A grinding machine with automatic closing function

A self-closing, functional technology, applied in the direction of manufacturing tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as burns and scalds, splashes on people, and potential safety hazards, and achieve the goal of avoiding splashes in gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

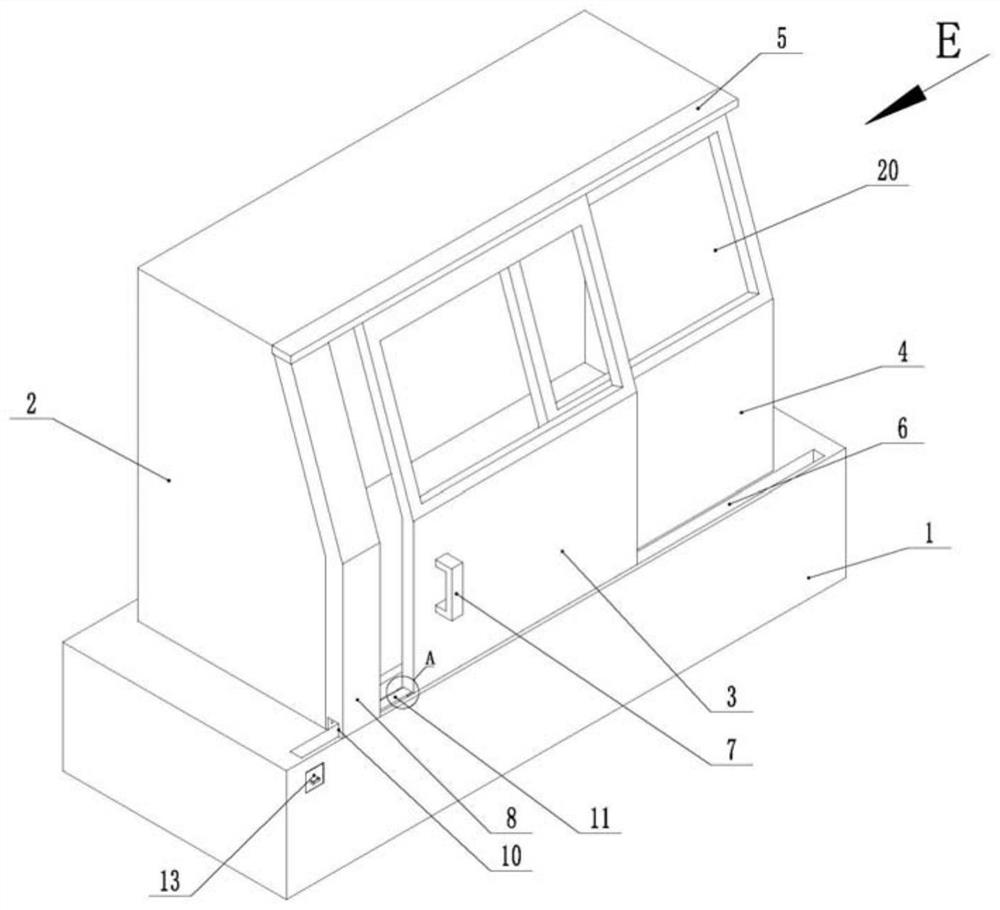

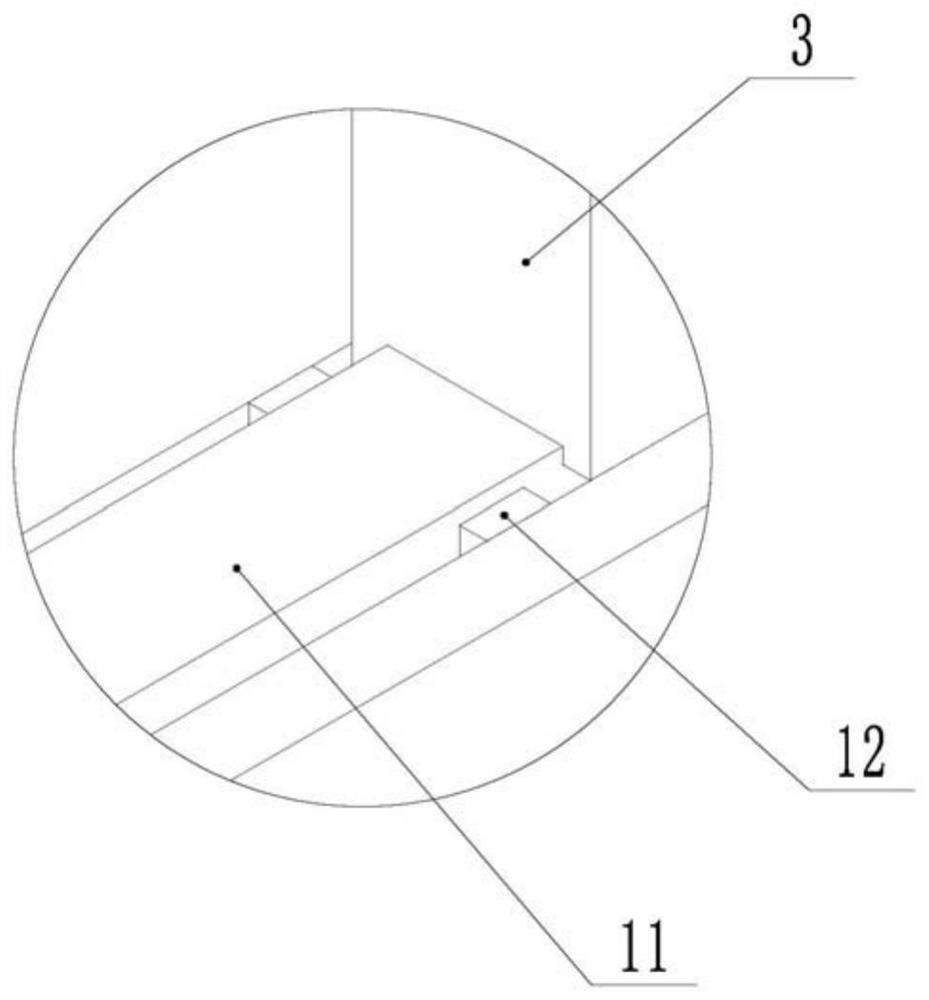

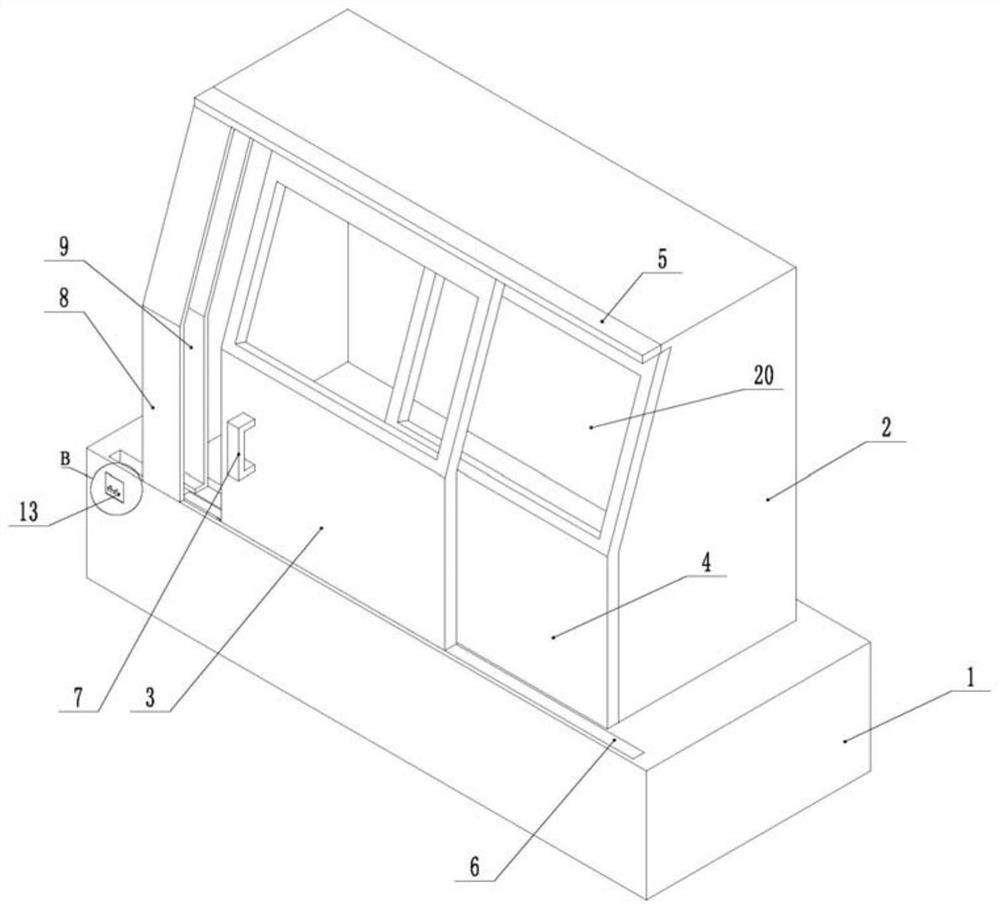

[0042] The embodiment is basically as attached figure 1 Shown: a grinding machine with automatic closing function, including a workbench 1, a grinding wheel arranged on the workbench 1, a driving unit for driving the grinding wheel to rotate, and a clamping unit for clamping workpieces. In this embodiment, the grinding wheel and the driving unit and The clamping units all adopt the basic equipment of the grinding machine in the prior art, and in this embodiment, the automatic closing function of the grinding machine is mainly realized, so the grinding wheel, the driving unit and the clamping unit are not shown in the figure.

