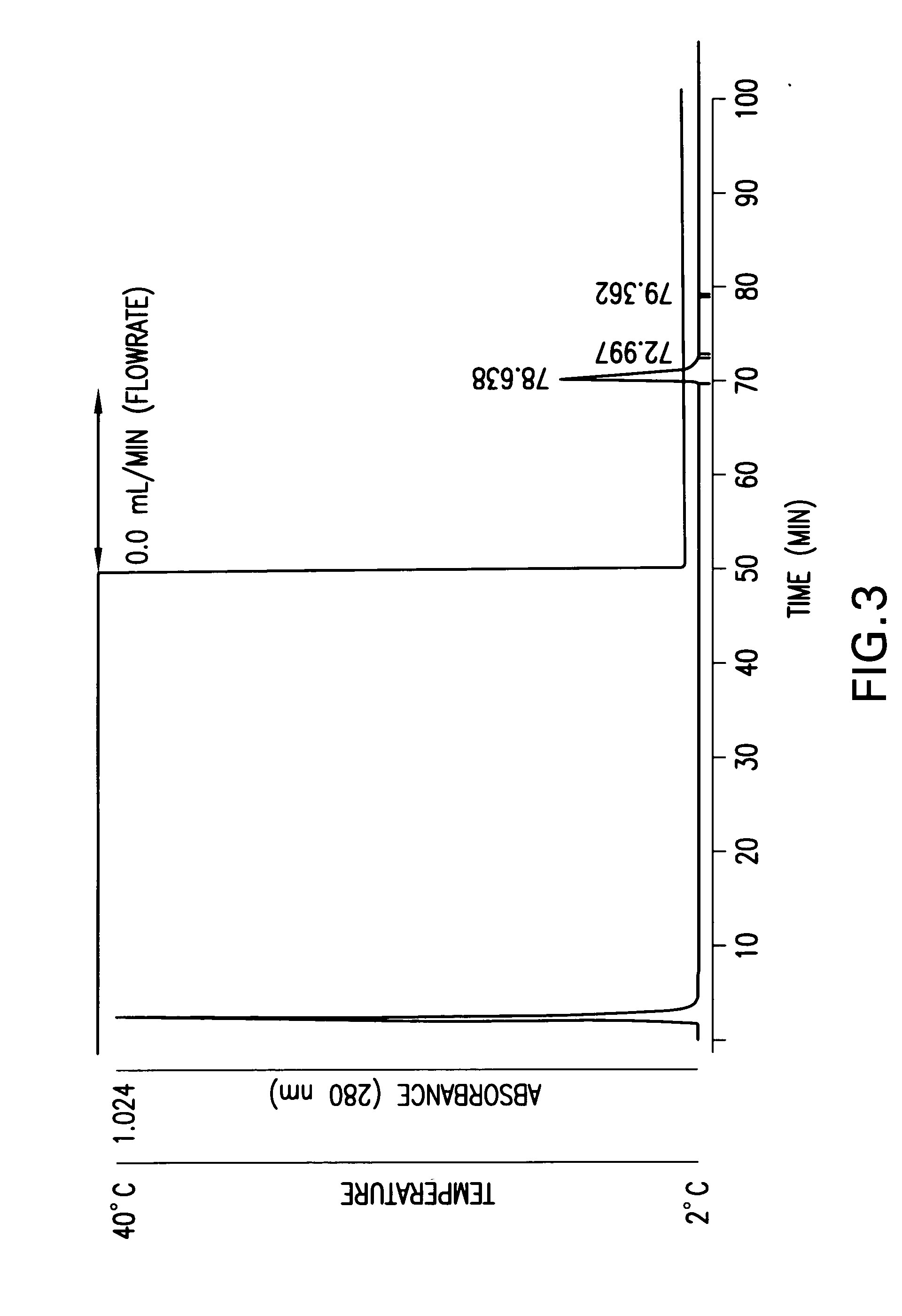

InactiveUS20040134846A1Small molecular weightEfficient changeIon-exchange process apparatusComponent separationPhysical contextResponsive polymer

A separatory material comprising a composite material containing a stimulus-responsive polymer and a substance interacting specifically with a target substance, wherein said stimulus-responsive polymer undergoes a structural change upon a physical stimulus so that the interaction of said substance interacting specifically with the target substance is affected by the chemical or physical environmental change, thereby causing a reversible change in the interaction force with the target substance due to the physical stimulus, which separatory material is characterized in that said stimulus-responsive polymer has no affinity with said substance interacting specifically with the target substance.

Owner:JAPAN CHEM INNOVATION INST +1

Method and apparatus for separating particles from a liquid

Owner:UNIVENTURE INC

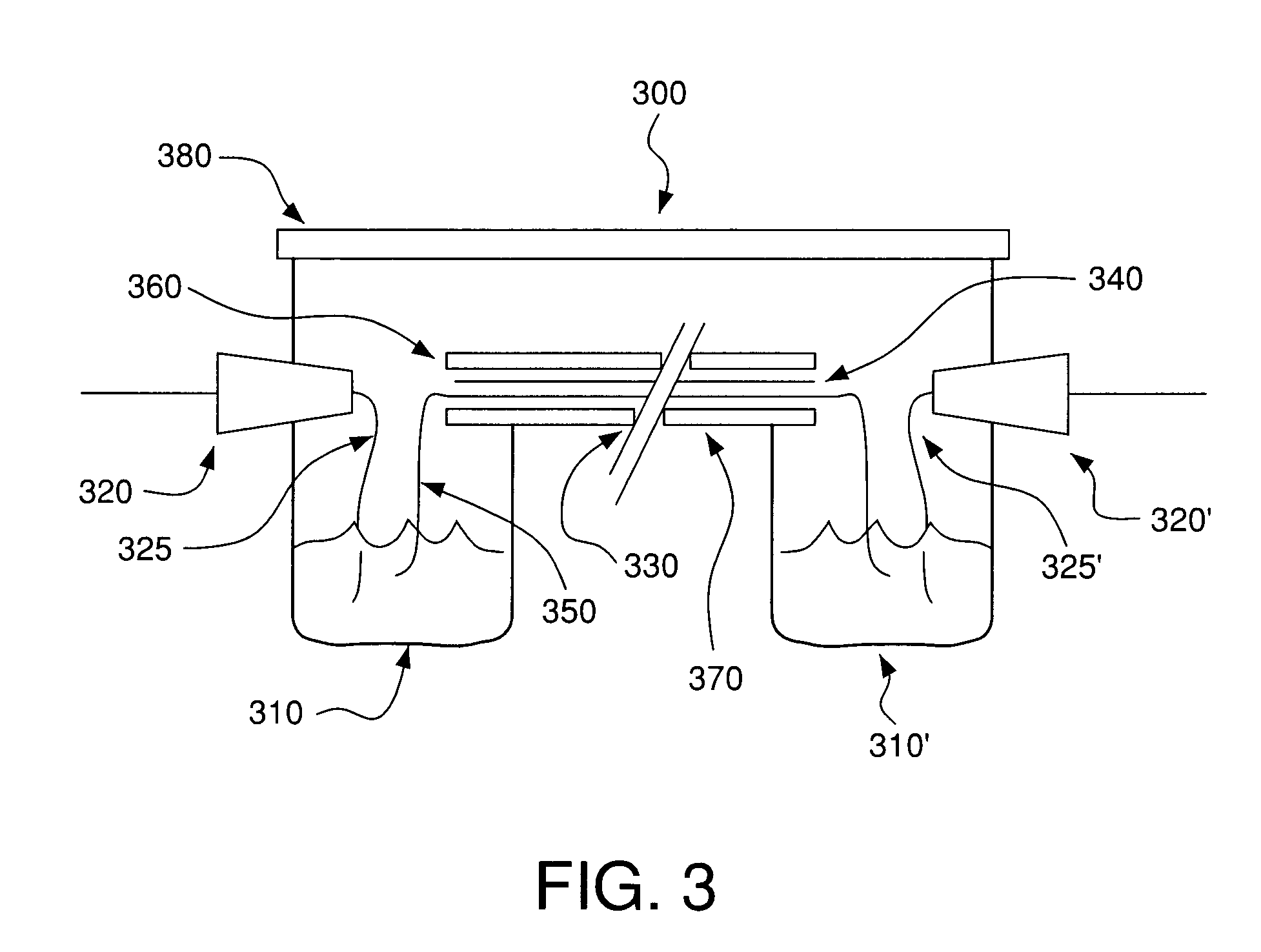

System and methods for electrophoretic separation of proteins on protein binding membranes

ActiveUS7326326B2Increase capacityEasy to separateSludge treatmentVolume/mass flow measurementProteinHeat generation

Proteins can be rapidly separated to a high degree of resolution by electrophoresis on polymeric membranes that have high protein binding capacity. The electrophoretic separation is carried out in a low conductivity, water-miscible organic solvent buffer. The low conductivity of the organic solvent buffer minimizes heat generation, and the water-miscible nature of the organic solvent buffer permits the analysis of hydrophobic and low molecular weight proteins as well as hydrophilic proteins. When electrophoresis is conducted under non-denaturing conditions, it allows the detection of enzymatic activities, protein-protein interactions and protein-ligand interactions.

