Anti-trap device for rubbish

An anti-clamping device and garbage technology, applied in the directions of garbage receptacles, transportation and packaging, can solve the problems of staying in the gap, hindering the movement of the sliding plate, affecting the appearance, etc. probability, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

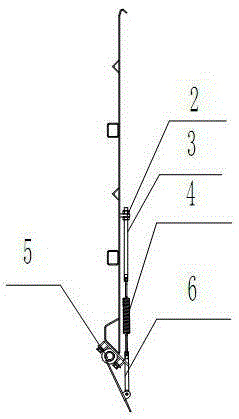

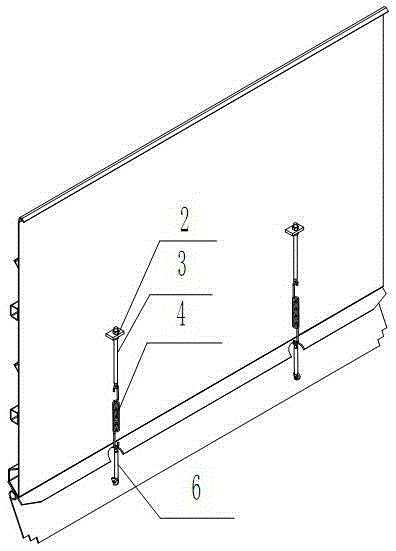

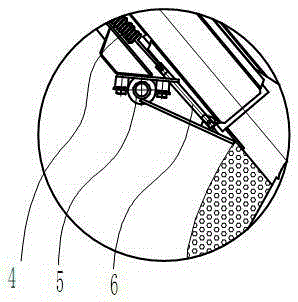

[0027] The working process of the packing device that has used the garbage anti-clamping device of the present invention is described as an example below: when it is necessary to collect rubbish, the crushing plate 9 of the packing device is opened, and the slide plate 7 moves downward to the initial state at the bottom, and the packing device After filling the garbage, use the crushing plate 9 to crush the garbage, and at the same time the sliding plate 7 moves up to the top to complete the action of crushing the garbage and lifting it into the carriage; It is fixed on the filling device housing 1-1, so that the movable baffle assembly 5 repeatedly removes the residual garbage between the sliding plate 7 and the filling device housing 1-1 back and forth during the repeated movement of the slide plate. After completing an action, the filling device is set to the initial state, and the garbage collection and compression are continued, and the cycle is repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com