Packaging box with gluing and absorbing combined sealing function

A packaging box and functional technology, applied in the field of packaging, can solve the problems of reducing viscosity, losing the sealing environment, and deformation of the sealing layer, and achieve the effects of repeated use, durability, brand recognition rate, and excellent sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

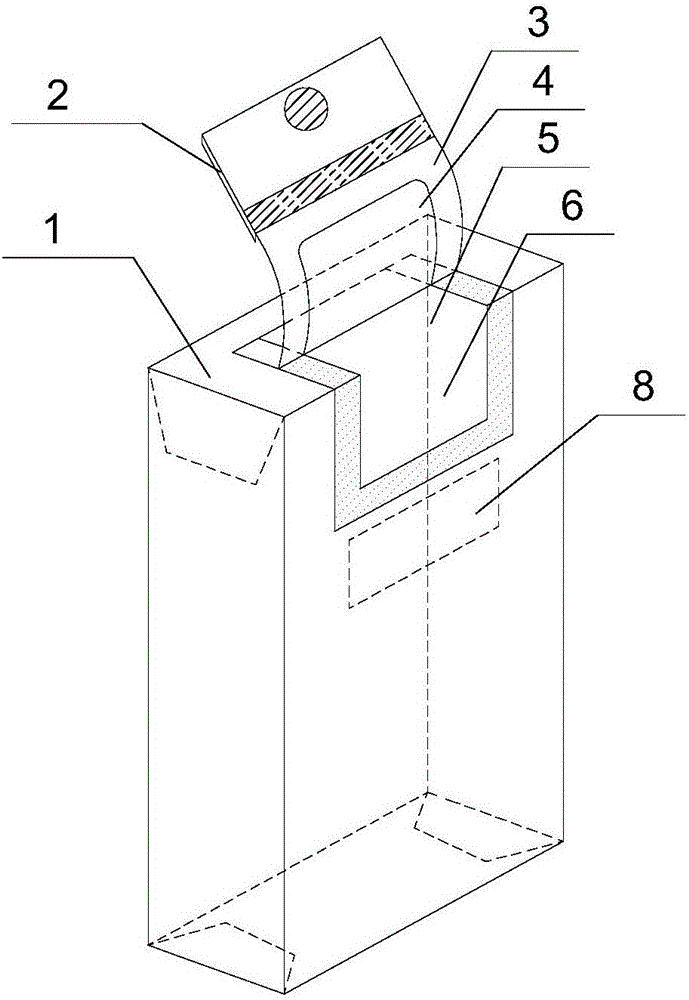

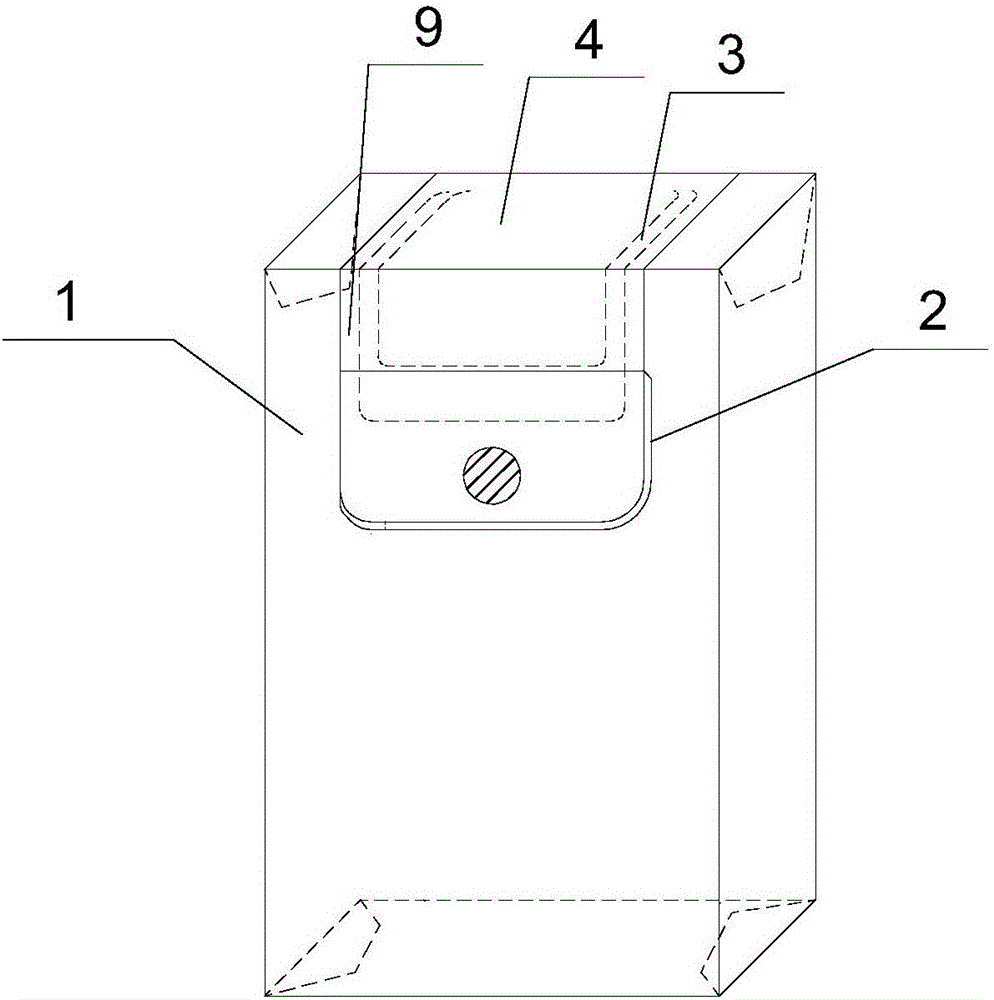

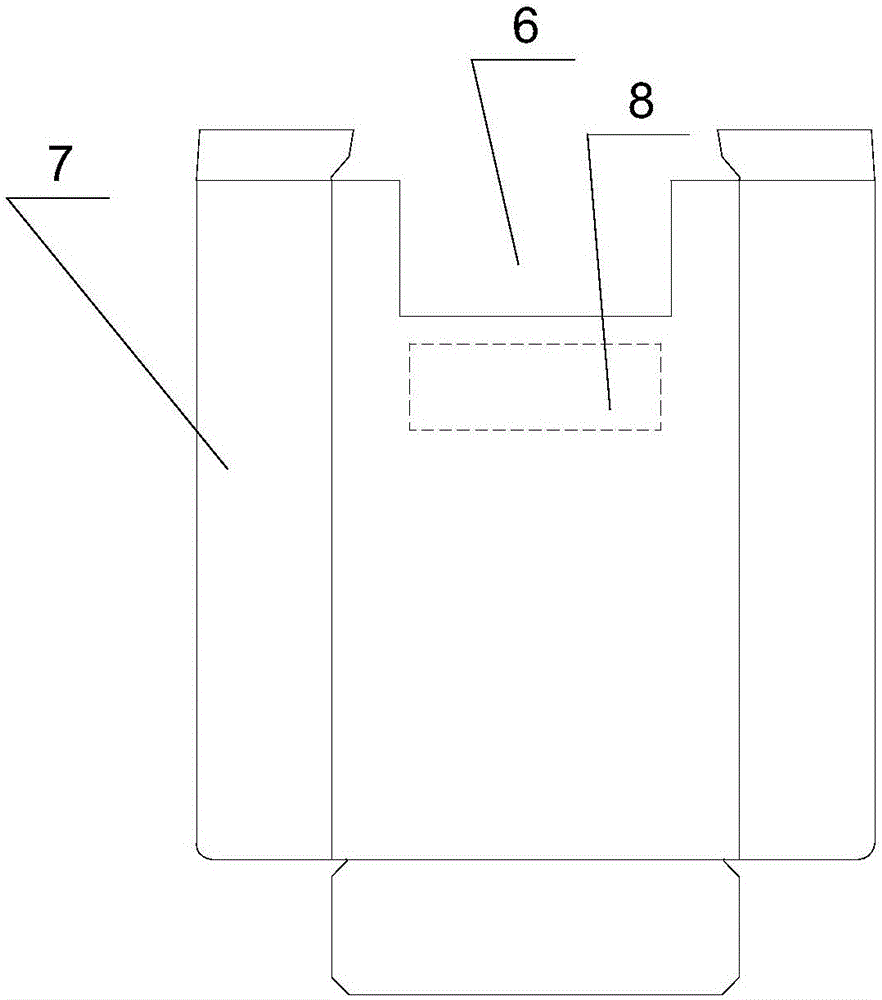

[0054] A packaging box with combined sealing functions of glue and suction is composed of a supporting frame (7) and a wrapping sheet (1). The support frame (7) is composed of front and rear end faces, left and right sides, and upper and lower end faces, and a frame opening (6) is provided on the front end face and the upper end face; the wrapping sheet is wrapped outside the support frame, and The frame together constitutes a packing box; the said parcel sheet is provided with a pick-up port (5), and a sealing piece (4) is provided on the pick-up opening, and the size of the said sealing piece is the same as that of the pick-up opening; Covered with an adhesive cover (3).

[0055] The packaging box is provided with an adsorption material (8), the cover sheet is pasted with a functional sheet (9), and the functional sheet is pasted with an activation label (2) that is mutually adsorbed with the adsorption material (8).

[0056] The startup label is composed of three layers of...

Embodiment 2