Owner:TEMPLE UNIVERSITY

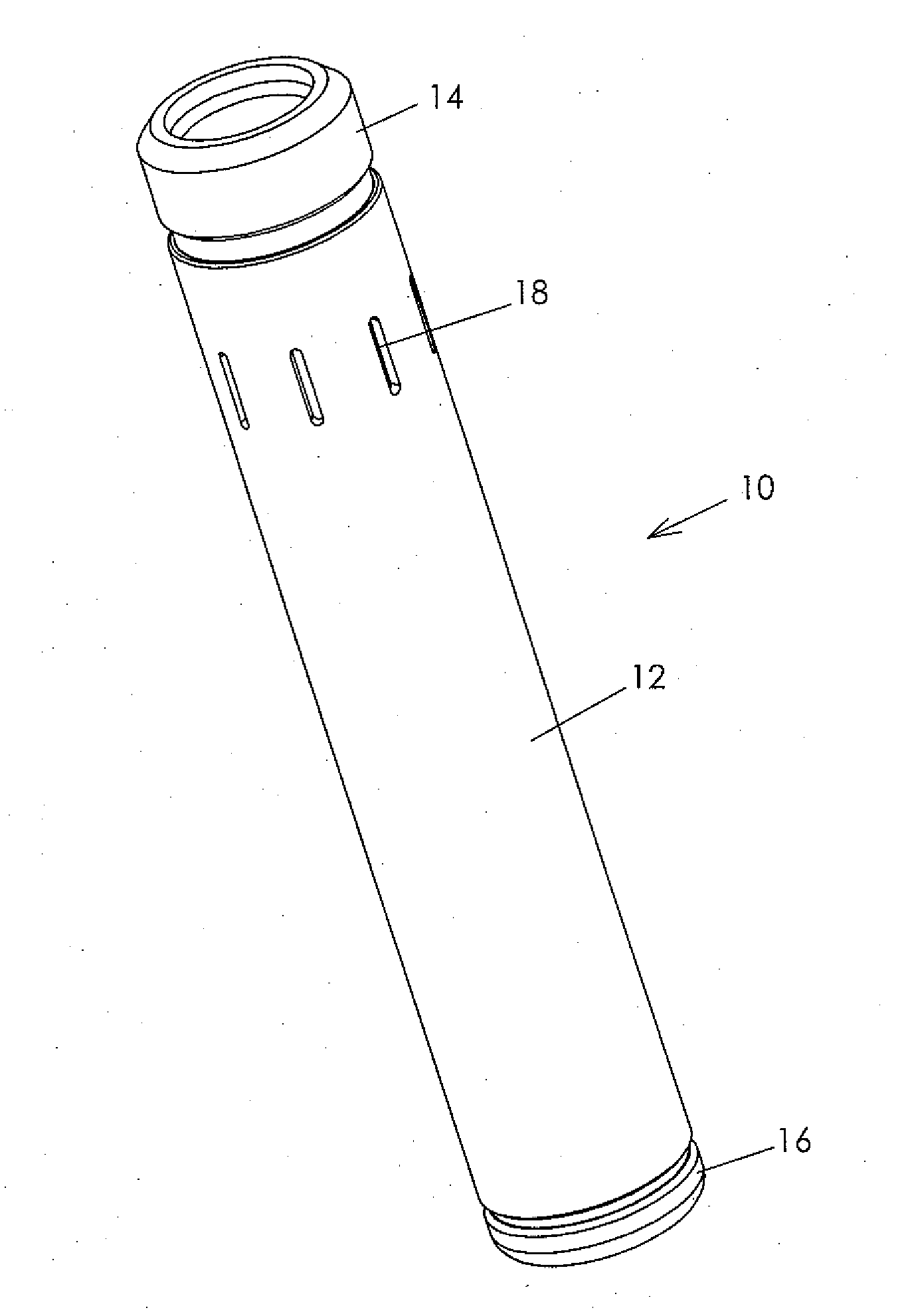

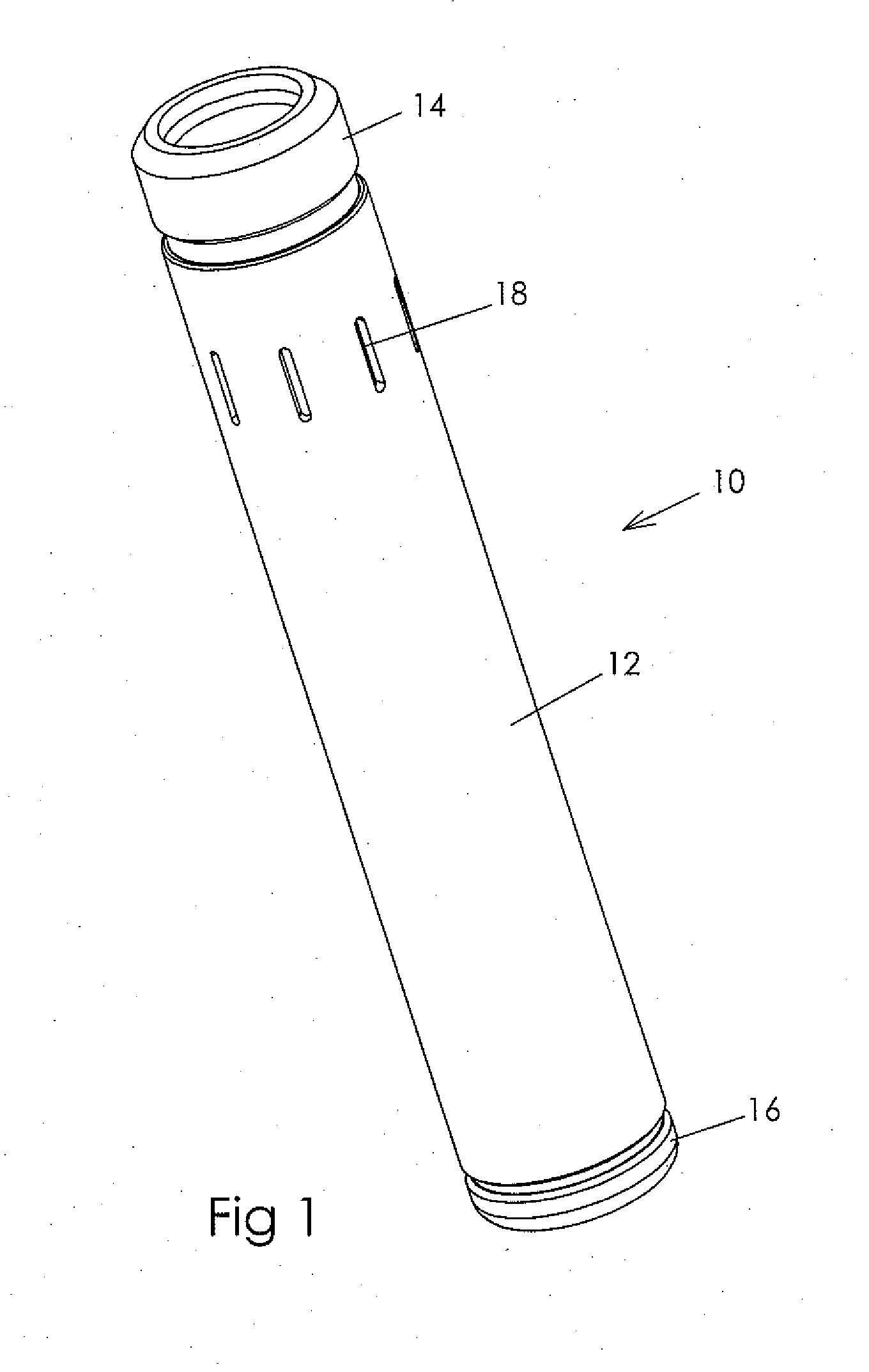

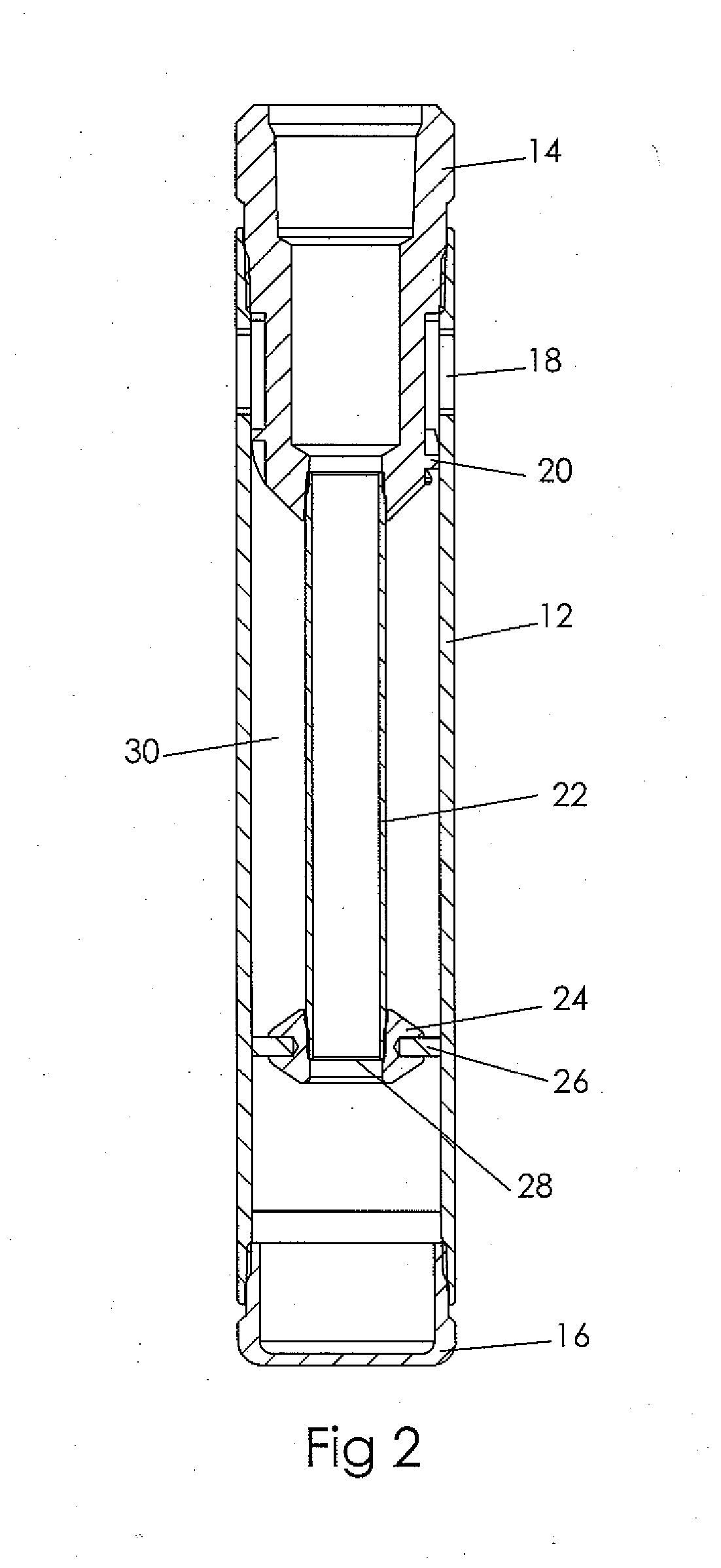

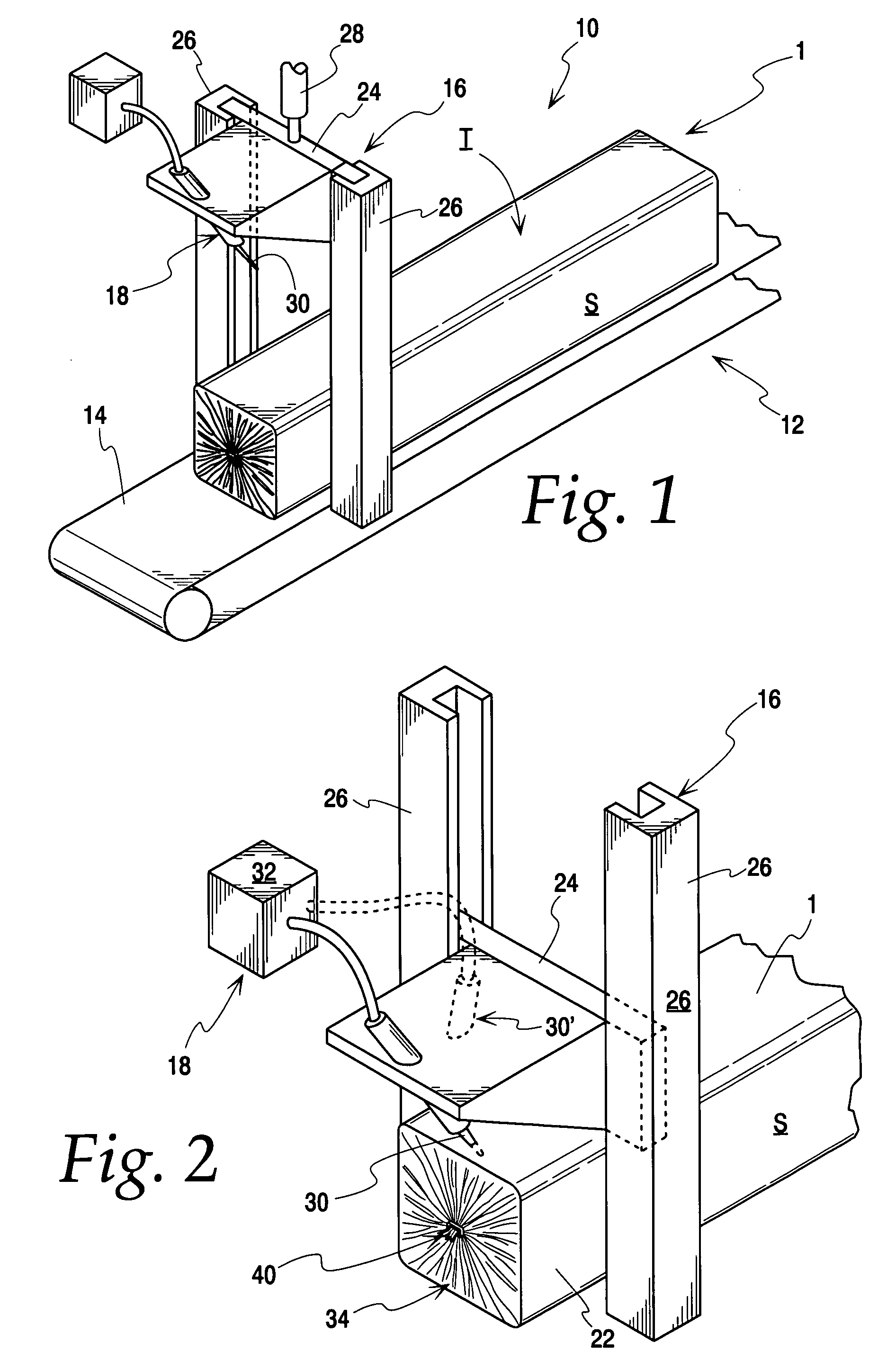

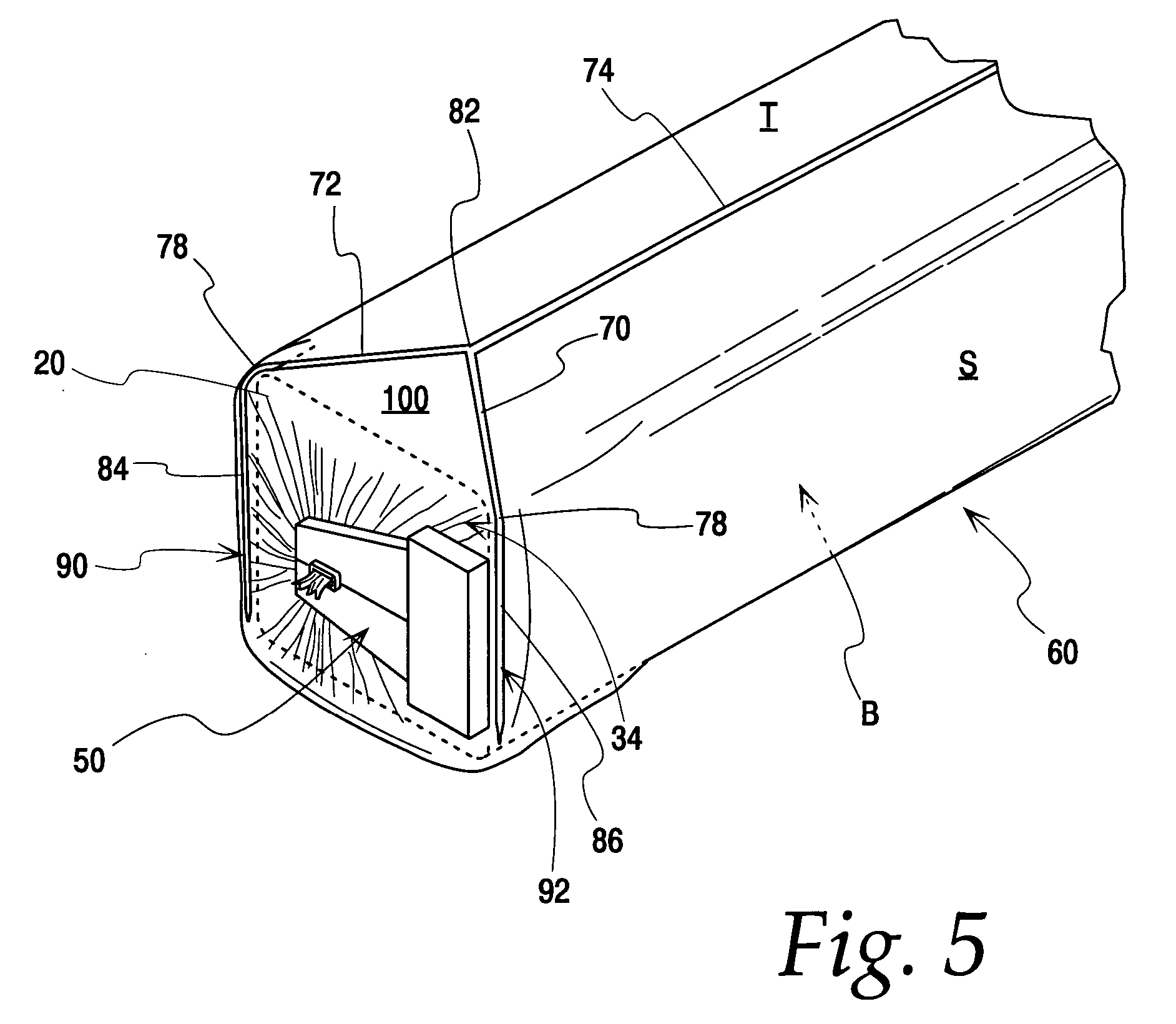

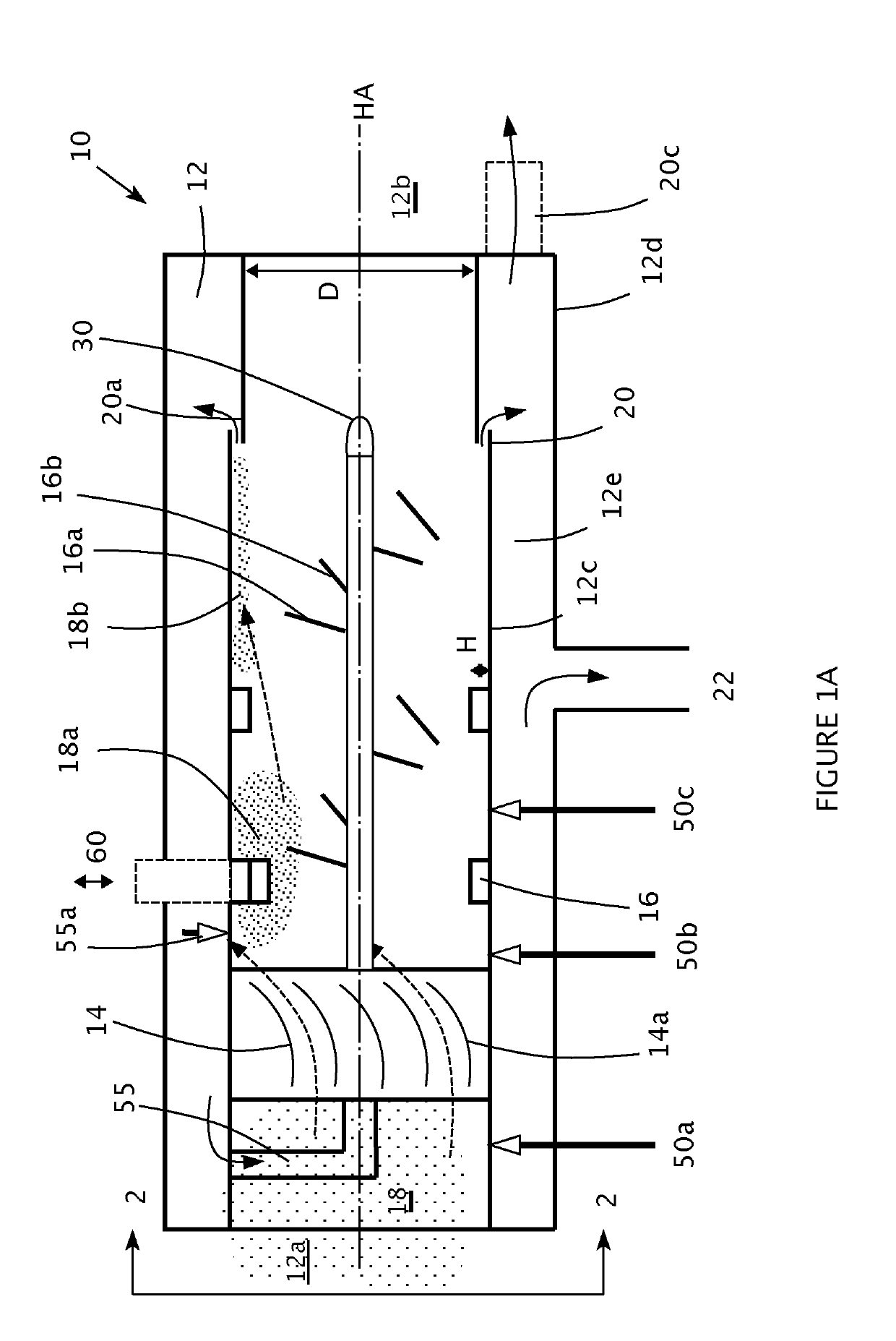

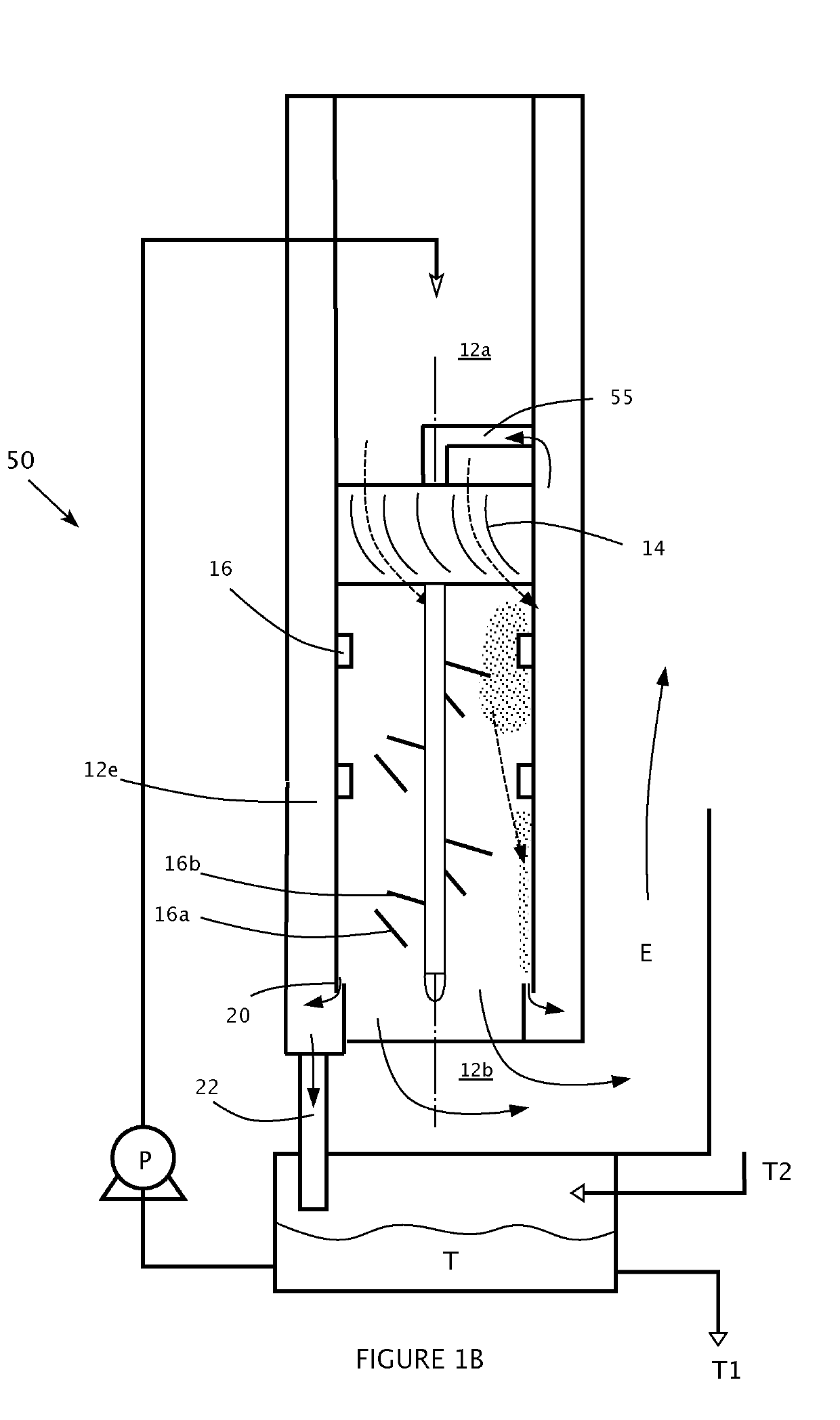

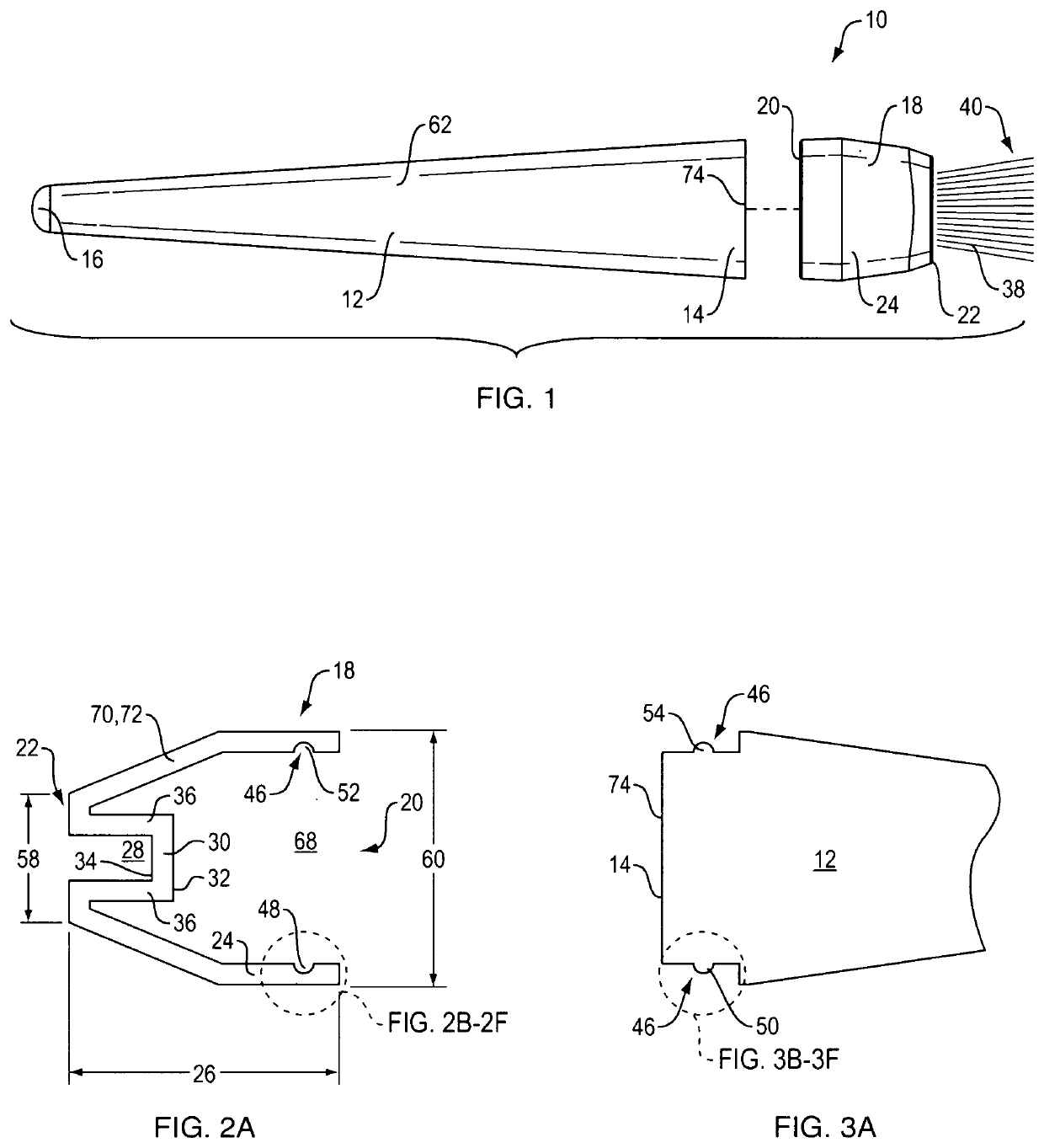

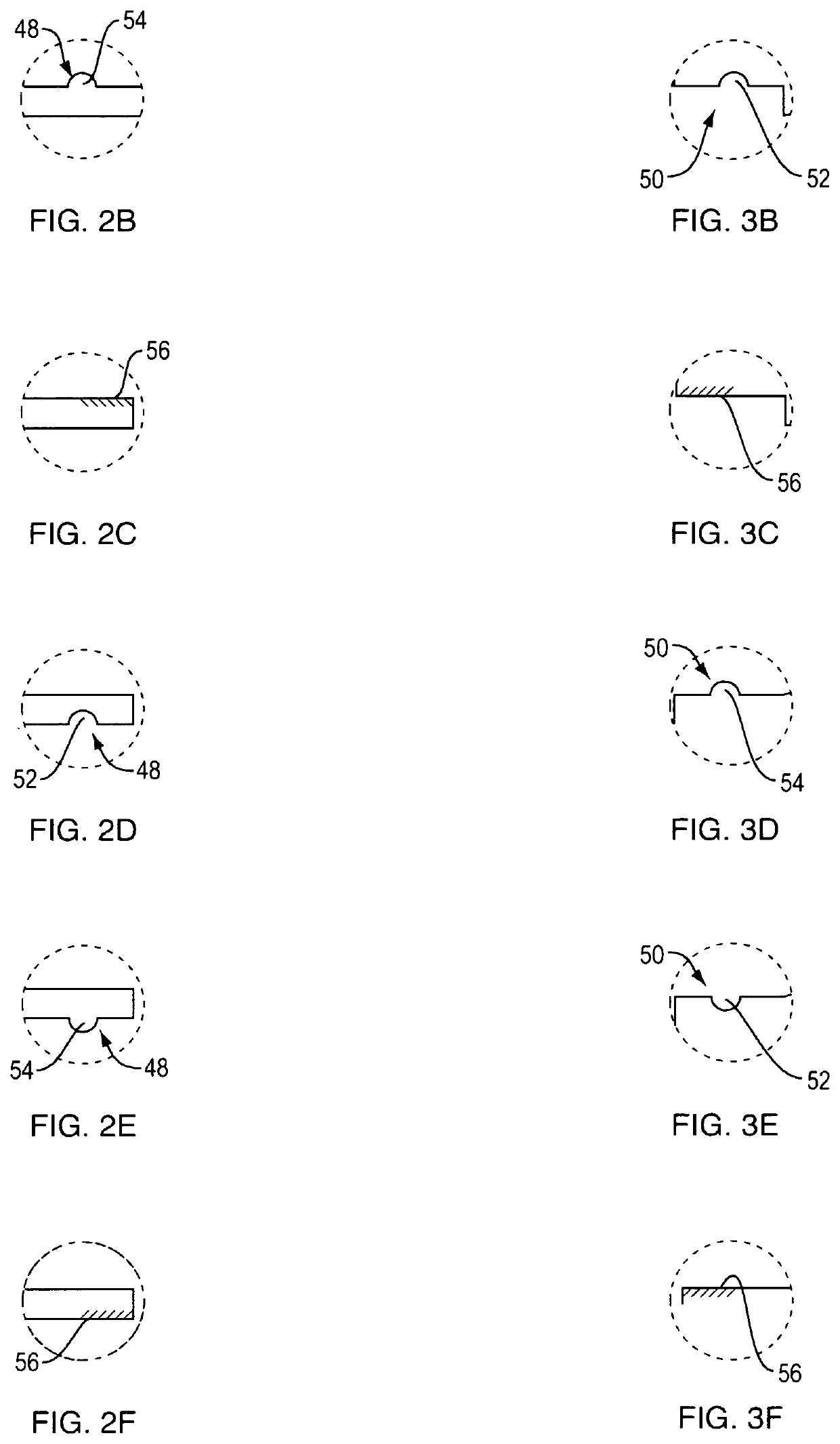

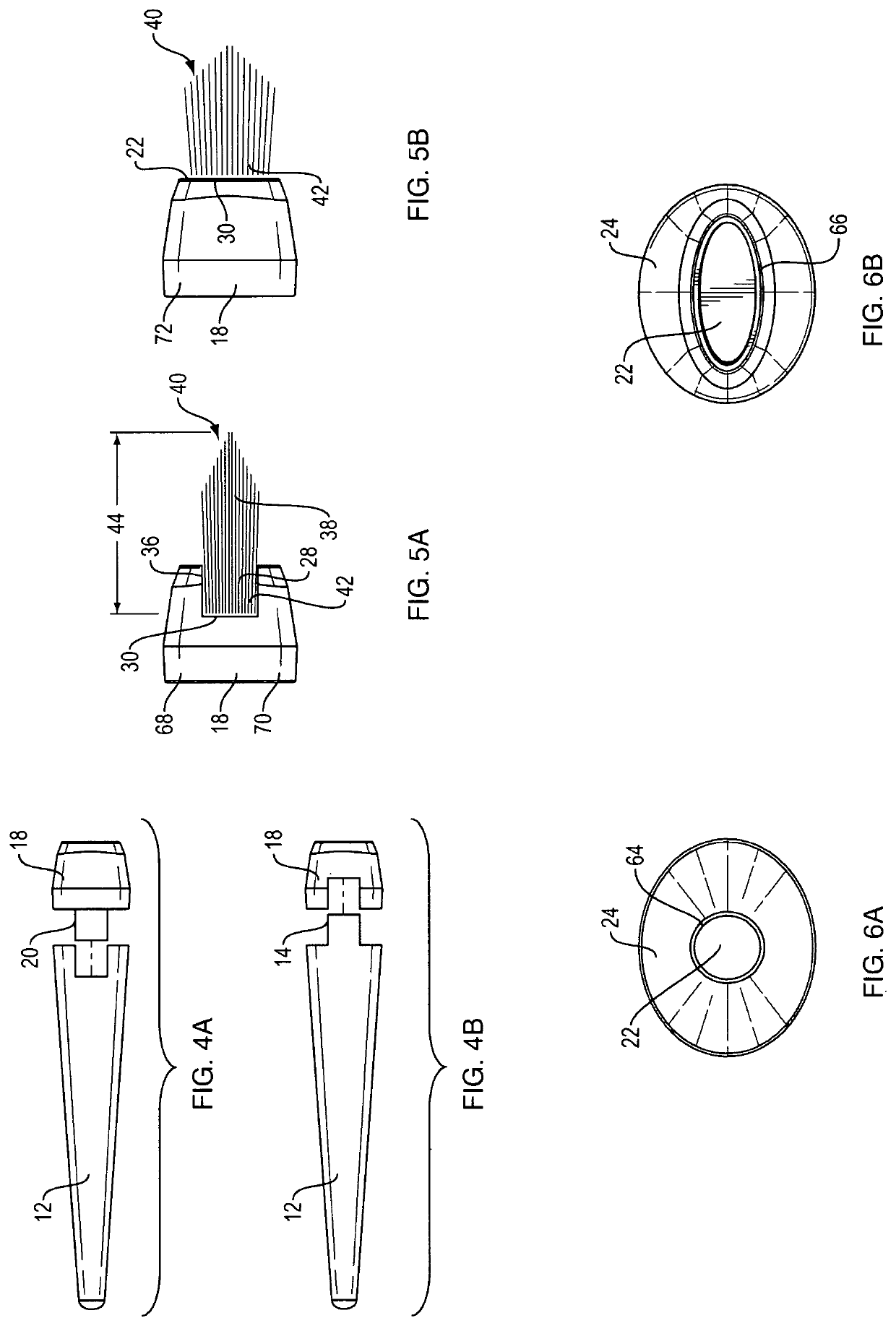

Downhole gas separator and method

A downhole separator (10) separates gas from well fluids which are pumped intermittently to the surface. The separator includes an outer tubular housing (12) and an inner flow tube (22) for passing well fluids to the surface after separation of the gas from the well fluids. A vortex flow generator or spiral gas separator (20) imparts a helical flow to effect separation of the gas from the well fluids. Gas from the gas chamber flows upward past the vortex flow generator when the pump is not pumping well fluids to the surface.

Owner:COBB DELWIN E +1

Friction plate and wet-type multi-plate clutch

InactiveUS7789209B2Improve heat resistanceReduce participationFluid actuated clutchesFriction clutchesEngineeringClutch

The present invention provides a friction plate having a friction surface formed by adhering a friction material to a substantially annular core plate and wherein the friction surface is provided with an oil passage communicated with inner and outer peripheral edges of the friction plate, a first oil groove having an opening portion opened to the inner peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges, and a second first oil groove having an opening portion opened to the outer peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges.

Owner:NSK WARNER

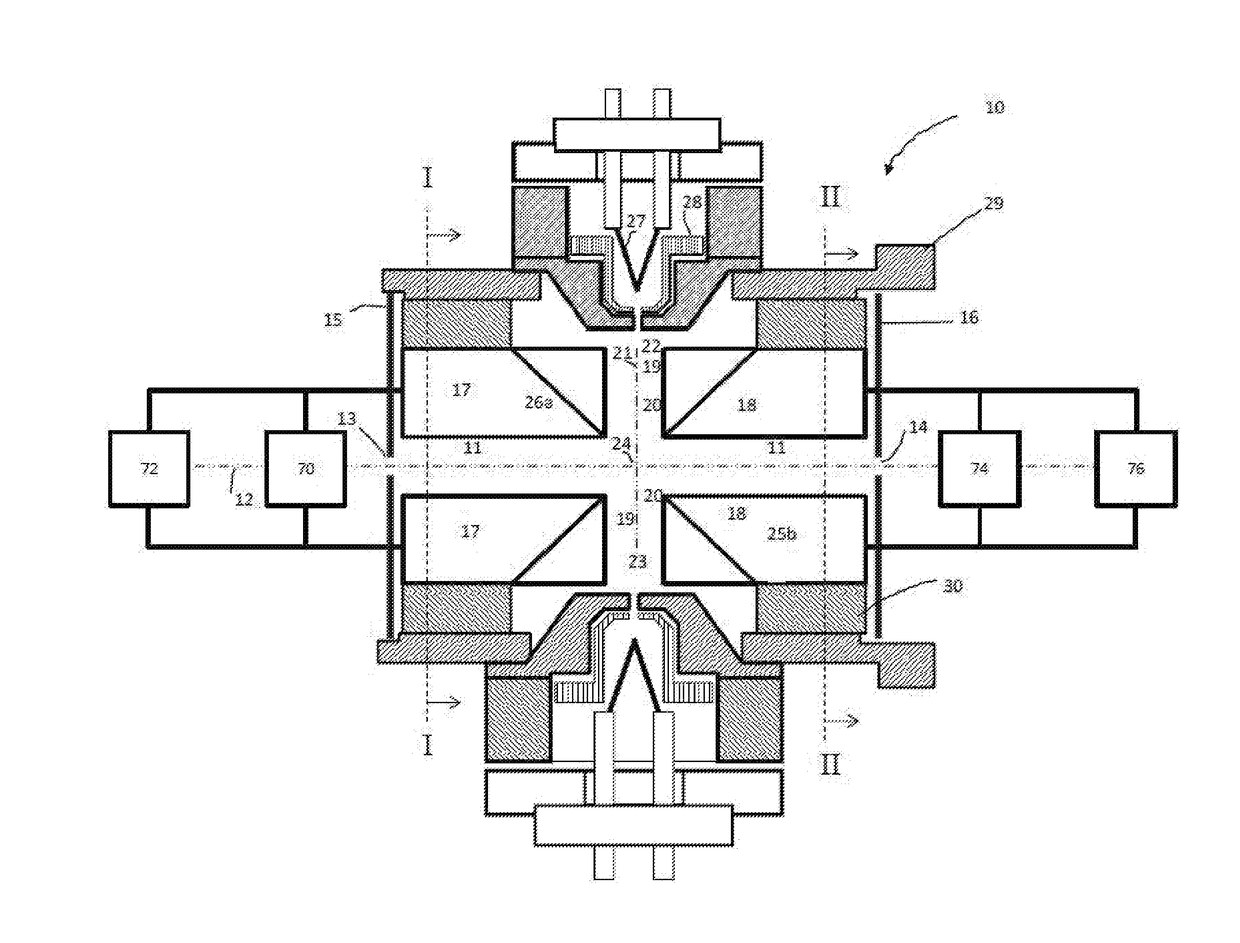

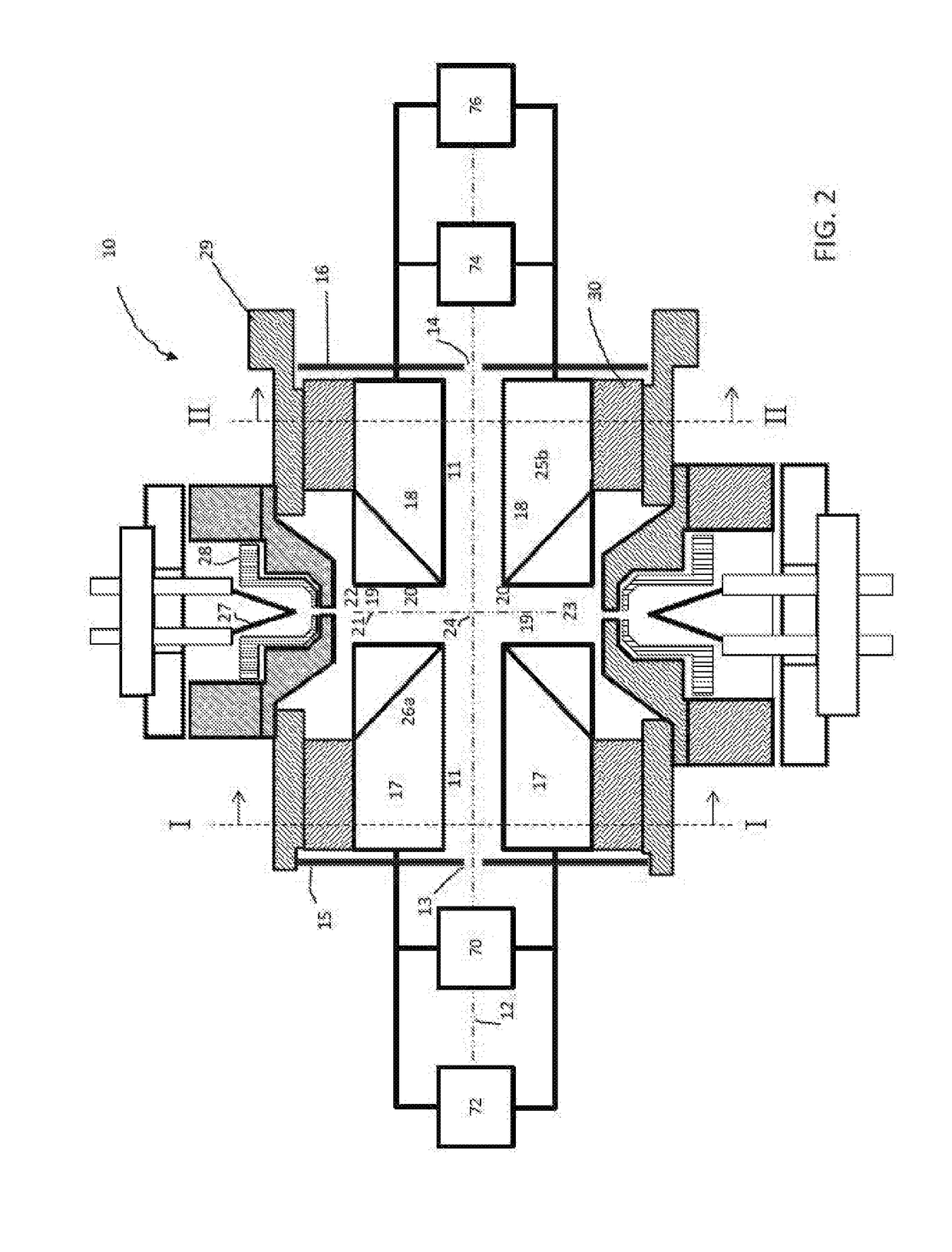

Methods For Analysis of Lipids Using Mass Spectrometry

ActiveUS20170117124A1Effect separationStability-of-path spectrometersBiological testingMass spectrum analysisDouble bond

A method and apparatus for analyzing samples using mass spectrometry are disclosed. The apparatus includes a reaction device configured to dissociate sample ions into fragments by reacting the sample ions with a charged species (e.g., electrons) such as through ECD, EID, or EIEIO. The kinetic energy of the charged species is such that the fragments may be detected and produce spectra that allow for the determination of isomeric species in the sample and the location of double bonds of sample molecules. The fragments may include radical fragments and non-radical fragments. The apparatus may also include an oxygen gas source configured to react with the radical fragments to produce oxygen-radical fragments. Spectra resulting from analysis of the fragments may allow for the determination of the oxygen-radical fragments resulting from the dissociation of the sample molecules.

