Flexible pneumatic bottle cap clamping part

A clamping component and flexible technology, applied in the field of liquid filling equipment, can solve the problems of unstable clamping force of the belt on the bottle cap, uncontrollable capping torque, difficult to control the capping force, etc., and achieve stable clamping force High performance, adjustable clamping force and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples illustrate the specific implementation of the present invention, but are not limited to this embodiment.

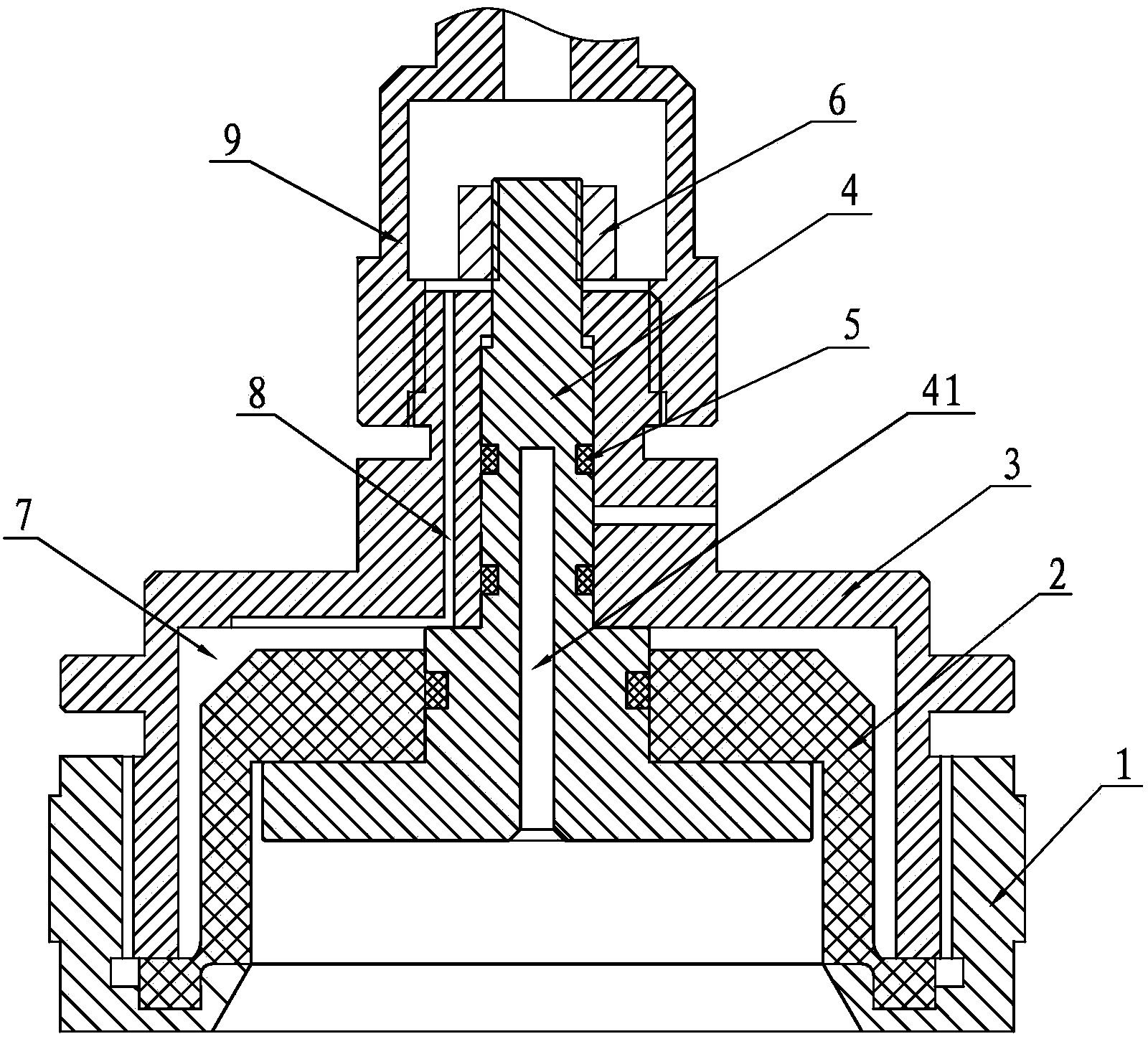

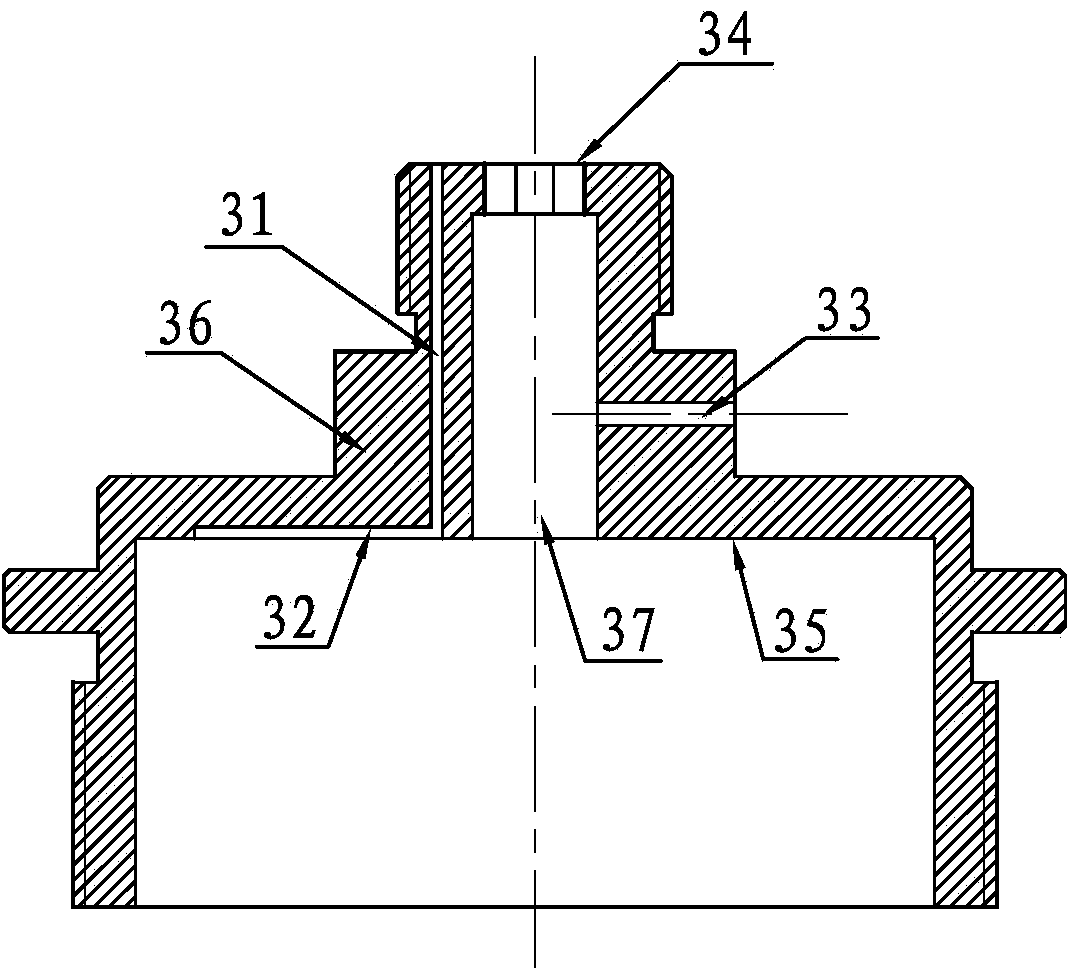

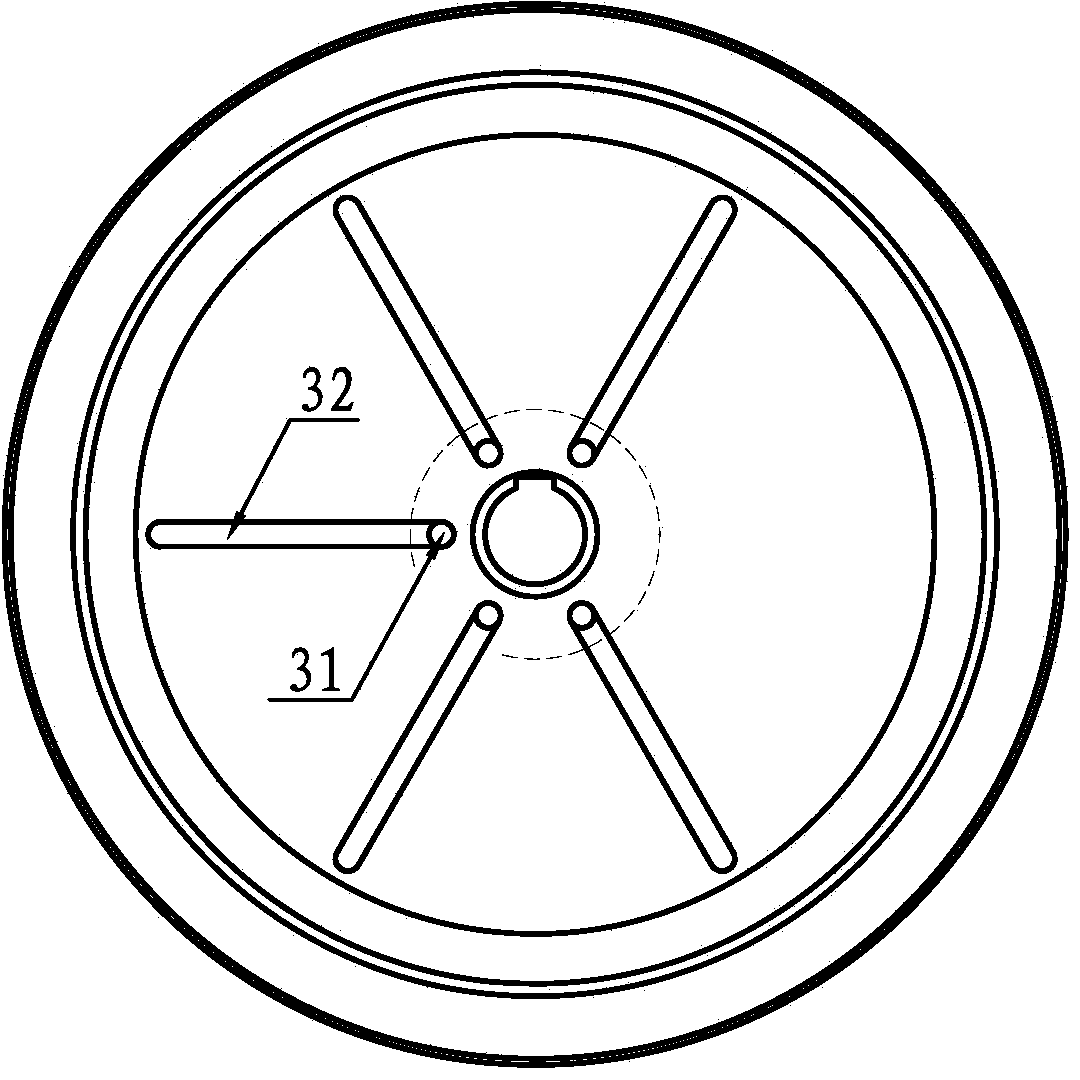

[0021] A pneumatic flexible bottle cap clamping part, such as Figure 1 ~ Figure 3 As shown, it includes screw cap threaded sleeve 1, elastic clip ring 2, rotary cover seat 3, gland core 4, mandrel sealing ring 5 and tightening nut 6, and elastic clip ring 2 is hermetically set on the gland core 4, An axial air inlet 31, an end surface air groove 32 and a decompression hole 33 are arranged on the rotating cover base 3, the axial air inlet 31 is opened on the upper end surface 34, the end surface air groove 32 is opened on the inner end surface 35, and the shaft The inlet port 8 is formed by the air inlet hole 31 and the corresponding end surface air groove 32, and the decompression hole 33 is opened on the transition shaft diameter 36, and the decompression hole 33 is staggered with the axial air inlet hole 31 in the circumferential direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com