Preparation method of diamond/copper composite high in heat conduction performance

A composite material and diamond technology, which is applied in the field of diamond/copper composite material preparation, can solve the problems of low bonding strength between diamond and copper matrix, low diamond protection effect, and difficult separation of diamond, so as to ensure the intrinsic thermal conductivity The effect of shortening the sintering cycle and shortening the sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

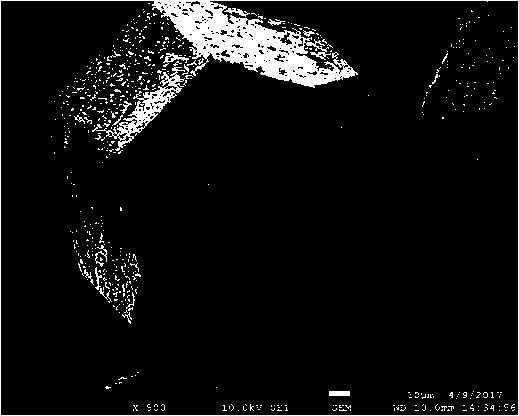

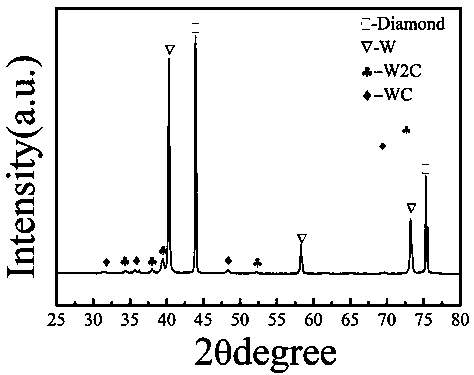

[0027] The diamond particles and tungsten powder after degreasing and roughening treatment on the surface are mixed evenly according to the mass ratio of 1:4.5-5, and the mixed powder is heated under vacuum conditions, and kept at 1025°C-1035°C for 2-8h, the vacuum degree 10 -2 -10 -4 Pa, the heating rate is 5-6°C / min, and finally the modified tungsten-coated diamond particles are separated;

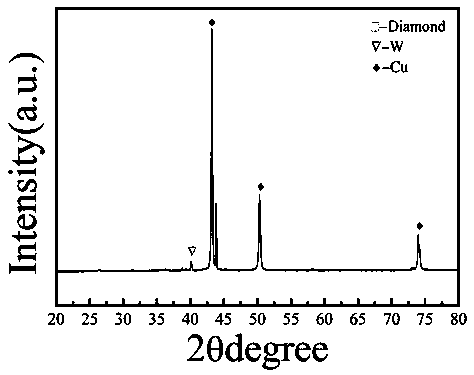

[0028] After surface modification, tungsten-coated diamond particles with an average particle size of 120 μm-130 μm are mixed evenly with copper powder with an average particle size of 30 μm-46 μm according to the volume content of 50%-60% of the total volume, and the obtained mixed powder is sintered. Sintering parameters: The pressing pressure is 20 MPa-40MPa, the temperature is 900°C-1050°C, the heating rate is 50-100°C / min, the sintering time is 5min-15min, the atmosphere is vacuum, and then cooled to room temperature with the furnace to obtain the diamond / copper composite material....

Embodiment 2

[0031] Mix diamond particles with an average particle size of 125 μm and tungsten powder with an average particle size of 0.3 μm in a mass ratio of 1:4.5, place the mixed powder in an alumina porcelain boat, and then place the porcelain boat in a vacuum furnace to heat, 1030 ℃ for 2 hours, with a vacuum of 10 -2 -10 -4 Pa, the heating rate is 5°C / min, and finally the modified tungsten-coated diamond particles are separated by a sample sieve.

[0032] The tungsten-coated diamond particles with an average particle size of 126 μm are mixed with copper powder with an average particle size of 45 μm according to the volume content of 55% of the total volume, and the resulting mixed powder is put into a spark plasma sintering furnace for sintering. Sintering parameters: pressing The pressure is 40MPa, the temperature is 1000°C, the heating rate is 100°C / min, the holding time is 10min, the atmosphere is vacuum, and then the diamond / copper composite material can be obtained by cooling...

Embodiment 3

[0035] Mix diamond particles with an average particle size of 125 μm and tungsten powder with an average particle size of 0.3 μm in a mass ratio of 1:4.5, place the mixed powder in an alumina porcelain boat, and then place the porcelain boat in a vacuum furnace to heat, 1030 ℃ for 2 hours, with a vacuum of 10 -2 -10 -4 Pa, the heating rate is 5°C / min, and finally the modified tungsten-coated diamond particles are separated by a sample sieve.

[0036]The tungsten-coated diamond particles with an average particle size of 126 μm are mixed with copper powder with an average particle size of 45 microns according to the volume content of 60% of the total volume, and the resulting mixed powder is put into a spark plasma sintering furnace for sintering. Sintering parameters: pressing The pressure is 40MPa, the temperature is 1000°C, the heating rate is 100°C / min, the holding time is 10min, the atmosphere is vacuum, and then the diamond / copper composite material can be obtained by coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com