Owner:DH TECH DEVMENT PTE

Blood analysis device and blood analysis method

InactiveUS7582259B2Reliable dischargeEffect separationBioreactor/fermenter combinationsBiological substance pretreatmentsMedicineBlood plasma

A blood analysis device for centrifugally separating plasma in a channel, wherein conveyance of blood, plasma and calibration liquid is effected within the device without using a pump or the like. The calibrator solution is reliably discharged from a sensor portion so as to make high precision analysis possible. A sensor section is provided in a plasma separating section and disposed on the side associated with a first centrifugal pressing direction as seen from a blood reservoir and a calibrator solution reservoir, while a calibrator solution waste reservoir is disposed in a second centrifugal pressing direction as seen from the plasma separating section (sensor section). The calibrator solution is conveyed to the sensor section by centrifugal operation in the first centrifugal direction. After sensor calibration, the calibrator solution can be reliably discharged from the sensor section by effecting centrifuging in the second centrifugal direction. After the calibrator solution discharge, centrifuging is effected again in the first centrifugal direction, thereby conveying the blood in the blood reservoir to the sensor section and effecting separation of blood cells and plasma. In the case of providing a plurality of sensors, a blood introducing channel from the blood reservoir is branched downwardly of a sensor groove for communication, with the blood cells being fractionated in the branch section. The individual sensors can be isolated from each other by blood cell fraction, making higher precision analysis possible.

Owner:JAPAN SCI & TECH CORP

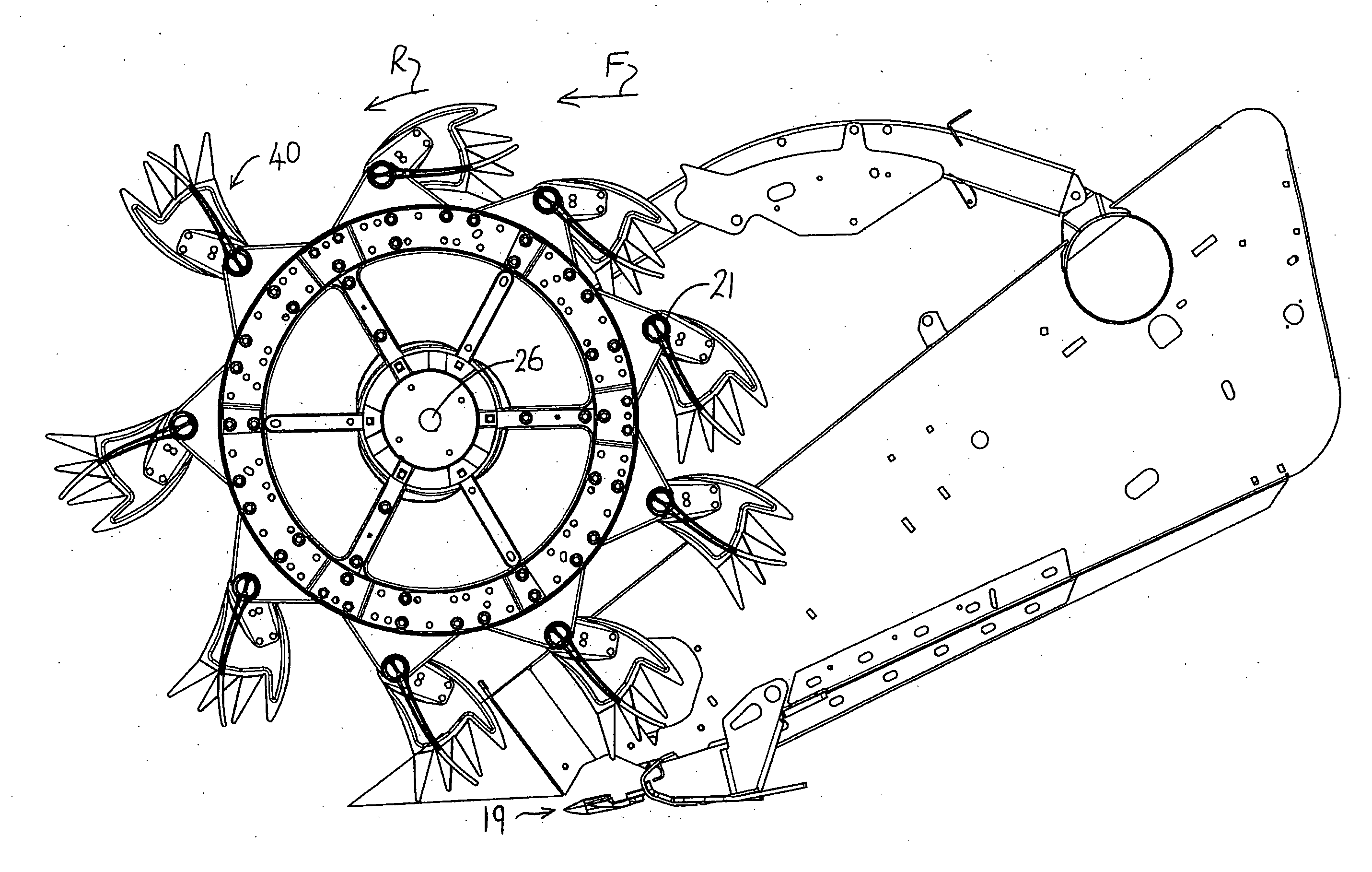

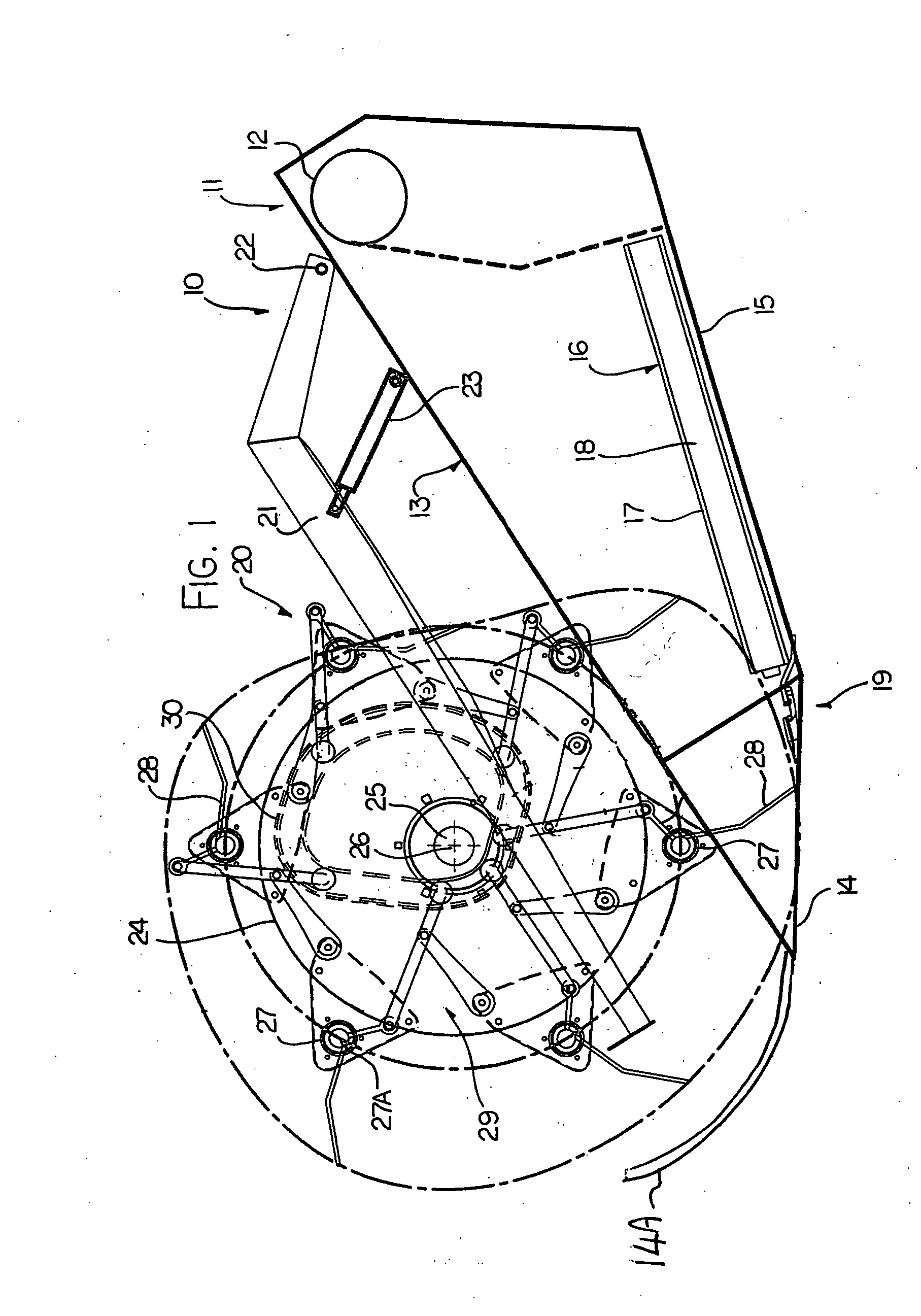

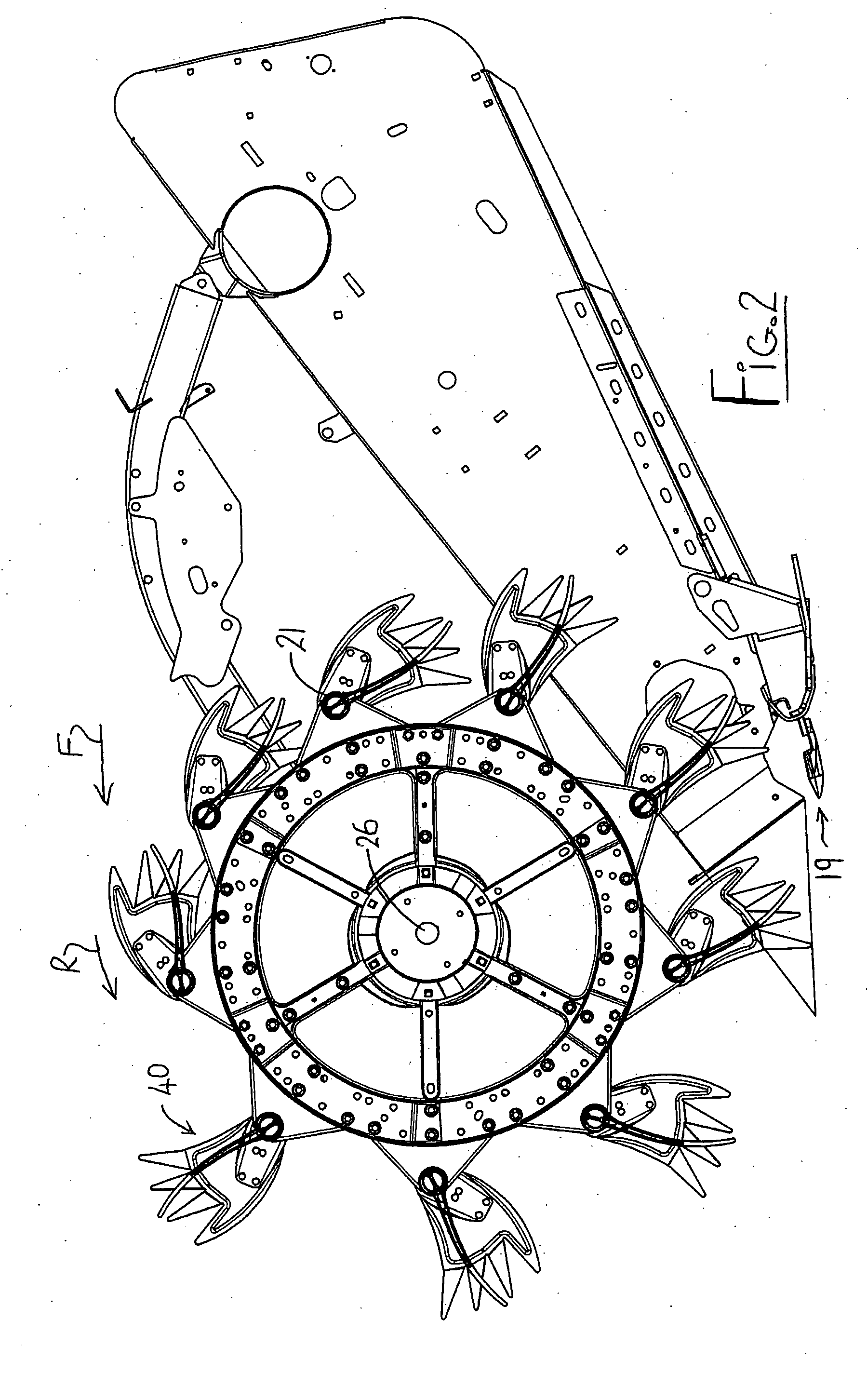

Crop harvesting header with crop divider members carried on the reel

ActiveUS20060201126A1Effect separationConvenient ArrangementMowersClimate change adaptationPropellerEngineering

A crop harvesting header includes a cutter bar arranged across a forward edge, a draper or auger transport arrangement for transporting the cut crop, and a reel mounted on reel arms having a plurality of reel bats at spaced positions around the reel axis each reel bat having reel fingers projecting generally radially outwardly from the reel axis. Each bat is mounted for pivotal movement about its bat axis. At both ends of each bat is mounted a crop divider which pivots with the bat and is formed with a plate lying in a radial plane of the bat with angularly spaced fingers around the outer edge. A leading edge of the plate and front finger is convexly curved relative to the concave curve of the front edge of the finger and is angularly advanced relative to the leading edge of the adjacent fingers such that the rotating crop dividers on the reel co-operate with a stationary crop on the header to separate the cut crop from uncut crop passing alongside the end of the header.

