Patents

Literature

43results about How to "Easy to change position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

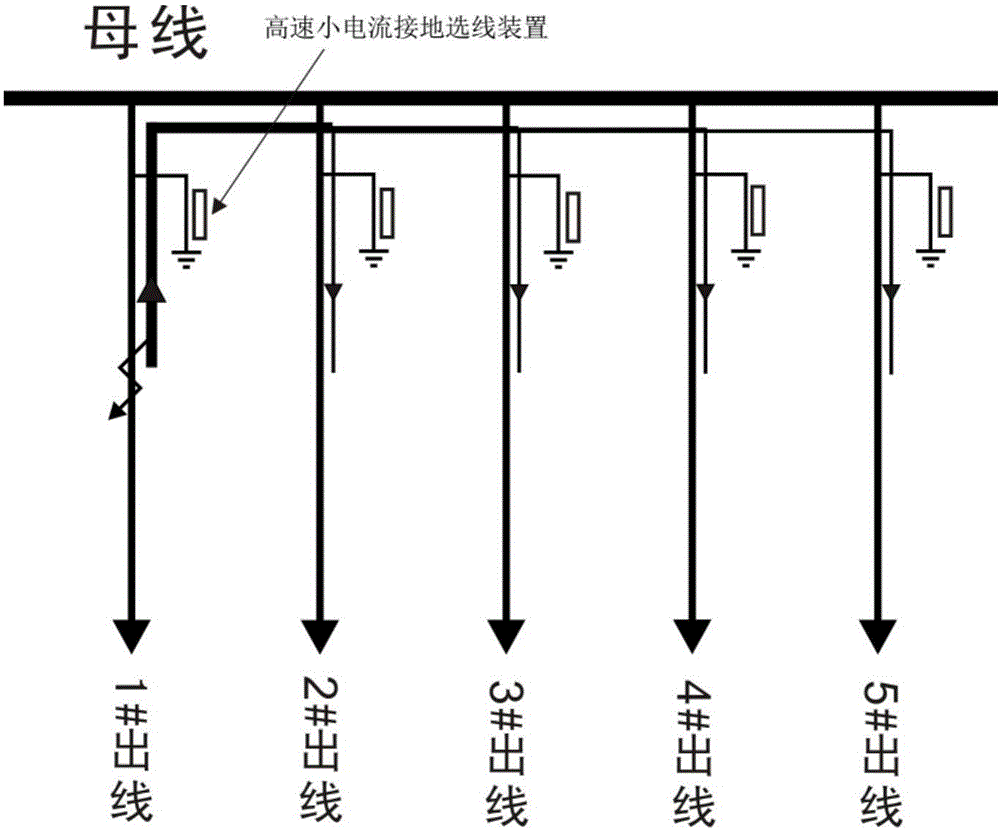

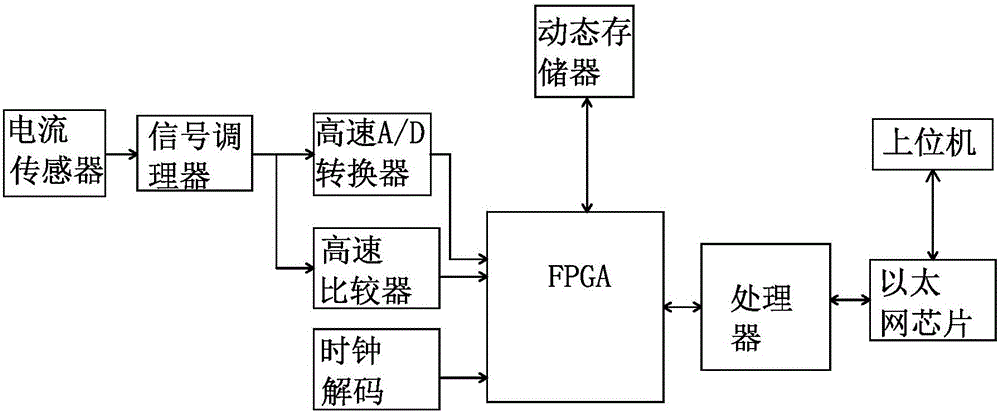

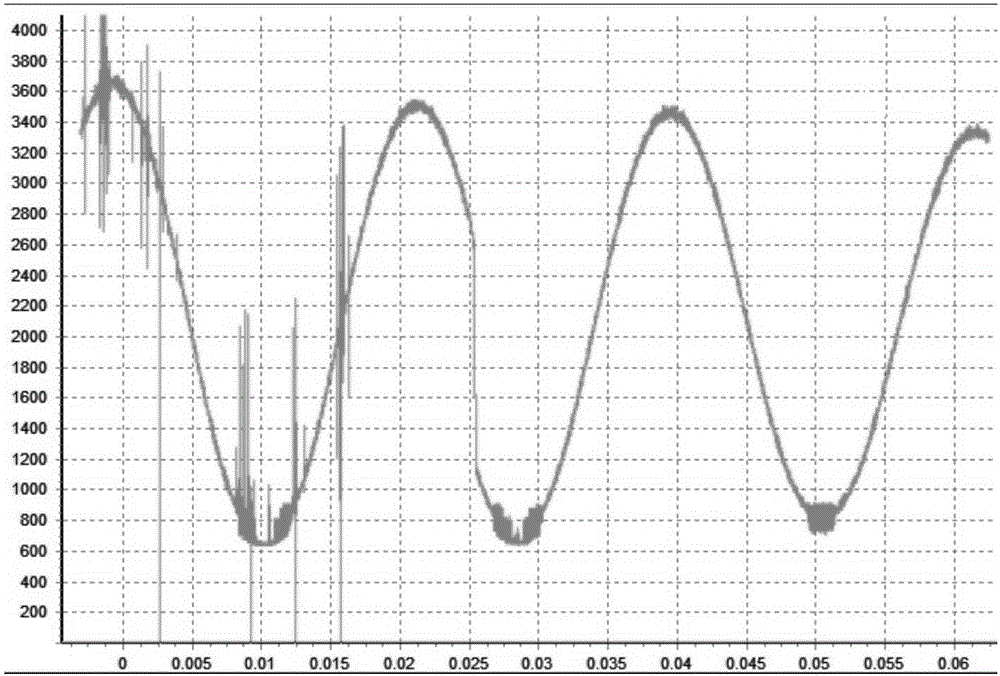

Line selection method for single-phase earth fault line of small current grounding system

InactiveCN106093714AThe method is accurate and reliableGood application conditionFault location by conductor typesSingle phaseSelection method

The invention discloses a line selection method for a single-phase earth fault line of a small current grounding system, and belongs to the electric power cable fault on-line monitoring field. The line selection method comprises a plurality of cables in the same bus with a small current grounding mode, and is characterized in that: transient current signals flowing through each cable outgoing line metal shielding layer grounding line are monitored and recorded through a high speed collection method, the transient current signals are generated by a fault loop when the single-phase grounding fault of the small current grounding system happens; and the fault line is selected by identifying the directions of wave heads of the transient current signals. The method compares the directions of the wave heads of grounding line current traveling waves of all the cables, and distinguishes a fault cable and a non-fault cable. In comparison with other small current grounding line selection methods at present, the accuracy of the line selection is high, and the multi-selection or missing report condition can be effectively avoided.

