Pipe clamping device

A technology for clamping devices and pipe fittings, applied in workpiece clamping devices, pipes/pipe joints/pipe fittings, pipe supports, etc., can solve the problems of poor self-locking performance, small dimensional tolerance, time-consuming and laborious loosening of workpieces, etc. Easy installation and operation, simple and compact structure, and achieve the effect of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

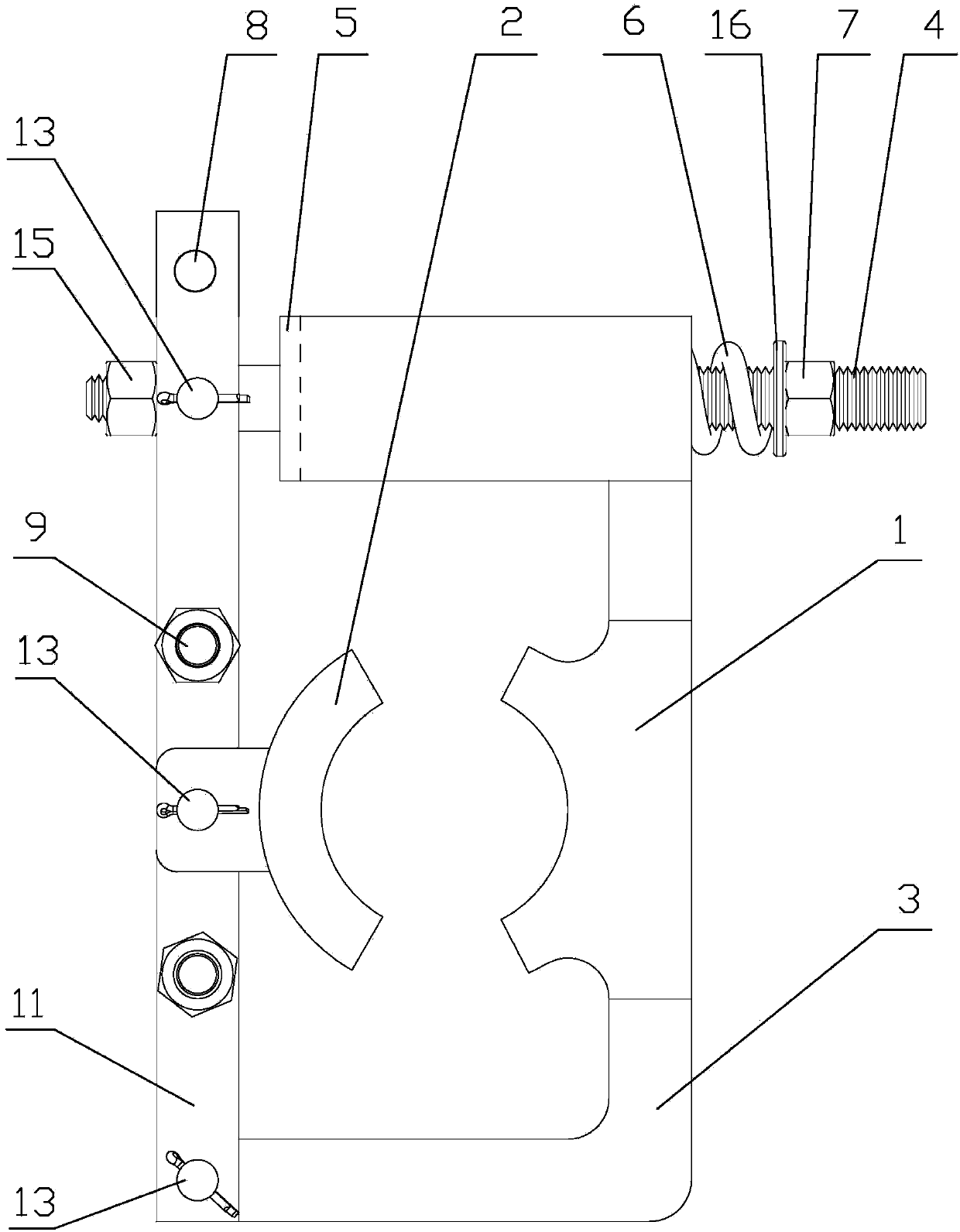