Owner:MACDON INDS

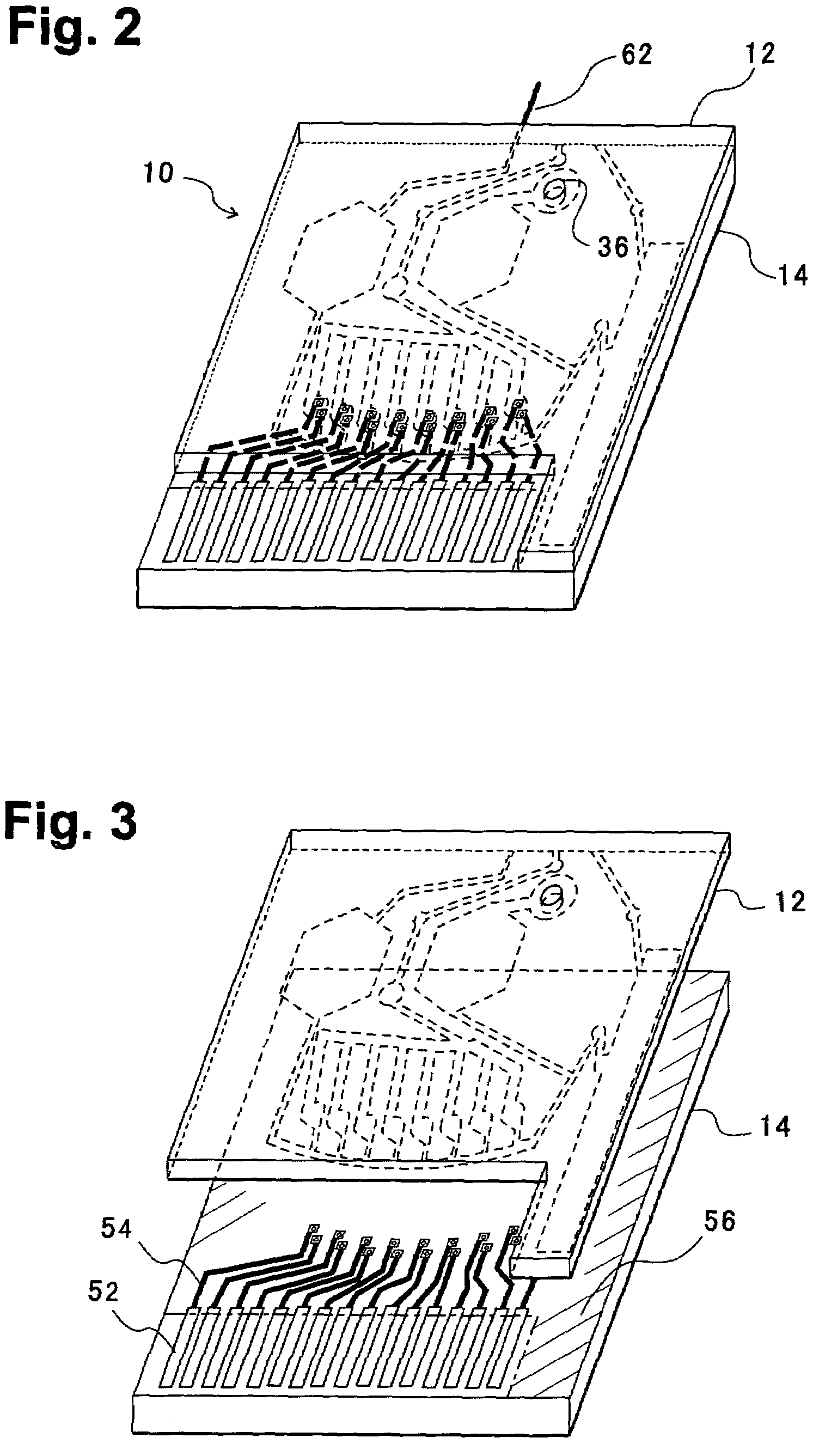

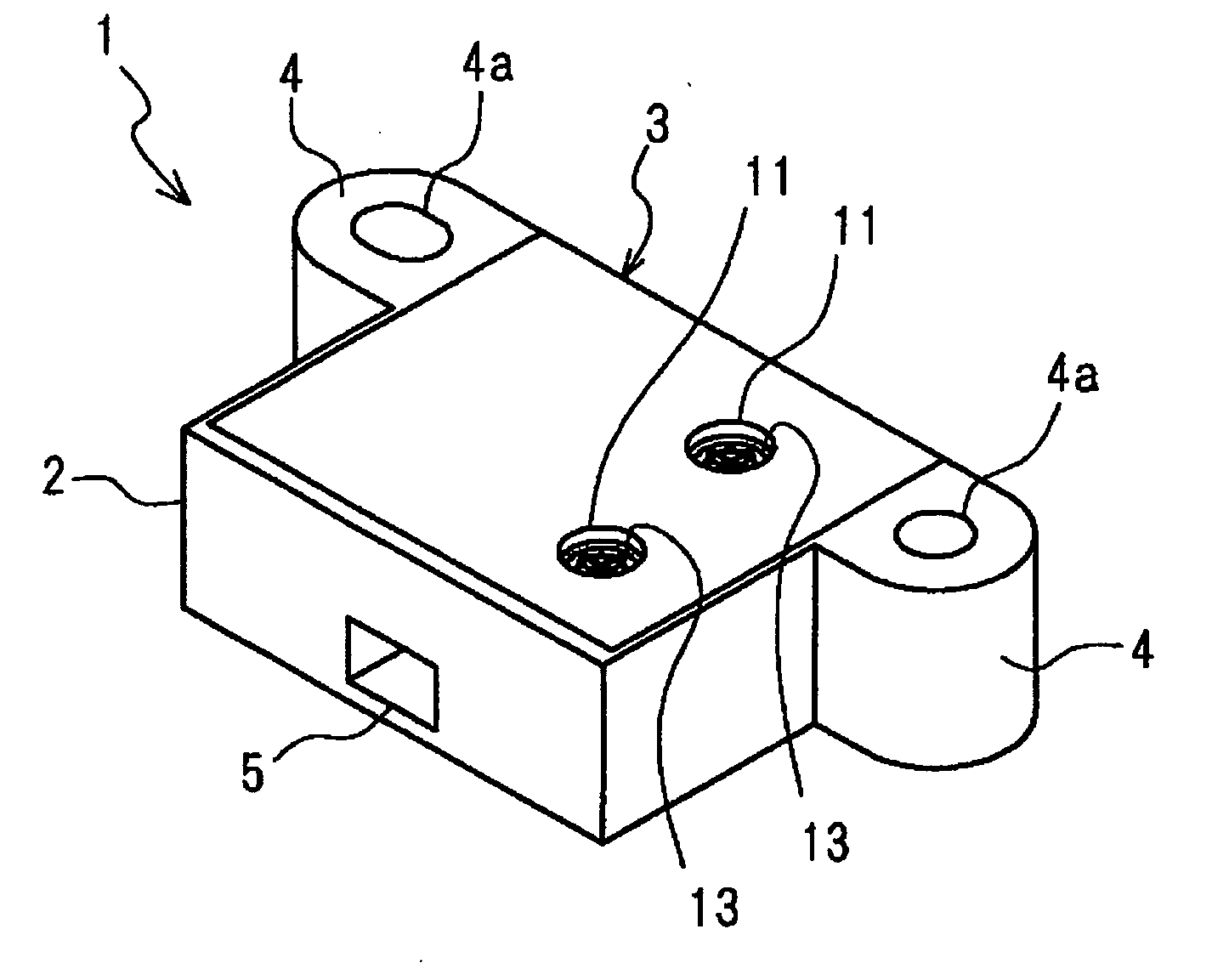

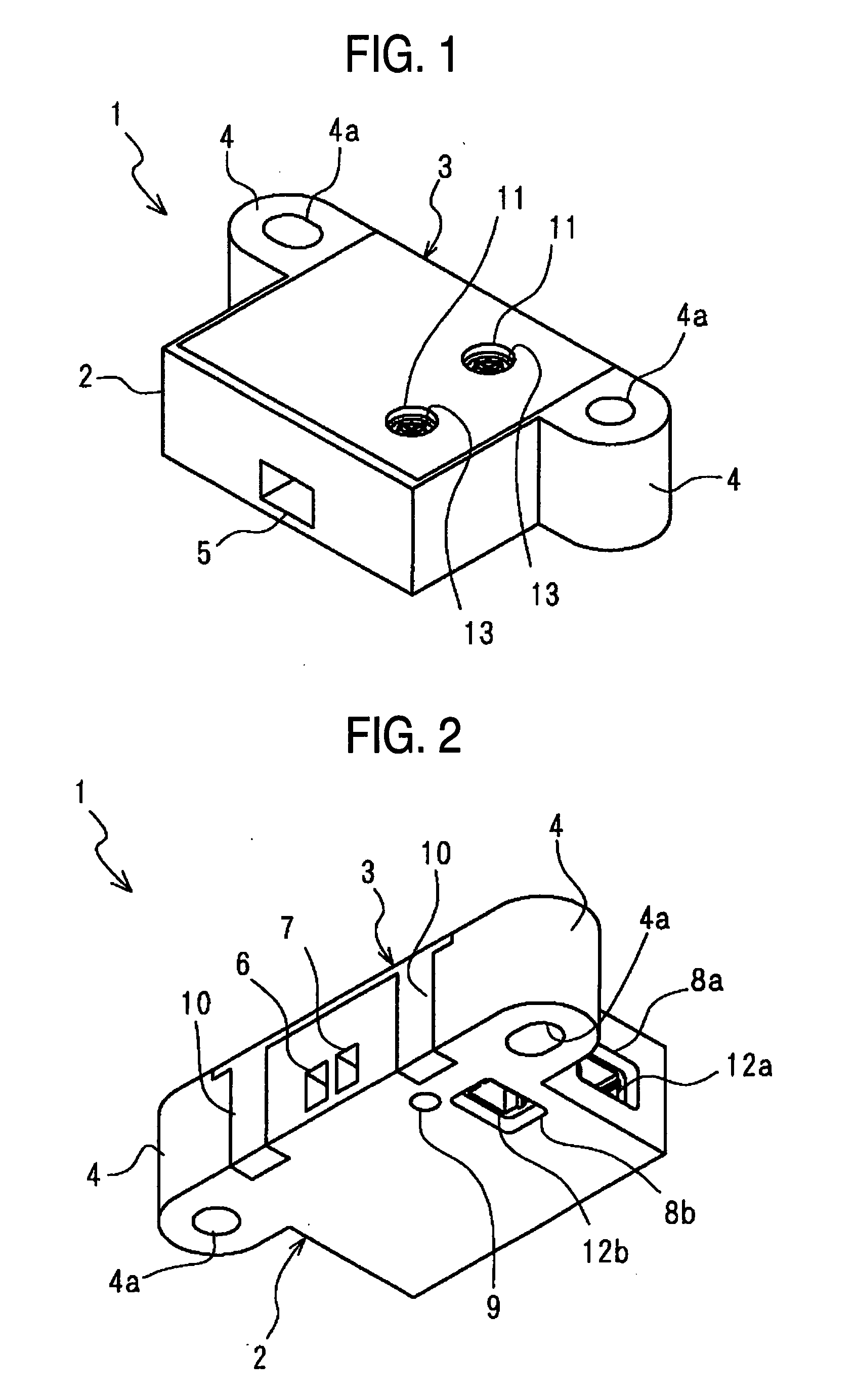

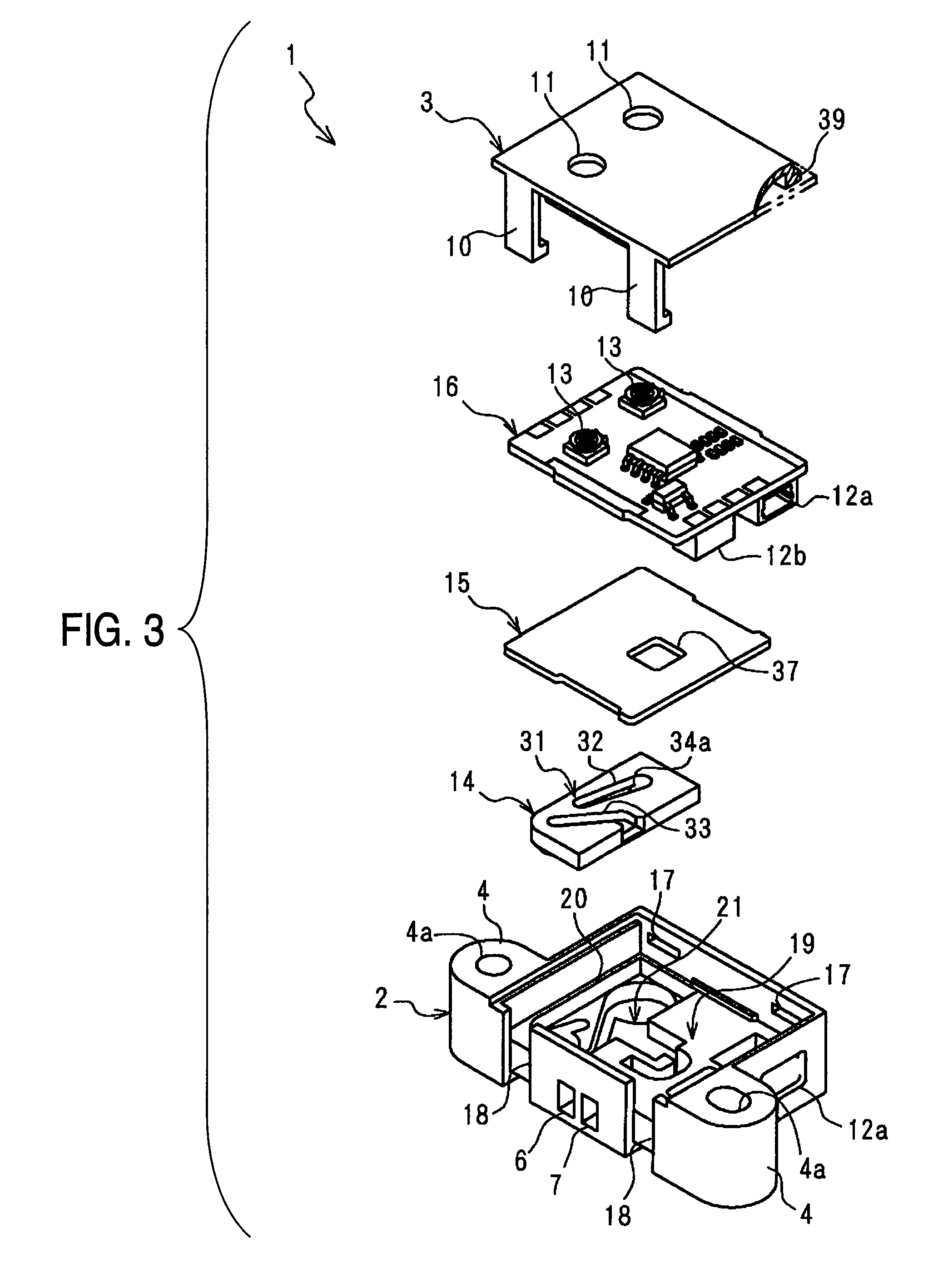

Flow velocity measuring device

ActiveUS20050188760A1Efficient separationNot as easy to enterVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringDirt

A flow velocity measuring device is able to conduct a fluid to a sensor element after removal of dust and dirt contained in the fluid to accurately measure the flow velocity of the fluid even when the fluid is low in flow velocity and the device is mounted in any direction. A flow passage is formed by internal spaces, which have curved wall surfaces, introduction passages connected to the internal spaces at one ends of the wall surfaces tangentially to the wall surfaces, discharge passages connected to the internal spaces at the other ends of the wall surfaces tangentially to the wall surfaces, and branch discharge passages connected to the internal spaces at substantially right angle to a direction, in which the wall surfaces are curved, and a sensor element is arranged in the branch passage or a flow passage connected to the branch passage.

Owner:ORMON CORP

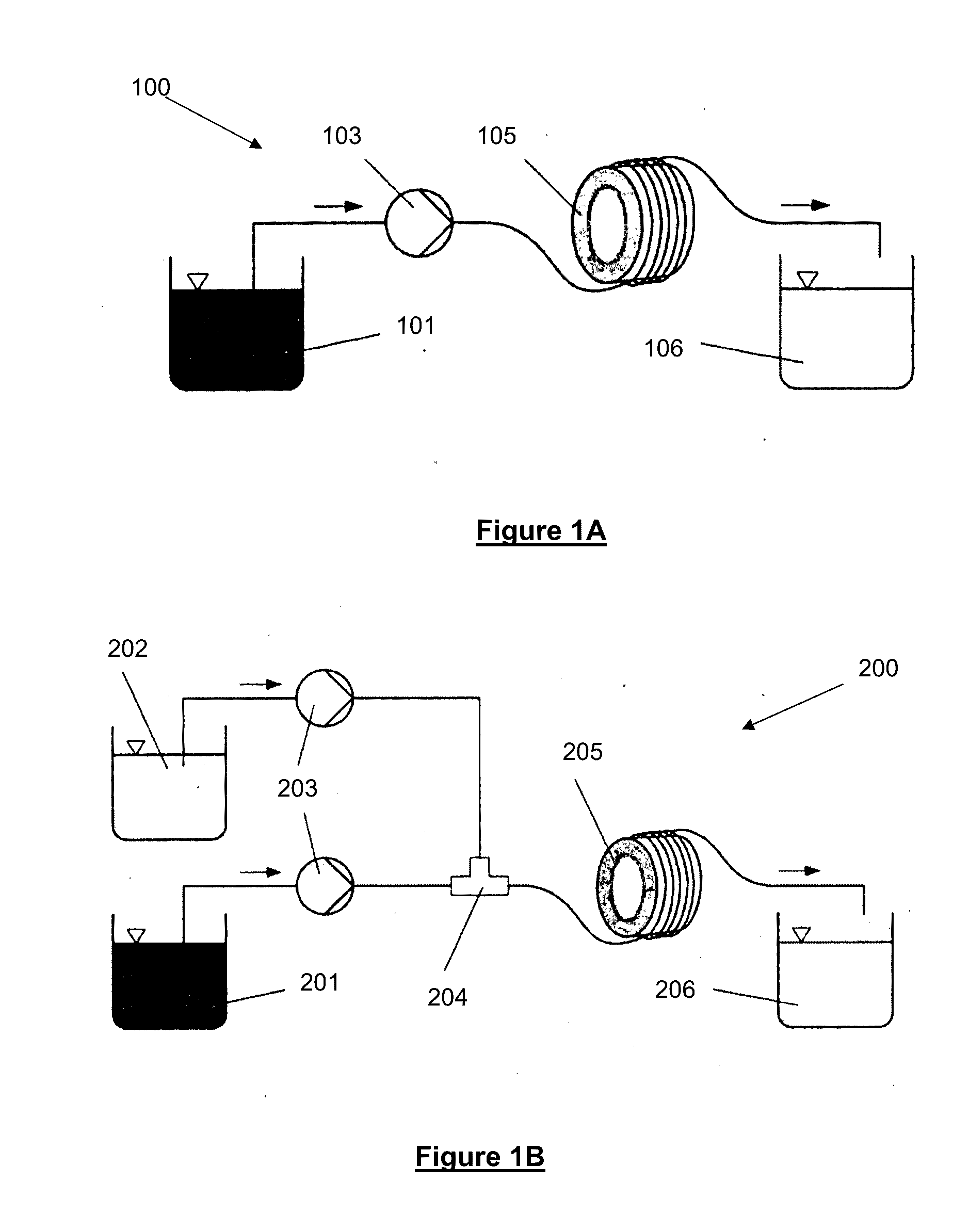

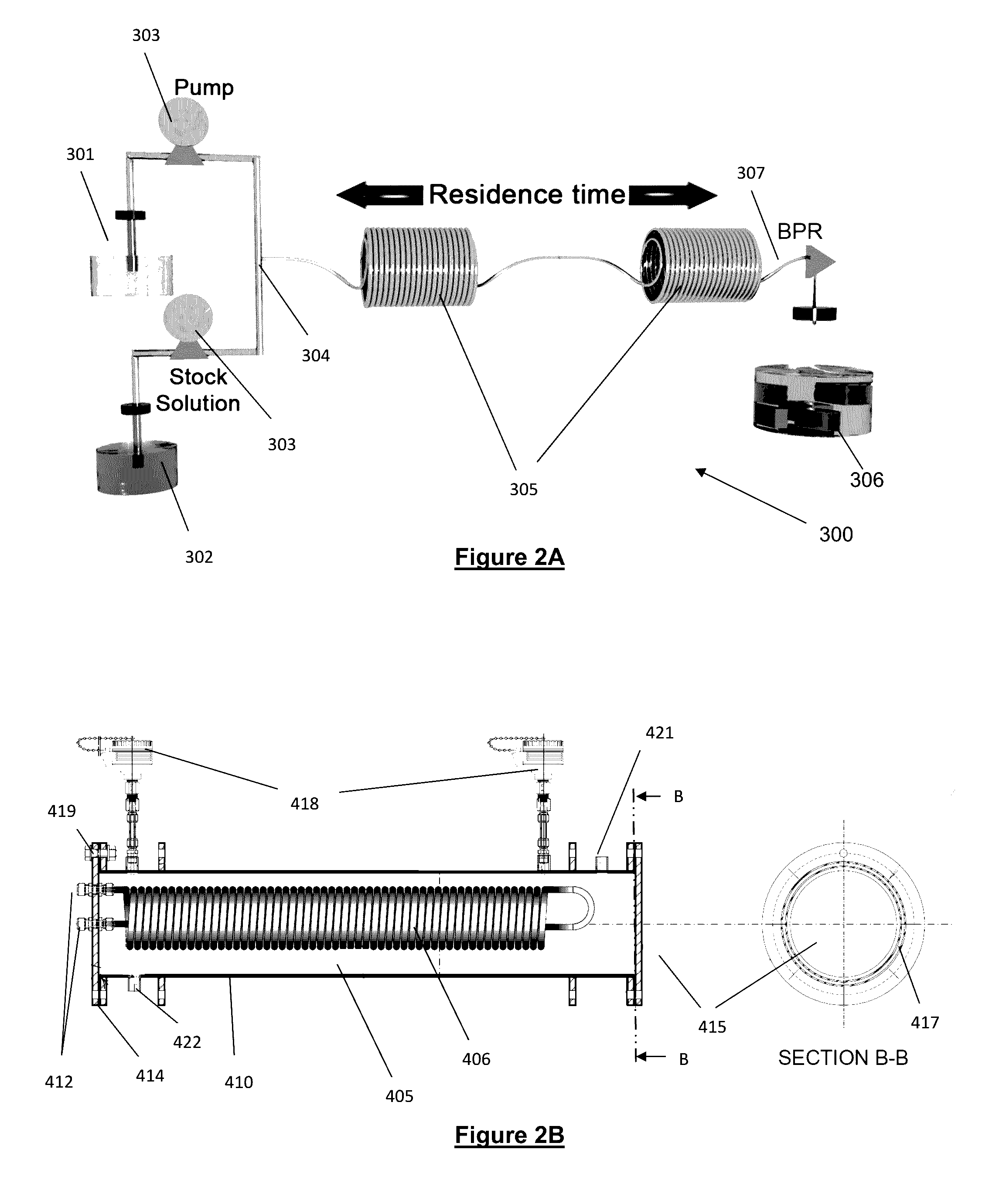

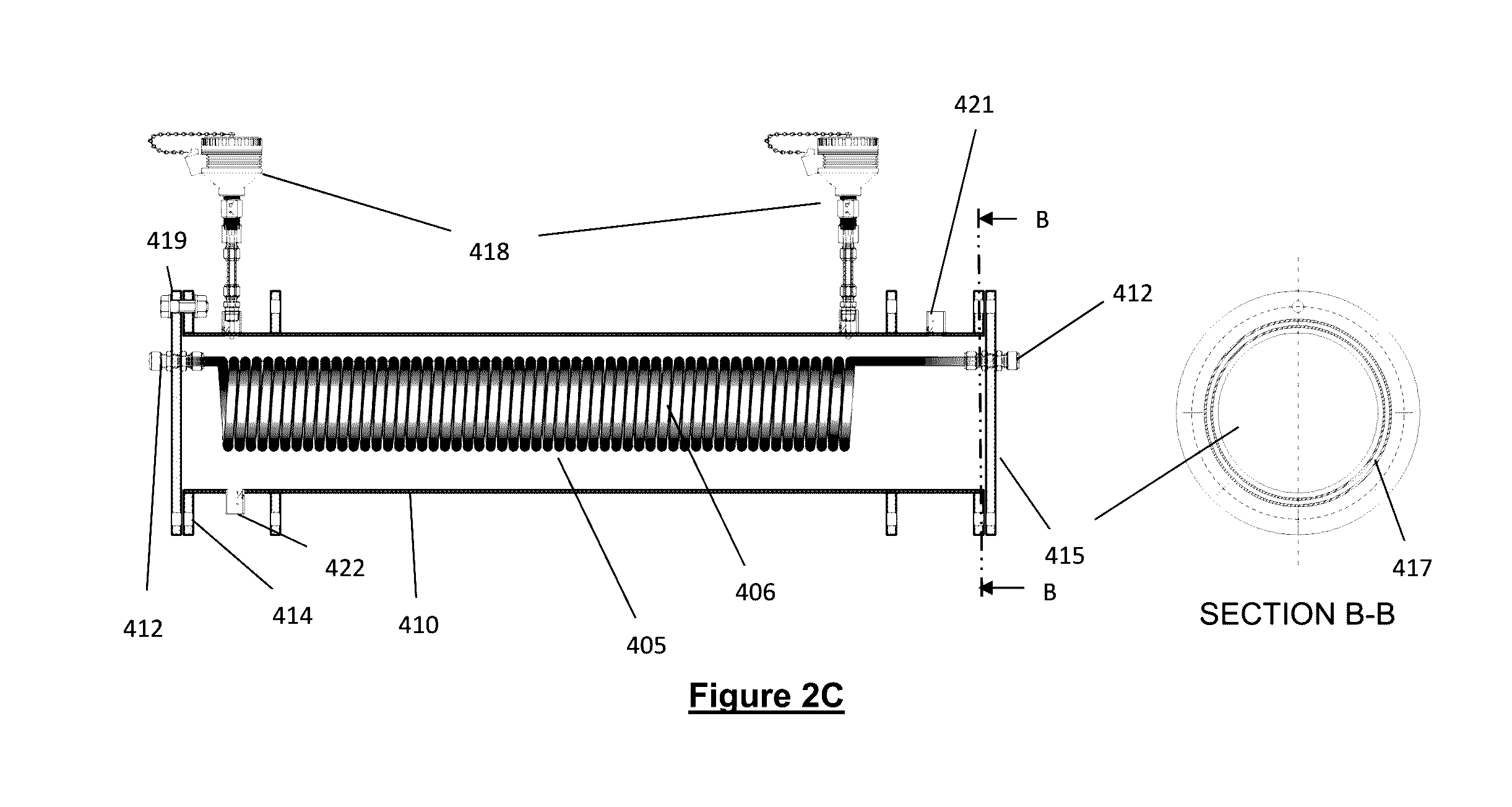

Production of metal-organic frameworks

ActiveUS20160347774A1Effect separationSpecificity of separationProcess control/regulationGroup 4/14 element organic compoundsMetal-organic frameworkMetal

Owner:COMMONWEALTH SCI & IND RES ORG

Method for detecting disease markers

InactiveUS20110031122A1Easy to separateHeat generation is minimizedCompound screeningElectrolysis componentsOrganic solventDisease markers

Disease specific markers, in particular cancer markers, can be detected by electrophoretically separating proteins and protein complexes from a biological sample on a protein binding polymeric membrane in a low conductivity, water-miscible organic solvent buffer. Electrophoretic separation profiles representing different diseases can be produced, and used in the diagnosis or prognosis of these diseases.

Owner:TEMPLE UNIVERSITY

Flow velocity measuring device

ActiveUS7062963B2Accurate measurementLess dustVolume/mass flow by thermal effectsVolume flow proportion measurementMeasurement deviceEngineering

A flow velocity measuring device is able to conduct a fluid to a sensor element after removal of dust and dirt contained in the fluid to accurately measure the flow velocity of the fluid even when the fluid is low in flow velocity and the device is mounted in any direction. A flow passage is formed by internal spaces, which have curved wall surfaces, introduction passages connected to the internal spaces at one ends of the wall surfaces tangentially to the wall surfaces, discharge passages connected to the internal spaces at the other ends of the wall surfaces tangentially to the wall surfaces, and branch discharge passages connected to the internal spaces at substantially right angle to a direction, in which the wall surfaces are curved, and a sensor element is arranged in the branch passage or a flow passage connected to the branch passage.

Owner:ORMON CORP

Automated extraction of casing clips from cooked meat products

InactiveUS20050100644A1Effect separationSkinless sausage makingBakery productsHEPAPulp and paper industry

A method apparatus for removing a casing, particularly a casing with a clip end embedded in the product, is disclosed where the clipped end is clamped and gas is injected into this end to blow out the clip and casing end while the clamped portion prevents the entire casing from being inflated. The air or gas, such as HEPA filtered air, is injected into the product with a needle, for instance, to balloon out the casing in the clamped area to free the previously embedded clip. The clip is then gripped, certain cuts are made in the casing, and the casing is pulled from the product. An injector such as a needle is inserted into the end portion of the product and pressurized gas, such as HEPA filtered air, is injected into the end portion. The injection of the gas causes the casing to balloon out from the product thereby freeing the previously embedded clip. The freed clip is then gripped while the casing is then cut for removal. The casing may be cut in a Y-shape with two cuts beginning approximately at two corners of one side of the square end and angled towards each other along a side of the product. The two cuts meet, and a third cut is made longitudinally along the length of the product beginning at the meeting point of the two angled cuts. The gripped clip and casing are pulled causing the casing to separate from the product along the cut lines.

