Industrial stirring equipment

A mixing equipment and industrial technology, applied in the field of industrial mixing equipment, can solve the problems of large influence of motor, influence on motor life, unbalanced force on the frame, etc., to reduce the probability of deformation, improve the mixing effect, and balance the overall force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

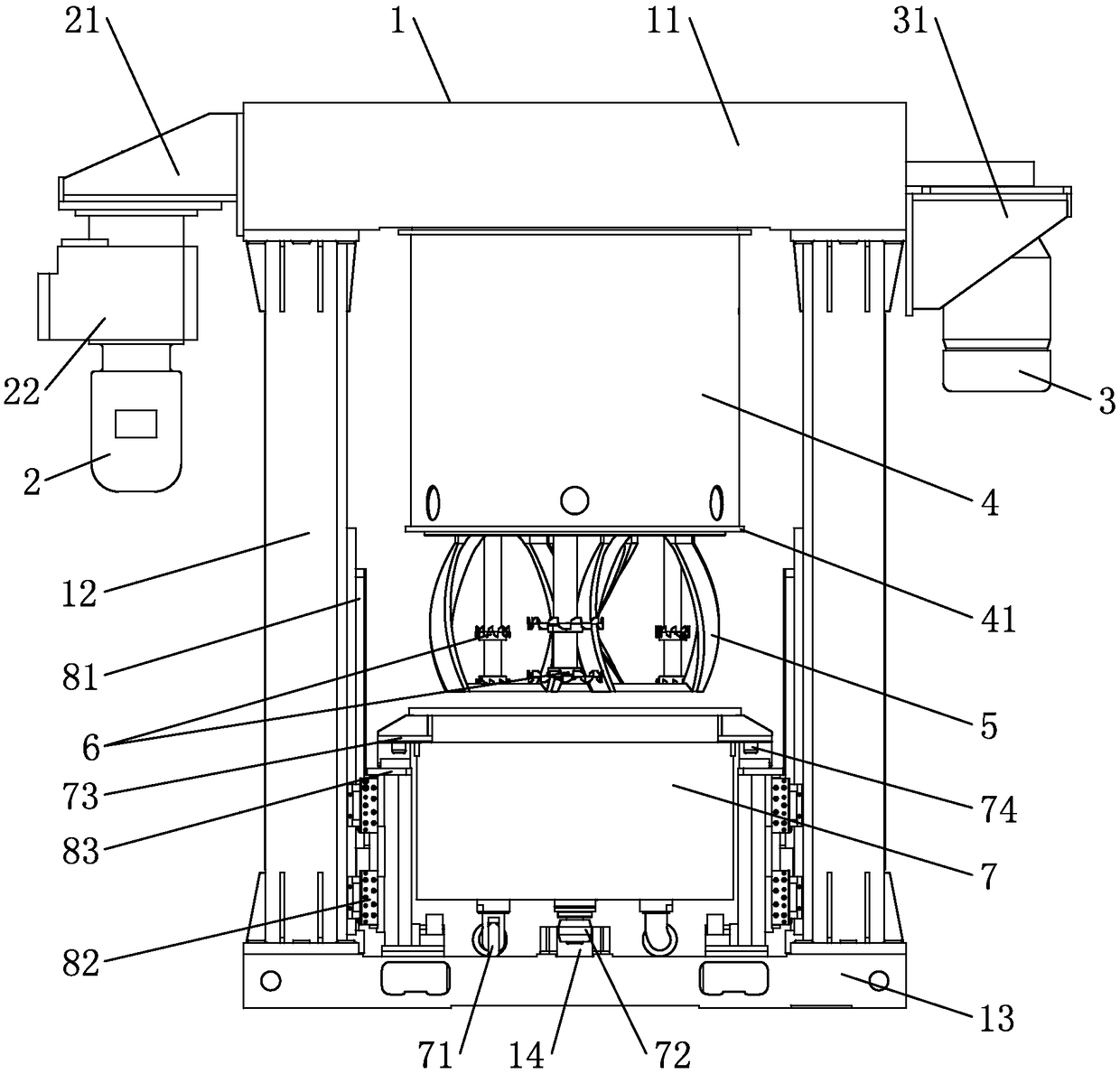

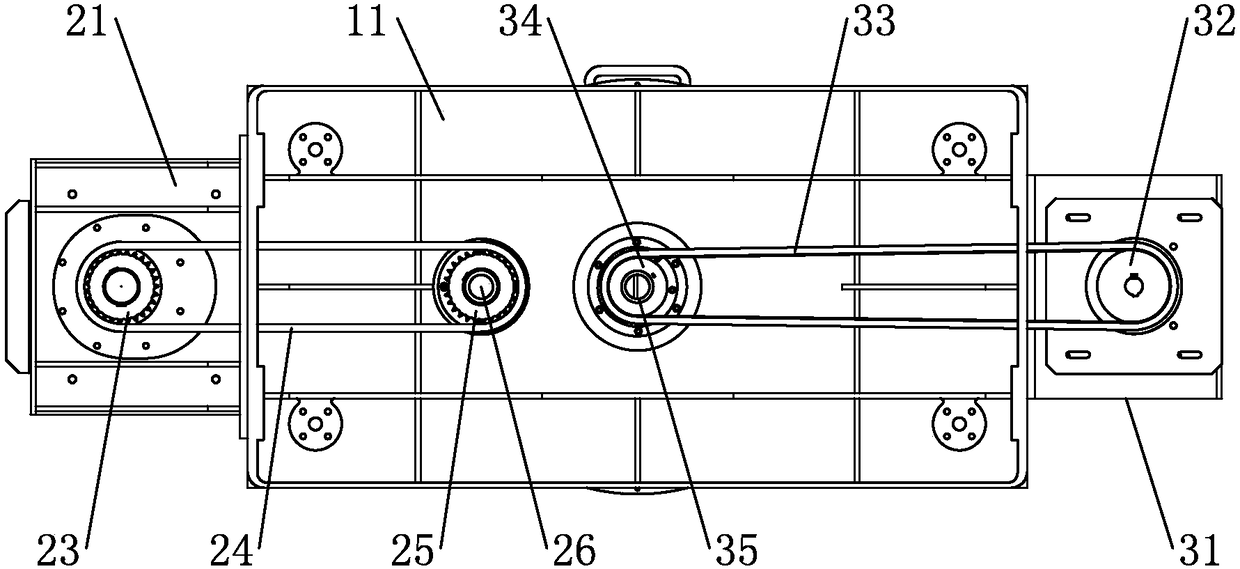

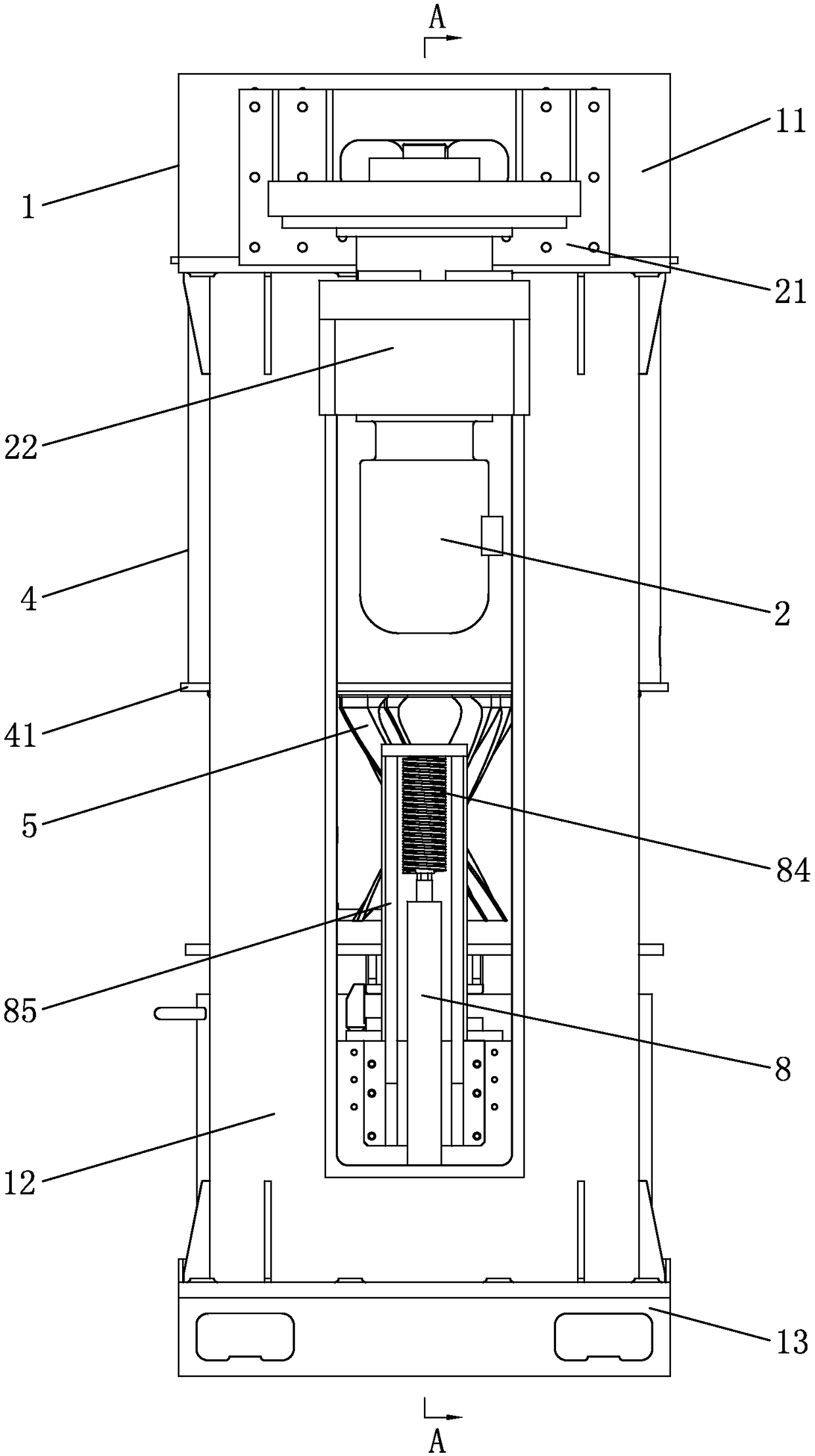

[0056] Embodiment one, see figure 1 - 8 and Figure 11 - As shown in 14, an industrial mixing and mixing equipment includes a gantry 1, the gantry 1 includes a base 13, a column 12 and a beam 11, the left and right sides of the top of the base 13 are provided with the column 12, and the two ends of the beam 11 are connected to the The top of the column 12 and the beam 11 are provided with a stirring mechanism, a dispersing mechanism, a fixed sleeve 4 and a protective cover 9 . Each part of the gantry 1 is casted, and the base 13 is provided with a lifting mechanism for the bucket 7. The lifting mechanism for