[0063] The wrapping sheet is a single-layer structure composed of different materials, and the pick-up opening is a window corresponding to the opening position of the frame partially cut on the wrapping sheet, and a part of the pick-up opening is One part is not cut off, and remains connected with the wrapping sheet, and the remaining part is cut to form an openable sealing sheet.

[0064] The cover sheet is an additional adhesive sheet covered on the sealing sheet, and the area of the cover sheet is larger than that of the sealing sheet. There is no functional sheet on the cover, and the activation label is directly pasted on the cover. All the other structures are with embodiment 1.

Embodiment 3

[0066] The wrapping sheet is a double-layer structure composed of upper and lower layers of materials, with viscous material coated between the two layers of materials, and the access port is a opening set on the lower layer of the wrapping sheet and corresponding to the opening position of the frame. A part of the access opening is not cut off, and is kept connected with the lower material of the wrapping sheet, and the remaining part is cut to form an openable sealing sheet.

[0067]The cover of the packaging box is formed by cutting on the upper material. A part of the cover is not cut and connected to the upper material of the wrapping sheet, and the rest is cut by a point-breaking process to form a cover that can be peeled off. The area of the cover is larger than The area of the seal piece.

[0068] In this embodiment, there is no functional sheet and activation label on the cover sheet, no adsorption material on the box body, and a simplified version of the packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com