Owner:KRAFT FOODS GRP BRANDS LLC

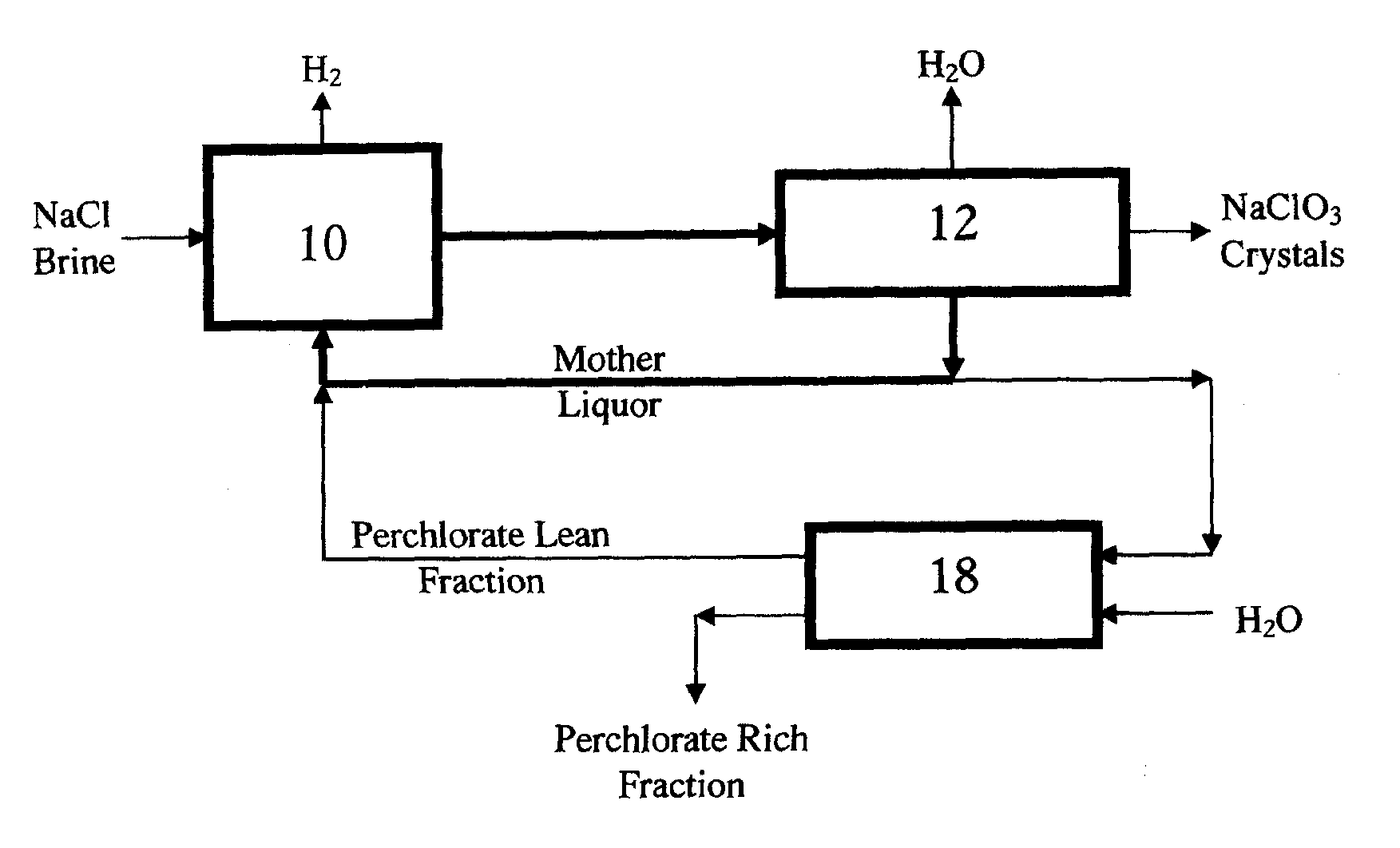

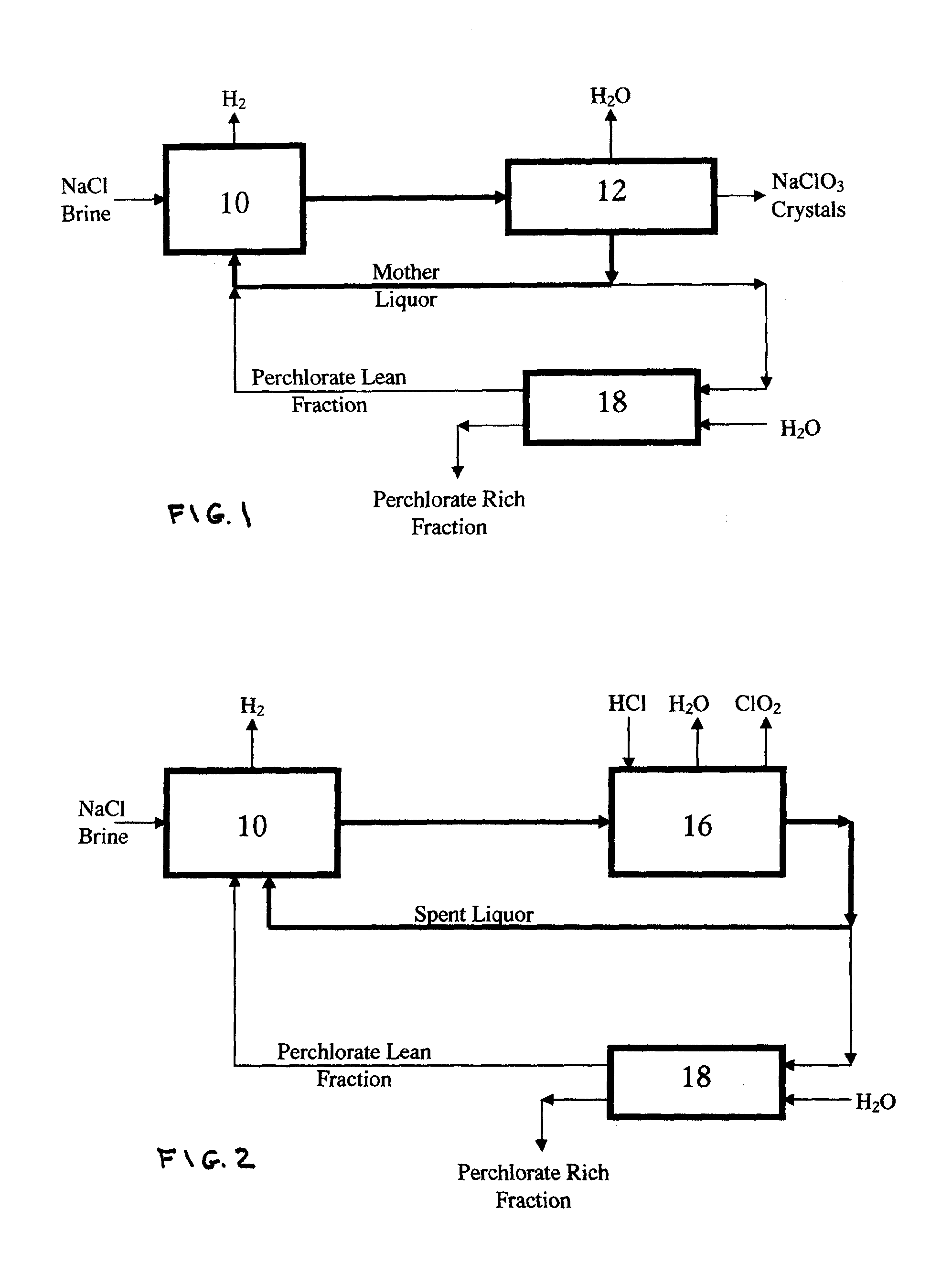

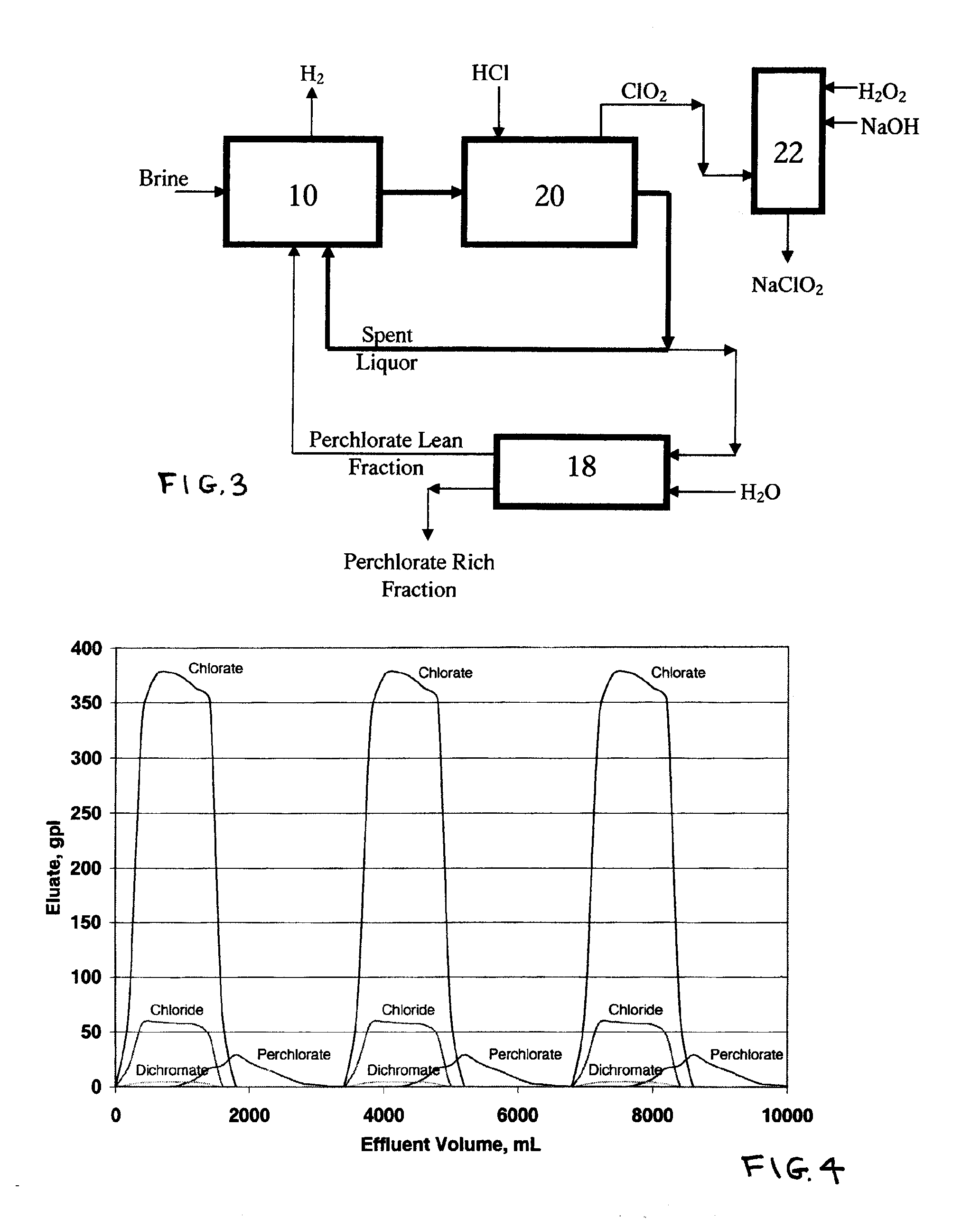

Perchlorate removal from concentrated salt solutions using amphoteric ion-exchange resins

InactiveUS20120152759A1Extended process operating timeHigh material utilizationIon-exchanger regenerationWater contaminantsChlorate ionSodium chlorate

A process for reducing the concentration of perchlorate in an aqueous concentrated multi-component salt solution comprising treating the salt solution with an amphoteric ion-exchange resin to provide an adsorbed perchlorate and multi anion-containing resin and a perchlorate depleted solution; and removing the perchlorate depleted solution. The multi-anion are selected from chloride, chlorate, perchlorate, sulphate, and dichromate, present in electrolytic processes for the production of sodium chlorate.

Owner:CHEMETICS

Size separation of analytes using monomeric surfactants

InactiveUS6878254B2Easy to separateEfficient separationSludge treatmentVolume/mass flow measurementEquivalent weightCell separation

A sieving medium for use in the separation of analytes in a sample containing at least one such analyte comprises a monomeric non-ionic surfactant of the of the general formula, B-A, wherein A is a hydrophilic moiety and B is a hydrophobic moiety, present in a solvent at a concentration forming a self-assembled micelle configuration under selected conditions and having an aggregation number providing an equivalent weight capable of effecting the size separation of the sample solution so as to resolve a target analyte(s) in a solution containing the same, the size separation taking place in a chromatography or electrophoresis separation system.

Owner:IOWA STATE UNIV RES FOUND

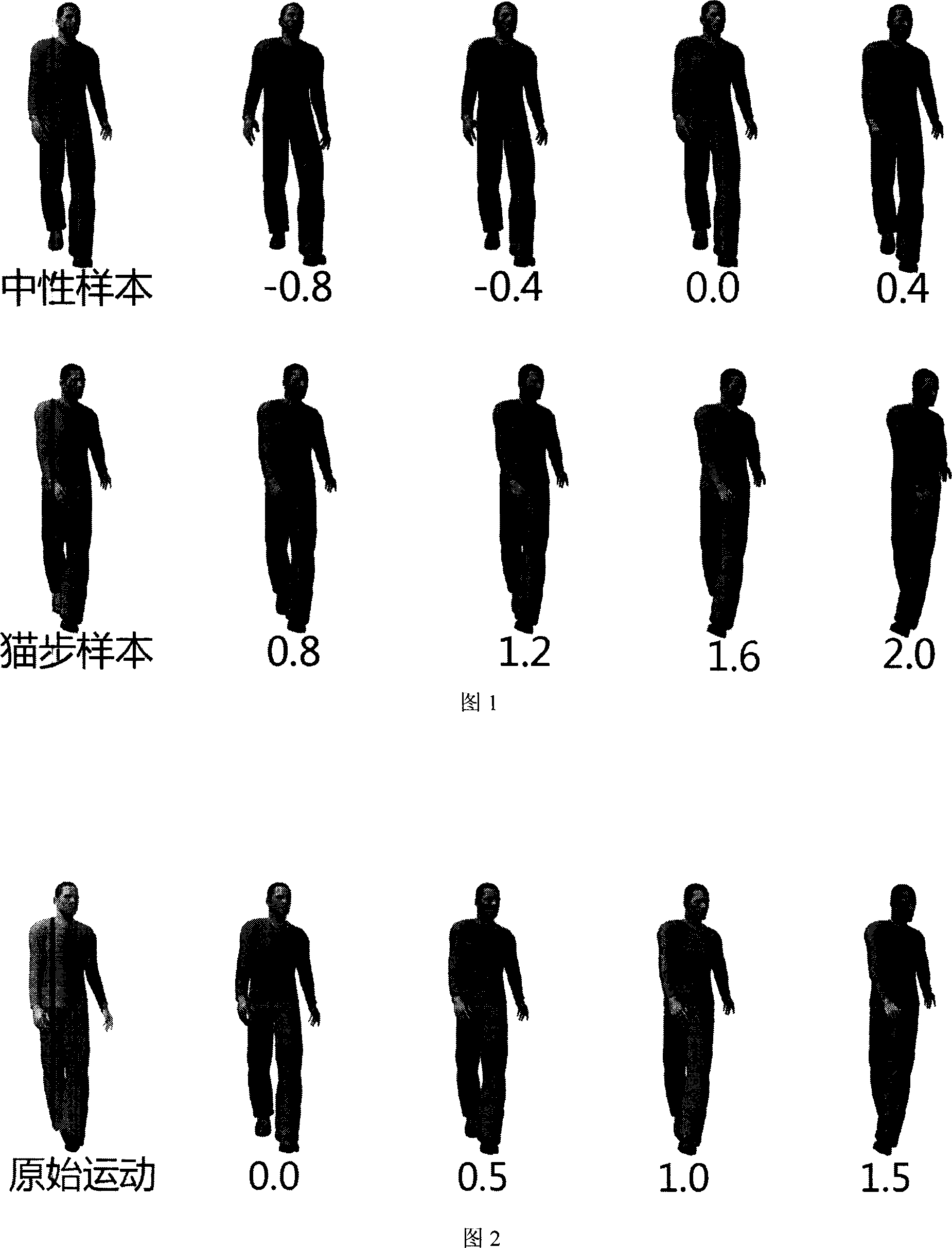

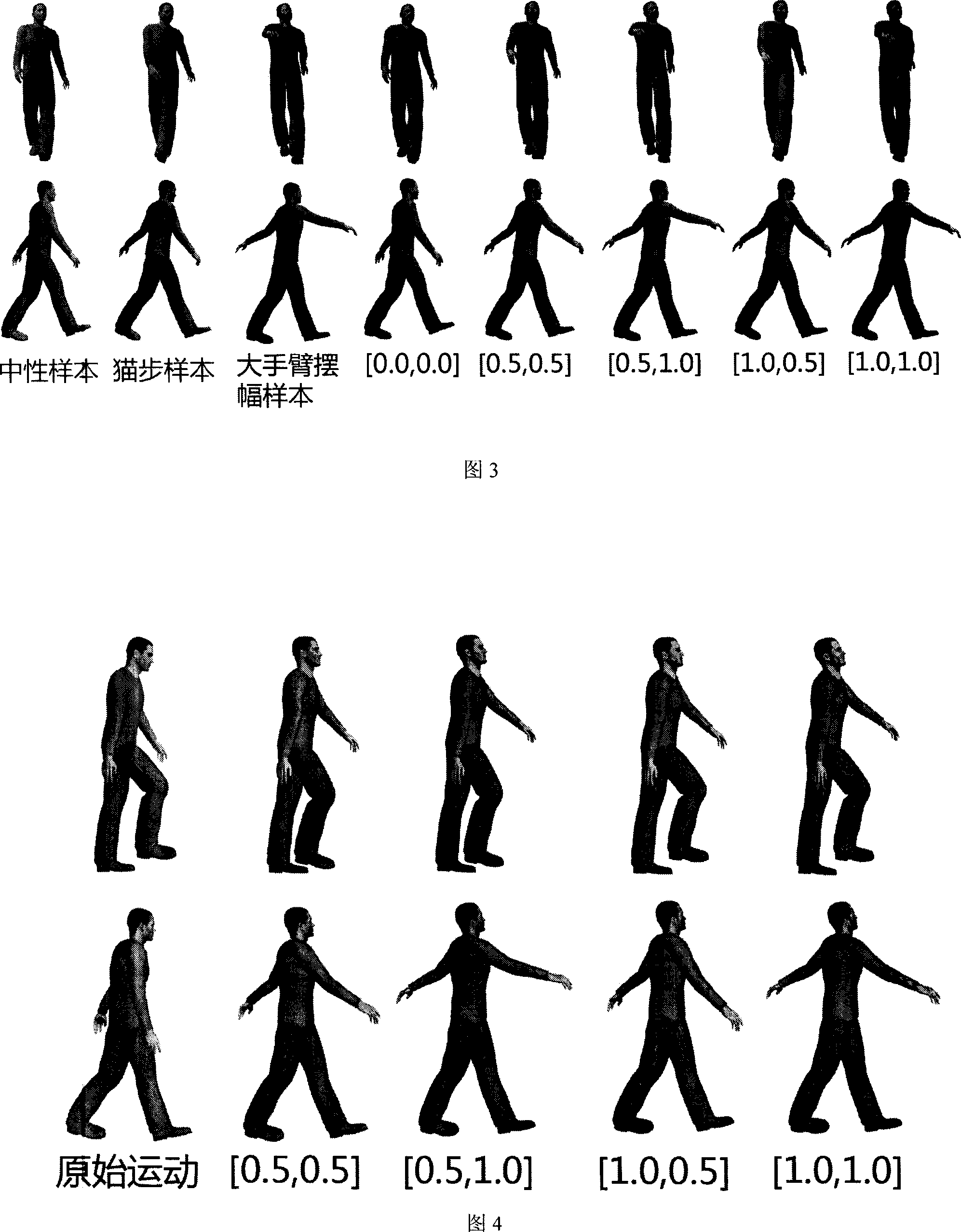

Stylized body movement generating and editing method based on sub-space technology

InactiveCN101071512ASolve mutually non-orthogonal problemsQuick buildAnimation3D-image renderingContact highData space

This invention discloses a generation and editing method, which bases on space technology style of human motion. Its Principal component analysis is used to establish a contact high-dimensional data space and movement style annihilator low-dimensional space mapping. Low-dimensional subspace has maintained a campaign by the inherent style, as well as because of significantly reducing dimension, lower cost, easy to quantify the degree of style. In low-dimensional subspace can conduct real-time calculation, and the results generated or edit reconstruction through mapping data movement in the high-dimensional space. By extrapolation, can be generated or editing samples than the style of training more exaggerated movement. Because of the diversity of human motion style, this method also proposed a new style of dealing with multiple sports programs, the program was effective in resolving the multiple styles between the weight of the problems brought about by orthogonal.

Owner:ZHEJIANG UNIV

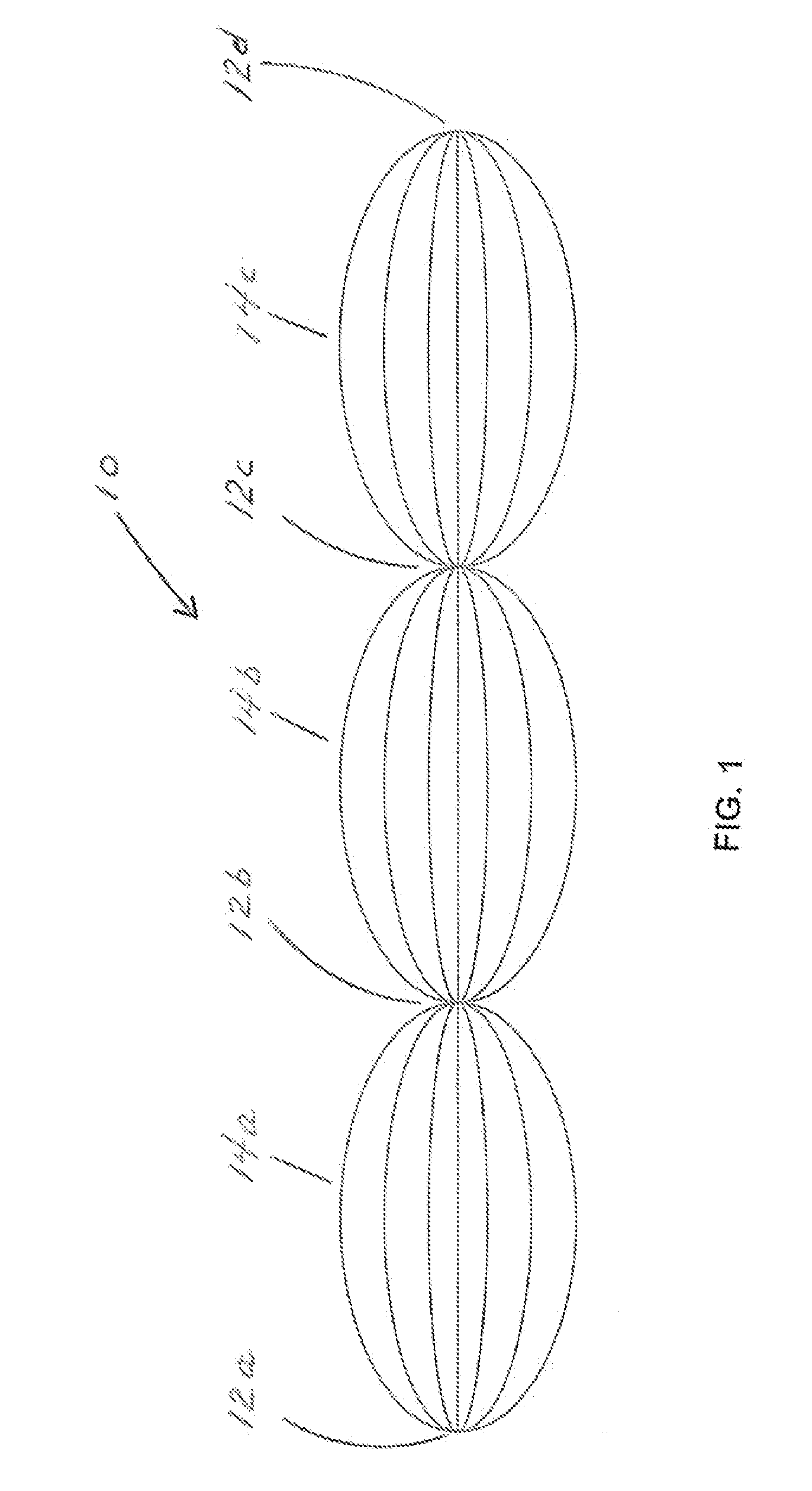

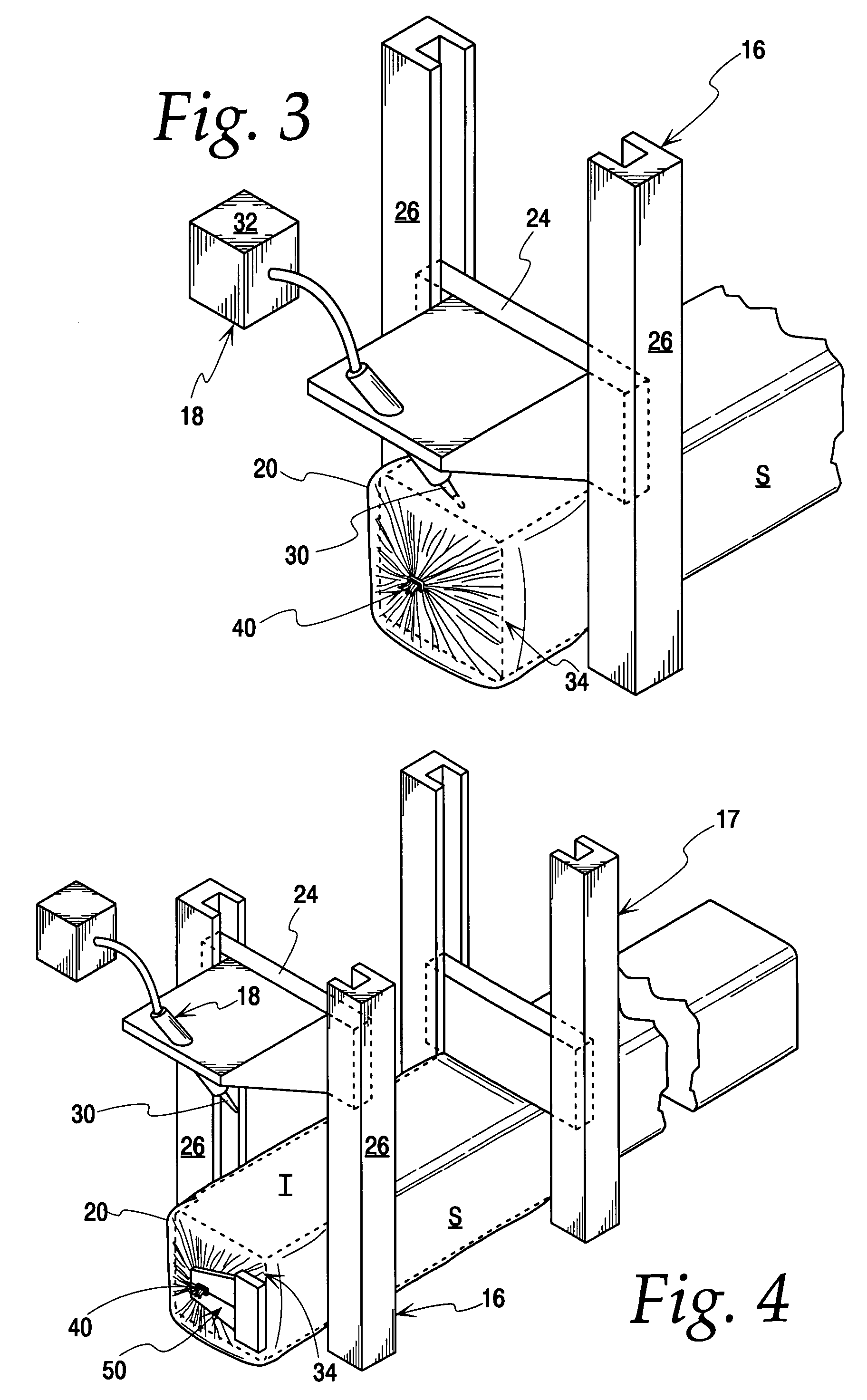

In-line swirl vortex separator

ActiveUS20190168147A1Effect separationReversed direction vortexDispersed particle separationEddy current separatorEngineering

An in-line swirl vortex separator to separate solids, liquids, particulate from a vapor stream. The swirl vortex separator includes a swirl element and a vortex element. The vortex element creates pairs of vortices that are substantially equal and opposite in direction.

