Method for separating and extracting sweet tea tannins

A sweet tea polyphenol and extraction method technology, applied in the field of separation and extraction of sweet tea polyphenols, can solve the problem that the separation and extraction method has not been reported, and achieve the effects of obvious anti-allergic activity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

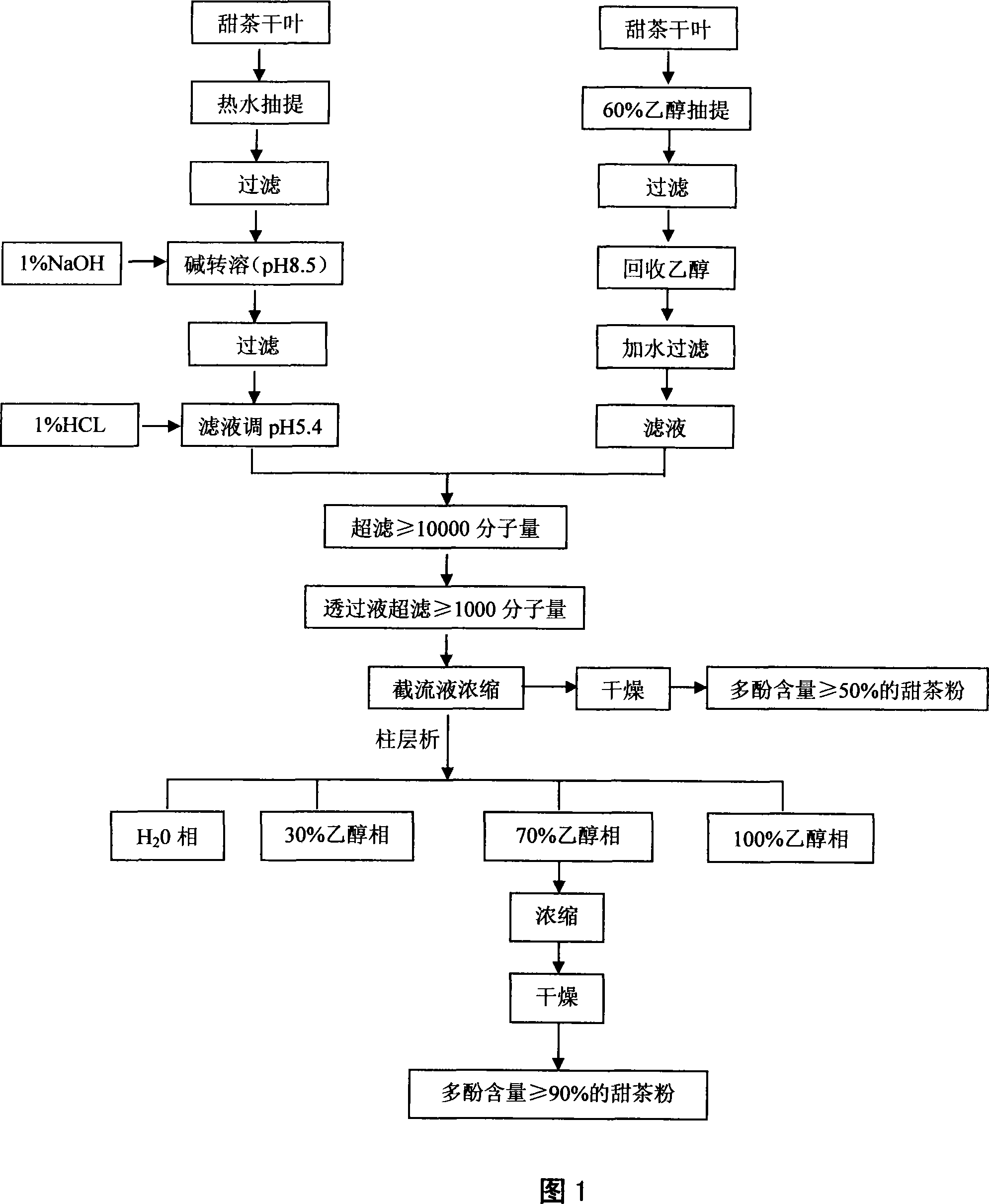

Method used

Image

Examples

Embodiment 1

[0031] Add 100 grams of sweet tea dry leaves, add 3000ml of distilled water, extract at 95°C for 20 minutes, filter to remove slag to obtain tea juice. After the tea juice is cooled, adjust the pH to 8.5 with 1% NaOH solution, then heat the tea juice to boil and cool it, centrifuge to remove insoluble matter to obtain 2750ml clear tea juice, adjust the pH of the tea juice to 5.4 with 1% HCL solution. Organic membranes with molecular weight cut-offs of 50,000 and 5,000 were used for ultrafiltration twice, and the retentate between 5,000 and 50,000 was concentrated and freeze-dried to obtain 16.1 grams of sweet tea powder with a content of sweet tea polyphenols of 50.2%.

Embodiment 2

[0033] 100 grams of sweet tea dry leaves, add 1000ml of distilled water to extract as in Example 1, transfer to dissolve, ultra-filter to obtain the retentate and concentrate, then use LSA-21 chromatography column to adsorb, use ethanol aqueous solution to carry out gradient elution, collect 70% The eluate was concentrated and freeze-dried to obtain 1.9 grams of sweet tea powder, with a sweet tea polyphenol content of 90.2%.

Embodiment 3

[0035] Add 100 grams of sweet tea dry leaves, add 3000 ml of 60% ethanol aqueous solution, extract at 60°C for 60 minutes, filter to remove residue, evaporate and recover ethanol to obtain 600 ml of tea juice. Add 1200ml of distilled water into the tea juice, stir and filter, take the clear juice and perform two ultrafiltrations, the molecular weight cut-offs of the filter membranes are 10000 and 1000 respectively. The retentate between 1000 and 10000 was concentrated, freeze-dried to obtain 16.7 grams of sweet tea powder, and the content of sweet tea polyphenols was 52.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com