Square sapphire monocrystal furnace heat field structure

A technology of sapphire and furnace heat field, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of low yield rate of pear-shaped crystal ingots, achieve good heat preservation effect, increase yield rate, increase Radian effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

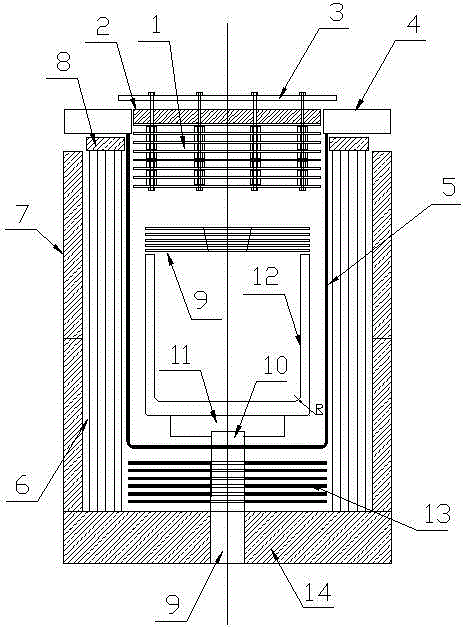

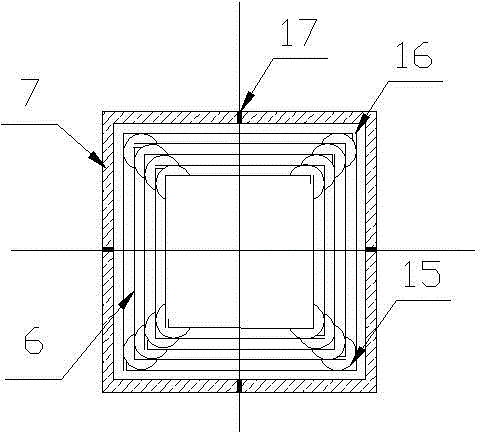

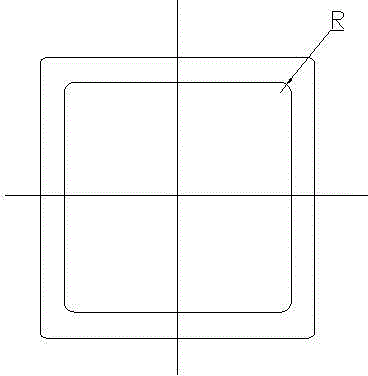

[0027] combine figure 1 , the present embodiment comprises upper heat shield, side heat shield and lower heat shield, crucible lid 9, and square crucible 12, square tray 11, circular pillar 10 made of metal tungsten, right-angled copper conductive plate 4 and tungsten The square heating body formed by connecting rods 5 is composed. The upper heat shield is composed of molybdenum heat shield 1, zirconia fiber brick insulation structure 2 and stainless steel bracket 3, the inner screen 6 of the side heat shield is a right-angle lap structure of multi-layer molybdenum plates, and the outer screen is square zirconia fiber Brick insulation barrel structure 7, a layer of ring-shaped zirconia fiber brick structure 8 is placed on the top of the side heat shield, and the lower heat shield is composed of square molybdenum sheet heat shield 13 and zirconia fiber brick insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com