Owner:山东博鸿电气股份有限公司

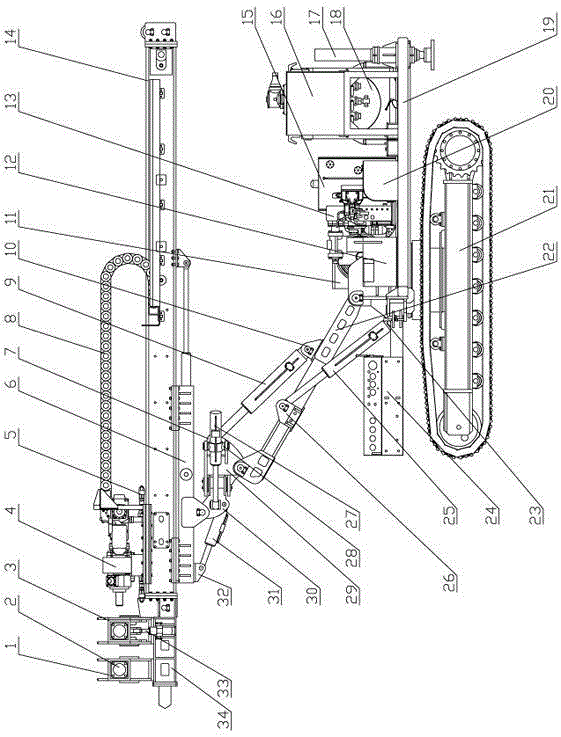

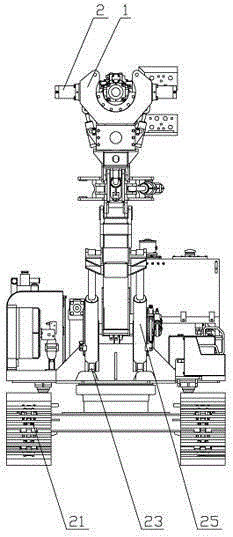

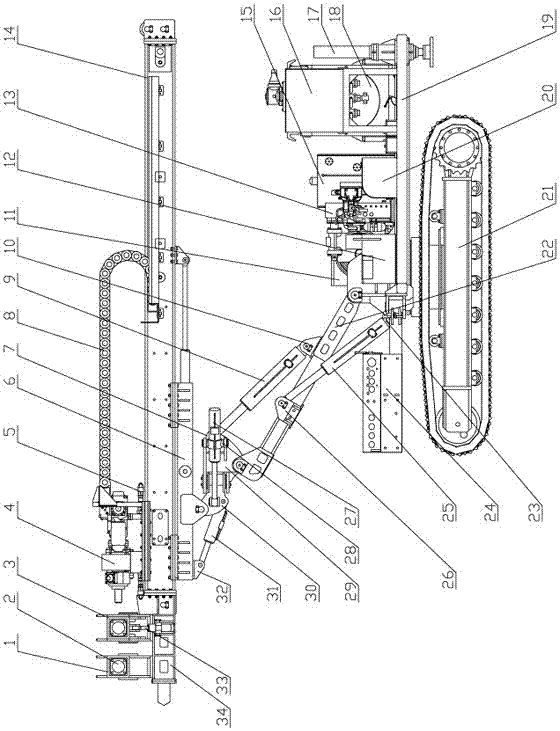

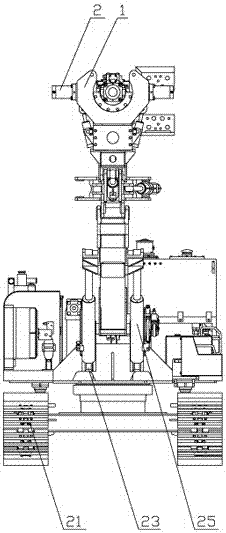

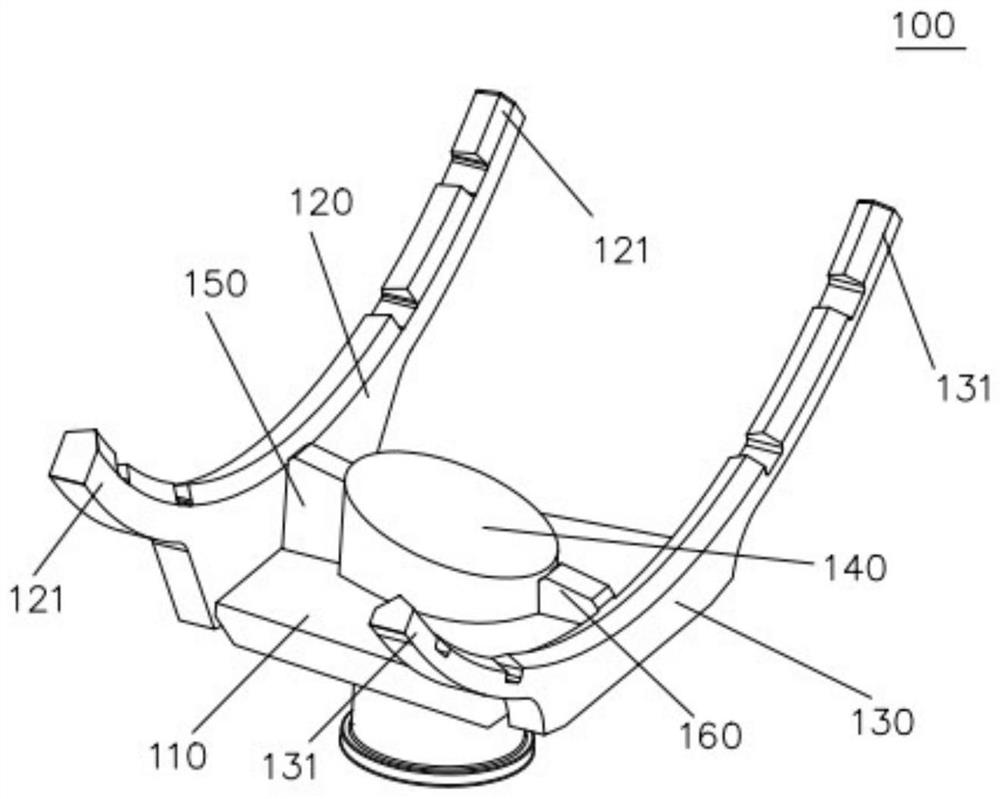

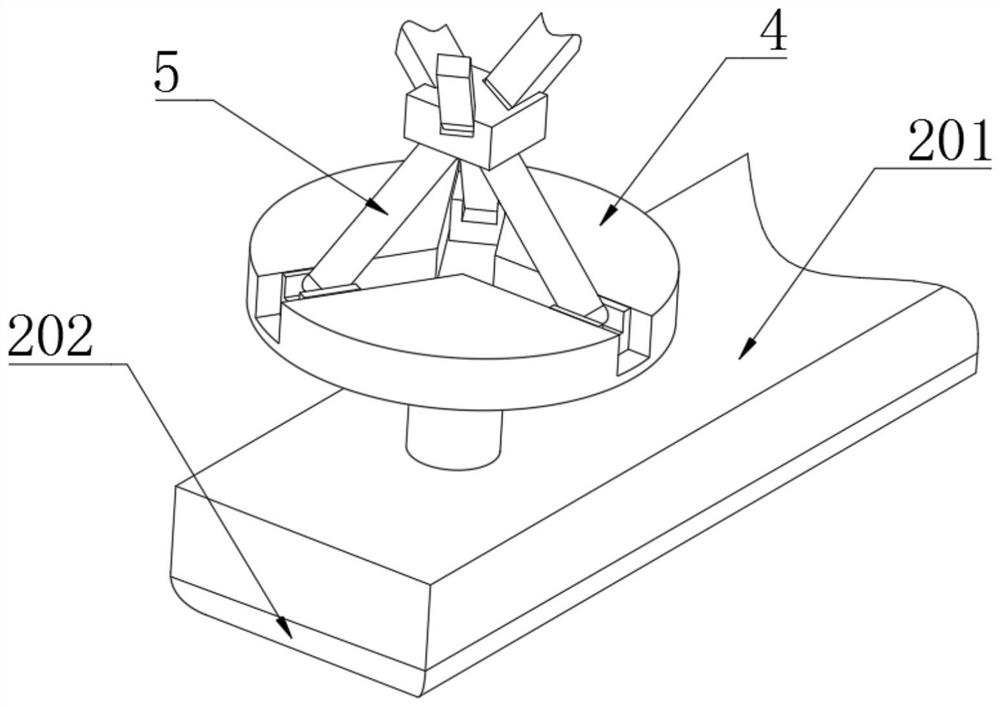

Anchor drill

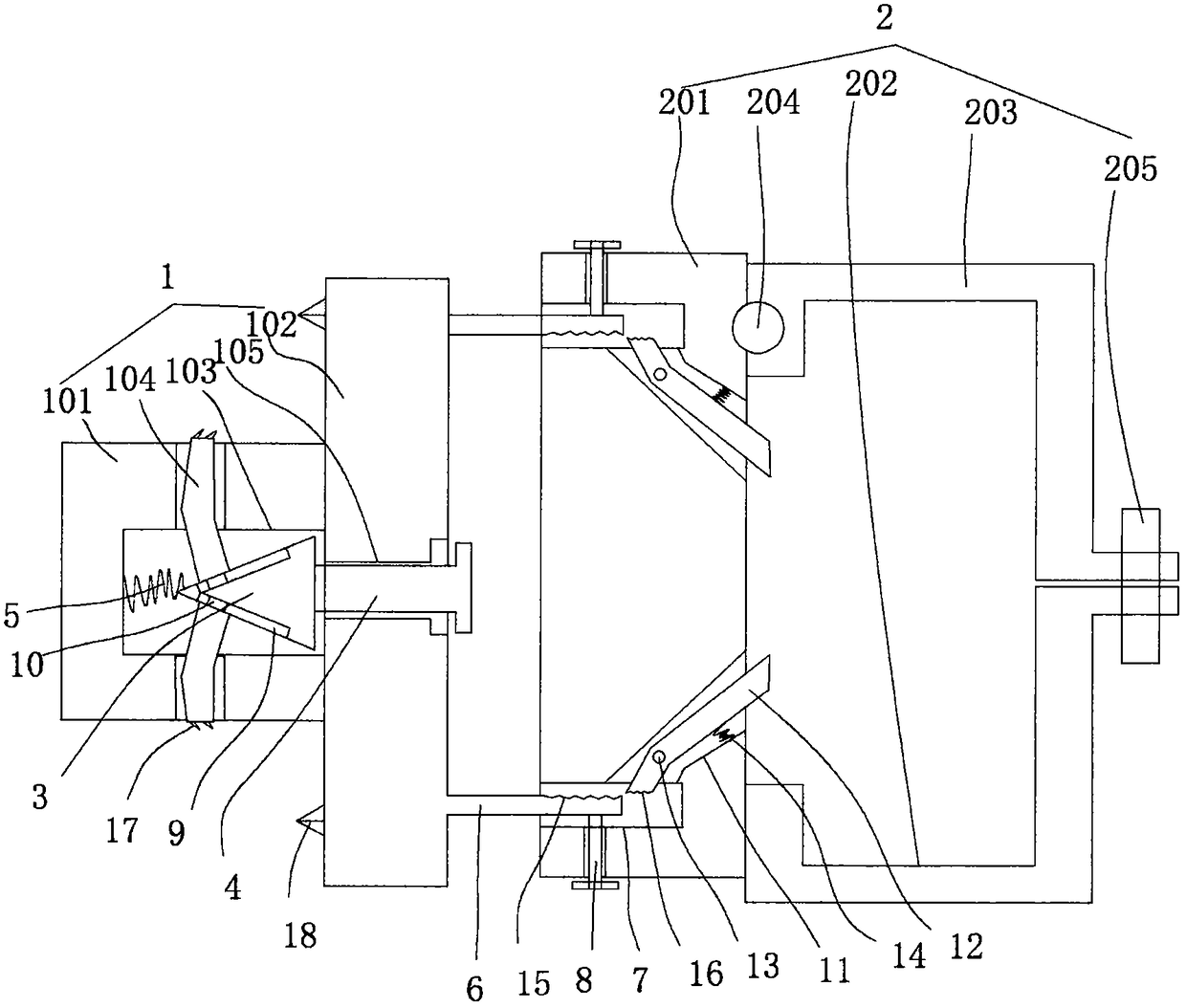

ActiveCN105350910AFlexible rotationEasy to change positionDrilling rodsDirectional drillingPropellerDiesel engine

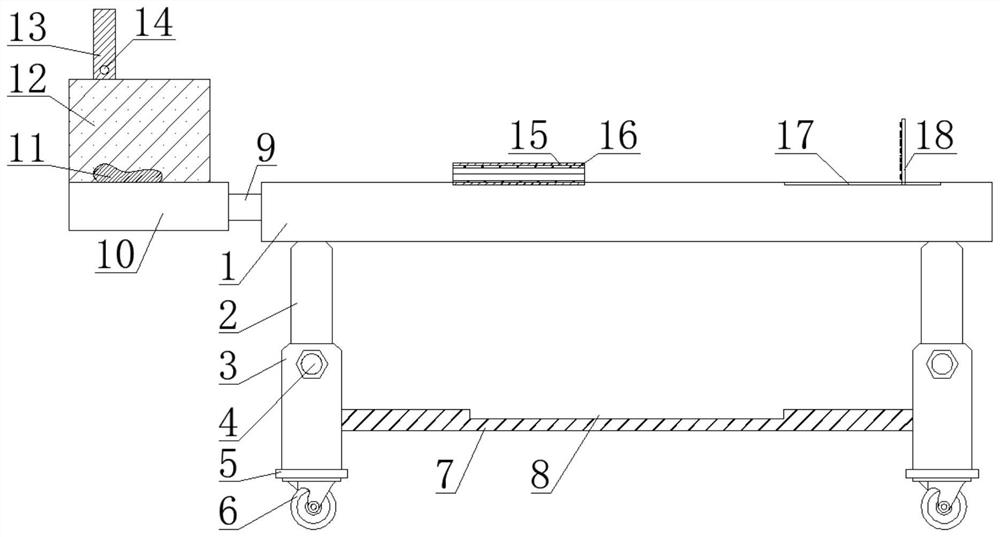

The invention provides an anchor drill which is provided with a movable chassis, wherein an upper turntable is arranged at the upper part of the chassis; a support leg, a support leg cylinder, a hydraulic oil tank assembly, a diesel engine power assembly, a diesel tank assembly, a tool kit, an oil return filtering assembly, an auxiliary control console, an oil cooler assembly, a main control console, an amplitude-changeable support arm device, a bracket and a propeller assembly are arranged on the upper turntable; and the propeller assembly comprises a guide rail, a power head assembly, a hose support chain and a rod disassembling device assembly. The anchor drill is compact and novel in structure and flexible and convenient in operation and can simultaneously adapt to multiple different working conditions; and compared with a common anchor drill, the anchor drill provided by the invention has the advantages of low use cost and good popularization and application values.

Owner:HUBEI SHOUKAI MACHINERY

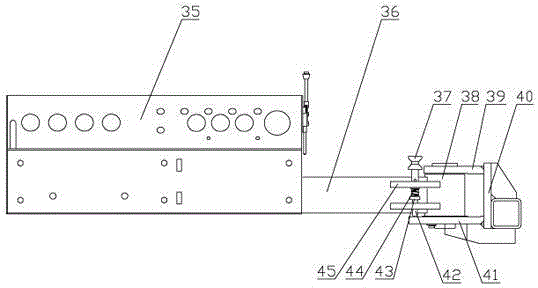

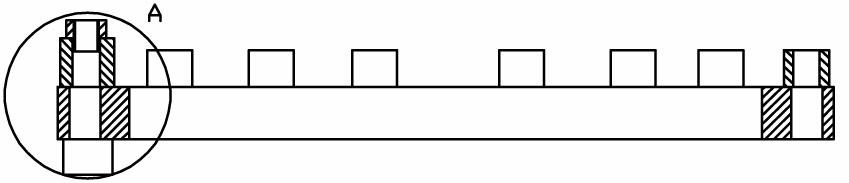

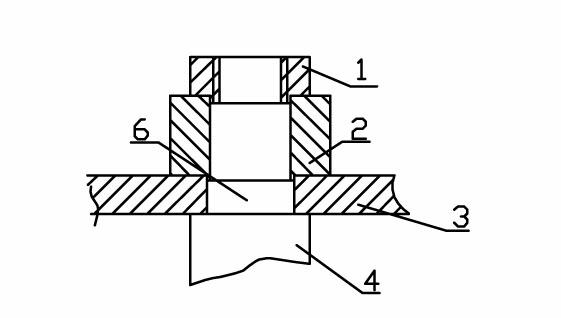

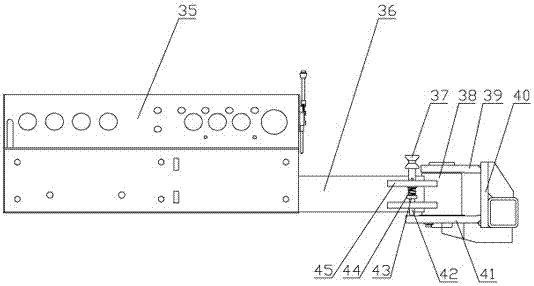

Cover-die hole-drilling device

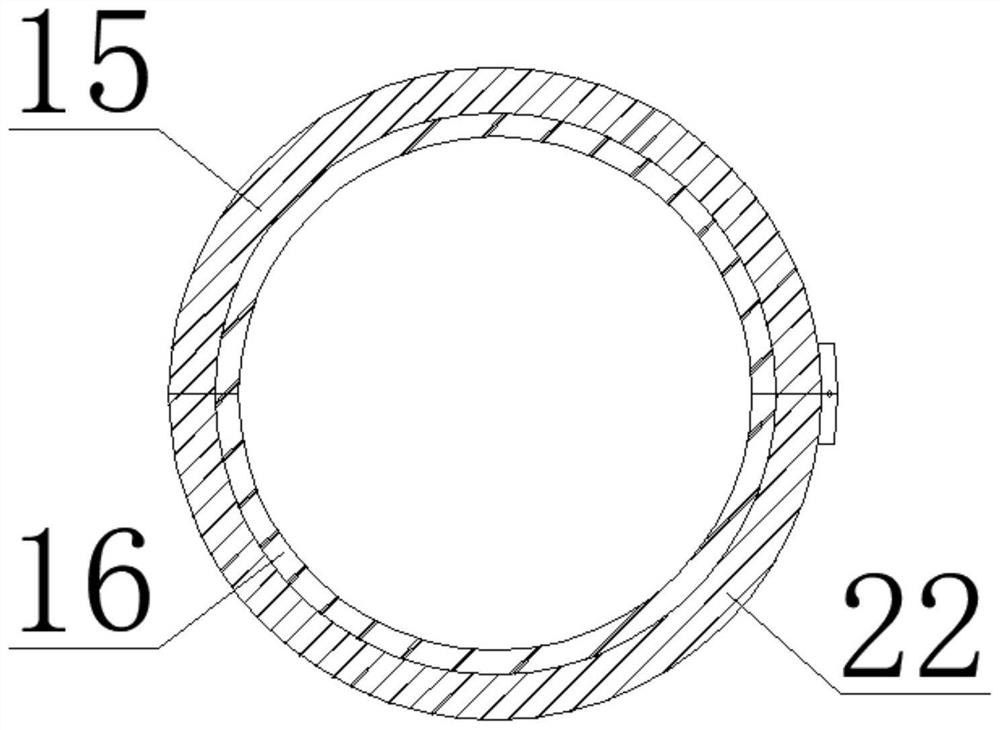

InactiveCN102463371ASolving Tolerance Control IssuesLow skill level requiredPositioning apparatusDrill jigsPosition toleranceTechnical grade

The invention relates to a cover-die hole-drilling device, which relates to an auxiliary device for hole-drilling machining, wherein at least one positioning hole is arranged on a template, and a positioning sleeve is coaxially arranged on the positioning hole; and the hole diameter of the positioning hole is larger than that of a machined hole, and the hole diameter of the positioning sleeve is equal to that of the machined hole. The problem of workpiece-position tolerance control is solved through the positioning sleeve and the template arranged on the cover-die hole-drilling device provided by the invention. Requirements on the technical grade of an operator are reduced, production links are decreased, the quality of products is ensured, the production benefit is improved, and the cover-die hole-drilling device is worthy of being widely popularized.

