Self controlled high efficient gas and liquid separator

A gas-liquid separator and gas-liquid separation technology are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., and can solve the problems of high technical requirements for use and maintenance, high requirements for control systems, and complex control processes. Achieve the effect of low manufacturing and use cost, good separation effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

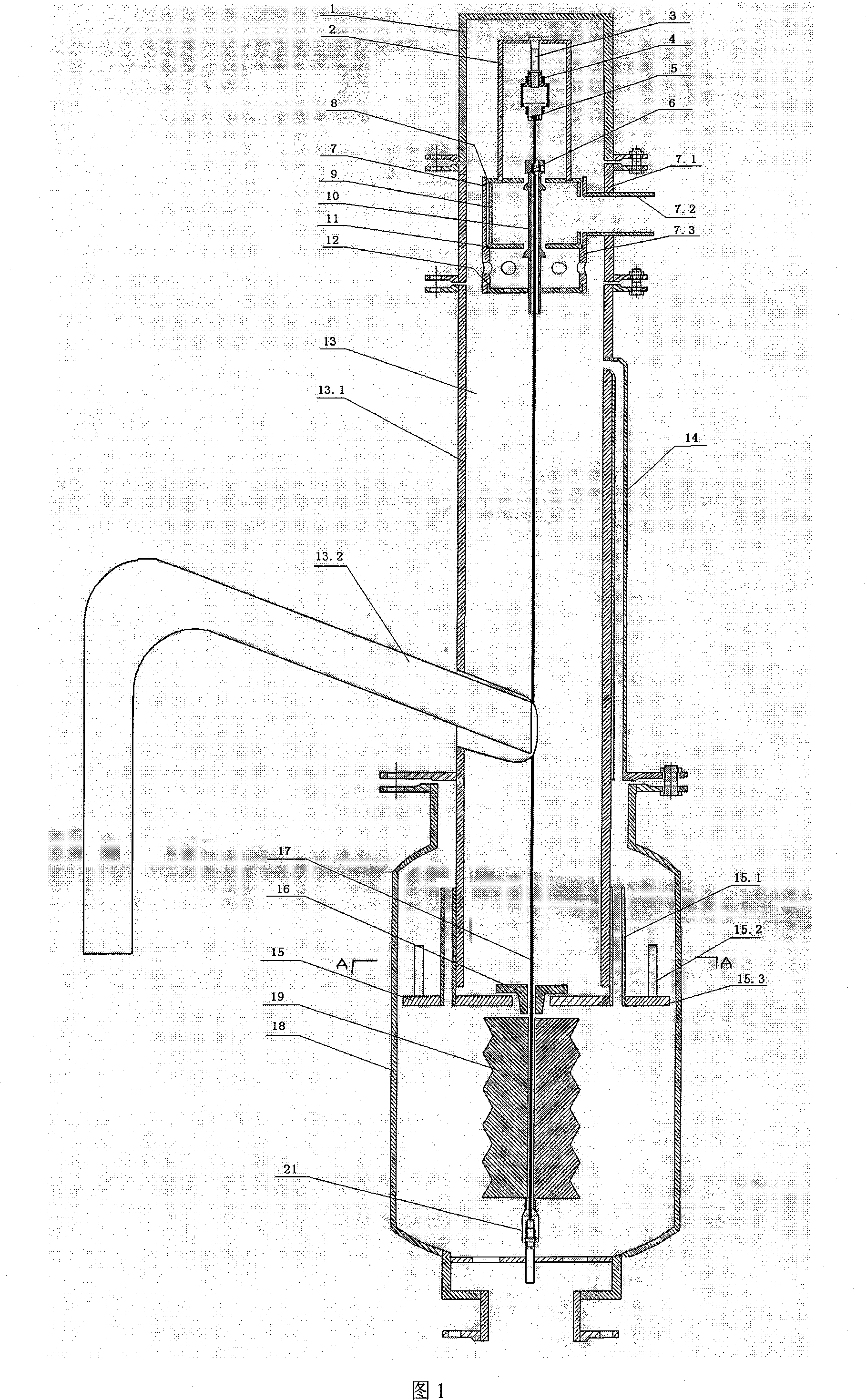

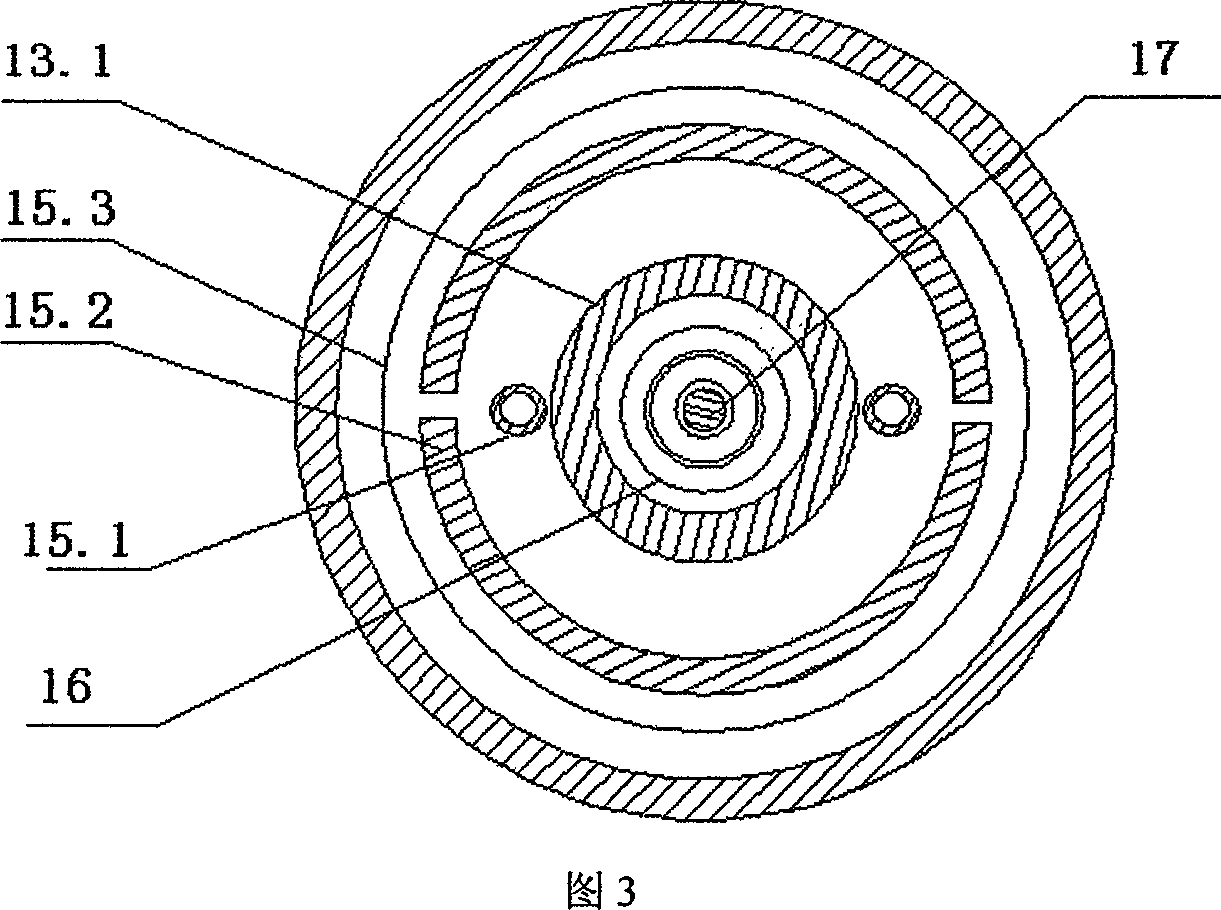

[0028] Embodiment 1: in conjunction with accompanying drawing 1 and 3, the present invention is described in further detail (gas-liquid mixed-phase medium can effectively separate gas phase through the scheme of above-mentioned automatic control high-efficiency gas-liquid separator):

[0029] Its technical scheme is: spring cover 1, bracket 2, adjustment rod 3, lock nut and washer 4, elastic element and connecting piece 5, air valve core fixing piece 6, air valve body 7, outer valve body 7.1, inner valve Body 7.2, outlet pipe 7.3, air valve seat 8, air valve positioning part 9, air valve core rod 10, air valve seat sealing ring 11, air valve centralizer 12, swirl separation unit 13, swirl separation body 13.1, air Liquid inlet pipe and nozzle 13.2, connecting pipe 14, auxiliary separation unit 15, 16, gas balance pipe 15.1, liquid level limit ring 15.2, disk 15.3, connecting rod 17, gravity separator 18, float 19.

[0030] The cyclone separation unit 13 is composed of a gas-li...