[0043]Workbench 1 is provided with protective cover 2, and protective cover 2 all covers emery wheel and clamping unit inside it, and in the present embodiment, with the position that the operator stands and operates in the process of processing (such as the operator's work when installing the workpiece position) as the front side of the protective cover...

Embodiment 2

[0055] like Figure 5 As shown, a grinding machine with an automatic sealing function differs from Embodiment 1 in that: the inside of the workbench 1 is hollow, and an air supply unit is installed in the workbench 1 through bolts. The air supply unit in this embodiment is an existing There is an air compressor 18 in the art.

[0056] combine Image 6 and Figure 7 As shown, the side of the scraper 11 facing the fixed door 4 is welded and fixed with an extension plate 16, and the top of the extension plate 16 is welded and fixed to the bottom end of the sliding door 3. The insides of the scraper 11 and the extension plate 16 are all hollow, and the scraper block 11 and the extension plate 16 are welded and fixed to each other, and one end of the scraper block 11 and the extension plate 16 is connected to each other, so that the scraper block 11 and the extension plate 16 are connected to each other. The air outlet hole 17 of the air outlet pipe 19 is arranged between the ex...

Embodiment 3

[0059] like Figure 8 As shown, a grinding machine with automatic closing function differs from Embodiment 1 in that: the side of the limit block 8 away from the sliding door 3 is slidably connected with the pull plate 21 capable of blocking the sliding door 3 along the length direction of the chute 6 , combined with Figure 9 and Figure 10 As shown, the pull plate 21 is inserted into the limit groove 9 of the limit block 8, and the shape of the pull plate 21 in this embodiment is similar to the shape of the limit block 8, so that the pull plate 21 can be in the limit groove 9 Normal sliding.

[0060] combine Figure 8 As shown, the first guide groove 22 provided on the slide plate 5 runs through the top end of the slide plate 5 and the bottom end of the slide plate 5, and the top end of the sliding door 3 is welded and fixed with a first rack 24, and the first rack 24 is fixed along the first guide. The slot 22 slides in the longitudinal direction, and the top of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com