Efficient heat insulation guide pipe bracket

A oriented and efficient technology, which is applied in the direction of protecting pipelines, pipeline supports, and pipeline protection through heat insulation, can solve the problems of reduced allowable load capacity, reduced bearing capacity, and easy damage to the heat insulation layer, so as to enhance integration and improve The effect of bearing capacity and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

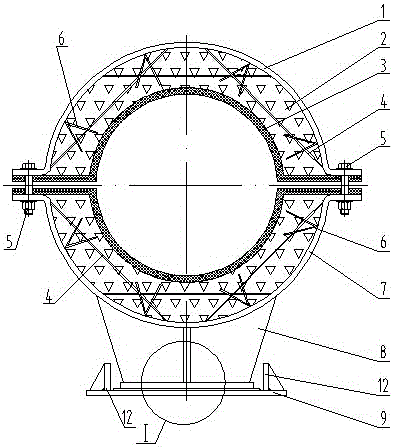

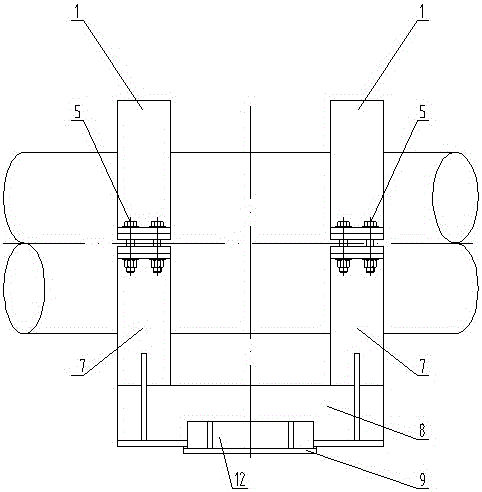

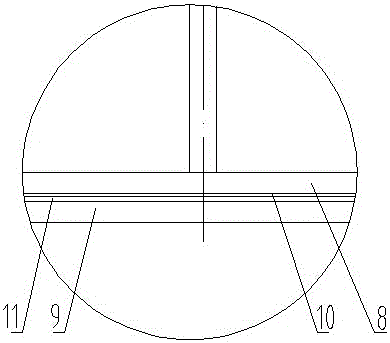

[0022] The high-efficiency heat-insulating guide pipe support shown in the attached figure includes upper hoop 1, heat-insulation tile 2, high-temperature-resistant soft thermal insulation material 3, pull rod 4, bolt fastener 5, anchor nail 6, lower hoop 7, The base 8, the base 9, the upper sliding plate 10, the lower sliding plate 11, and the guide supports 12 on the left and right sides of the base 9; the upper hoop 1 and the lower hoop 7 are all semi-ring structures, and the two sides extend to form At the fixed end, the inner walls of the upper hoop 1 and the lower hoop 7 are poured with heat-insulating tiles 2, and the inner walls of the heat-insulating tiles 2 are pasted with high-temperature-resistant soft thermal insulation materials; the upper hoop 1 and the lower hoop 7 are fixed by The bolt fasteners 5 at the ends are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com