Embodiment 2

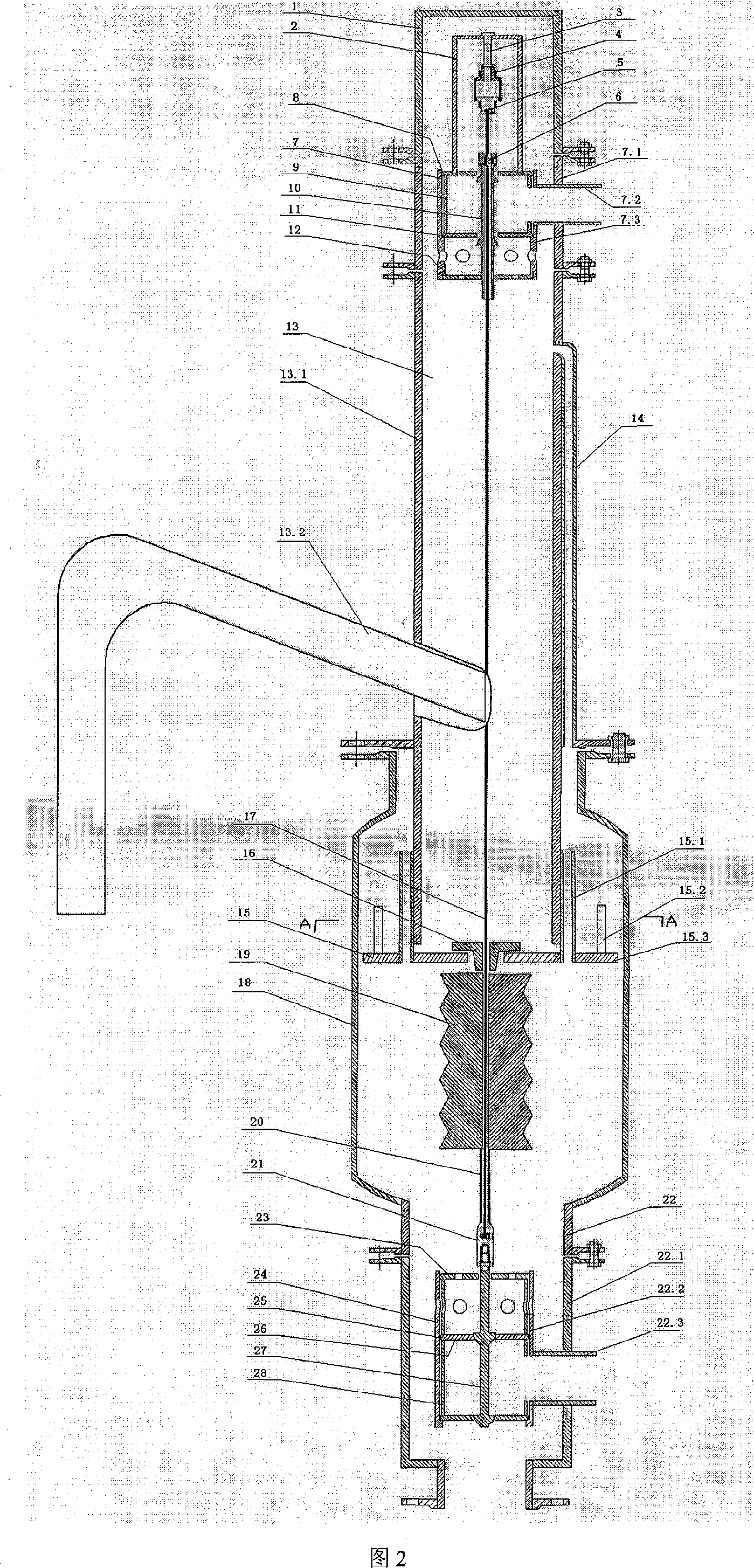

[0033] Embodiment 2: in conjunction with accompanying drawing 2 and 3, another kind of embodiment of the present invention is described in further detail (gas-liquid mixed-phase medium can effectively separate gas phase and liquid phase through the scheme of above-mentioned automatic control high-efficiency gas-liquid separator):

[0034] Its technical solution is: the above other structures remain unchanged, and the lower end of the gas-liquid separation unit can also be connected with a liquid adjustment unit. The outer valve body 22.1, the inner valve body 22.2, the liquid outlet pipe 22.3, the liquid valve centralizer 23, the liquid valve seat sealing ring 25, the liquid valve seat 26, the liquid valve core rod 27, and the liquid valve positioner 24,28 are formed.

[0035]The liquid valve body 22 is composed of a liquid valve outer valve body 22.1, an inner valve body 22.2, and a liquid outlet pipe 22.3. The upper end of the inner valve body 22.2 has an internal thread for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com