Owner:BRATTON RODNEY ALLAN

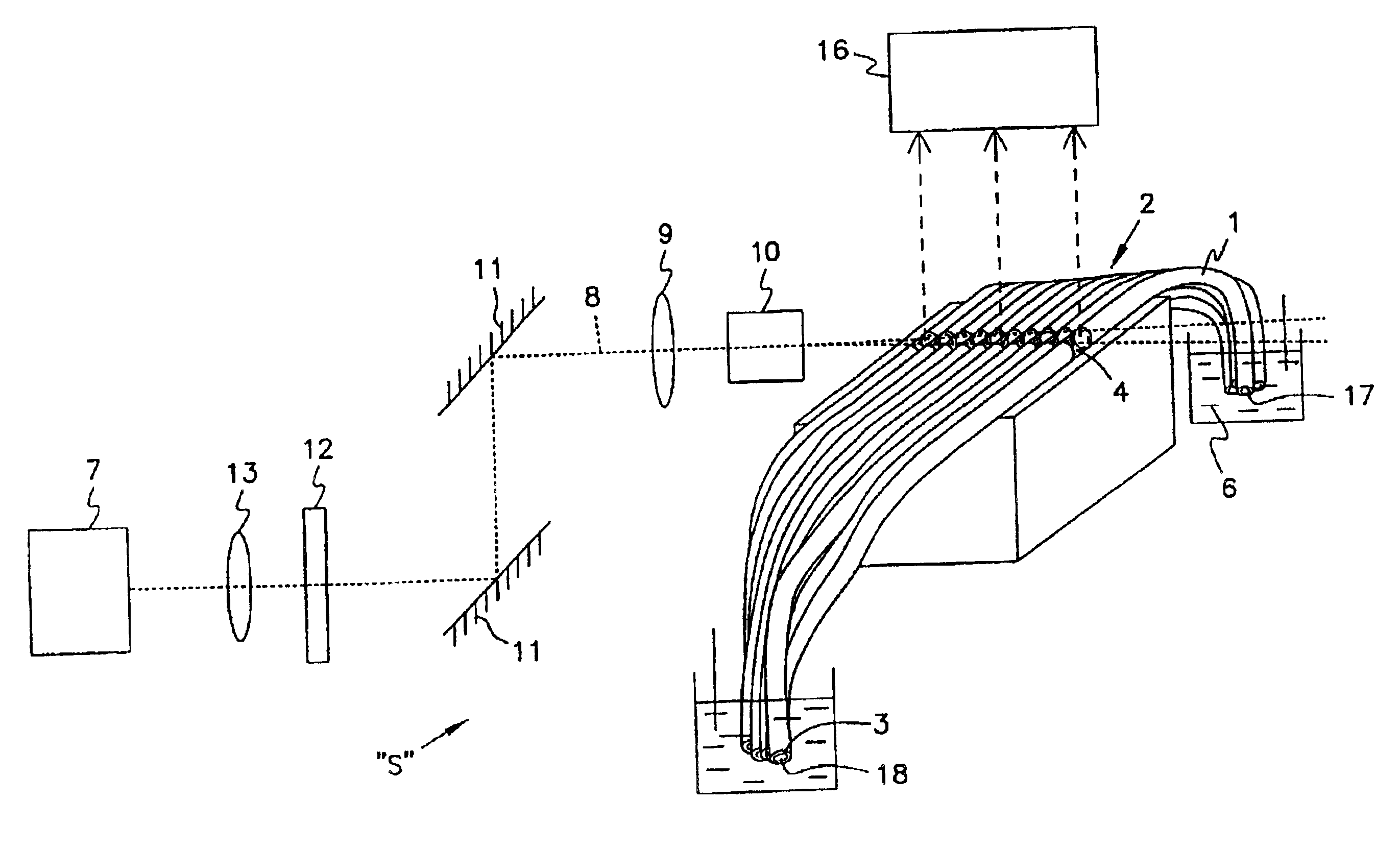

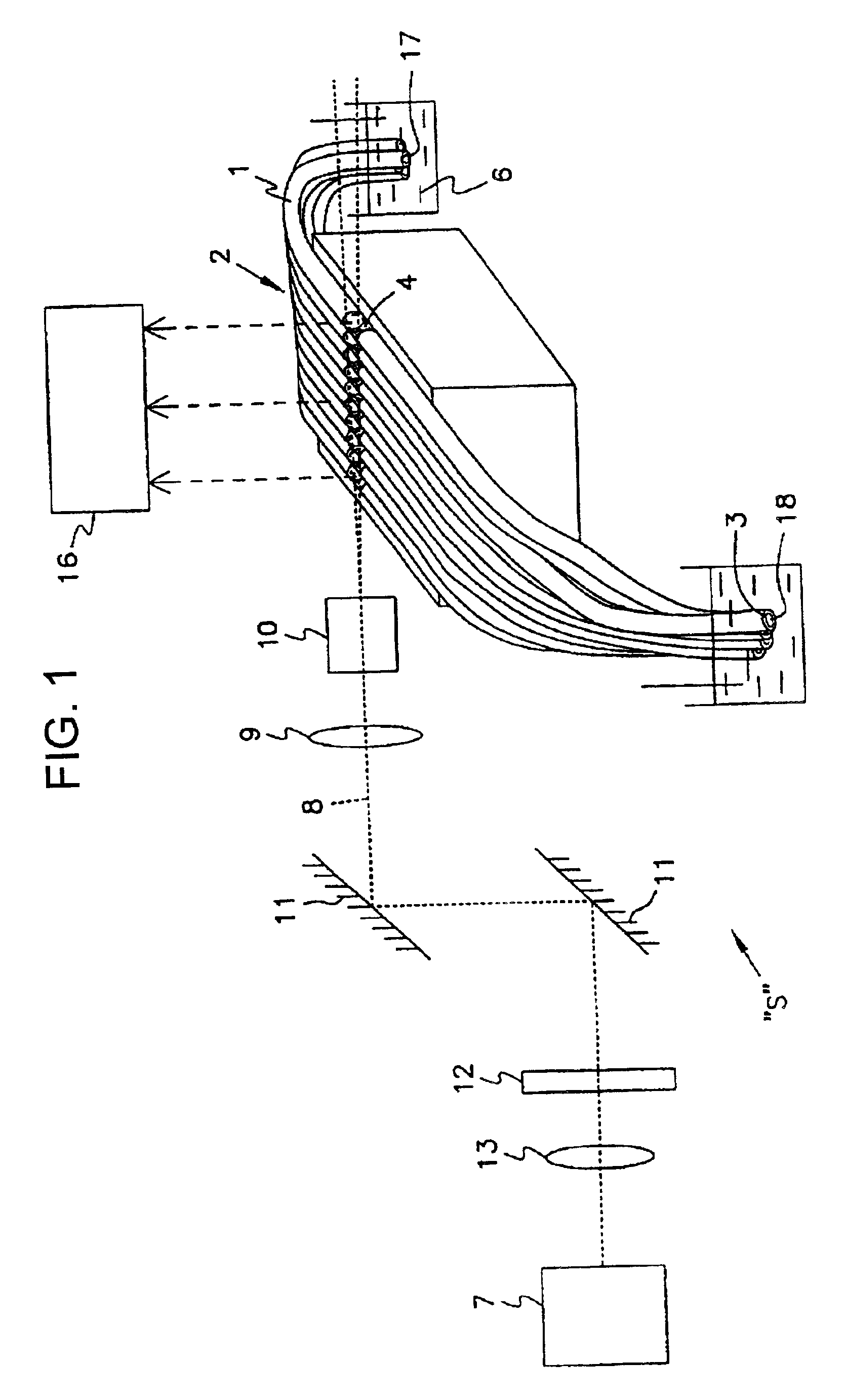

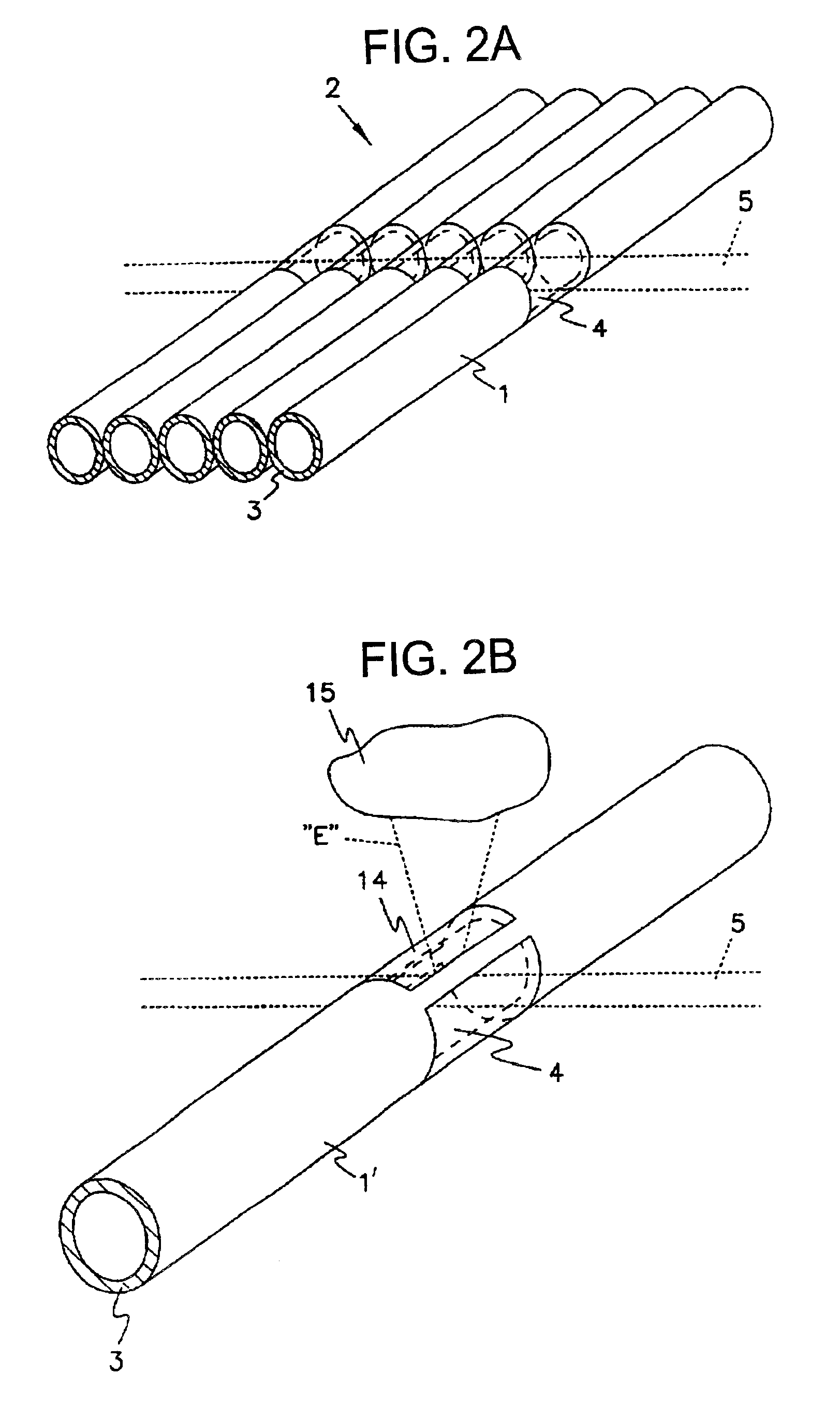

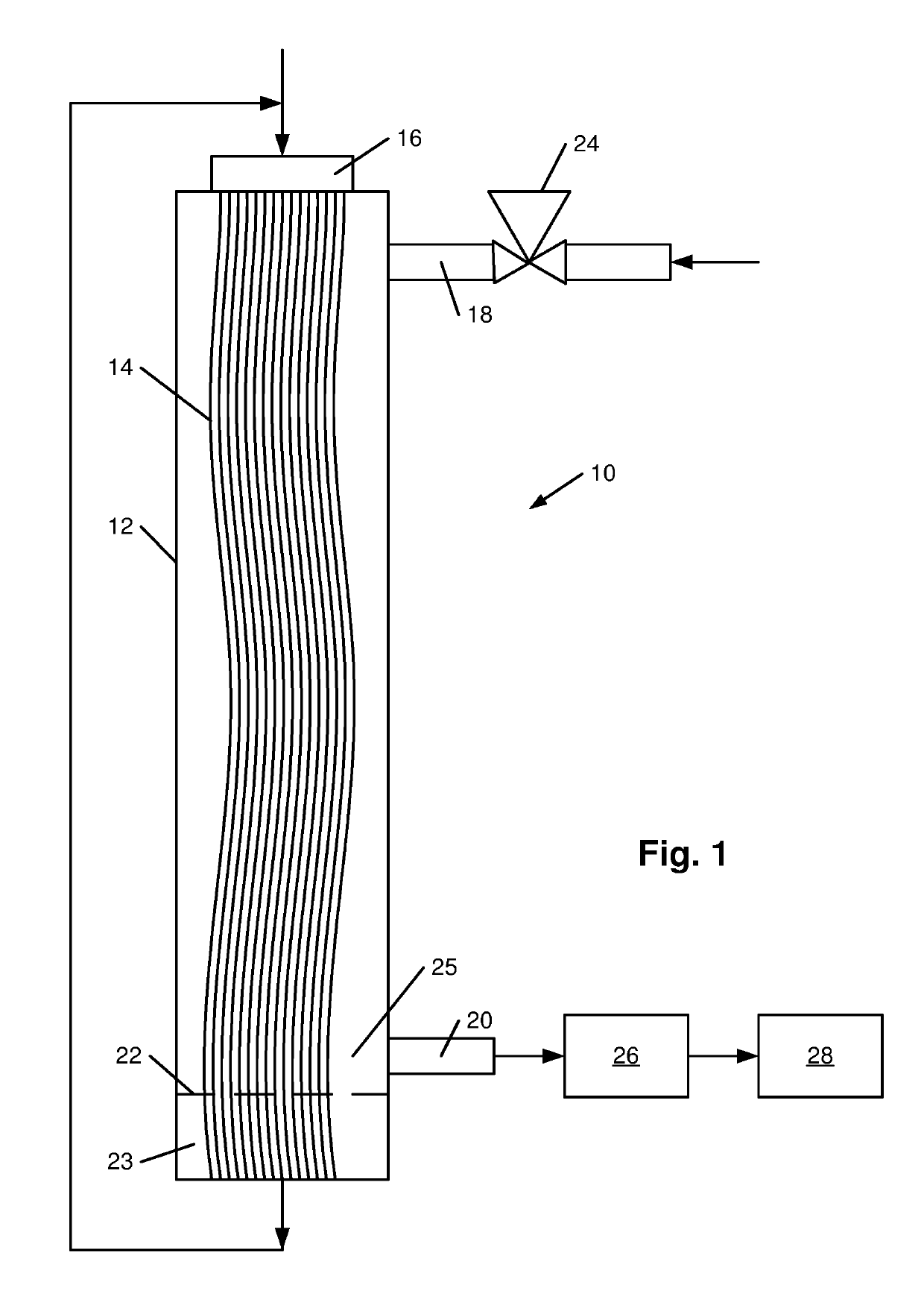

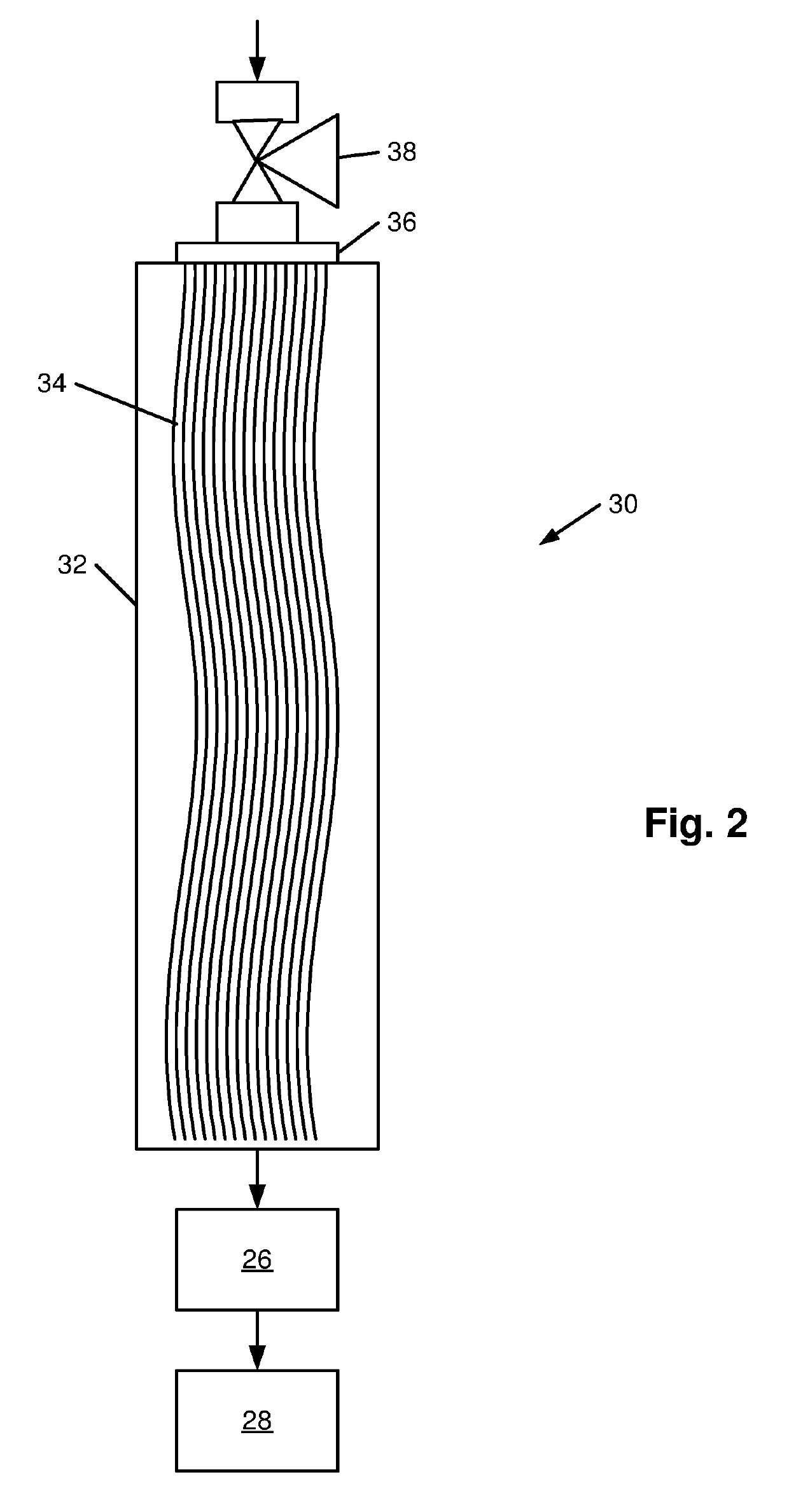

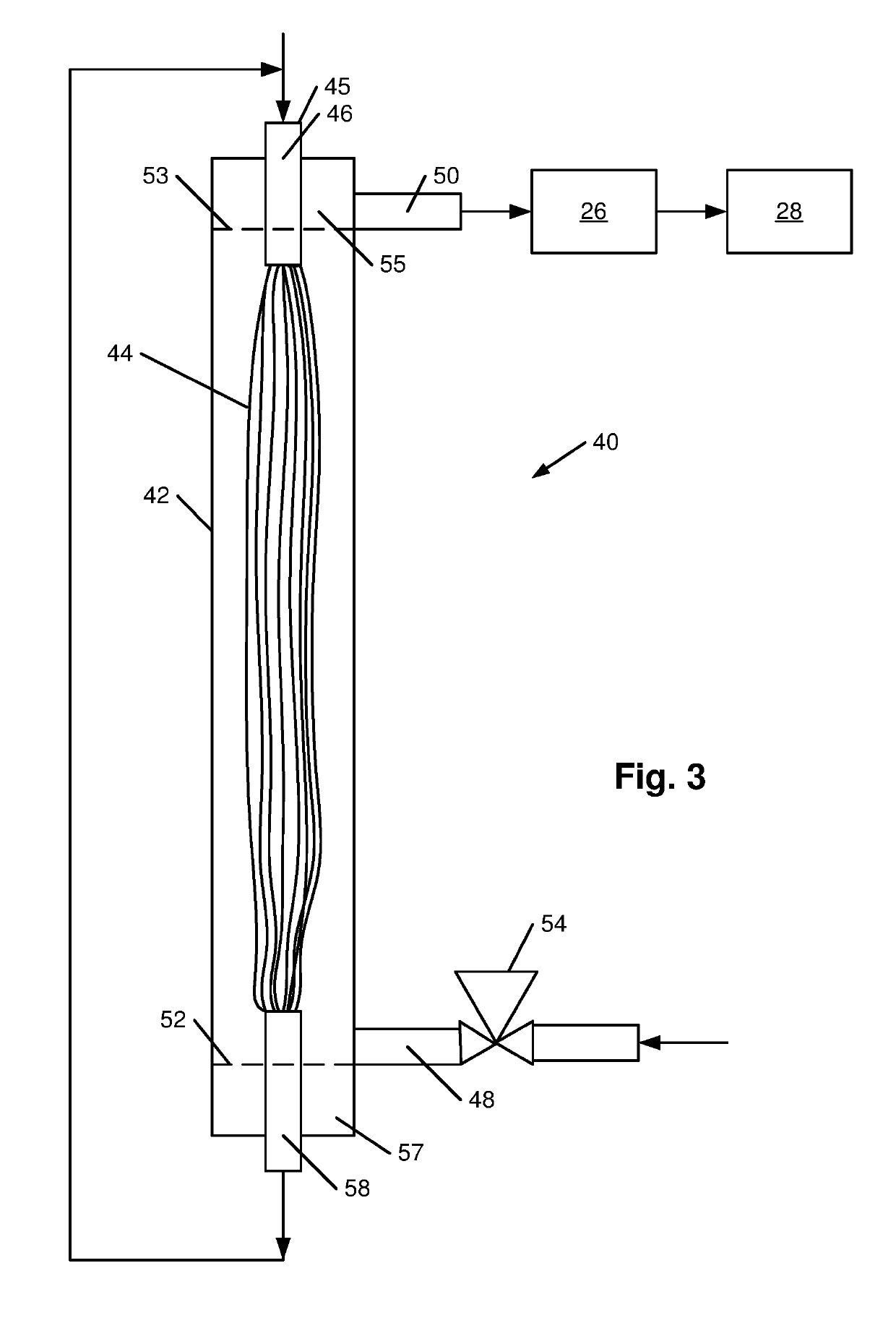

Fiber Chromatography

Chromatographic processes are provided which utilize fiber conduit contactors to effect separation of chemical substances from a mixture. In particular, processes are provided which constrain a substance on the fibers and move a mixture of chemical substances and another fluid through the coated fibers to effect separation of a substance from the mixture. In addition, fiber conduit contactors configured to affect such processes are disclosed. Some apparatuses include a sample injection mechanism for selectively inserting an analytical or preparative chromatography mixture into a fluid being supplied to the conduit. Additional or alternative apparatuses include fibers positioned longitudinally within a conduit with their opposing ends respectively bundled into a fluid inlet and a fluid outlet at opposing ends of the conduit. The portions of the fibers between the bundled ends are sufficiently slack such that larger spaces exist between individual fibers along the slack portions than at the bundled ends.

Owner:CHEMTOR LP

Makeup Brush

ActiveUS20210120945A1Easily swapped outEasy to cleanBrush bodiesBristle carriersPolymer scienceBristle

The method for manufacturing a makeup brush includes: molding a ferrule and welding bristles to the ferrule. The ferrule includes a ferrule inner end; a ferrule outer end; a ferrule body; an interior; and a well. The well has a well base parallel to the ferrule outer end. The well base has an inner side and an outer side. The step of welding the bristles includes the steps of disposing the bristles in contact with the outer side of the well base and exposing the inner side of the well base to welding.