Owner:长航集团宜昌船厂有限公司

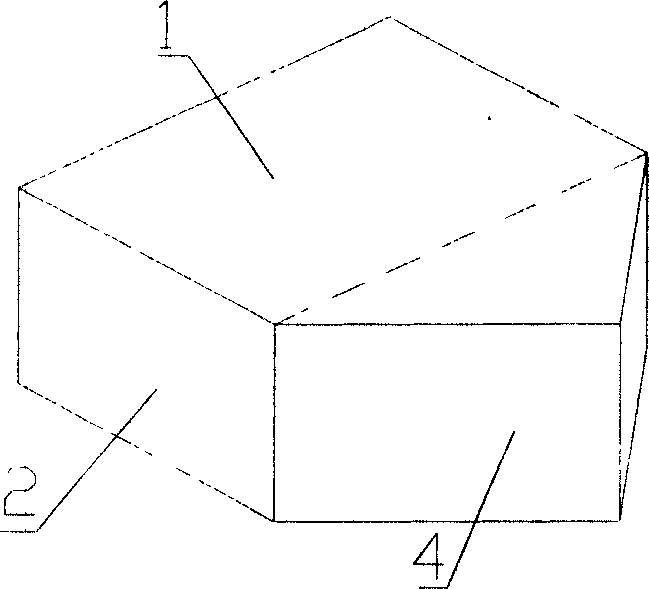

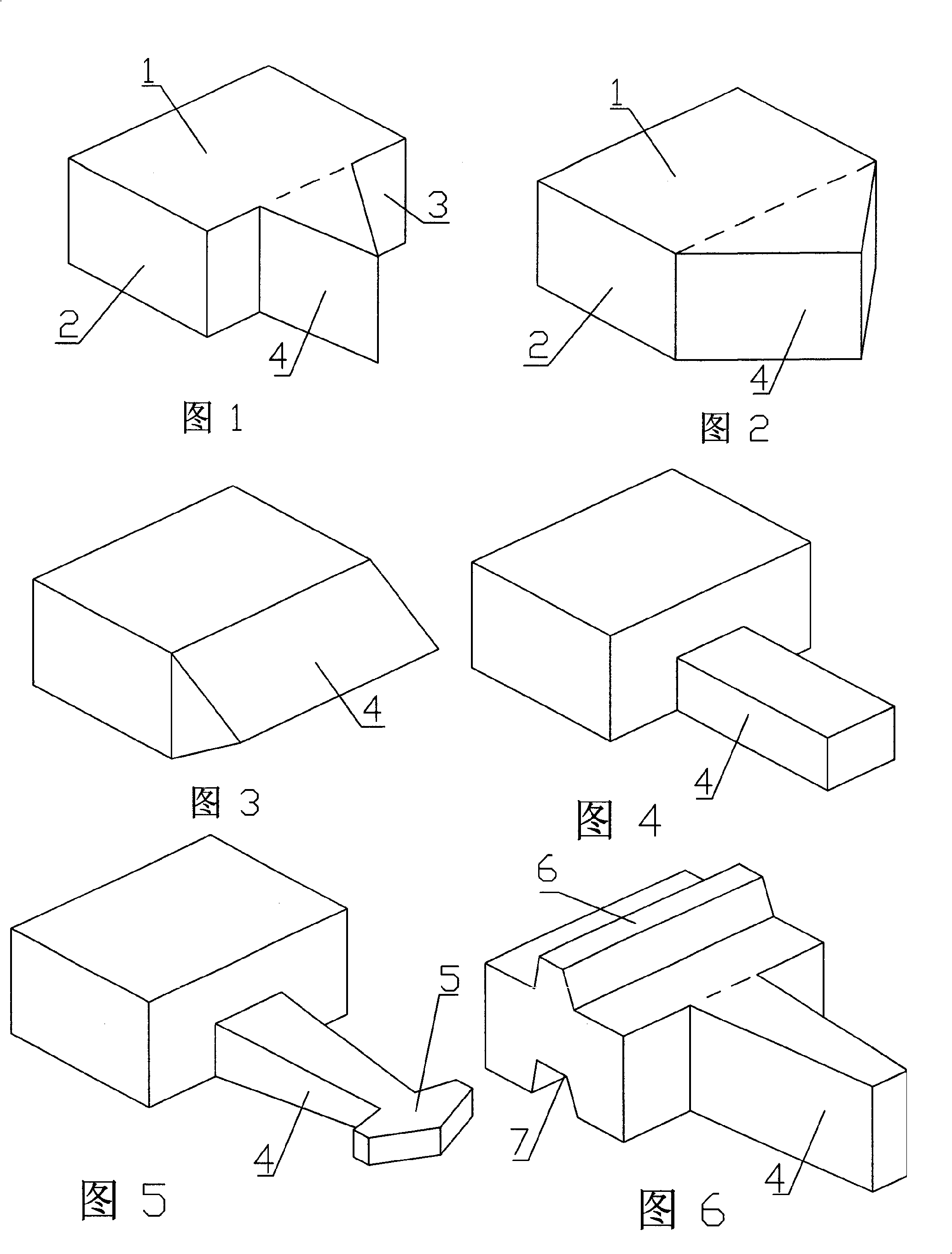

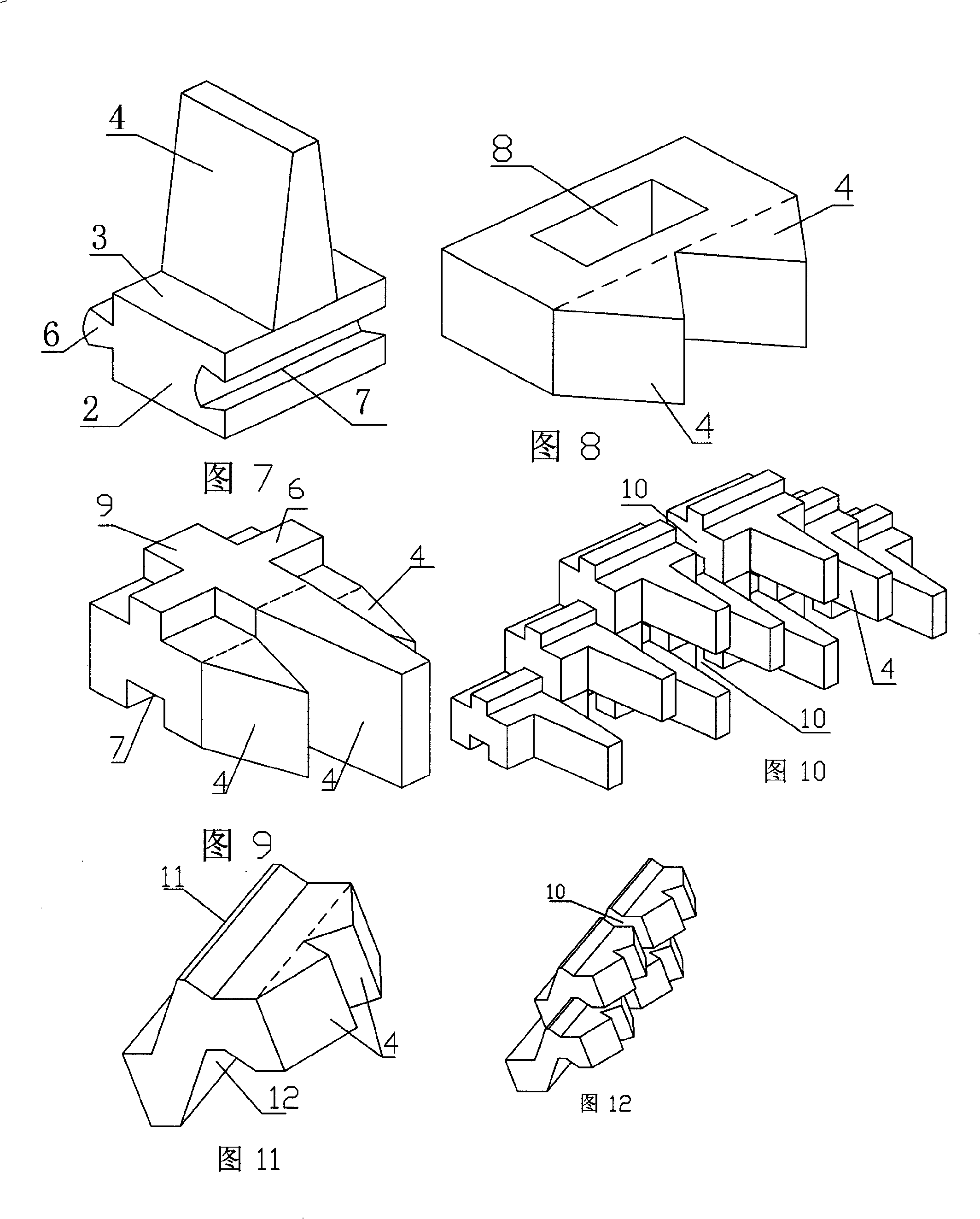

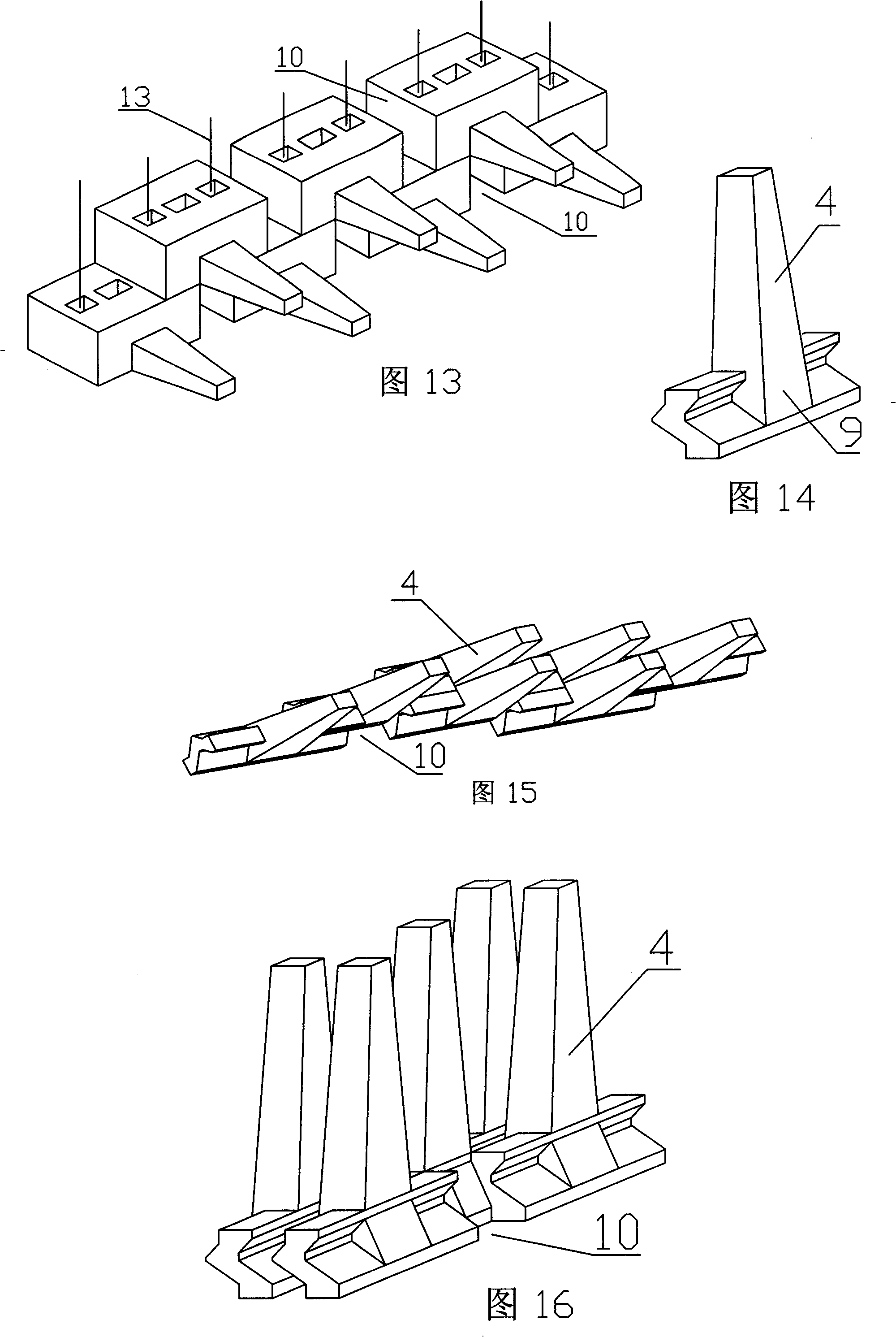

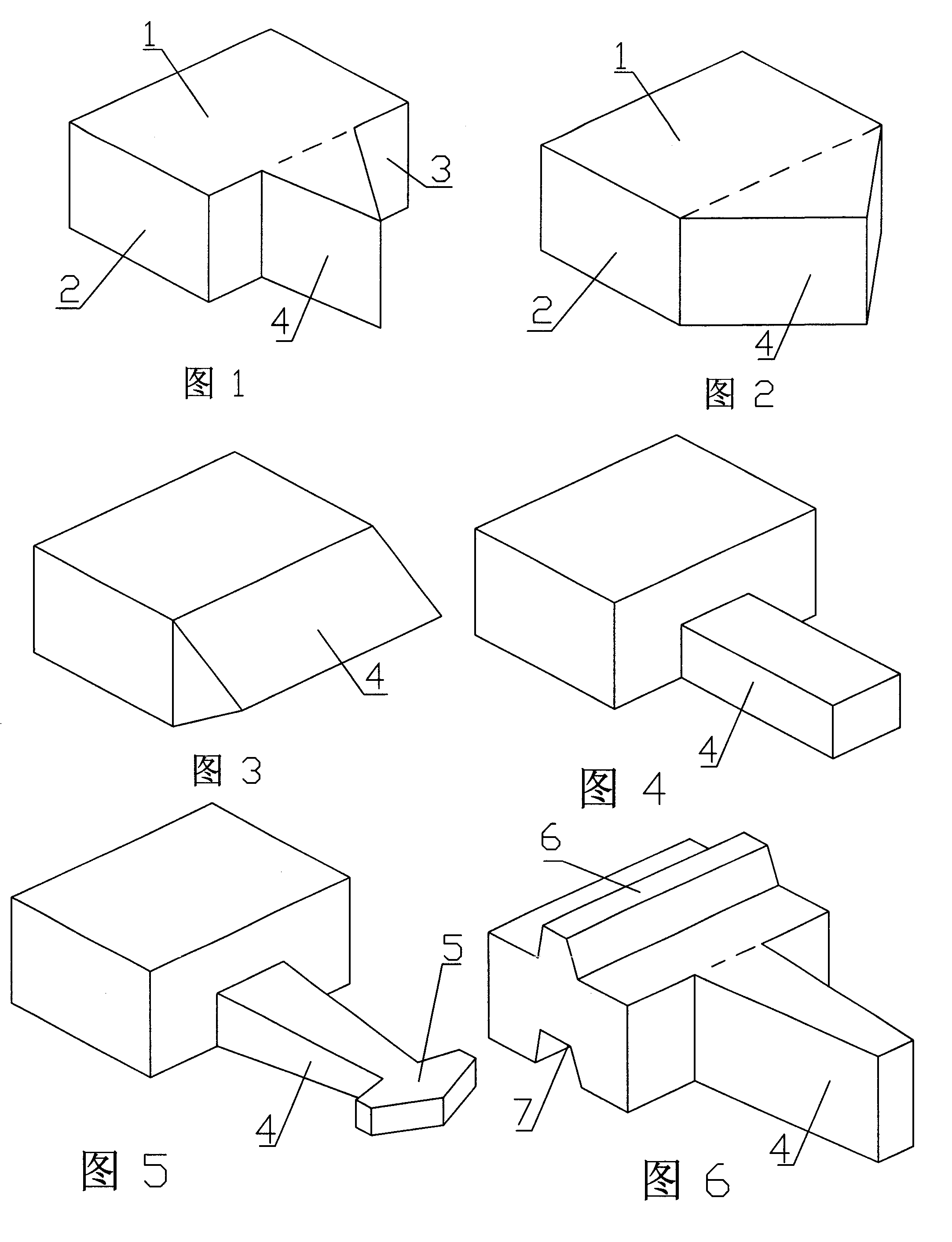

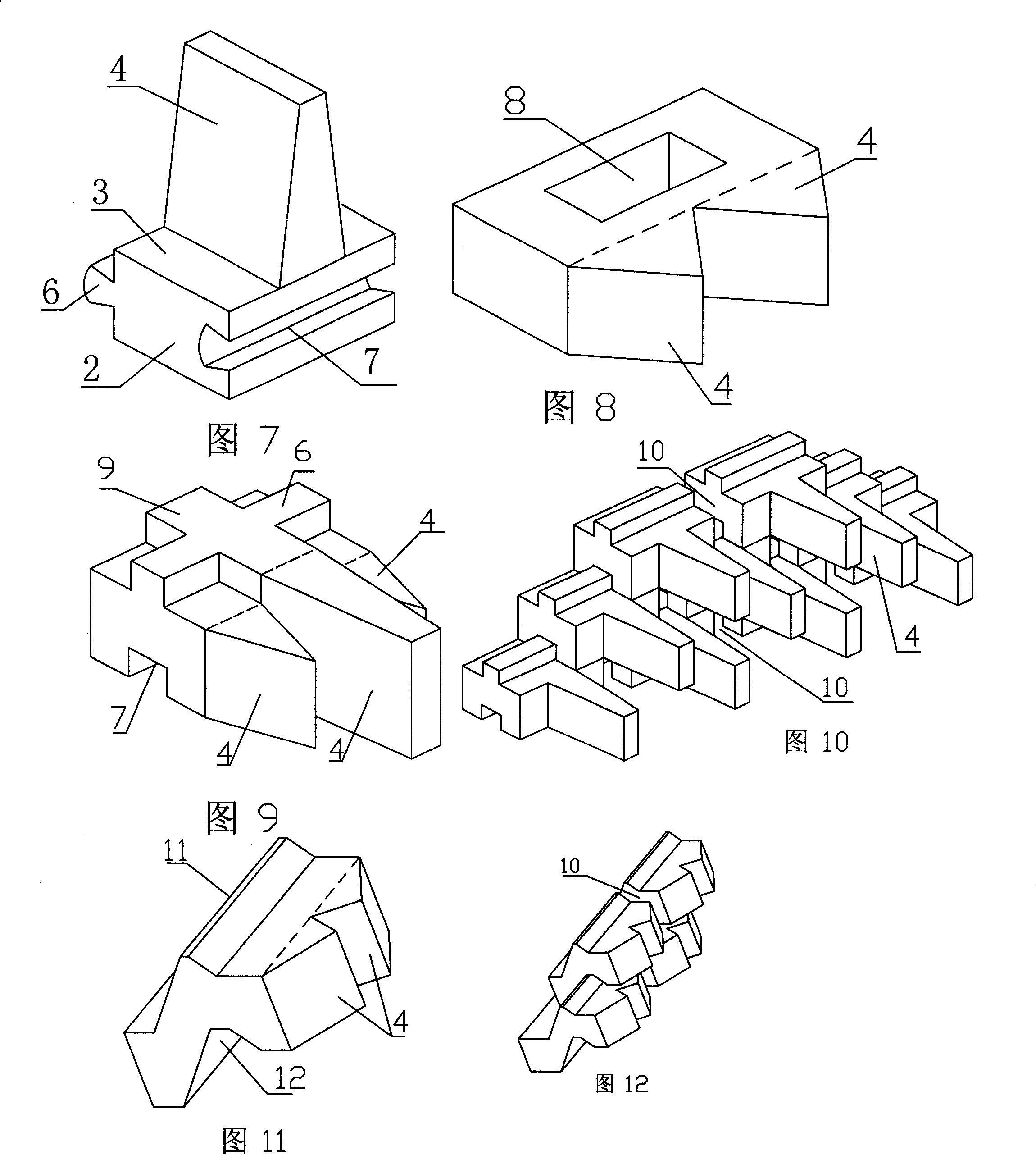

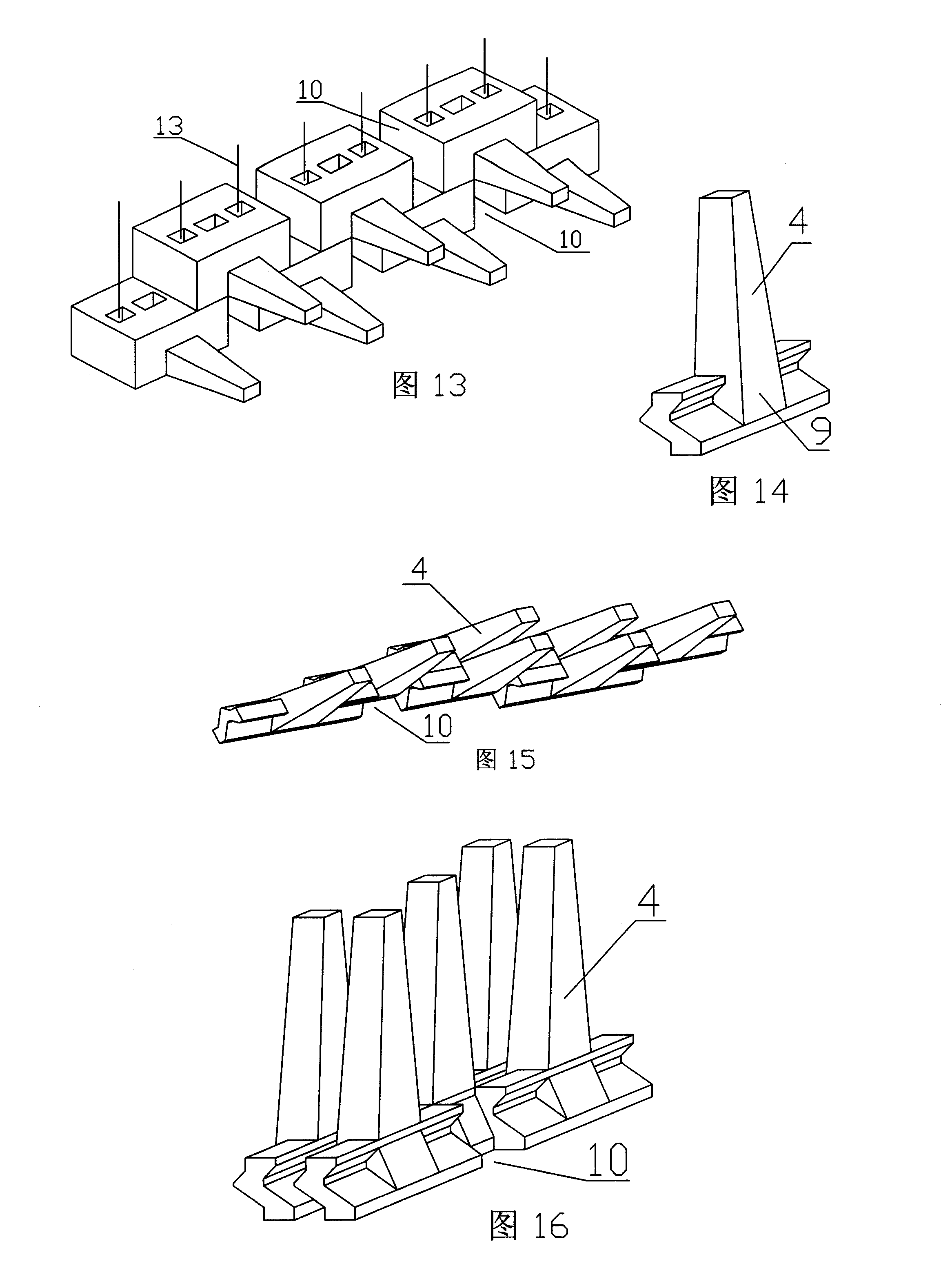

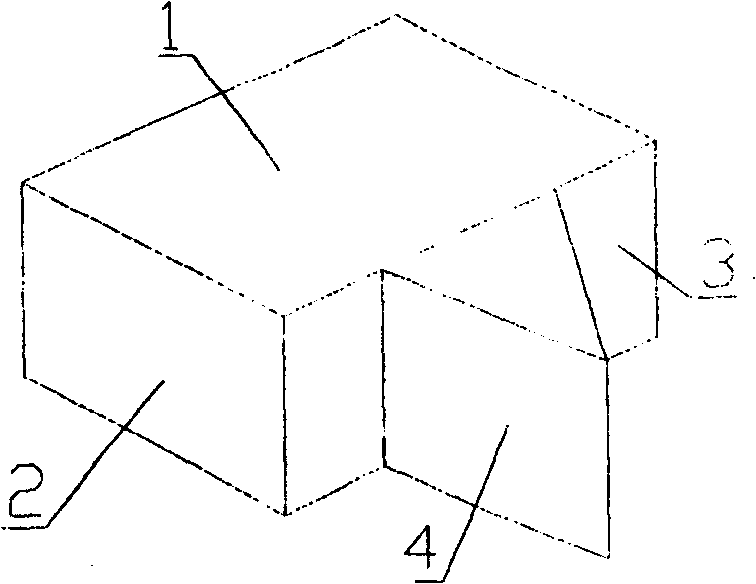

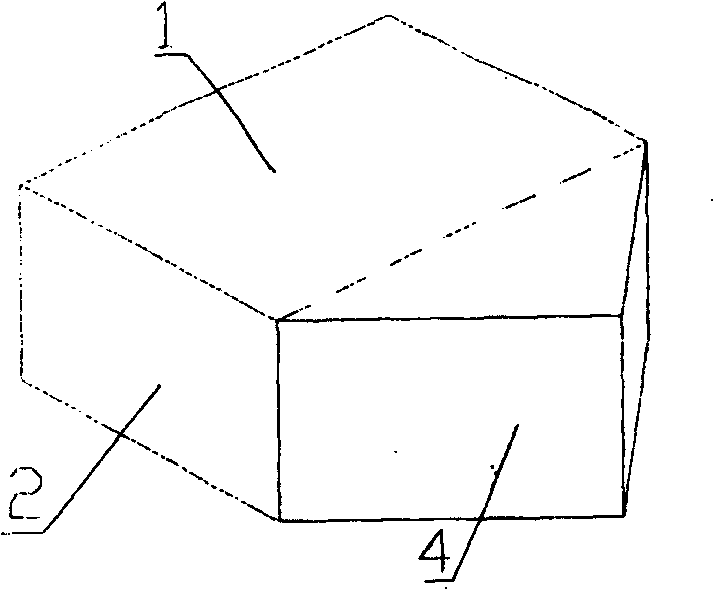

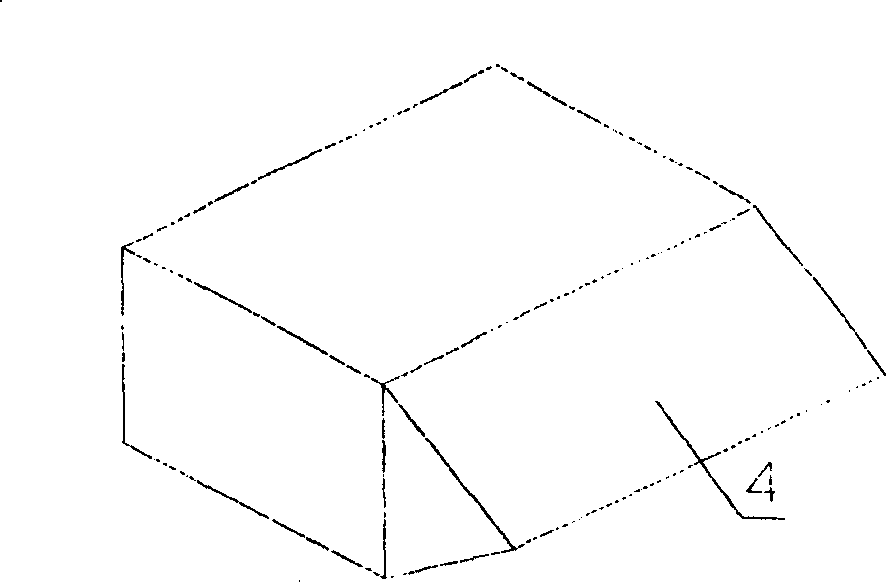

Dewave block for forming dewave wall and its formed wall

InactiveCN1912251AGood wave dissipation effectConvenience for masonryBreakwatersQuaysDislocationEngineering

The invention relates to wave removing building block used to form wave removing wall body. The wave removing building blocks includes building blocks main body includes top side, under side, two end sides. The side surface of the head sea direction is set protrusive convex body includes end and root connected with the building blocks. Many similar wave-removing building blocks are processed dislocation stacking to form wall body. The protrusive convex faces head sea direction. The invention provides wave removing building blocks and the forming wall body with wave removing function.

