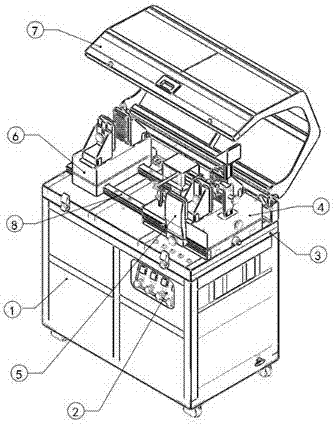

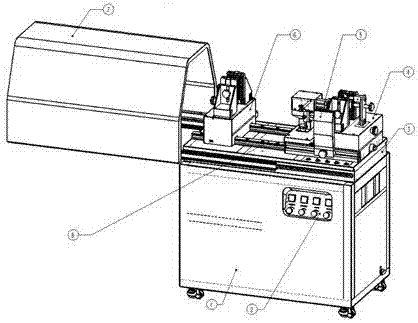

Universal shooting frame for long guns and short guns

A short gun and rear clamping technology, which is applied in weapon accessories, offensive equipment, weapon testing, etc., can solve the problems of potential safety hazards, unreliable clamping force firing, damage to guns, etc., and achieve the effect of avoiding unreliable firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

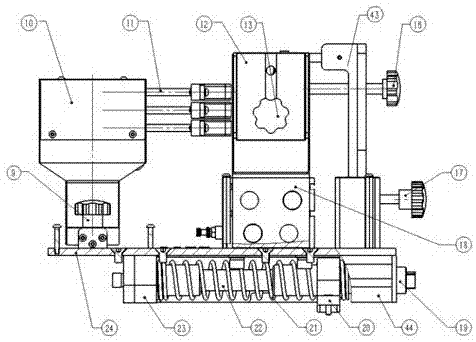

Embodiment 1

[0038] When clamping the short gun, first move the front support frame 10 to the front end of the slideway 25 and lock it by the locking screw I9. Then install the short gun movable pin shaft in the pin shaft hole sleeve 26 on the rear clamping block 14, adjust the short gun muzzle adjustment part 15 to a suitable height, lock it through the stop screw III17, start the air compressor 49, adjust the rear clamp Hold the pressure knob 35 to start the corresponding power actuator 39 so that the compressed gas enters the cylinder of the two synchronous jaws I18, pushes the rear clamping block 14 on the two synchronous jaws I18 to clamp the rear seat of the short gun, and passes The finger pressure knob 53 starts the power executive element 39 to promote the finger 11 on the support frame 10 to clamp the front end of the short gun. After the short gun is clamped, the adjusting screw 16 is adjusted to realize the adjustment of the muzzle position of the short gun.

[0039] Then, the ...

Embodiment 2

[0041] When clamping a long gun, move the front support frame 10 and the finger 11 installed on it to the rear end of the slideway 25 and lock it with the set screw I9, remove the pin hole sleeve 26 and the muzzle adjustment of the short gun Part 15, change the long gun rear seat 27, the long gun rear seat is placed on the long gun rear seat 27, the long gun muzzle is placed on the support member 30, then, start the air compressor 49, adjust the clamping pressure knob 35 to start and The corresponding power actuator 39 makes the compressed gas enter the cylinder of the two synchronous jaws I18, pushes the rear clamping block 14 on the two synchronous jaws I18 to clamp the rear seat of the long gun, and at the same time, opens the front clamping pressure Knob 52 starts its corresponding power execution element 39 to promote two synchronous jaws II 32 to clamp the muzzle of the long gun.

[0042] Then, the magnetic suction base 55 is sucked on the base 1, the net bag 57 is adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com