Owner:LUMETIQUE

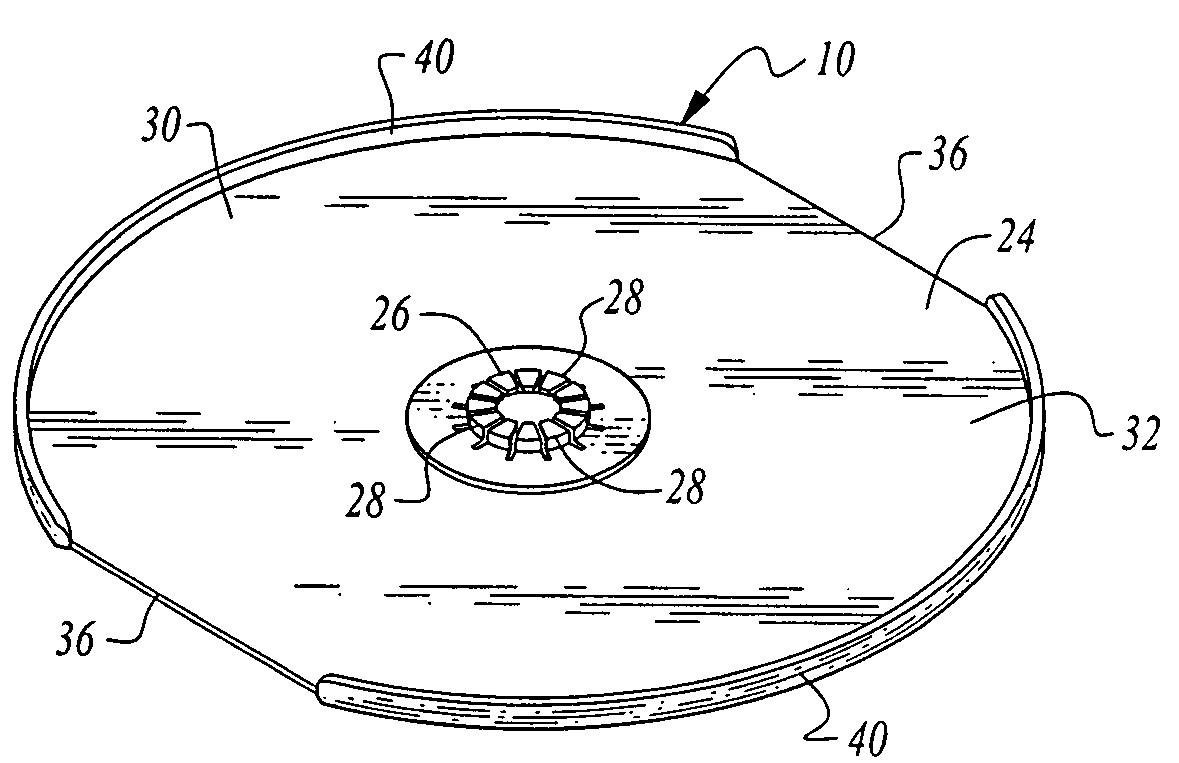

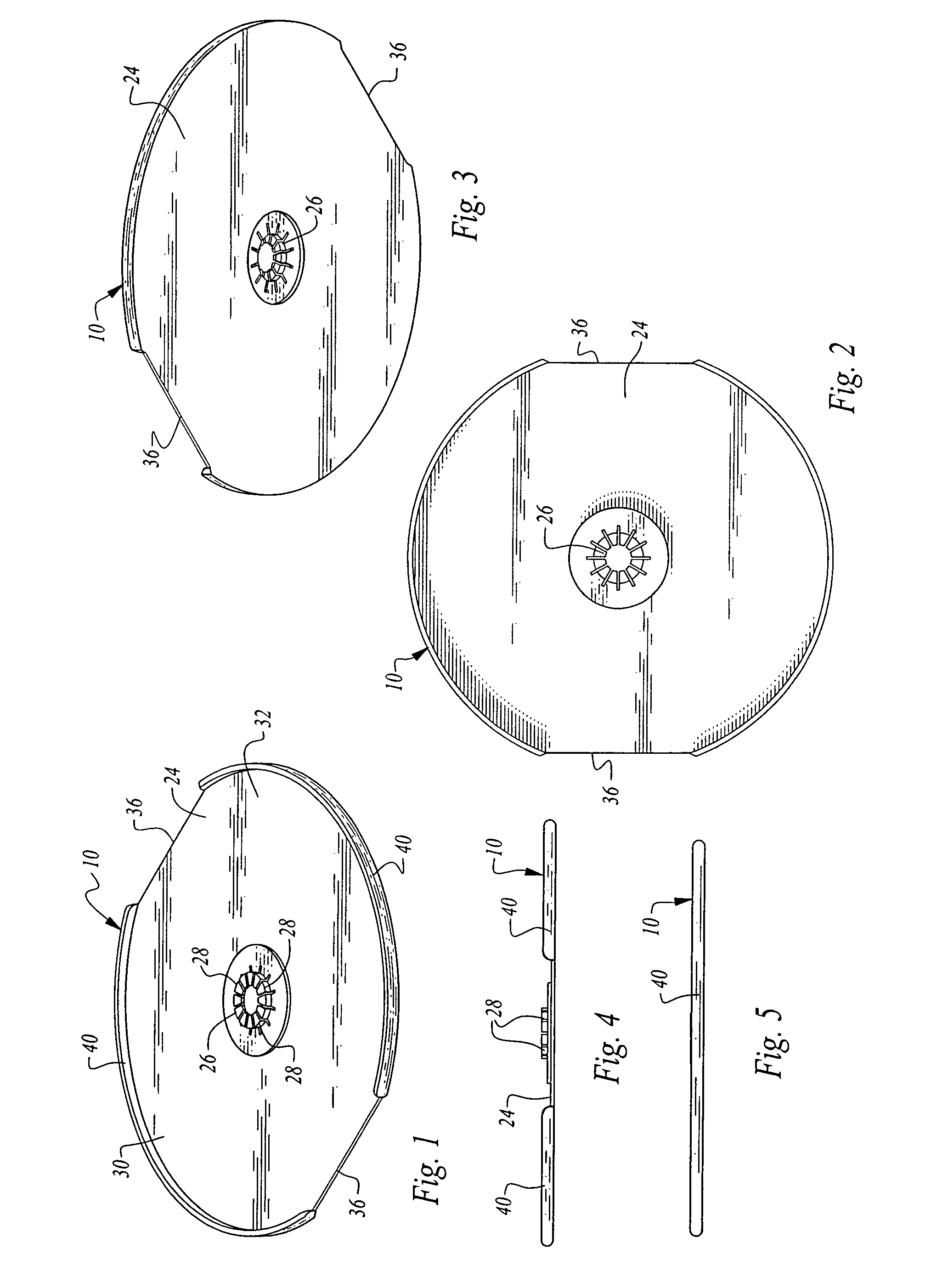

Optical disc cover

InactiveUS7472790B2Low costEasy to useRecord information storageOther accessoriesEngineeringOptical disc

An optical disc is releasably held by a device which covers only one side of the disc. The device and disc are separated by the user simultaneously manually engaging an outer disc rim at two device notch locations and pushing against disc retainer structure of the device.

Owner:MARCAP

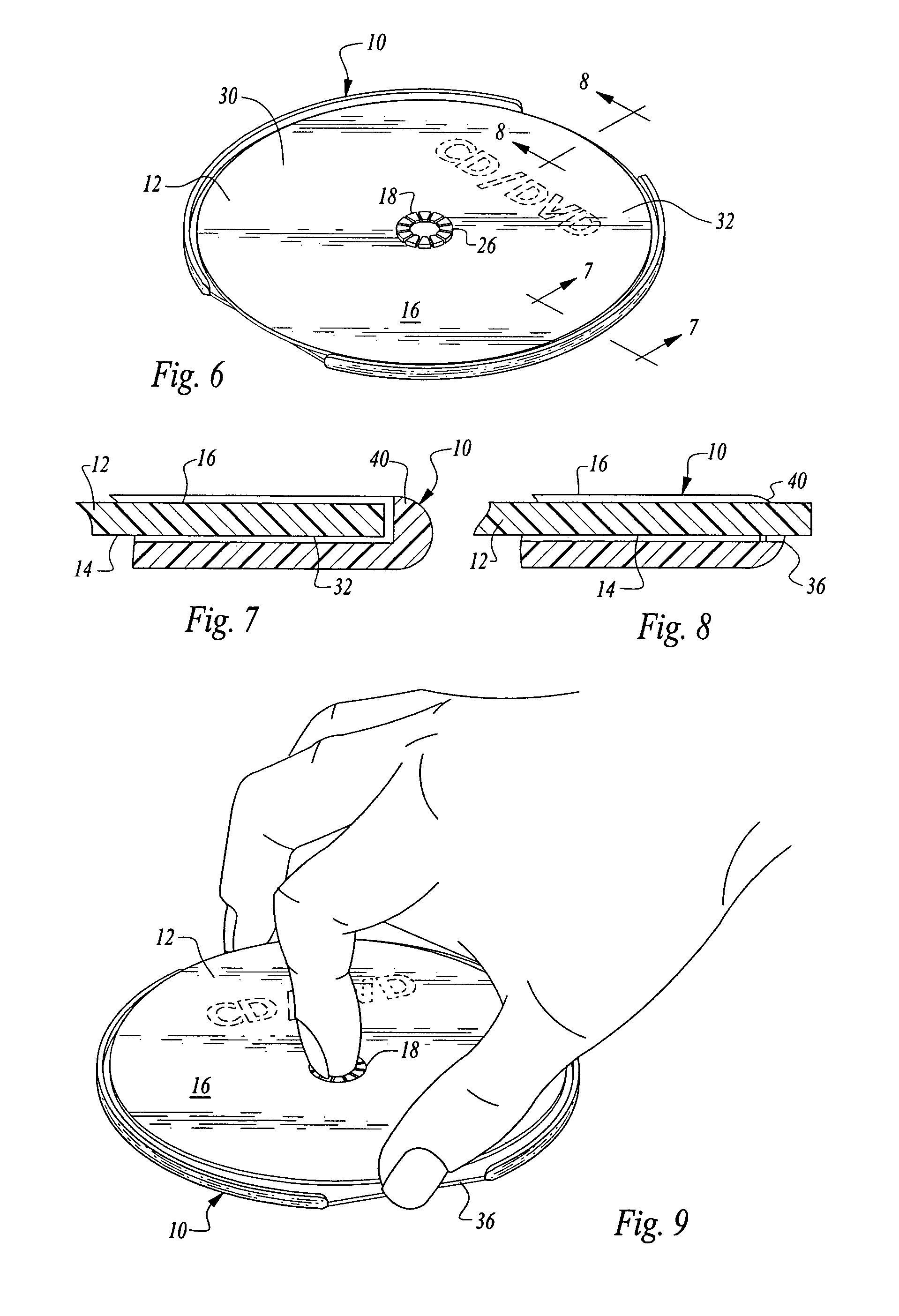

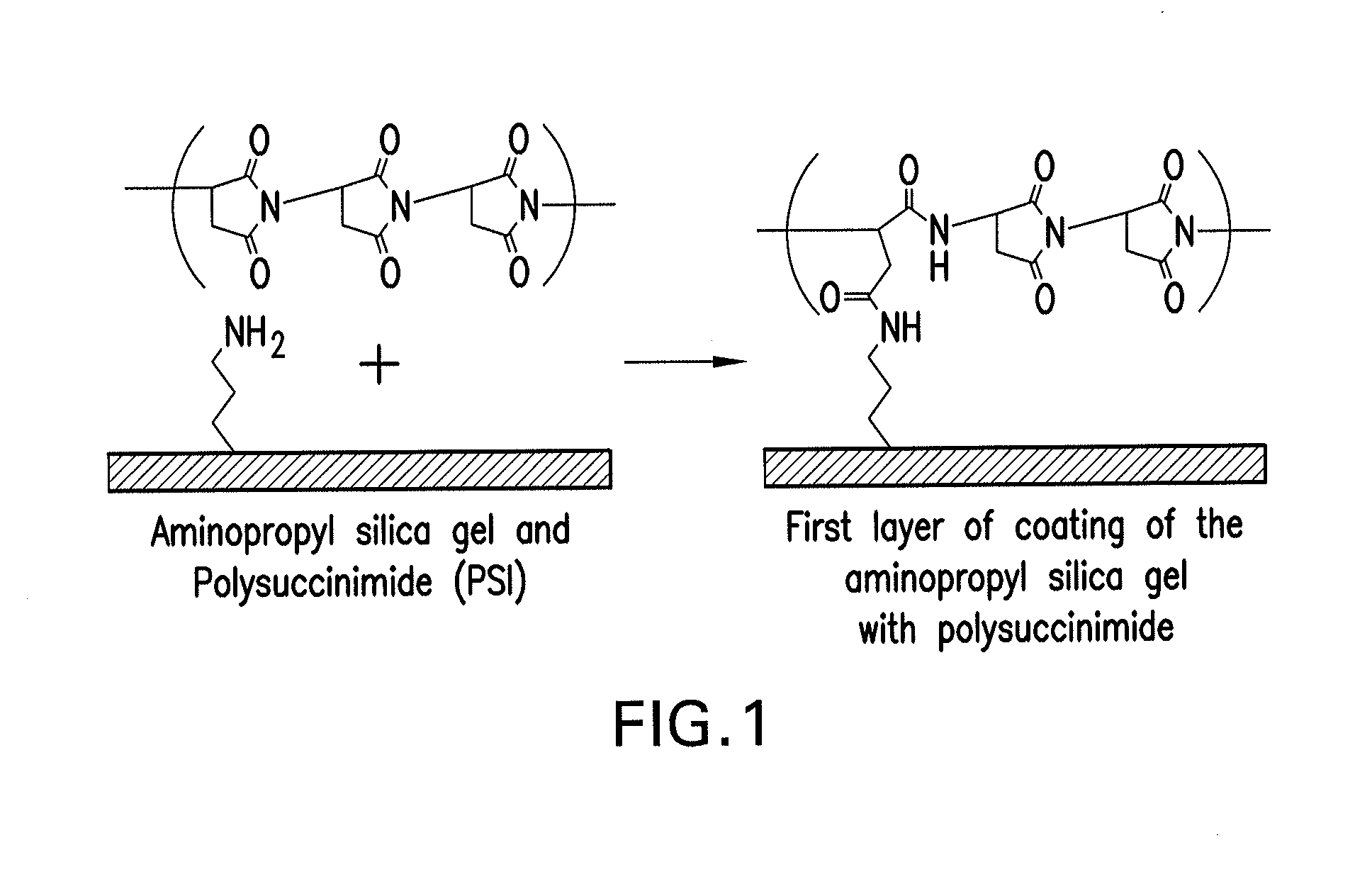

Chromatography media

ActiveUS9156879B1Avoid interferenceEffect separationOther chemical processesPeptide preparation methodsSerum albuminRestricted access

The present invention provides, in part, a chromatographic restricted access media comprising aminopropyl groups derivatized with polysuccinamide that is derivatized with 1-ethylpropylamine and denatured human serum albumin. Methods of purifying polypeptides and complexes thereof are also provided.

Owner:MERCK SHARP & DOHME LLC

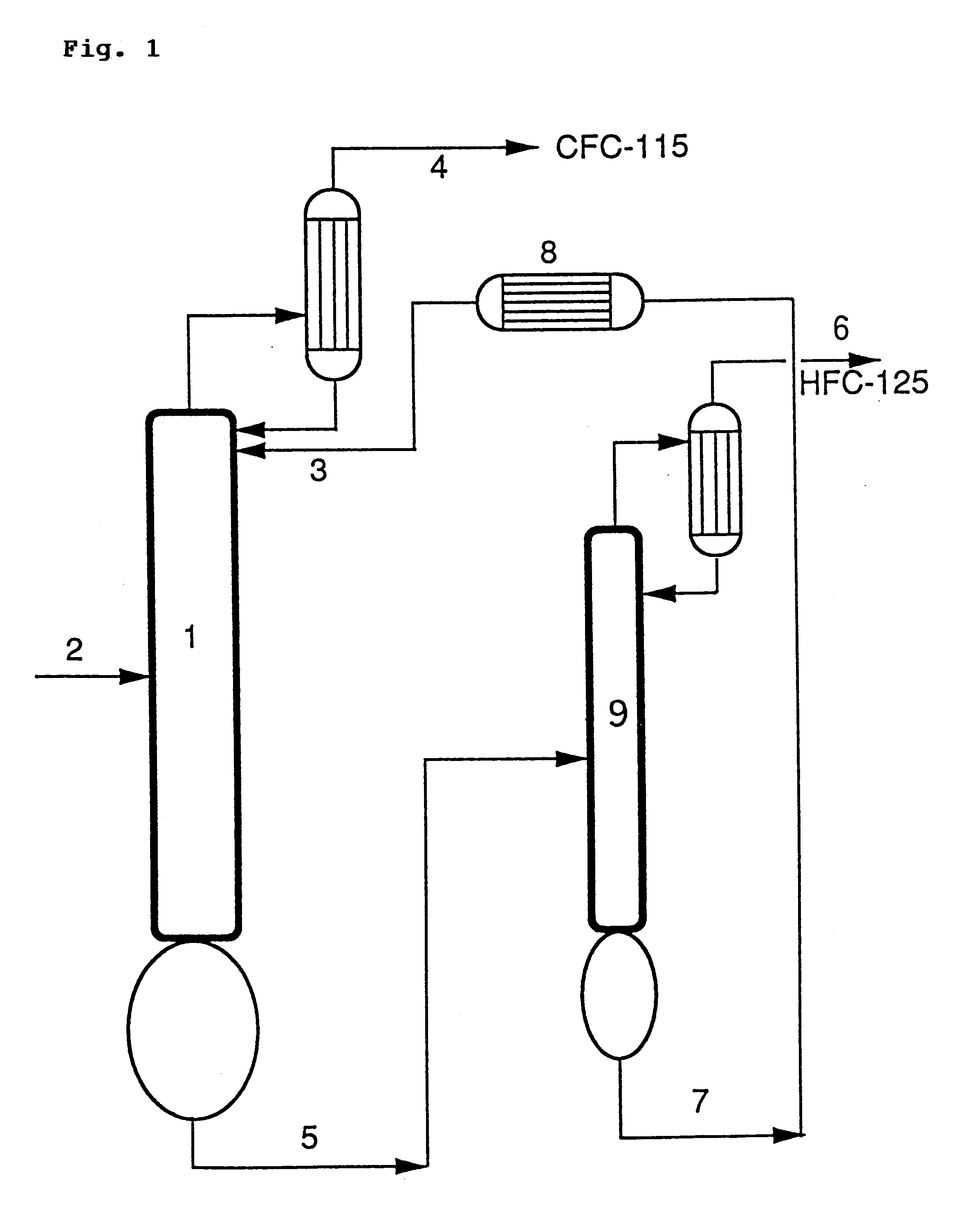

Process for the preparation of pentafluoroethane

InactiveUS6175045B1Effect separationEasy to carryHalogenated hydrocarbon separation/purificationDistillation separationCarbon atomEthylene glycol

There is provided a process of effectively separating pentafluoroethane (HFC-125) from a mixture of HFC-125 and chloropentafluoroethane (CFC-115).When the mixture of HFC-125 and CFC-115 is subjected to an extractive distillation to obtain a concentrated HFC-125, ethyleneglycol-based compounds (3) having a general formula:wherein R1 and R2 may be the same or different and are each independently selected from the group consisting of hydrogen and an alkyl group having 1 to 4 carbon atoms, and n is an integer with a value from 1 to 3 is used as an extractant, whereby CFC-115 is obtained as a distillate product (4) and a mixture of HFC-125 and the extractant as a bottom product (5) is obtained. Then, the extractant is separated from HFC-125 by distilling the mixture and re-used in the extractive distillation.