Owner:汪荣勋

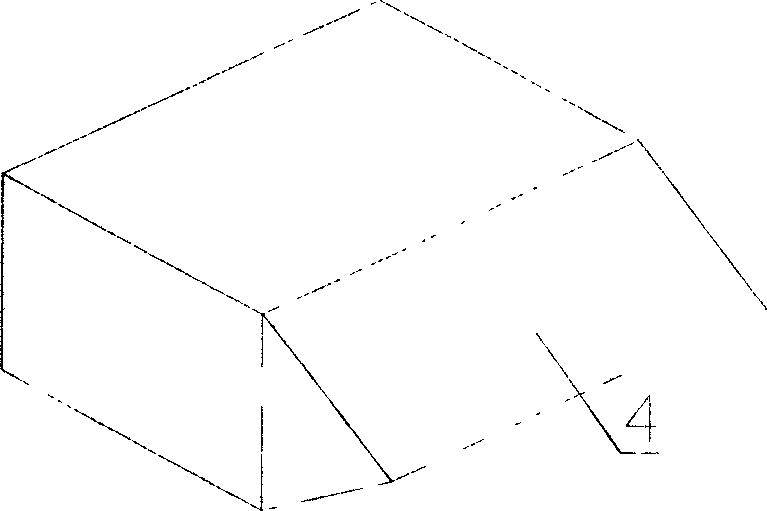

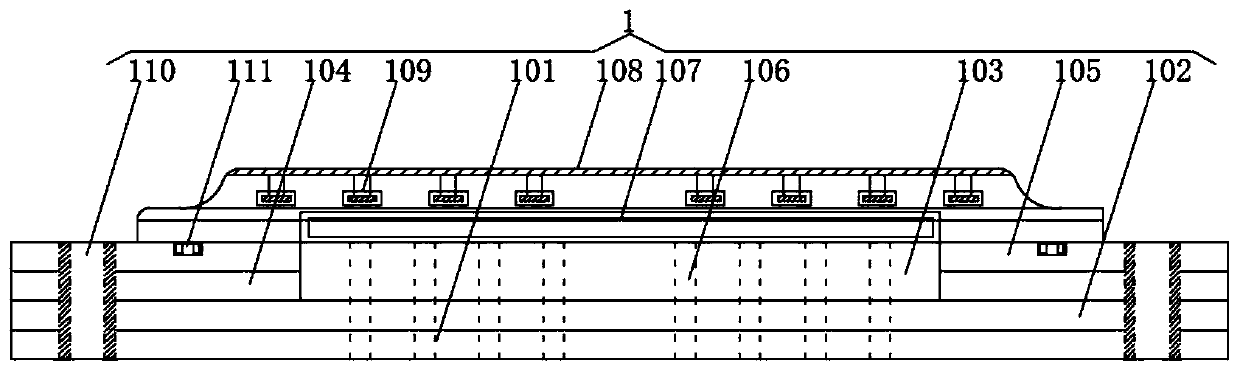

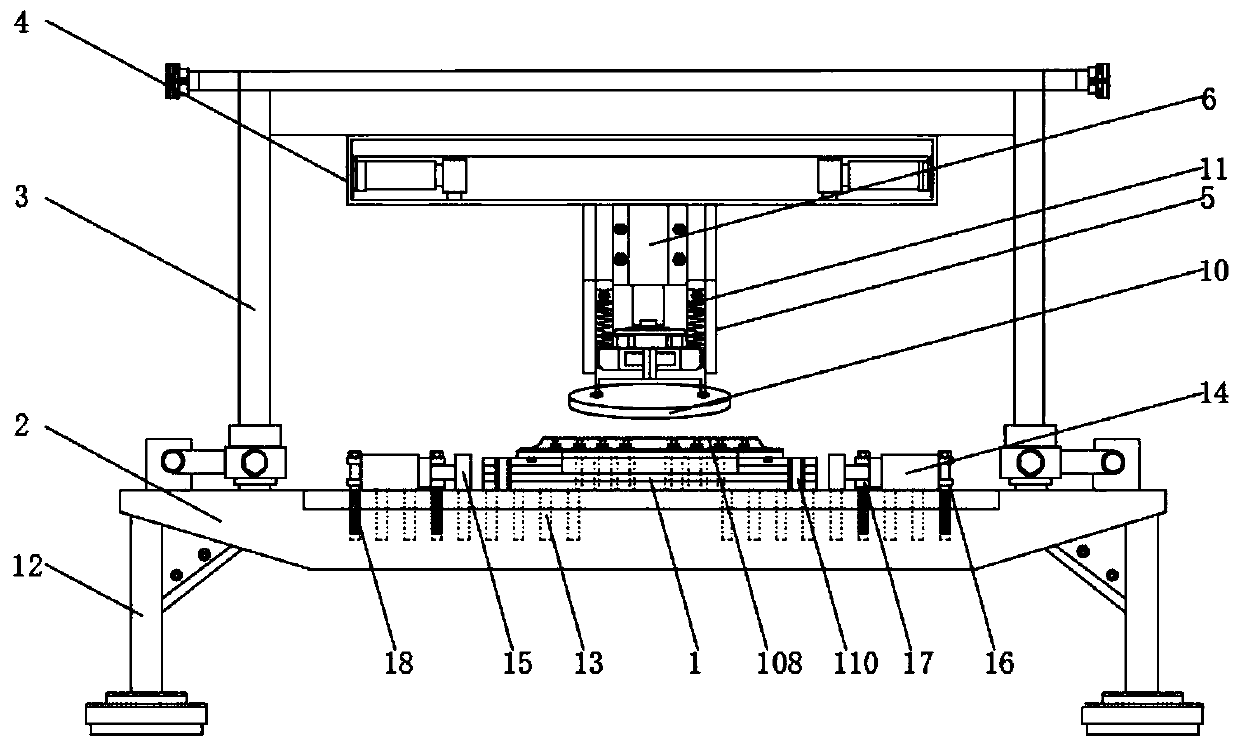

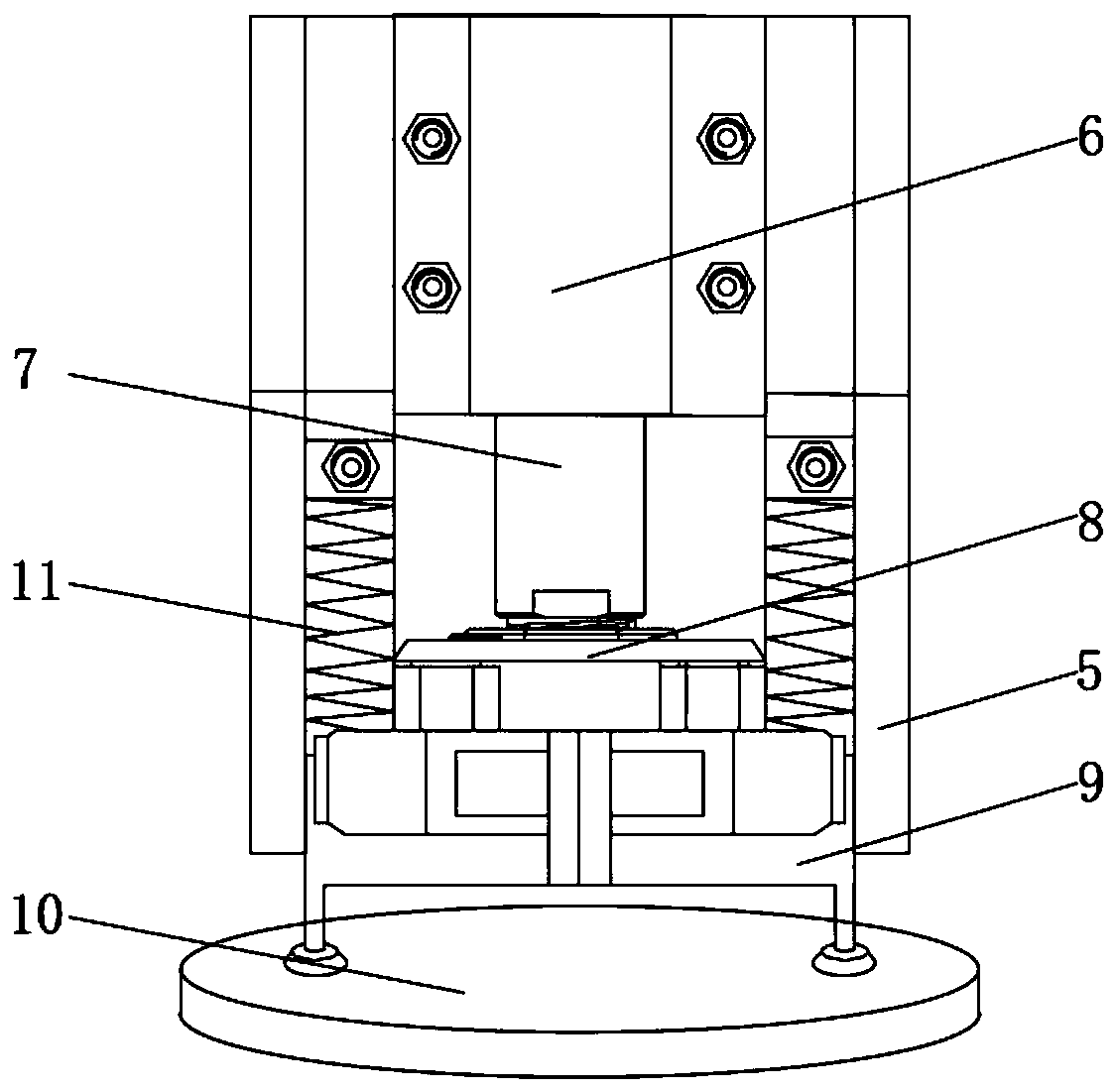

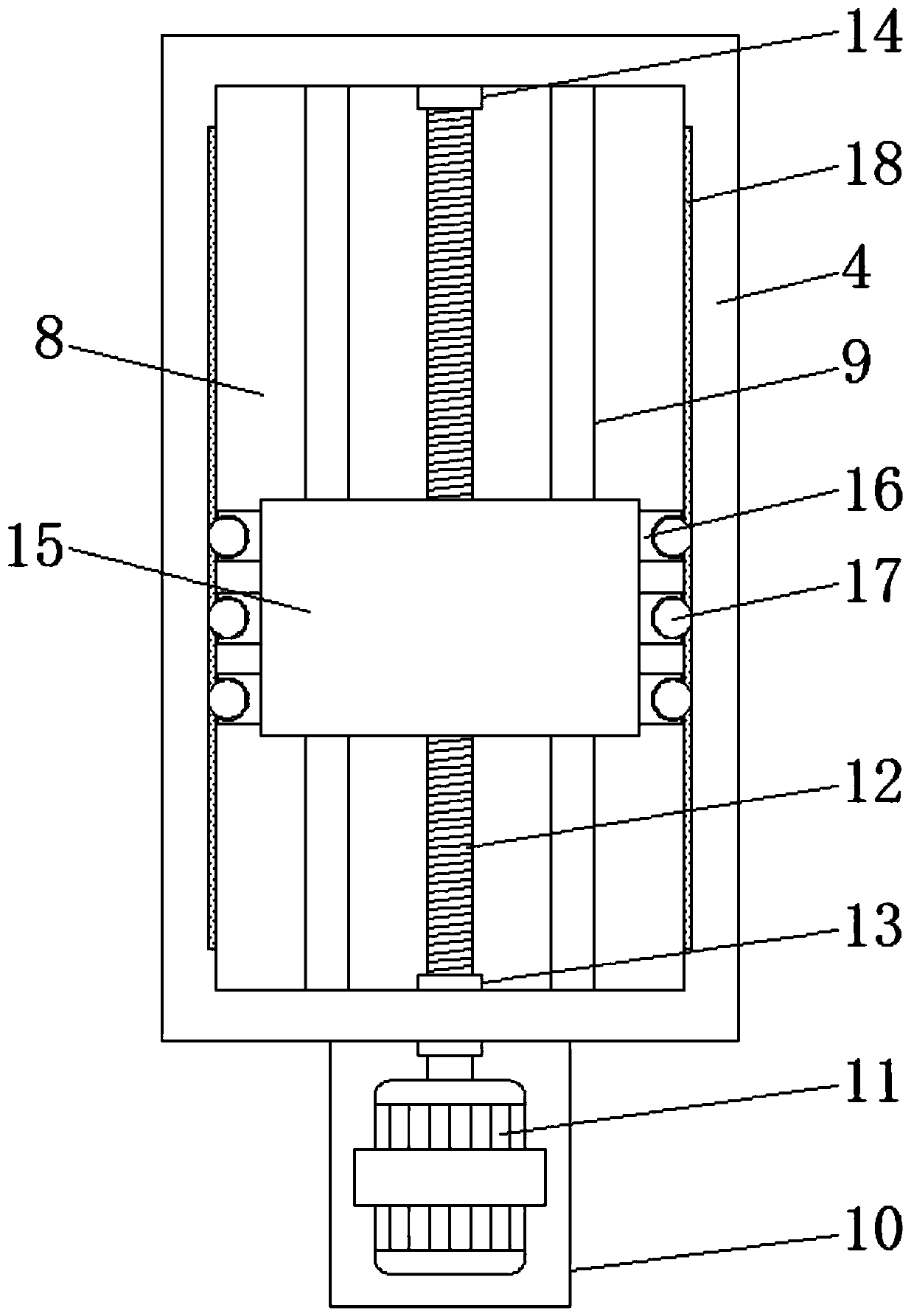

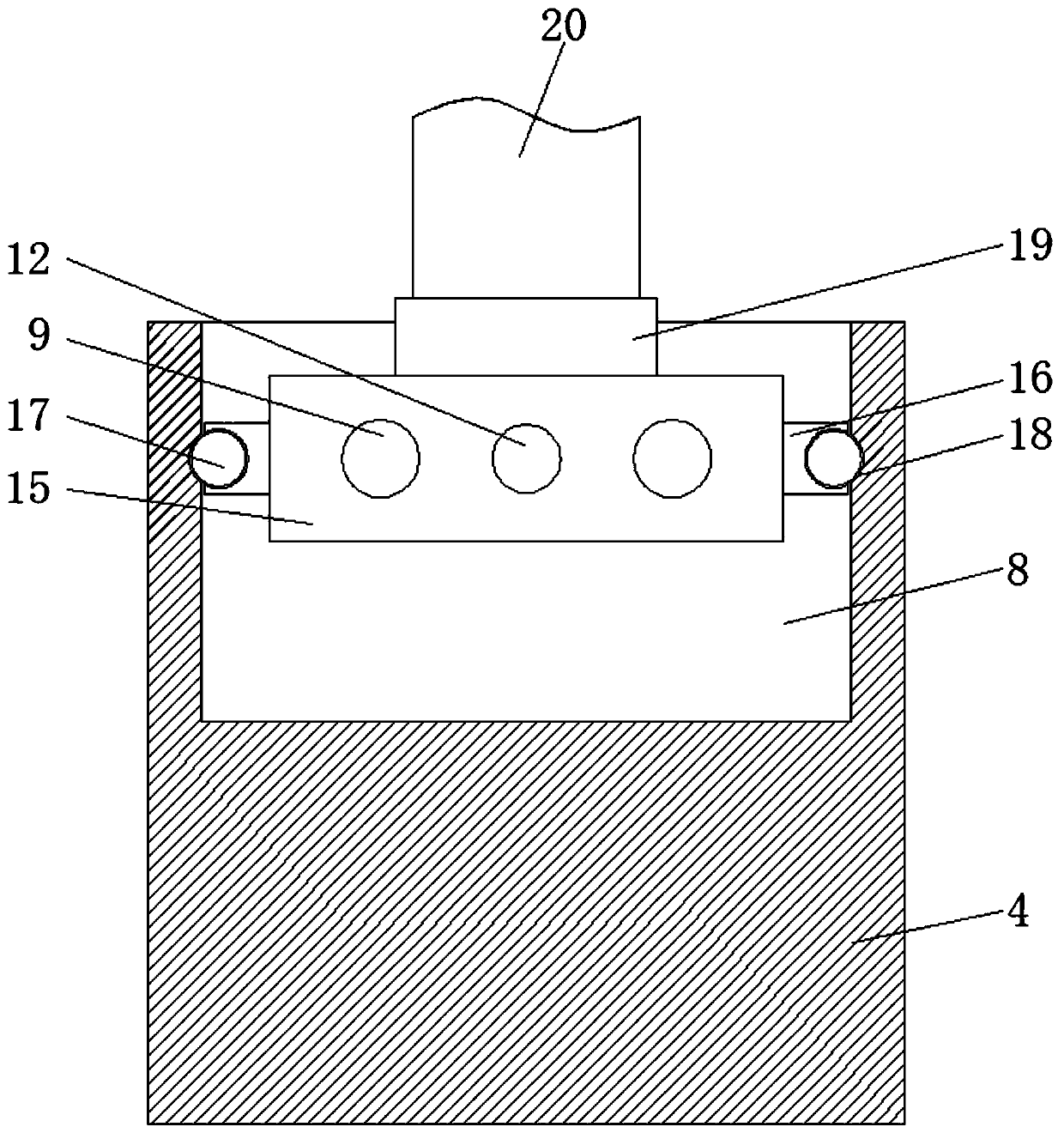

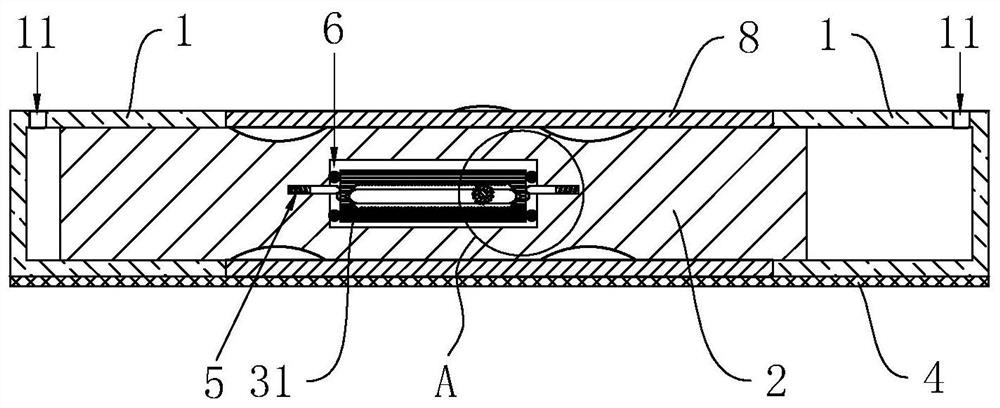

Integrated circuit packaging board and mounting device thereof

ActiveCN109887863AGood coolingEasy to assembleSemiconductor/solid-state device detailsSolid-state devicesEngineeringGraphite

The invention discloses an integrated circuit packaging board and a mounting device thereof. The integrated circuit packaging board comprises an integrated circuit packaging board and a mounting workbench, wherein the integrated circuit packaging board is placed on the mounting workbench, and the integrated circuit packaging board comprises a bottom board, a substrate, a heat dissipation graphitefilm layer and a top board, wherein the bottom board, the substrate, the heat dissipation graphite film layer and the top plate are sequentially arranged from bottom to top; an IC chip mounting grooveis formed in the middle of the heat dissipation graphite film layer and the top board, and an IC chip is placed at the top of the IC chip mounting groove; and a pin hole is formed in the lower portion of the IC chip, and a heat conduction silica gel sheet is arranged above the IC chip. The invention relates to the technical field of integrated circuit packaging boards. According to the integratedcircuit packaging board and the mounting device thereof, the heat dissipation of the integrated circuit packaging board is high, and the mounting is convenient; the packaging board with the compositeheat conduction structure and a heat dissipation cover on the packaging board are higher in heat dissipation efficiency, so that the service life of the IC chip is prolonged, the force of pressing down a pressing type disc rubber disc is reduced, and damage is prevented.

Owner:王晓青

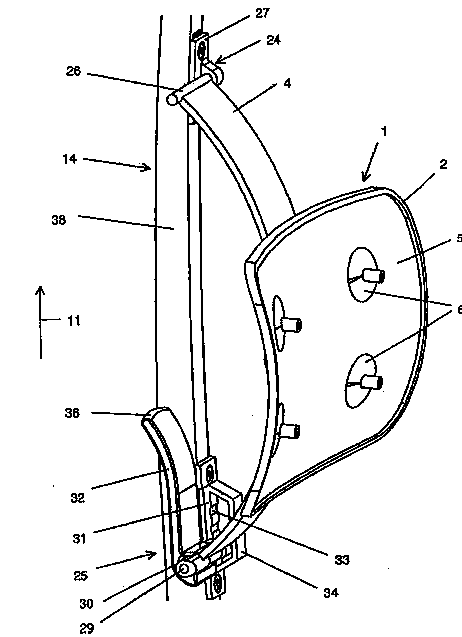

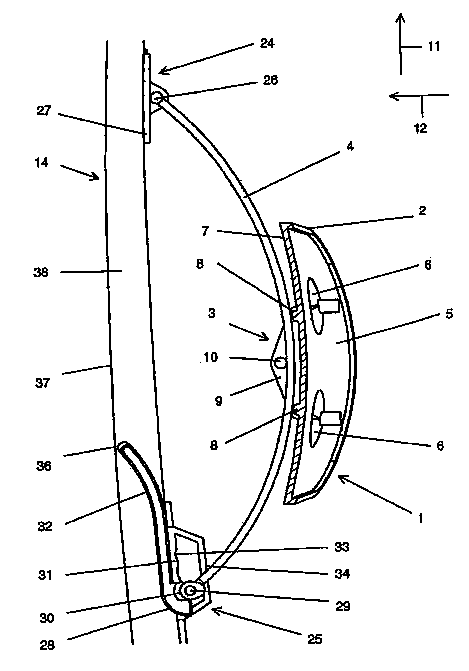

Office seat

InactiveCN103371657AImprove comfortEasy to change the position of the supportStoolsChairsEngineeringLumbar

The invention relates to seat furniture and particularly relates to an office seat provided with a backrest with a waist support (1). In order to improve the comfort and the simplicity of using the seat furniture, the waist support (1) is arranged on a flexible guide belt (4) in a height adjustable manner.

