Industrial park heavy metal wastewater advanced treatment device and method

An advanced treatment, industrial park technology, applied in multi-stage water treatment, water/sewage treatment, biological water/sewage treatment, etc. Water quality, ensure normal operation, low sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Take a heavy metal-related sewage treatment plant (design scale: civil engineering and equipment according to 4500m 3 / d scale design) as an example, the parameters are set as follows:

[0027] System water quality

[0028]

[0029] System effluent quality

[0030]

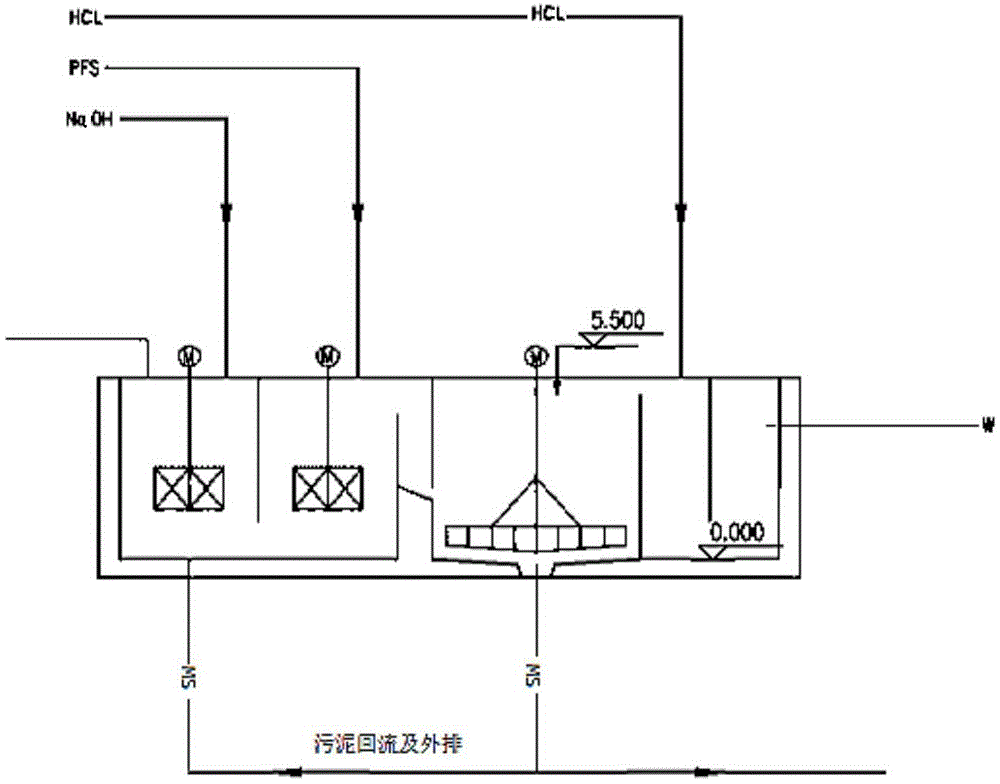

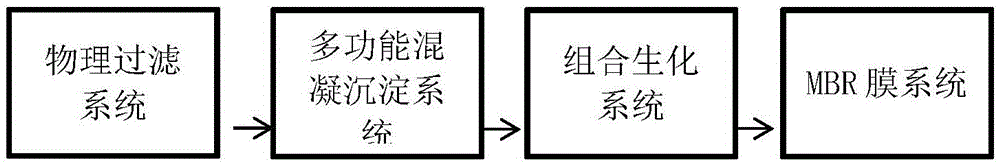

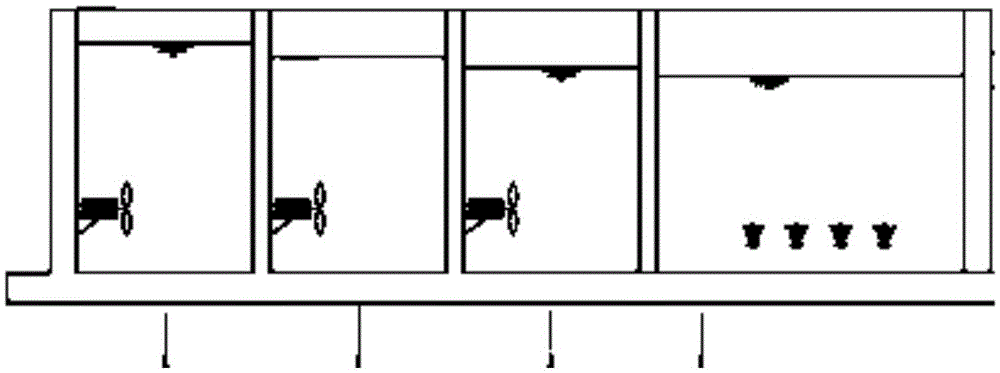

[0031] The device for the advanced treatment of heavy metal wastewater in industrial parks of the present invention comprises four parts: a physical filtration system (1), a multifunctional coagulation sedimentation system (2), a combined biochemical system (3), and an MBR membrane system (4) connected in sequence; The filtration system is a 2mm fine grid filter and the wastewater is lifted by a lifting pump to remove small floating objects and solid substances with a diameter greater than 2mm in the sewage to ensure the effect of the subsequent biological treatment system and the stable operation of the maintenance equipment. The combined biochemical pool consists of hydrolysis + A2O pool, MBR memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com