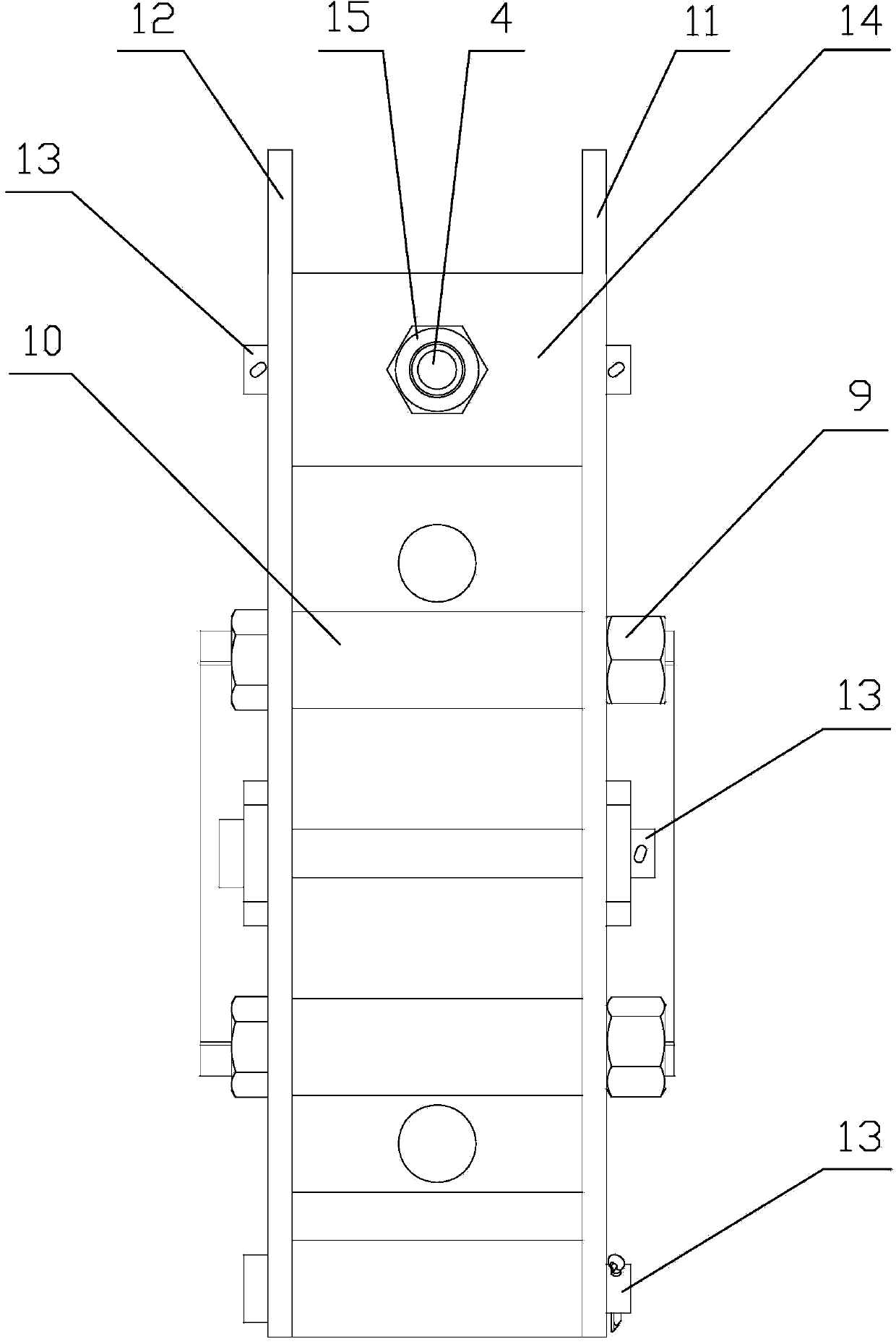

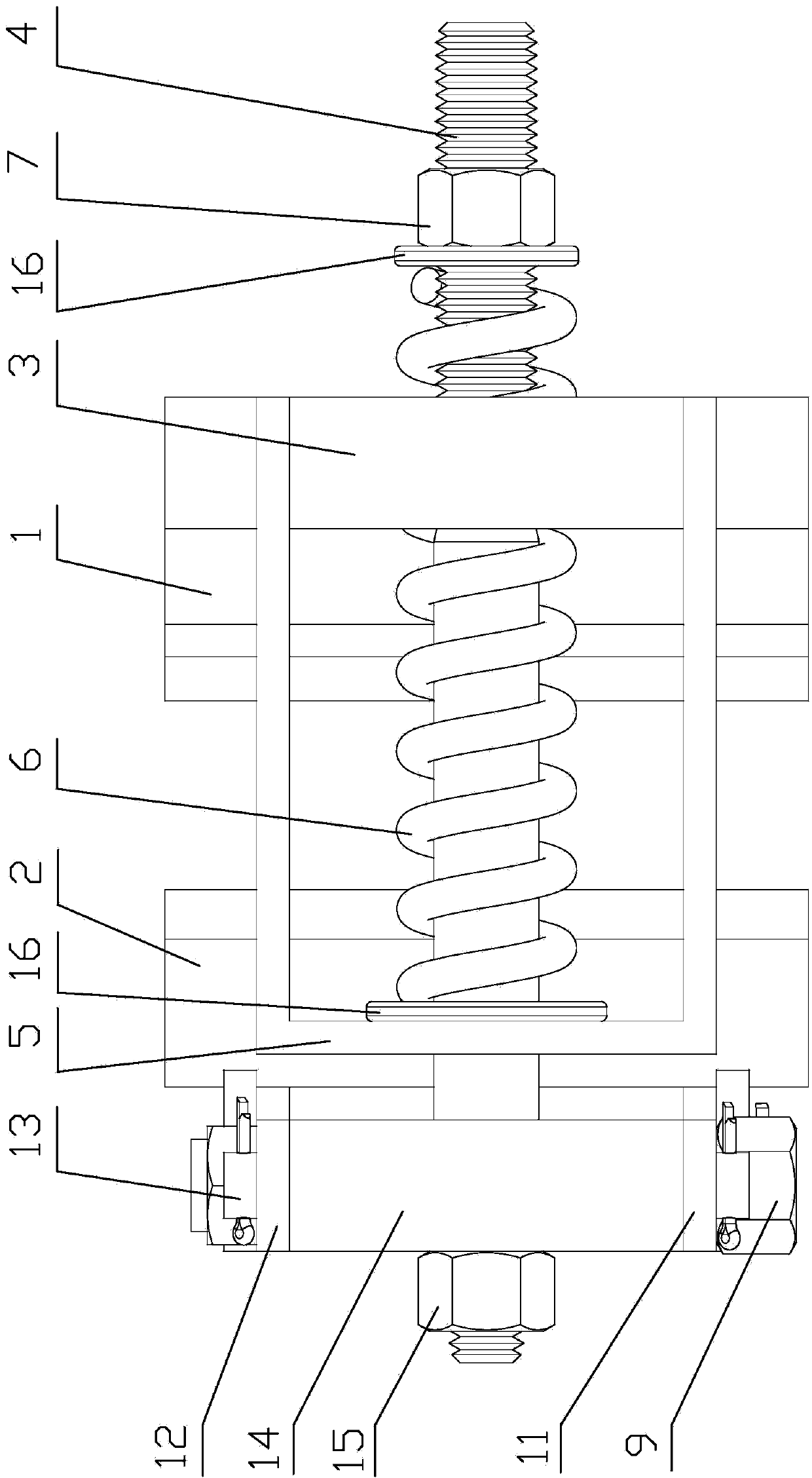

[0020] The clamping device for pipe fittings of the present invention comprises a swing arm, an "L" shaped fixed arm 3 and a clamping mechanism.

[0021] The swing arm includes an upper plate 11 and a lower plate 12 parallel to each other. The upper plate 11 and the lower plate 12 are connected as a whole with bolts 9, and the upper plate 11 and the lower plate 12 are connected by bolts 9. The axle sleeve 10 keeps the distance; the lower end of the upper plate 11 and the lower plate 12 is hinged with the transverse section end of the fixed arm 3 through the fixed pin 13, and a support block 14 is set between the upper swing end of the upper plate 11 and the lower plate 12, the described Support block 14 is hinged with upper plate 11 and lower plate 12 by fixed pin 13; In the tight clamping state, the upper plate 11 and the lower plate 12 are parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com