the bucket 7 includes a bracket 83 for lifting movement, and a horizontal limit is provided between the bracket 83 and the bucket 7. structure. The hoisting mechanism of the bucket 7 also includes a servo electric cylinder 8, a vertical guide rail 81 and a slide block 82. The corresponding servo electric cylinder 8 is provided with a limit frame 85 on the gantry 1, and t...

Embodiment 2

[0070] Embodiment two, the difference with embodiment one is: see Figure 17 and Figure 18As shown, four stirring paddles 5 are provided, and four dispersion shafts 61 are provided. L1 is the outer peripheral rotation path of the four stirring paddles 5 when they rotate, and L2 is the inner wall of the material barrel 7 (the center of the inner cavity of the material barrel 7 can theoretically be It is understood as the rotation center of the protective cover 9, the two centers overlap or basically overlap), and the four small circles such as L3, L4, etc. are the outer peripheral rotation paths of the four dispersion shafts 61 corresponding to the dispersion disc 6 when they rotate; among them, the four The center point O' of the virtual plane formed by the sequential connection of O1, O2, O3 and O4 is respectively the center point of the rotation path of the stirring paddle 5, which deviates from the center point O of the inner cavity of the barrel 7.

Embodiment 3

[0071] Embodiment three, the difference with embodiment one is: see Figure 19 As shown, two stirring paddles 5 are provided, and two dispersion shafts 61 are provided. L1 is the outer peripheral rotation path of the two stirring paddles 5 during autorotation work, and L2 is the inner wall of the material barrel 7 (the center of the inner cavity of the material barrel 7 can theoretically be It is understood as the rotation center of the protective cover 9, the two centers overlap or basically overlap), L3 and L4 are the outer peripheral rotation paths corresponding to the dispersion disc 6 when the two dispersion shafts 61 rotate; wherein, the two stirring paddles 5 rotation rotation paths The centers of circles are the center point O' of the line connecting O1 and O2, which deviates from the center point O of the inner cavity of the barrel 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com