Method and device for continuously producing isosorbide

A technology of isosorbide and sorbitol, which is applied in the field of continuous production of isosorbide, can solve the problems of complicated process, high material consumption and high energy consumption, and achieve the effects of simplified separation process, low temperature and energy consumption, and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

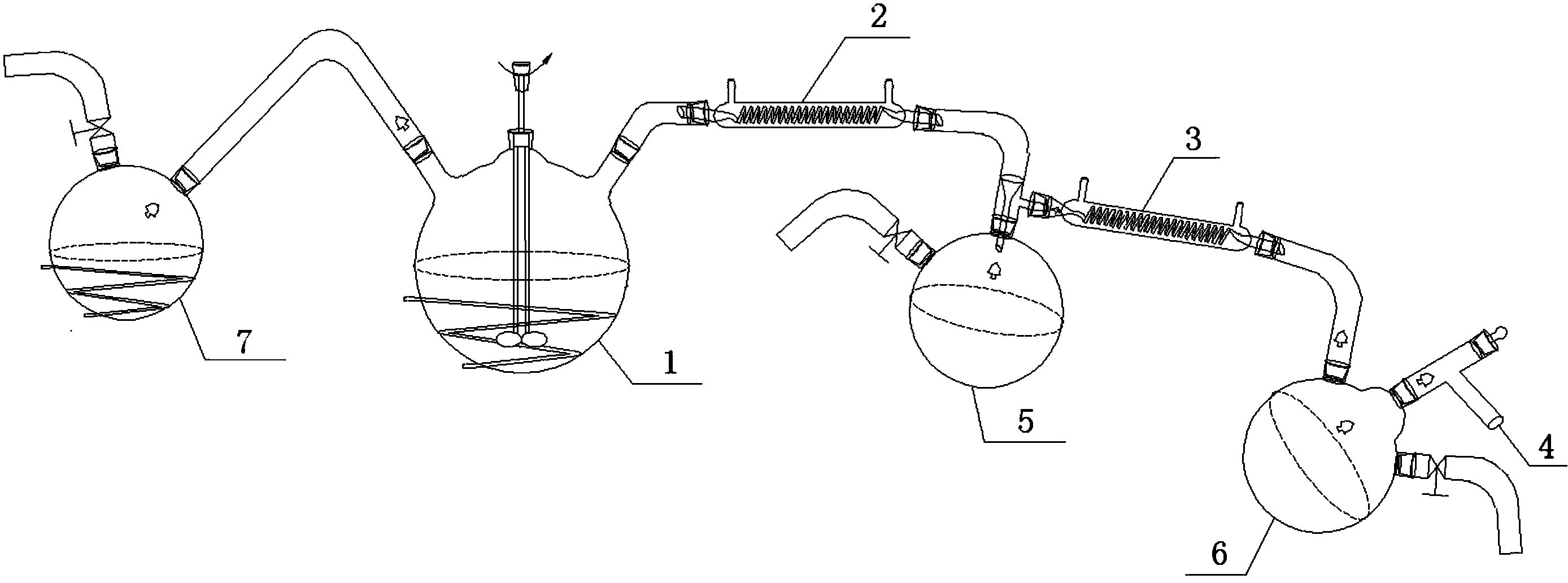

Image

Examples

Embodiment 1

[0037] In the 500mL reactor that is provided with stirrer, add the polyphosphoric acid of 180 grams solid sorbitol and 0.9 gram, each component of reaction device is according to figure 1 Connect as shown, and then evacuate. Maintain a vacuum degree of 200pa and heat at a temperature of 130°C. Under the action of polyphosphoric acid, the molten sorbitol reacts for 1 hour, then the oil bath is heated to 280°C, and the temperatures of the first condenser and the second condenser are controlled to be 60°C and -10°C, a total of 112.6 grams of product were collected in the product tank (yield: 78.0% of theoretical value), with a purity of 99.5%.

[0038]The resulting product had a melting point of 61-62°C.

[0039] HRMS-EI(m / e,%): 146.0578(M + ,5.14),86.0340(C 4 h 6 o 2 ,100),69.0325(C 4 h 5 O, 18.20), 58.0408 (C 3 h 6 O, 13.41), 44.0254 (C 2 h 4 O, 17.57).

[0040] The peak at 146.0578 is the molecular ion peak, and the peak at 86.0340 is the fragment ion generated aft...

Embodiment 2

[0044] In the 500mL reactor that is provided with agitator, add 100 grams of 70% sorbitol aqueous solution and 0.4 gram of polyphosphoric acid, each assembly of reaction device is according to figure 1 Connect as shown, and then evacuate. Maintain a vacuum degree of 300pa, heat at a temperature of 135°C, and proceed the reaction under the action of polyphosphoric acid until the reactor is anhydrous, then the oil bath is heated to 260°C, and the temperatures of the first condenser and the second condenser are controlled respectively At 52°C and -15°C, a total of 44.1 g of product (yield: 78.5% of theoretical value) was collected in the product tank with a purity of 99.6%.

[0045] The obtained product characterization result is similar to Example 1.

Embodiment 3

[0047] In the 500mL reactor that is provided with stirrer, add the polyphosphoric acid of 60 gram solid sorbitol and 0.3 gram, each component of reaction device is according to figure 1 Connect as shown, and then evacuate. Maintain a vacuum of 200pa and heat at a temperature of 130°C. Under the action of polyphosphoric acid, the molten sorbitol reacts for 1 hour, then the oil bath is heated to 240°C, and the temperatures of the first condenser and the second condenser are controlled to be 52°C and -15°C, after collecting 15 grams of product in the product tank, add 30 grams of sorbitol to the system through the raw material tank, continue the reaction under the same conditions, collect 30 grams of product, and then add 30 grams of sorbitol to the system The polyphosphoric acid of gram and 0.1 gram still reacts under the same conditions, and a total of 75.2 grams of products are collected (yield: 78.1% of theoretical value), with a purity of 99.5%.

[0048] The obtained produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com