Bidirectional self-centering power chuck

A self-centering and chucking technology, applied in the direction of the chuck, can solve the problems of affecting the machining accuracy of the workpiece and easy deformation, and achieve the effects of improving machining accuracy, convenient machining and high pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

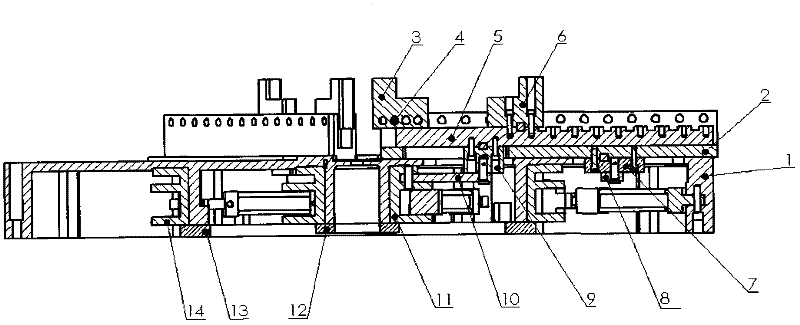

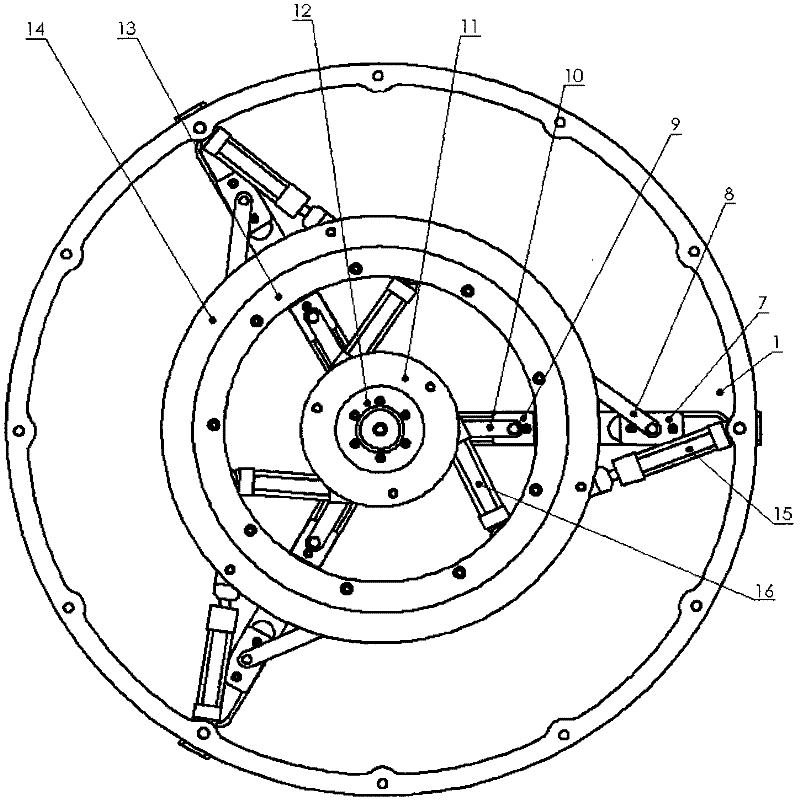

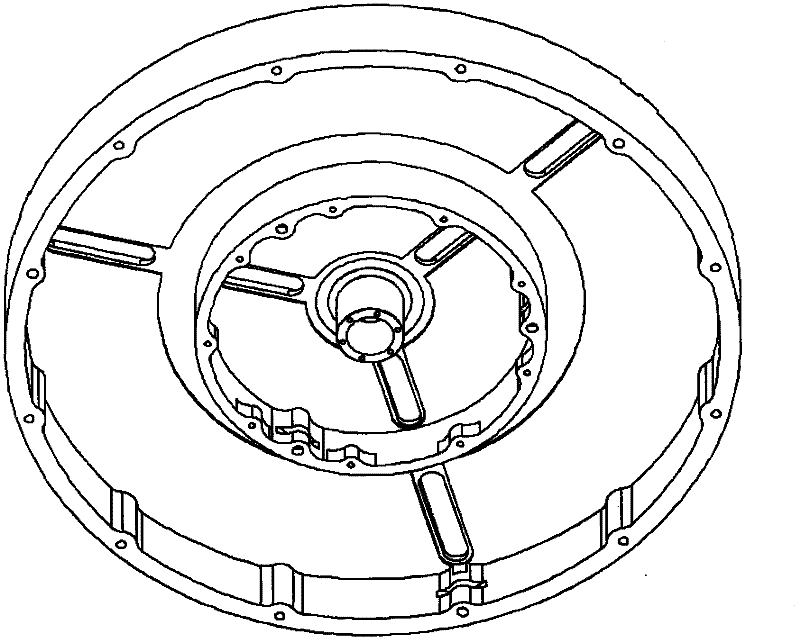

[0026] exist figure 1 , 2 In the first embodiment, the inner turret 11 and the outer turret 14 have the same structure and different diameters, and they are respectively set on the concentric inner pipe wall and the middle pipe wall under the chuck body 1, the inner flange 12, the outer flange Lan 13 is respectively fixed on the inner pipe wall and the middle pipe wall below the chuck body 1 and limits the axial displacement of the inner turret 11 and the outer turret 14 respectively. On the outer tube wall, the cylinder rod is hinged on the outer turret 14, the cylinder body of the inner oil cylinder 16 is hinged on the middle tube wall of the chuck body 1, the cylinder rod is hinged on the inner turret 11, and the inner jaws 3 are used The inner jaw pin 4 is fixed on the inner jaw seat 2, the inner jaw seat 2 is installed in the upper chute of the chuck body 1, the outer slider 7 is fixed on the inner jaw seat 2 through the slot hole of the chuck body 1 One end of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com