Owner:蔡芳华

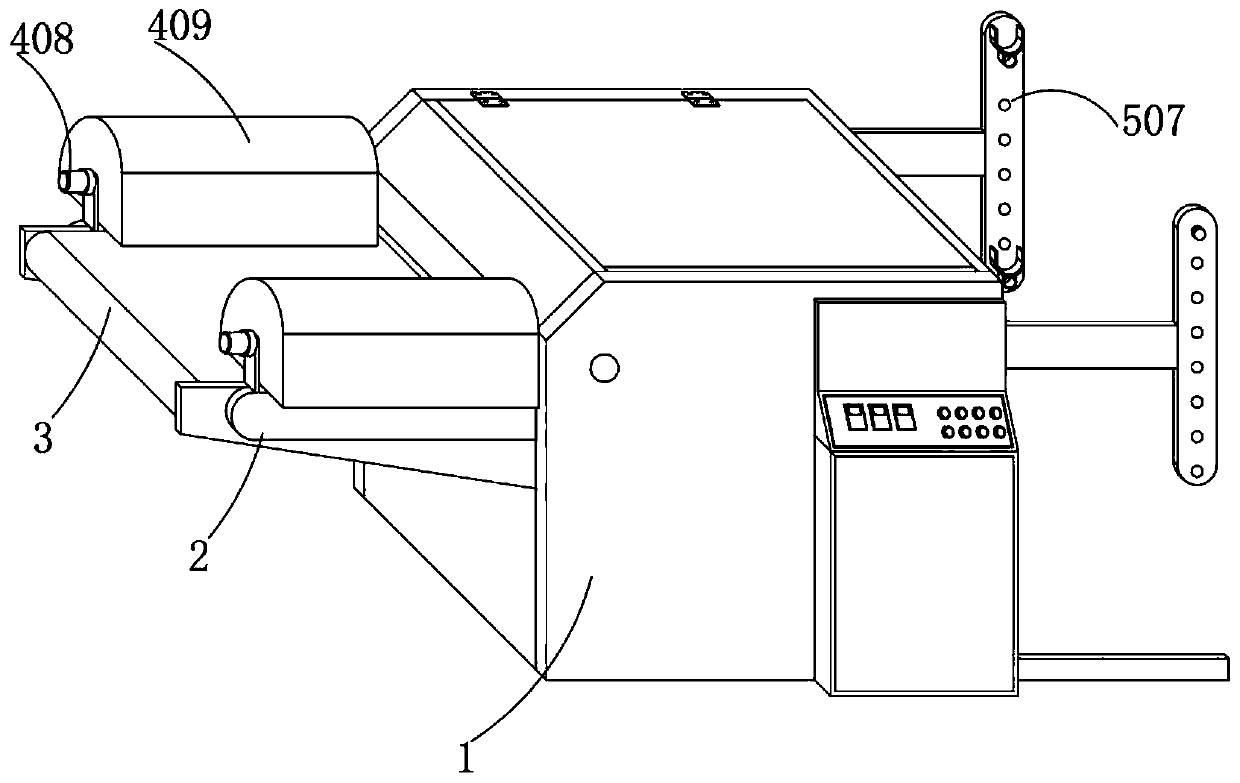

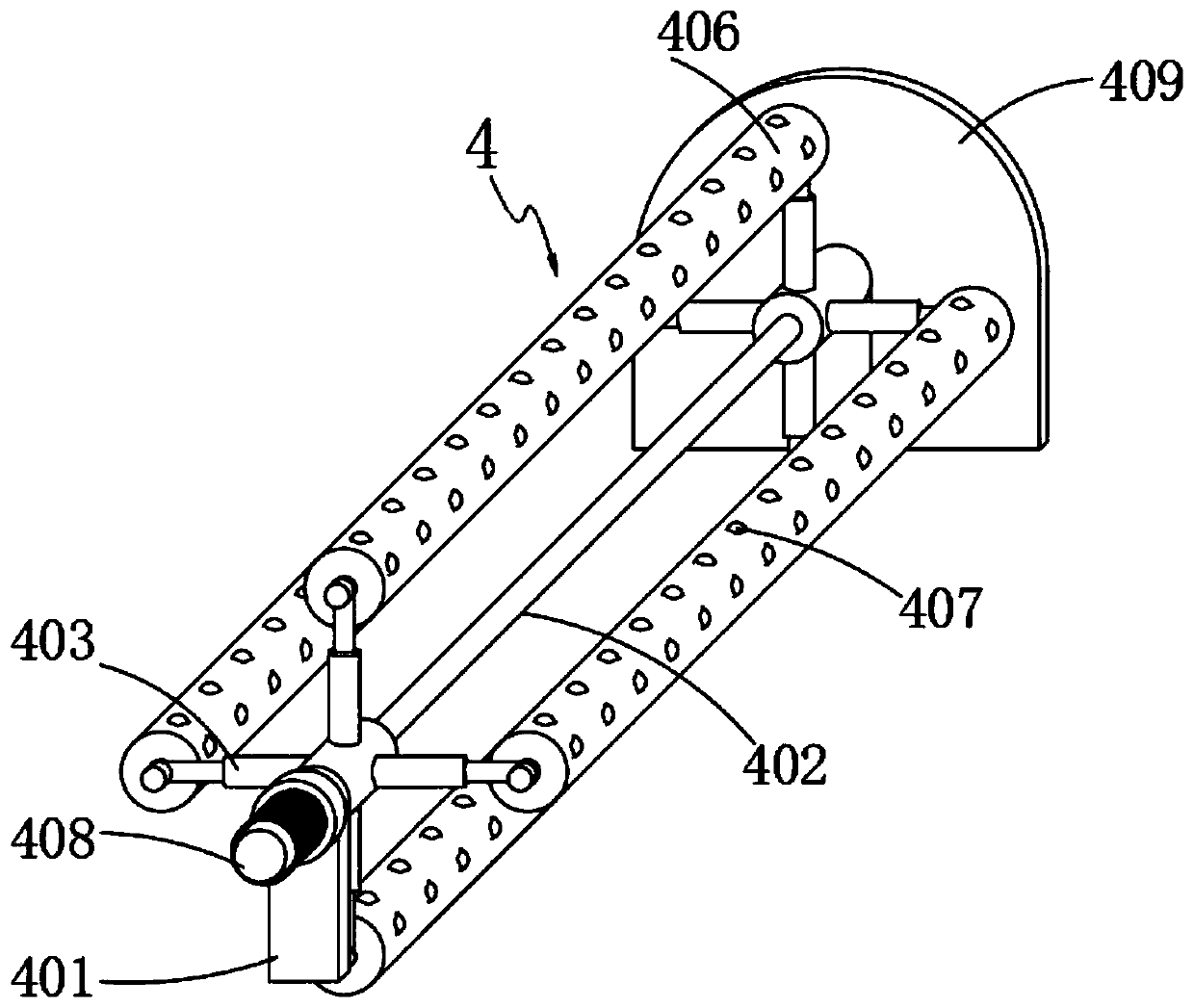

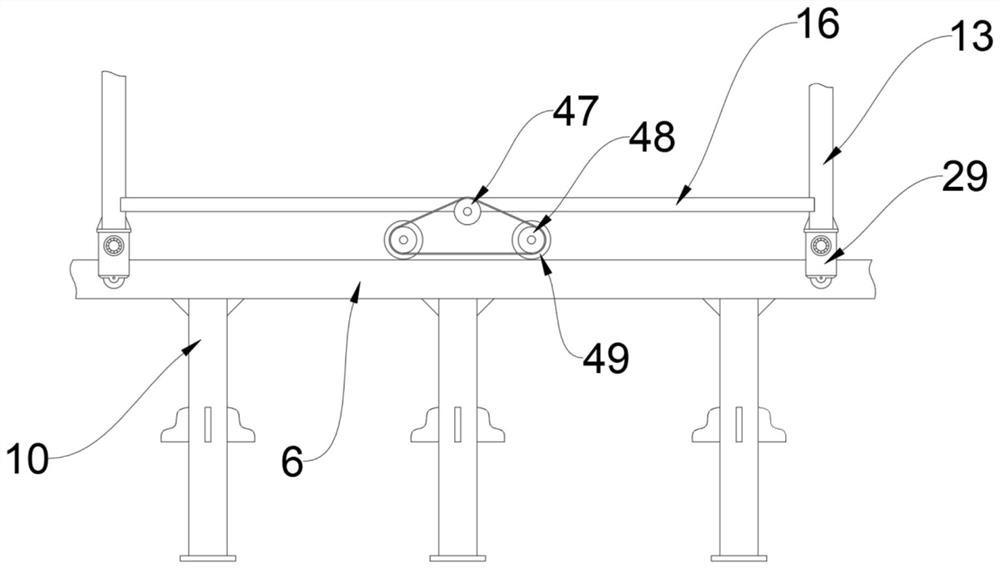

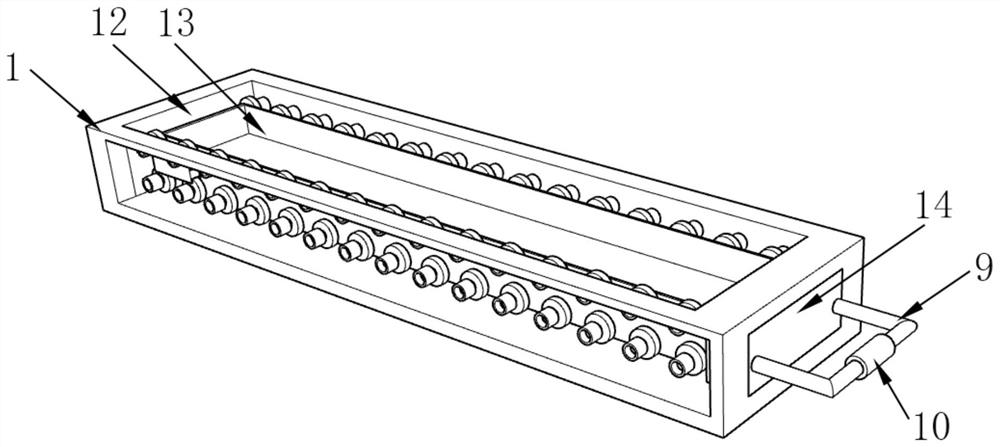

Fabric compounding equipment for textile production

InactiveCN110696476APrevent warpingGood adhesionLamination ancillary operationsLaminationAdhesive glueElectric machinery

The invention discloses fabric compounding equipment for textile production. According to the fabric compounding equipment, smoothening assemblies are mounted at the top ends of mounting frames; a connecting shaft is rotationally mounted between each pair of supporting plates; movable rods are welded to the top ends of springs; balls are evenly and movably embedded in the outer side of smoothing rollers; a motor is mounted at one end of each smoothing roller; a feeding assembly is mounted at one end, away from a corresponding mounting frame, of a fabric compounding machine body; a movable opening is formed in the middle of each supporting frame; a dust removal pipe is welded between each pair of air suction pipes; supporting semi-circular rings are installed on the opposite side faces of the two unwinding installation plates through screws; blocking plates are welded to the two ends of each supporting semi-circular ring. According to the fabric compounding equipment, when compounded fabric is pulled out of the fabric compounding machine body, the connecting shafts are driven by the motors to rotate, at the moment, the smoothing rollers at the end of the movable rods are driven to get close to each other and extrude the top face of the compounded fabric, the spring contracts, glue in the compounded fabric is brushed to the edges, the edges of the compounded fabric is extruded and bonded, and edge warping of the fabric is prevented.

Owner:浙江森悦纺织科技有限公司

anchor drilling rig

ActiveCN105350910BFlexible rotationEasy to change positionDrilling rodsDirectional drillingFuel tankPropeller

Owner:HUBEI SHOUKAI MACHINERY

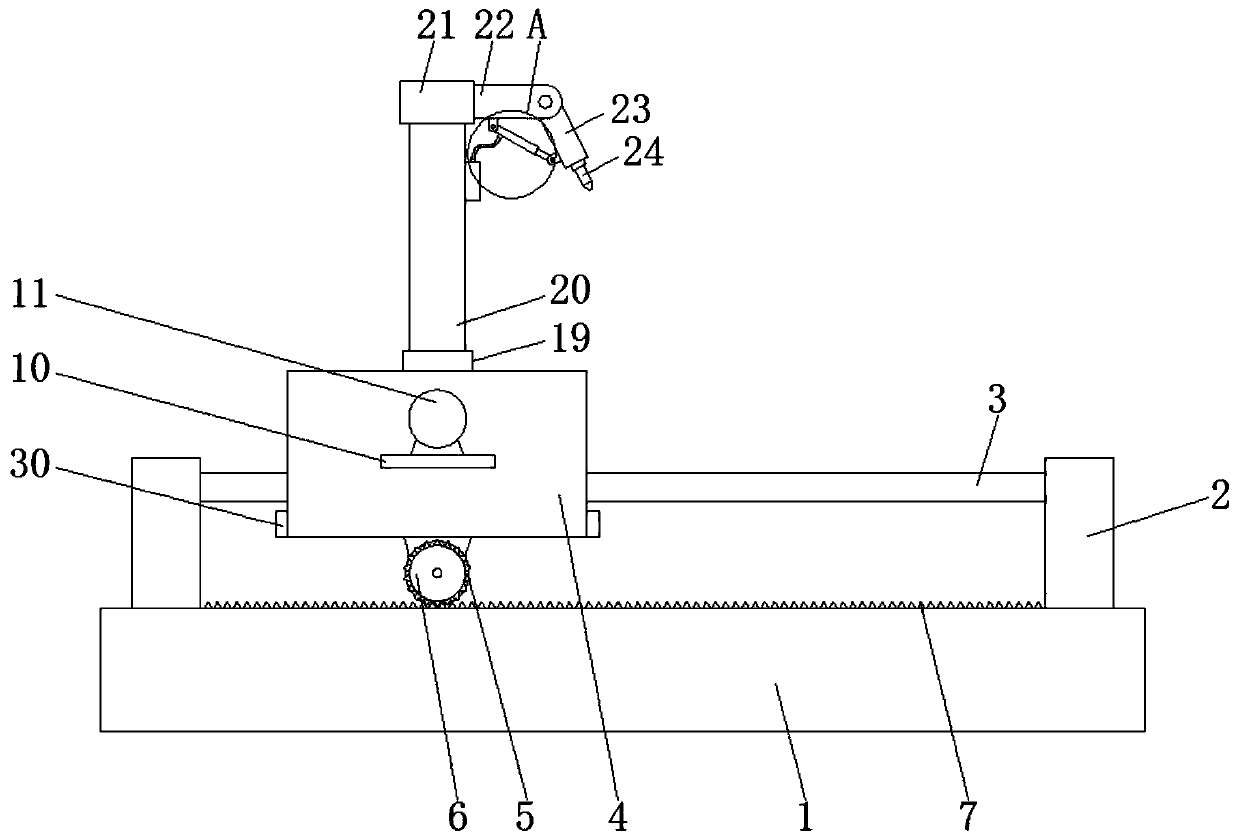

Automatic welding robot for industrial workshop machining

InactiveCN110328476AEasy to change positionStable fore and aftWelding/cutting auxillary devicesAuxillary welding devicesEngineeringGear tooth

The invention relates to the technical field of welding robots, and discloses an automatic welding robot for industrial workshop machining. The automatic welding robot for industrial workshop machining comprises a base, wherein fixing plate are fixedly connected to the left side and the right side of the top of the base; two first sliding rods are fixedly connected between the two fixing plates; sliding blocks sleeve surfaces of the two first sliding rods; a first driving motor is fixedly connected to the bottoms of the sliding blocks; an output shaft of the first driving motor is fixedly sleeved with a gear; gear teeth are arranged at the top of the base; the surfaces of the gear are engaged with the surfaces of the gear teeth; and the top of the sliding blocks is fixedly connected with asecond bearing. According to the automatic welding robot for industrial workshop machining, the gear is driven to rotate together by the rotation of the first driving motor, the gear is engaged withthe gear teeth at the top of the base, and the first driving motor is fixedly connected to the bottom of the sliding blocks, so that the sliding blocks are driven to slide on the surface of the firstsliding rods by the rotation of the gear, and the welding robot is driven to move left and right.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

Wave dissipation building blocks forming wave dissipation wall body and formed wall body

InactiveCN101353886AGood wave dissipation effectConvenience for masonryBreakwatersQuaysMechanical engineeringStructural engineering