Owner:DAIKIN IND LTD

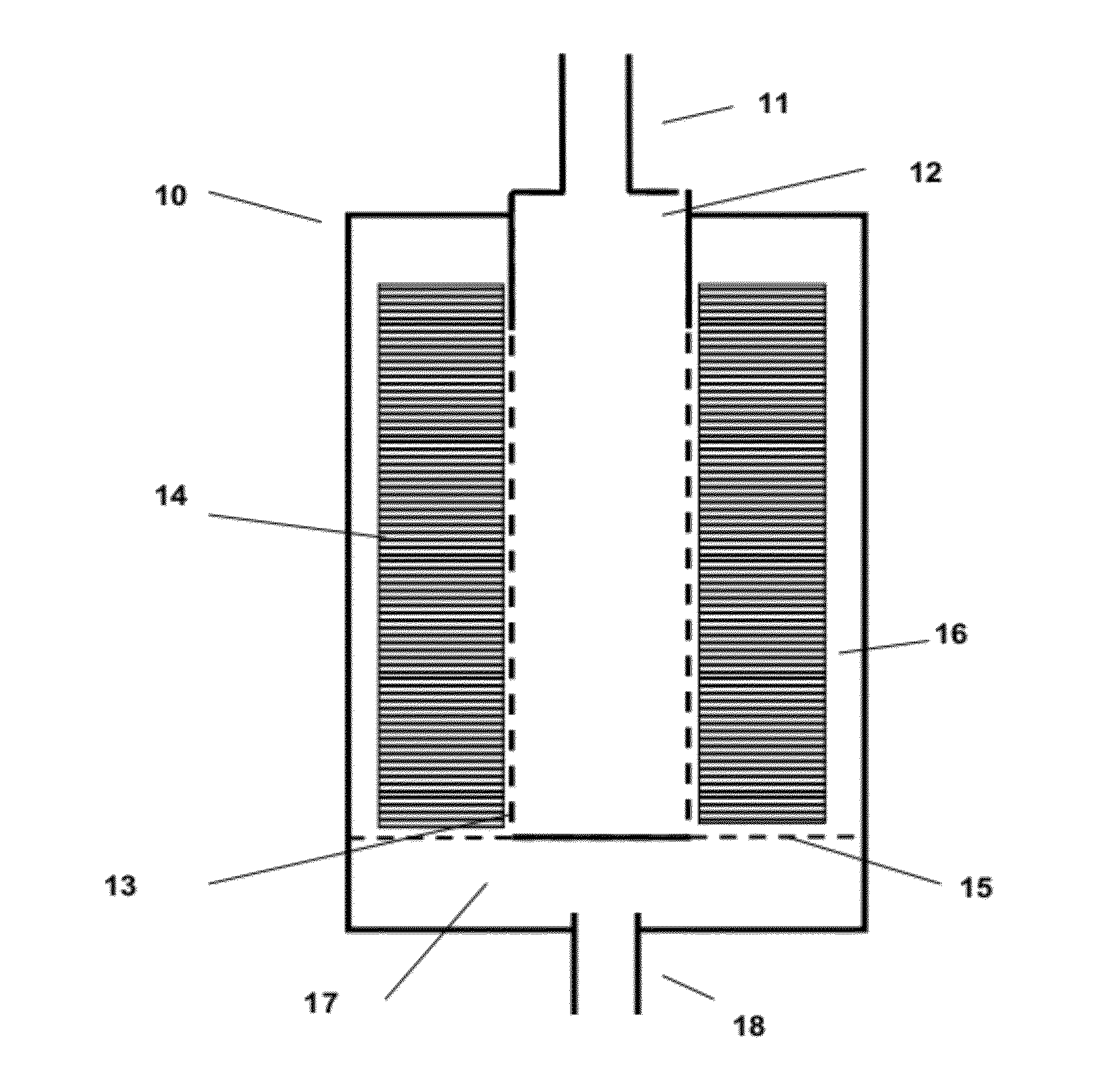

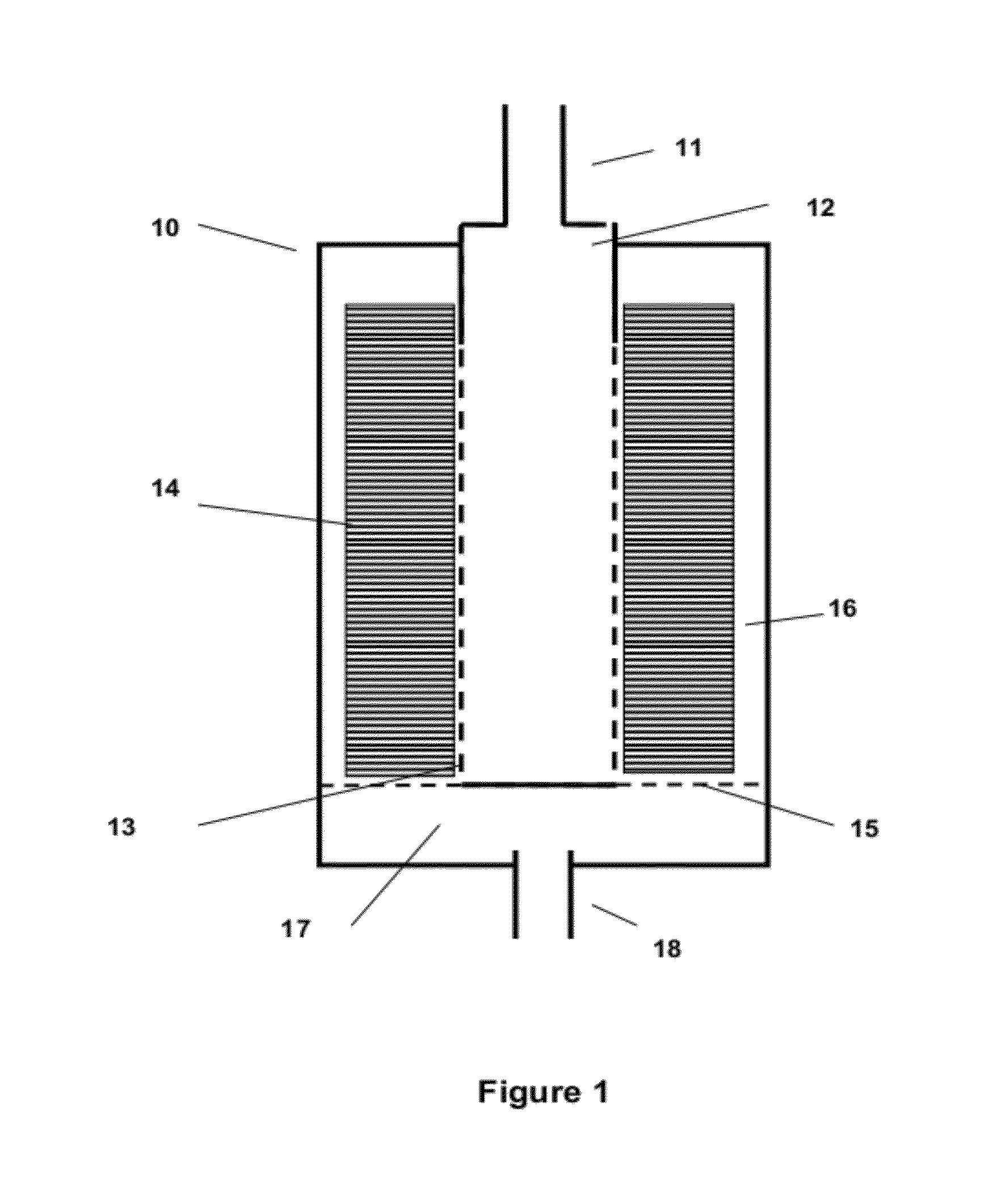

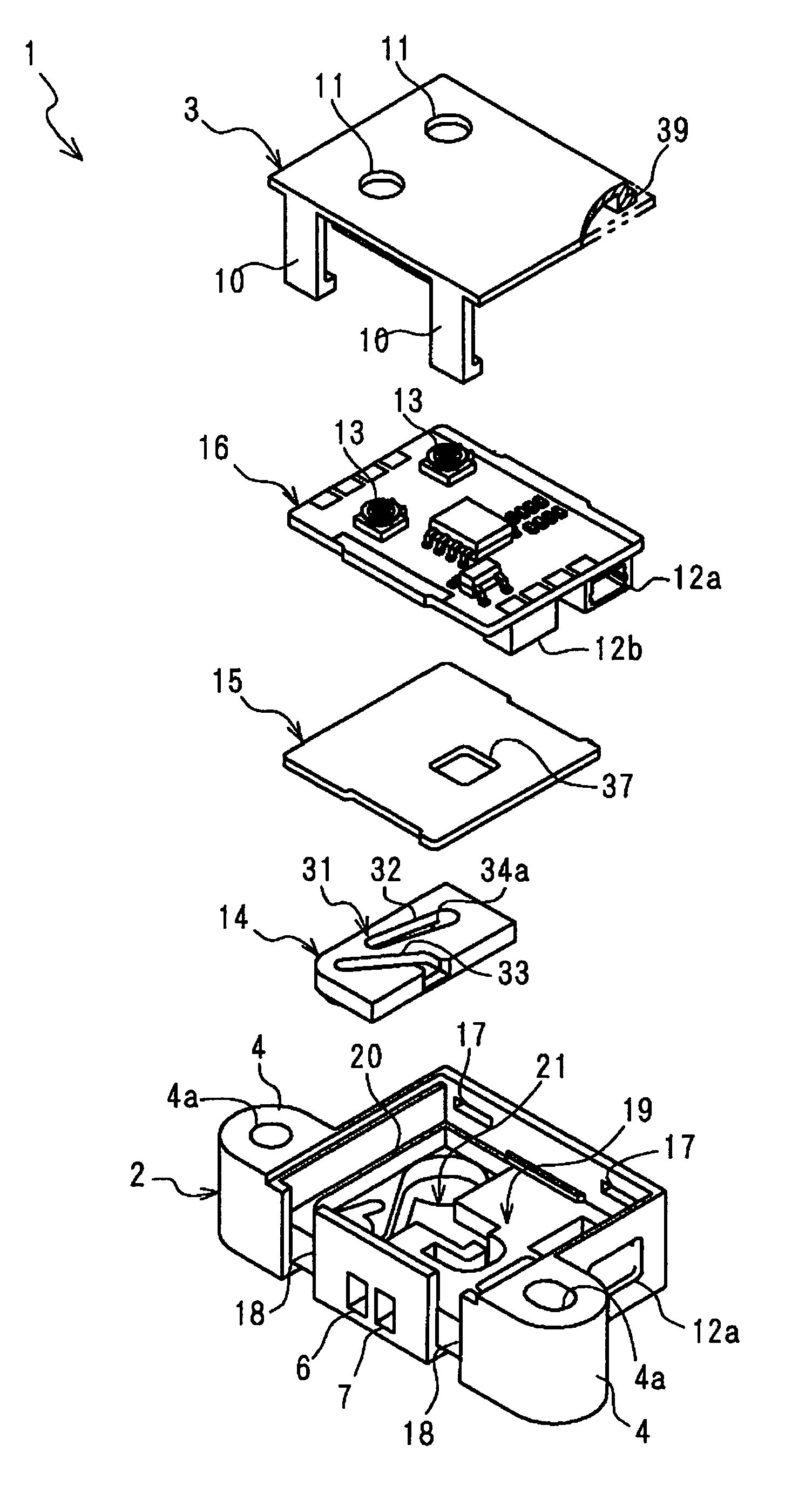

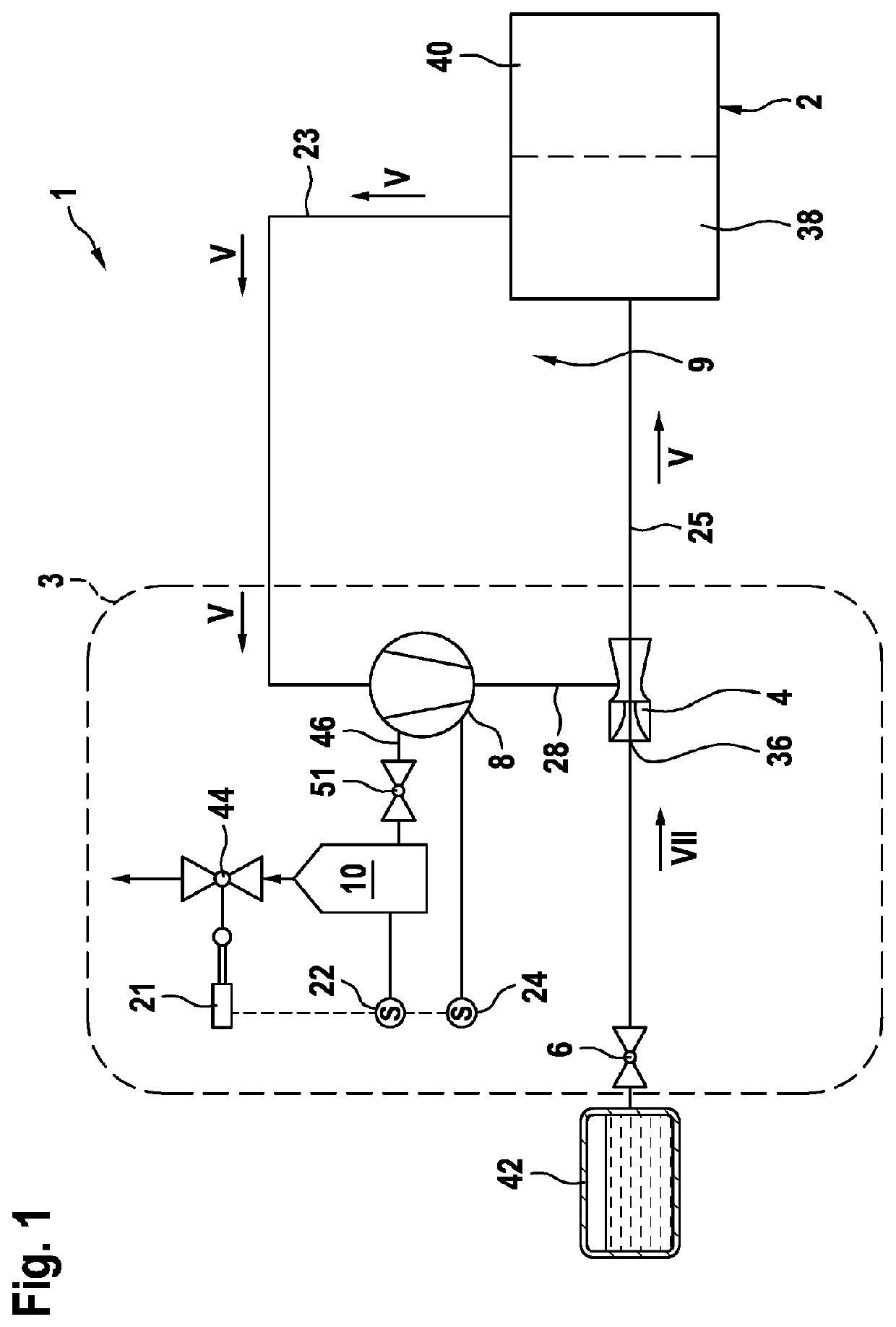

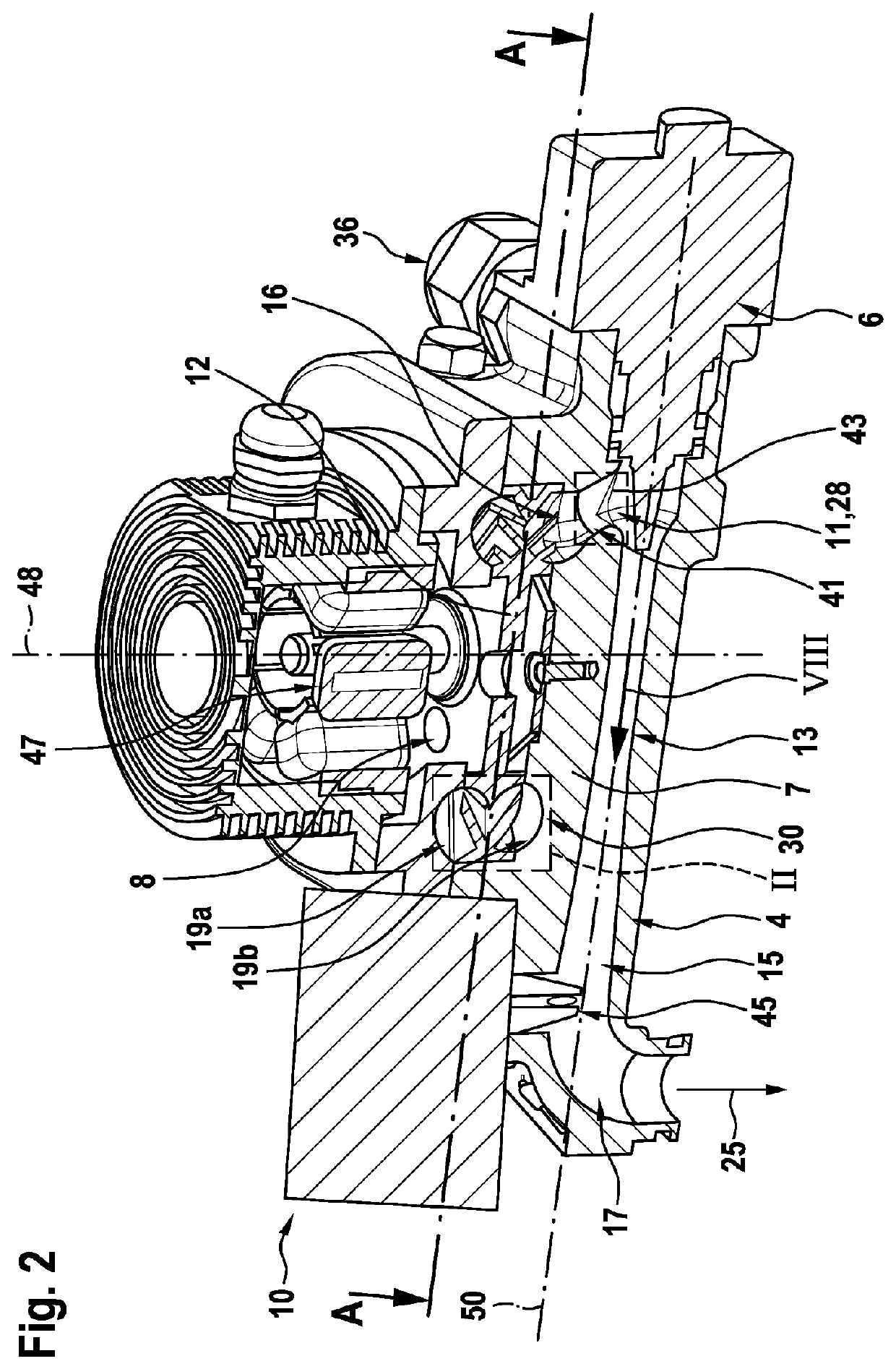

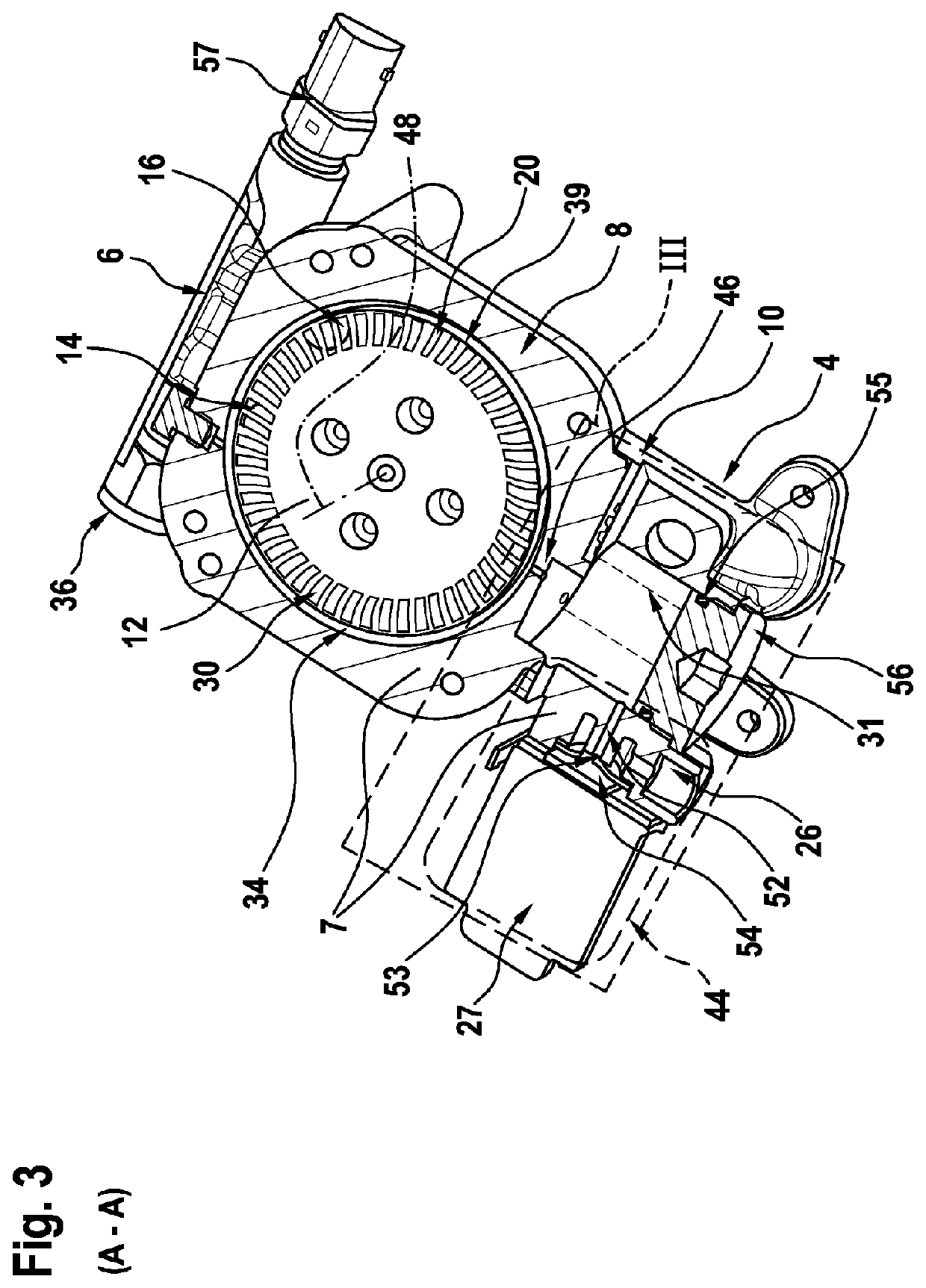

Delivery unit for an anode circuit of a fuel cell system for delivering a gaseous medium

PendingUS20220102742A1Easy dischargeEase of evacuationGas treatmentPump componentsFuel cellsHemt circuits

Disclosed is a delivery unit (3) for an anode circuit (9) of a fuel cell system (1) for delivering a gaseous medium, in particular hydrogen, from an anode region (38) of a fuel cell (2), said delivery unit (3) comprising at least one recirculation fan (8) and being at least indirectly fluidically connected to the outlet of the anode region (38) by means of at least one connection line (23) and being fluidically connected to the inlet of the anode region (38) by means of an additional connection line (25). According to the invention, in addition to the recirculation fan (8), the delivery unit (3) comprises a jet pump (4), a metering valve (6) and a separator (10) as other components, and the flow contours of the components (4, 6, 8, 10) for the gaseous medium are at least almost entirely arranged in a common housing (7).

Owner:ROBERT BOSCH GMBH

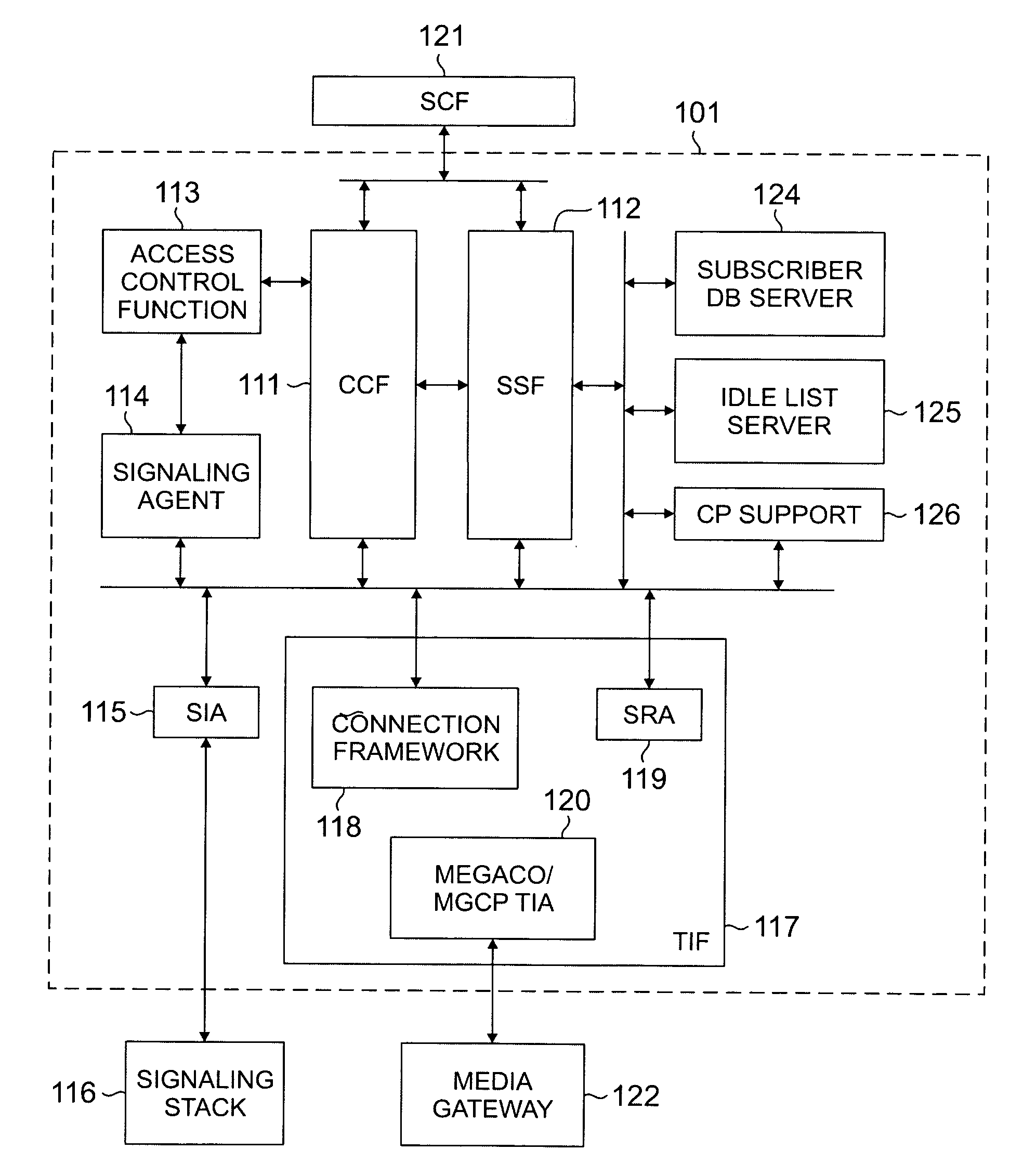

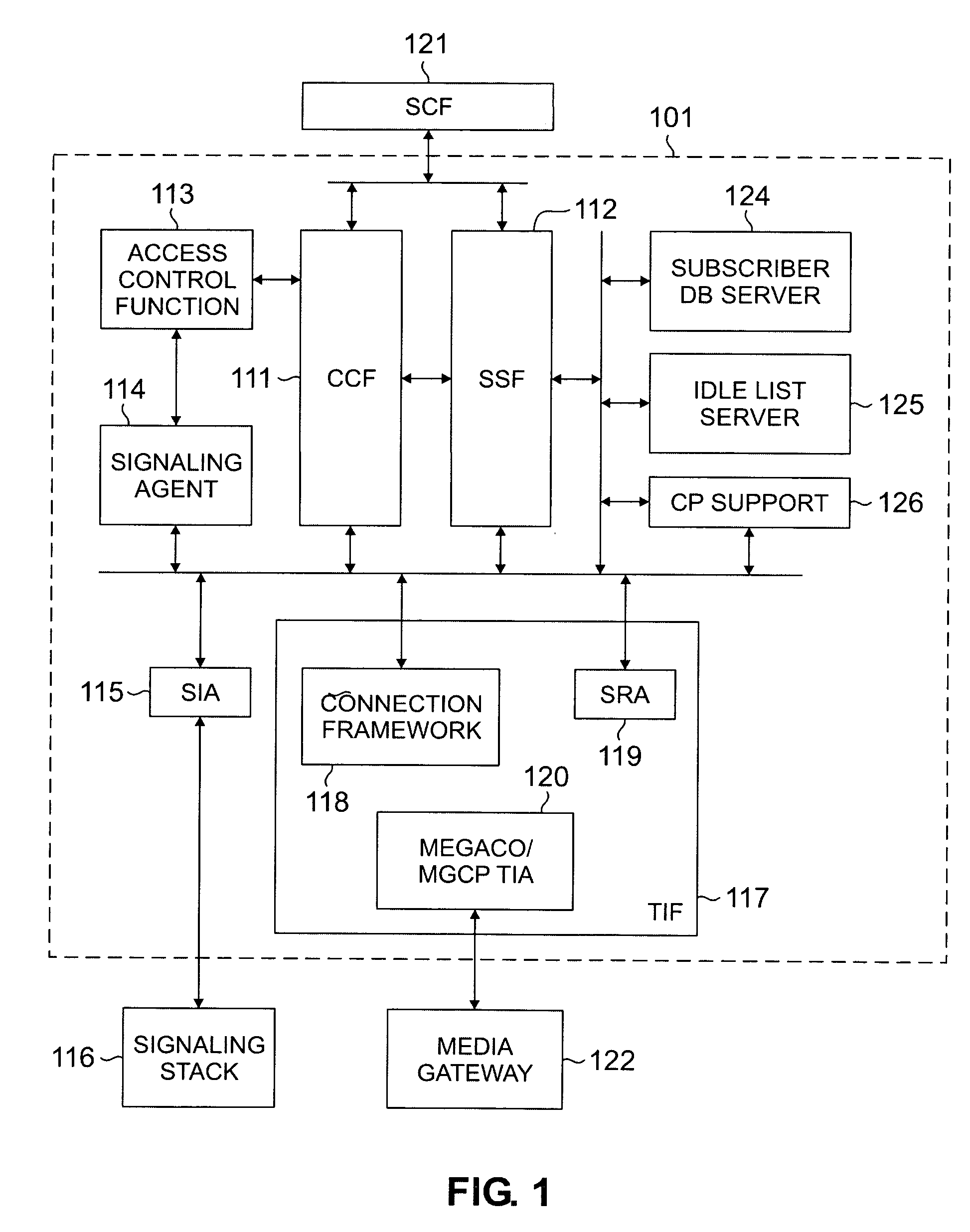

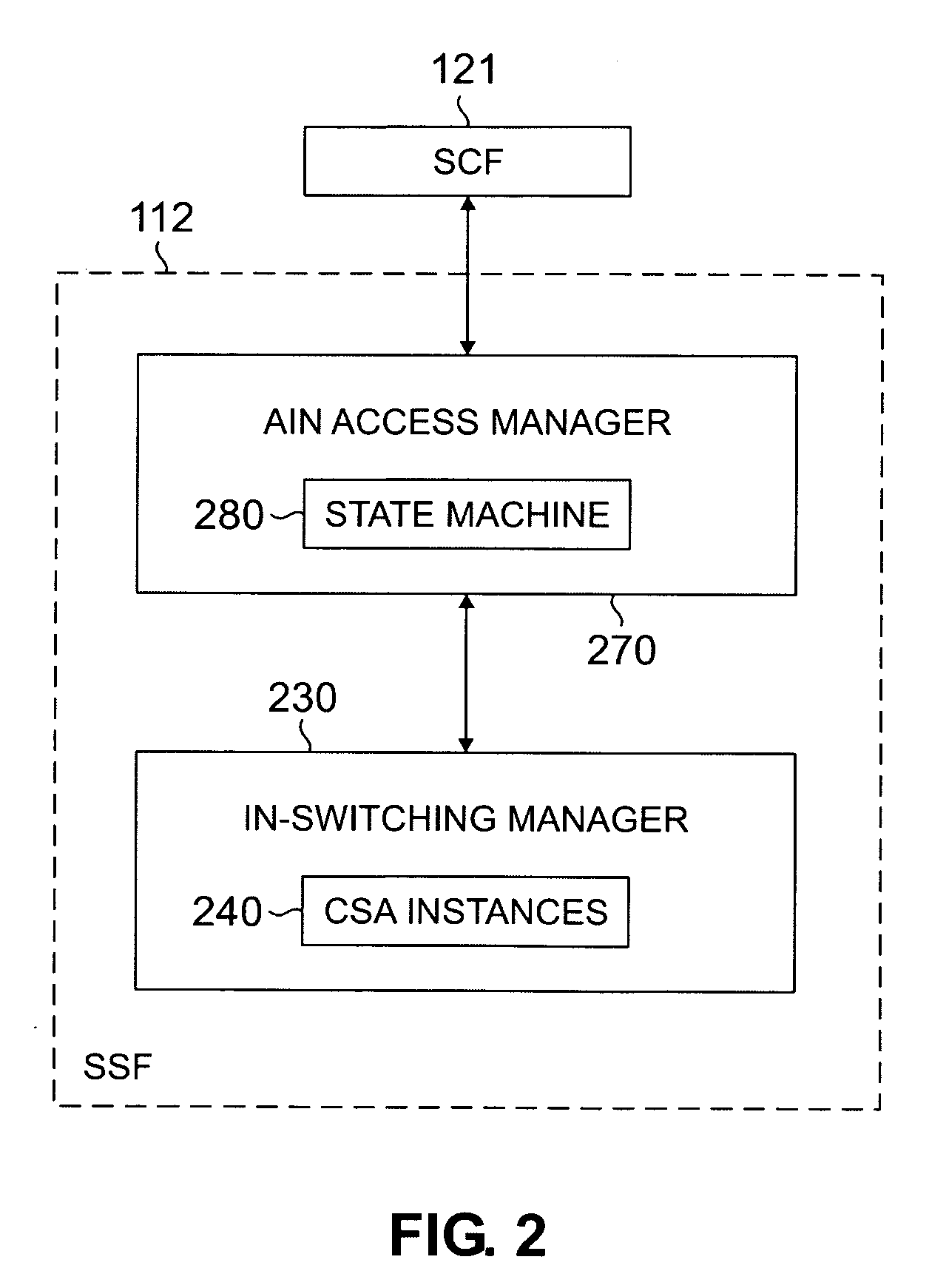

Advanced intelligent network access manager with state machine for processing multiple TCAP component messages

InactiveUS20060251235A1Effect separationNetworks interconnectionNetwork connectionsIntelligent NetworkTelecommunications network

A service control function is interfaced to a call segment association in a telecommunications network. TCAP messages are used for communication with the service control function. In correspondence with the processing of information carried in the TCAP messages, a state machine assumes a plurality of states, one of which corresponds exclusively to the processing of component information carried in component portions of the TCAP messages.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com