Perovskite solar cell with high-quality electron transport layer and preparation method thereof

A technology of electron transport layer and solar cell, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problem that the defect state density and surface charge trap density cannot be simultaneously and effectively reduced, so as to facilitate charge transport, wet Enhanced properties and spreadability, improved structure and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

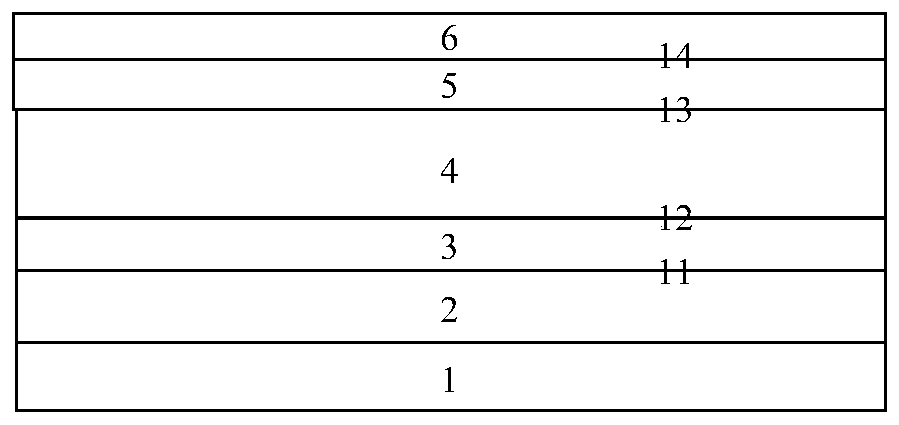

[0028] A method for preparing a perovskite solar cell with a high-quality electron transport layer, comprising the following steps:

[0029] Step 1: sequentially form a transparent conductive electrode 2 and a metal oxide electron transport layer 3 on a glass substrate 1, and the metal oxide electron transport layer 3 is deposited by chemical bath deposition, magnetron sputtering, electron beam deposition, spin coating method or non-vacuum chemical deposition method, the preparation temperature of the metal oxide electron transport layer 3 is 23-600°C, the thickness of the metal oxide electron transport layer 3 is 10-100nm, and the metal oxide electron transport layer 3 is oxidized Titanium, zinc oxide or tin oxide;

[0030] Step 2: After preparing the metal oxide electron transport layer 3, use the plasma-enhanced chemical vapor deposition method to bombard the oxygen-containing element plasma to generate oxygen radicals in the chemical vapor deposition system, and transport ...

Embodiment 1

[0035] A method for preparing a perovskite solar cell with a high-quality electron transport layer, comprising the steps of:

[0036] 1) Cleaning of transparent conductive electrode 2: based on figure 1 The glass substrate 1 with FTO transparent conductive electrodes 2 is selected as the structure, and the cleaning of the substrate in the ultrasonic cleaning machine is divided into the following four steps, ①cleaning with ethanol for 15 minutes; ②cleaning with acetone for 30 minutes; ③cleaning with isopropanol for 30 minutes; ④cleaning with ethanol for 15 minutes ; Then the cleaned glass substrate with electrodes was blown dry with nitrogen.

[0037] 2) Preparation of the metal oxide electron transport layer 3: after step 1), when the metal oxide semiconductor layer 3 is prepared by magnetron sputtering, the target material is titanium oxide as an example, the deposition gas atmosphere is argon and oxygen, The ratio is 29.4:0.6 sccm, the deposition temperature is 150° C., the...

Embodiment 2

[0043] A method for preparing a perovskite solar cell with a high-quality electron transport layer, comprising the steps of:

[0044] 1) Cleaning of transparent conductive electrode 2: based on figure 1 The glass substrate 1 with FTO transparent conductive electrodes 2 is selected as the structure, and the cleaning of the substrate in the ultrasonic cleaning machine is divided into the following four steps, ①cleaning with ethanol for 15 minutes; ②cleaning with acetone for 30 minutes; ③cleaning with isopropanol for 30 minutes; ④cleaning with ethanol for 15 minutes ; Then the cleaned glass substrate with electrodes was blown dry with nitrogen.

[0045] 2) Preparation of the metal oxide electron transport layer 3: after step 1), when using the non-vacuum chemical vapor deposition method to prepare the metal oxide semiconductor layer 3, taking zinc oxide as an example, the precursor solution is zinc acetate, and the solvent is water and methanol , 10 and 90 mL respectively, stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com