Owner:汪荣勋

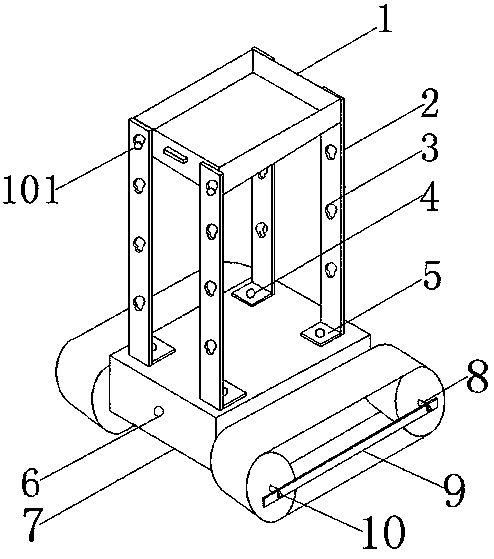

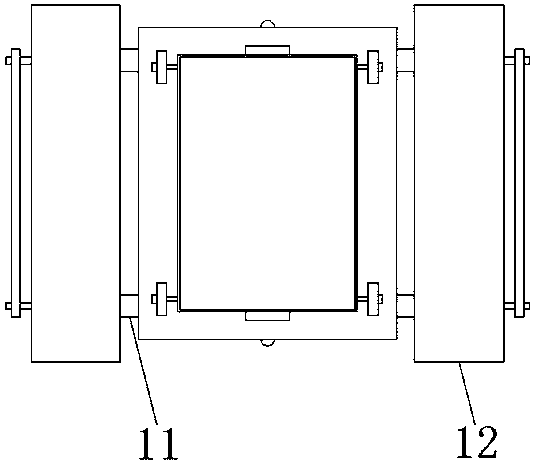

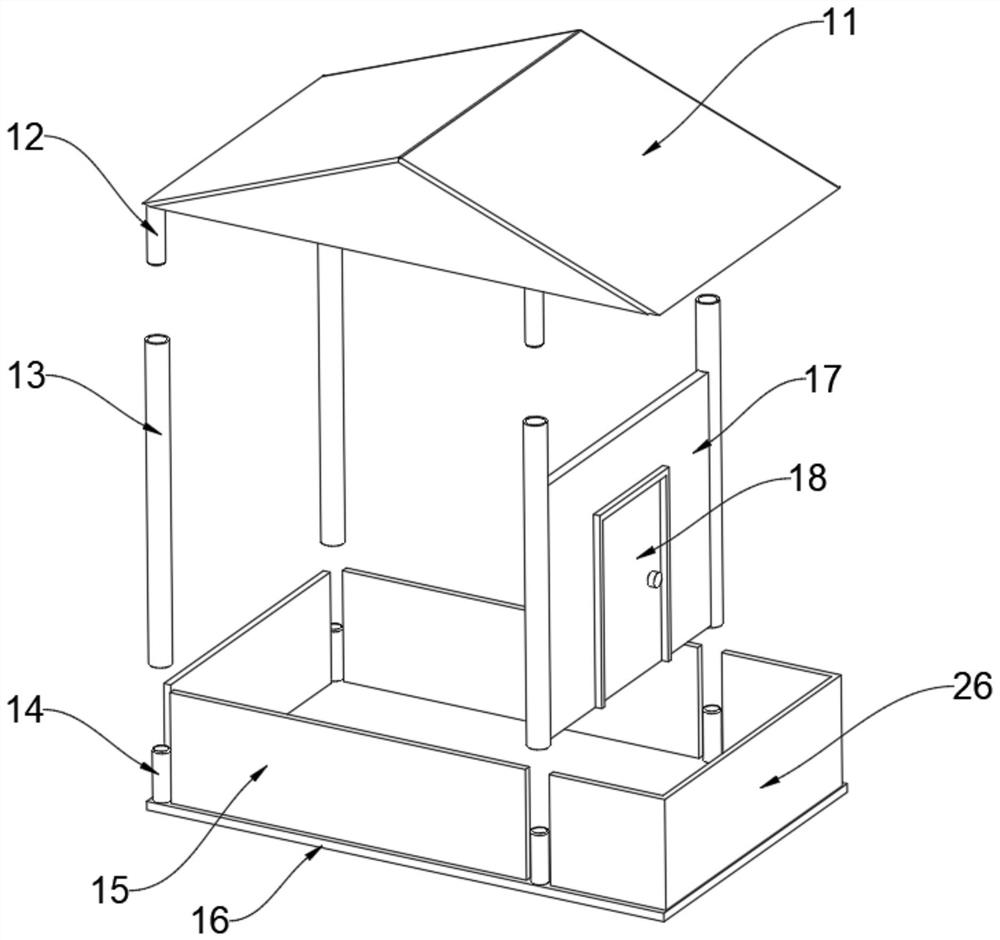

Mobile robot meal serving device

The invention discloses a mobile robot meal serving device. The mobile robot meal serving device comprises a tray, a support, a base body and collision alarming devices, wherein the base body is a rectangular base, the upper end surface of the base body is fixedly connected with the support, the support is in a rectangular frame structure and comprises support fixing blocks and support bars, the four groups of support bars are vertically arranged on the four corners of the upper end surface of the base body, the bottom end of every support bar is fixedly welded with the corresponding support fixing block, and the support fixing blocks are fixedly connected with the base body through bolts; the tray is arranged inside the support bars, and every support bar is provided with four first fixing hole vertically formed at equal intervals; the front end and the rear end of the base body are provided with the collision alarming devices. The mobile robot meal serving device is reasonable in structure, high in overall efficiency and capable of reducing the management cost and well meeting the demands of practical application.

Owner:SUZHOU SAIYA INTELLIGENT TECHNOLOGY CO LTD

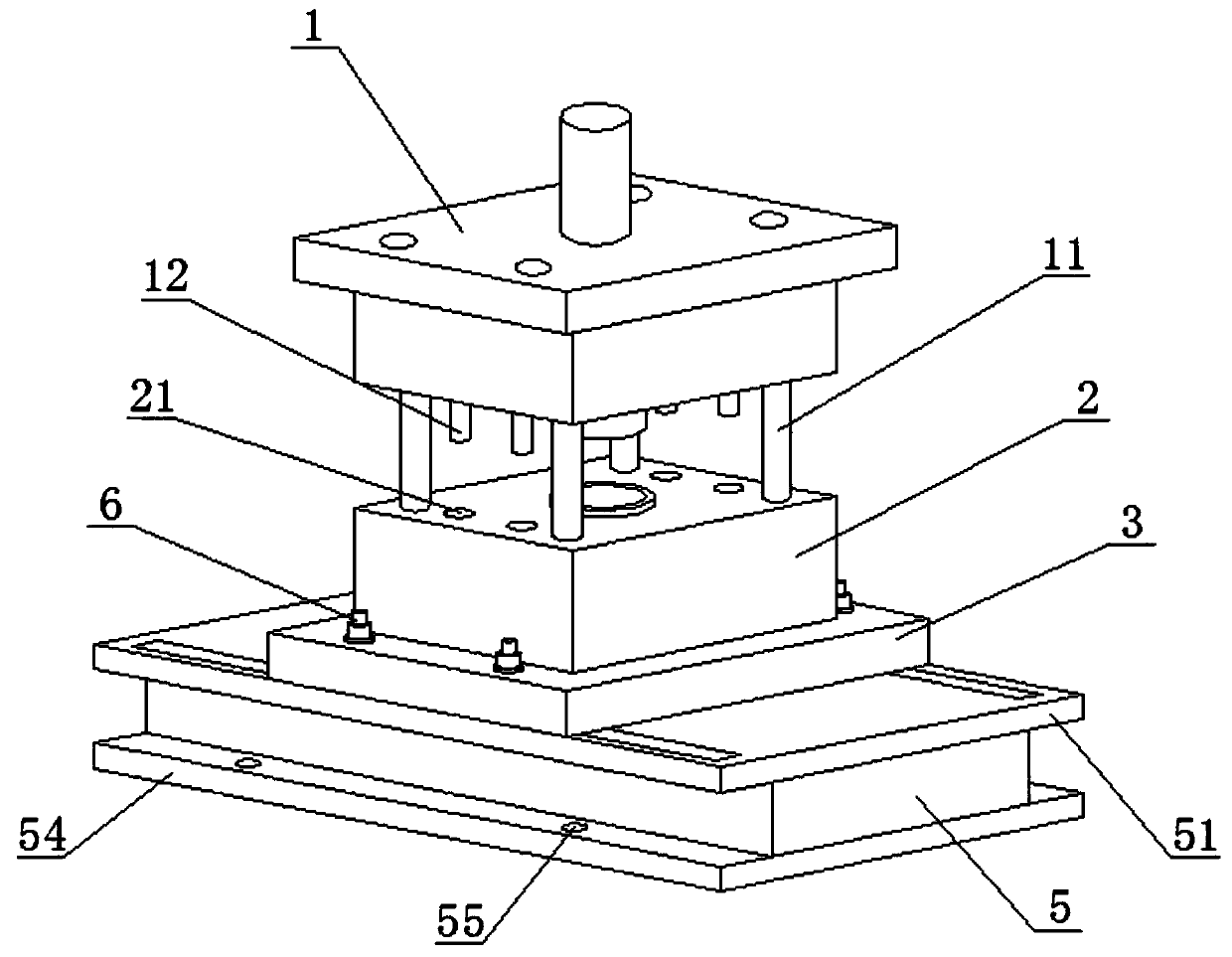

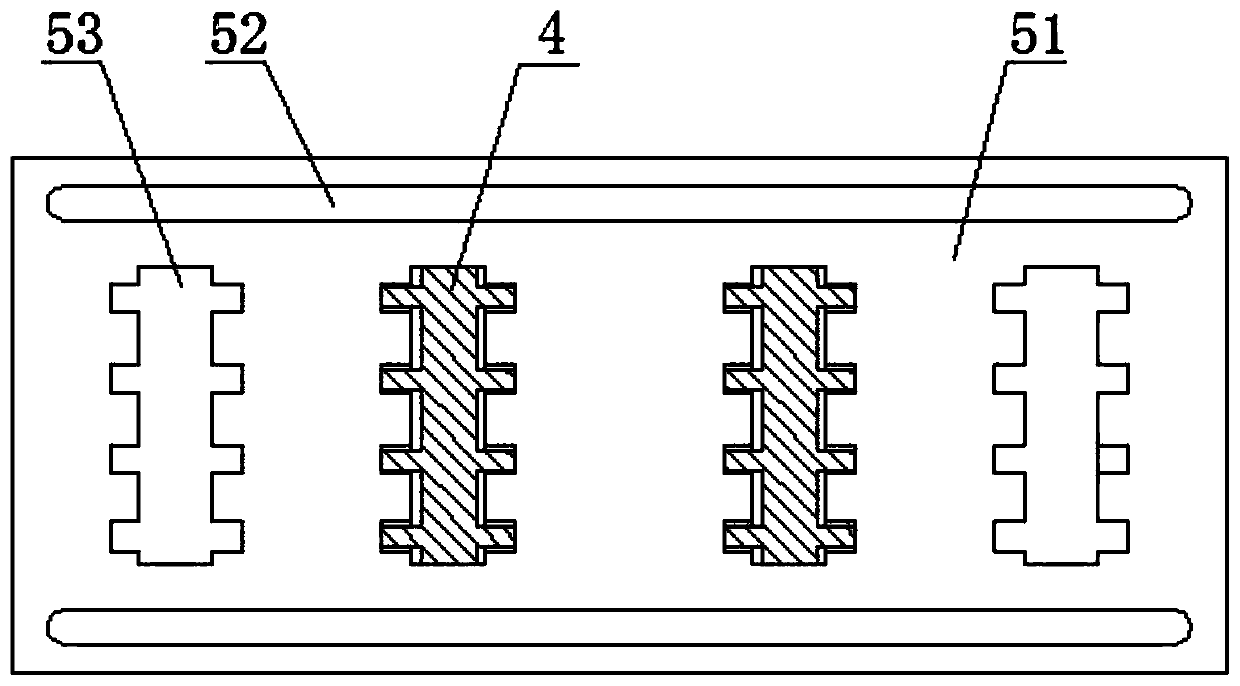

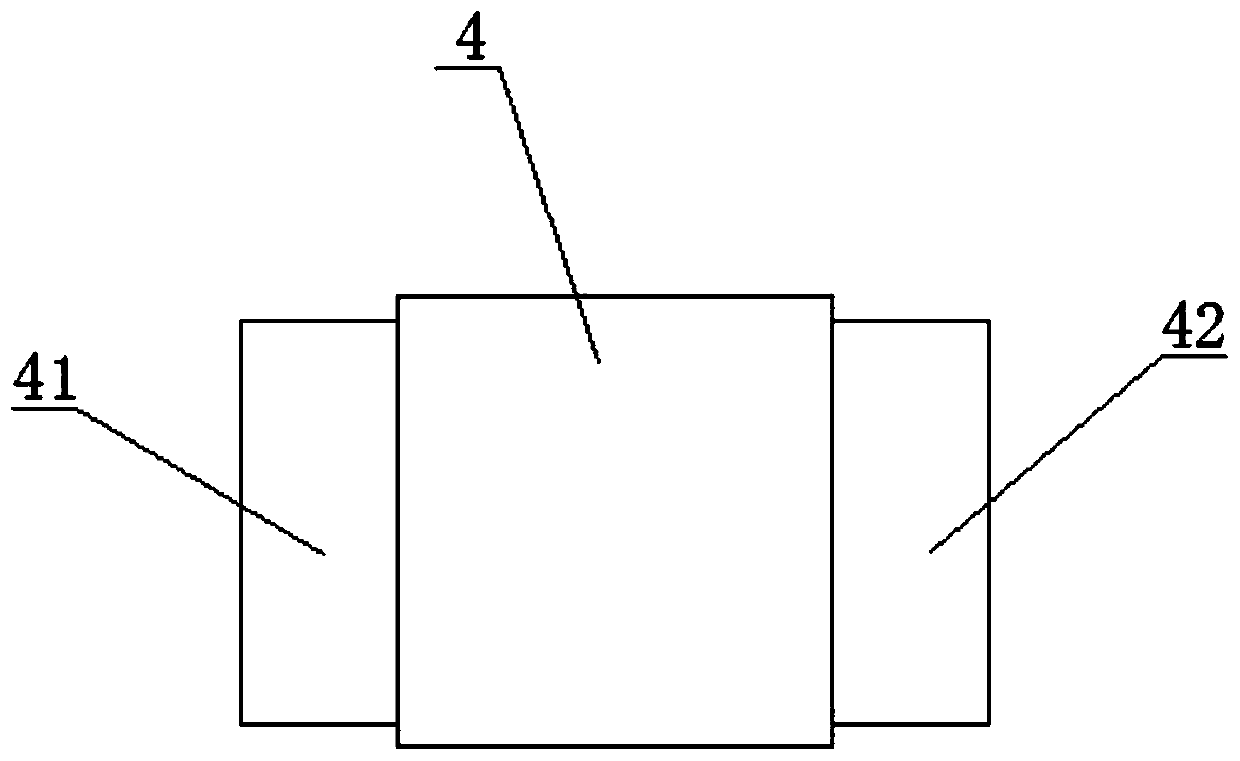

Punching machine mold stable in mold assembly

The invention discloses a punching machine mold stable in mold assembly, and belongs to the technical field of mechanical production devices. A guide rod and a buffer rod are fixedly mounted on one surface of an upper mold, the other end of the guide rod is slidingly sleeved with a lower mold, the surface of the lower mold is provided with a buffer hole, the bottom of the buffer hole is provided with a thread hole, the thread hole is connected with a fastening rod through a thread, the other end of the fastening rod is fixedly connected with a buffer block, the other face of the lower mold isfixedly provided with a lower mold plate, the other surface of the lower mold plate is provided with a through hole and an upper clamping groove, the buffer block of the machine mold is located in thebuffer hole, when the buffer block is extruded by a buffer rod, the buffer block cannot deflect, work intensity of the guide rod can be prevented from being increased, the buffer rod has the guide effect, the mold assembly stability of the machine mold can be improved, a mold holder is mounted, rapid setup of the machine mold is facilitated, a clamping base has the anti-sliding limiting function,and the mounting firmness of the machine mold can be greatly improved.

