All-steel radial heavy-duty tire

A radial and tire technology, applied in the field of all-steel radial heavy-duty tires, can solve problems such as insufficient bead structure support performance, difficulty in meeting, and empty tire bead, so as to meet the requirements of the ultra-high and heavy-duty market and reduce the probability of tire deformation. Effect of reducing possibility of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

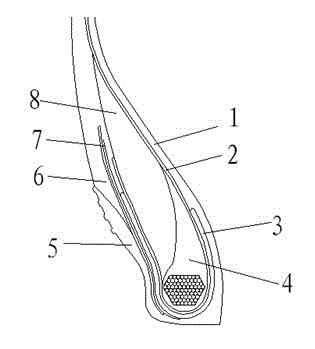

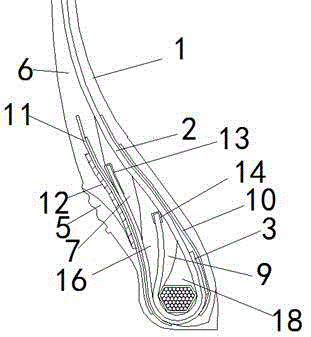

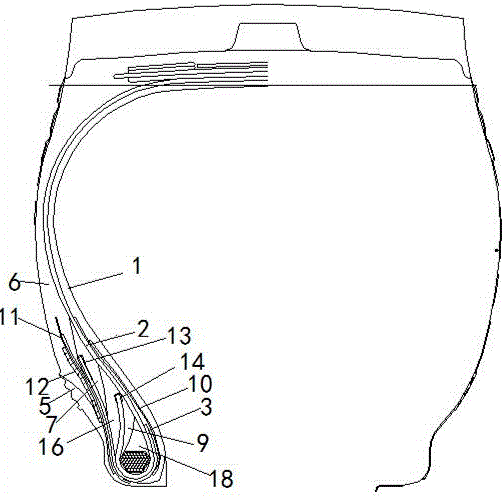

[0026] figure 2 It is a schematic cross-sectional view of an all-steel radial heavy-duty tire along its meridian line according to an embodiment of the present invention. The all-steel radial heavy-duty tire of the present invention includes an annular tread portion extending in the tire circumferential direction; a pair of sidewall portions arranged on both sides of the tread portion; and arranged on the inside of the sidewall portion in the tire radial direction A pair of bead portions, at least one carcass ply 2 is bridged between the pair of bead portions, and the carcass ply 2 includes a plurality of carcass cords whose direction is along the radial direction of the tire. The carcass ply 2 has a main body part that reaches the bead core of the bead part from the tread part through the sidewall part, and is connected to the main body part and wraps around the bead core from the axially inner side to the axial direction of the all-steel radial heavy duty tire. The reentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com