Owner:TAIZHOU VOCATIONAL COLLEGE OF SCI & TECH

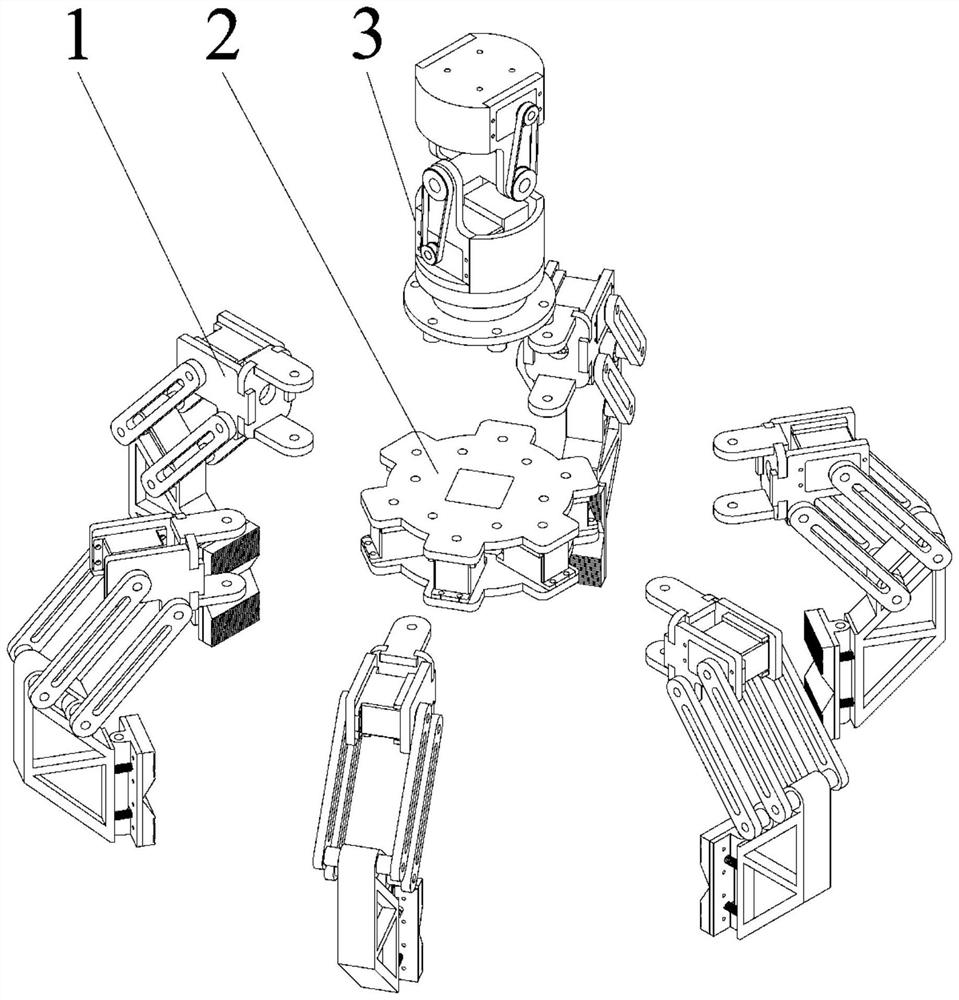

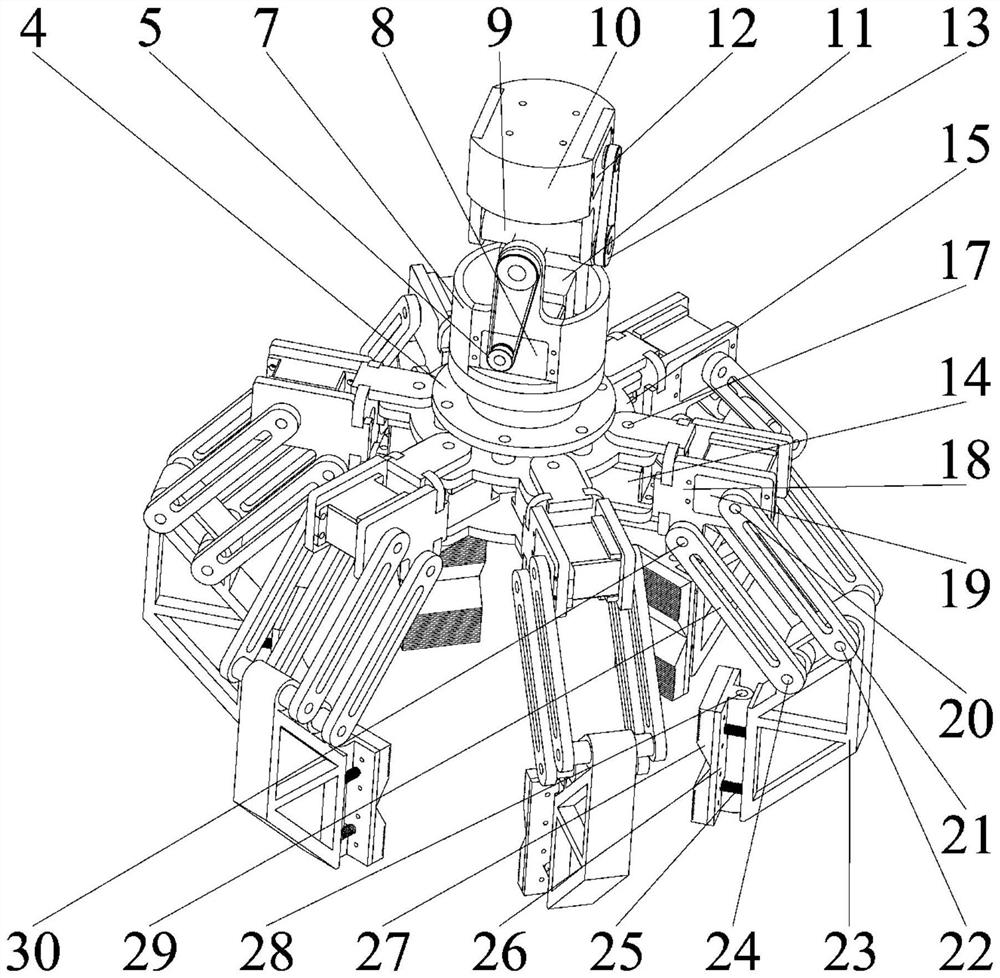

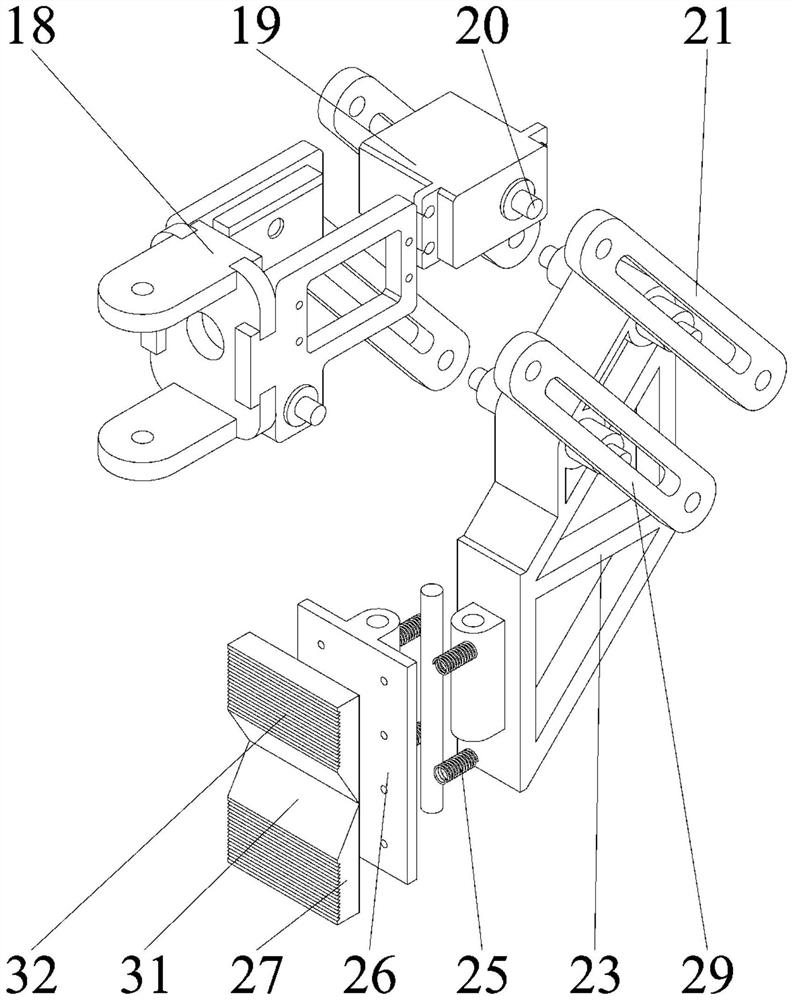

Monocular vision-based six-finger manipulator capable of changing grabbing modes

PendingCN114425785AImprove the level of intelligenceReal-time judgmentJointsGripping headsPhysicsShape control

Owner:HARBIN UNIV OF SCI & TECH

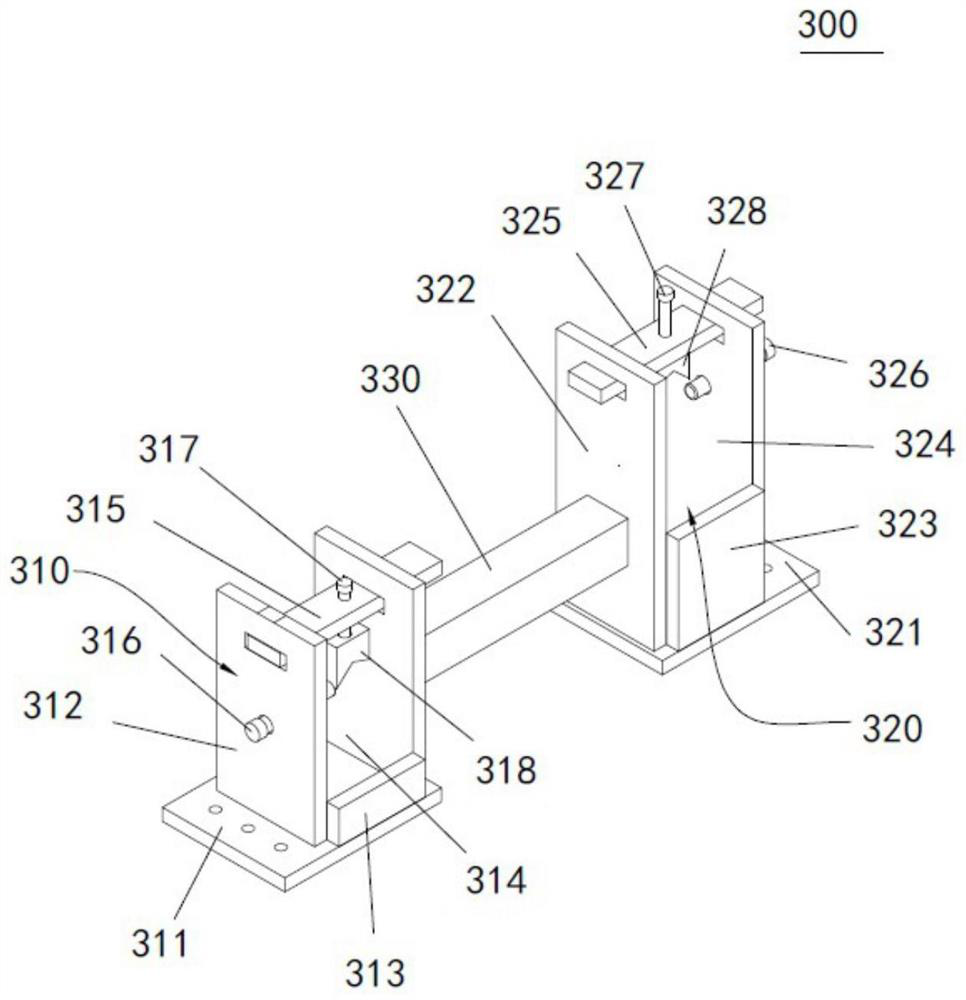

Auxiliary tool for welding cinder ladle trunnion seat and welding technology

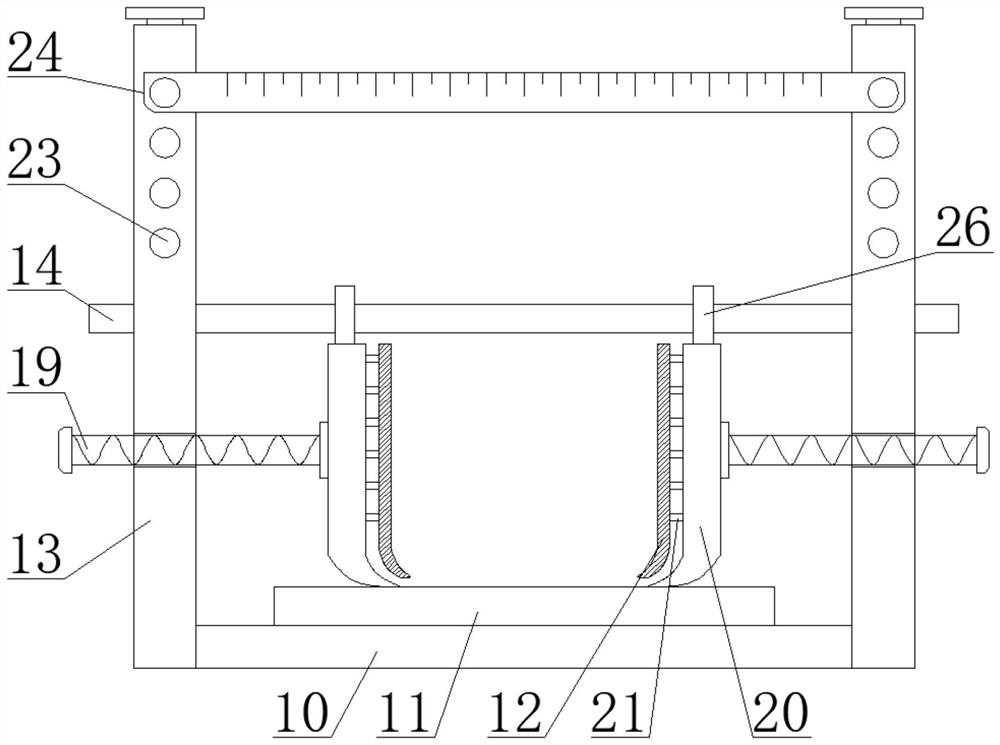

InactiveCN112247463AEasy to change positionEasy to assemble and disassemble the workpieceWelding/cutting auxillary devicesAuxillary welding devicesChanging equipmentTrunnion

The invention provides an auxiliary tool for a welding cinder ladle trunnion seat and a welding technology. The auxiliary tool comprises a clamping device and a position changing device, and the position changing device comprises a rack and a overturning frame rotationally arranged on the rack. The clamping device is arranged on the overturning frame and comprises two clamping parts arranged on the overturning frame in a spaced mode, and each clamping part comprises middle ring foot fixing parts used for fixing middle ring feet and upper ring foot fixing parts used for fixing upper ring feet.A mounting space allowing a trunnion plate to penetrate out is further formed in the overturning frame, 360-degree all-around welding of the welding cinder ladle trunnion seat can be achieved fast andefficiently, and crane hoisting is not needed; and meanwhile, a welding robot can be applied to be linked with position changing equipment, and thus full-automatic welding of a gas shielded welding part can be achieved.

Owner:MCC BAOSTEEL TECH SERVICE

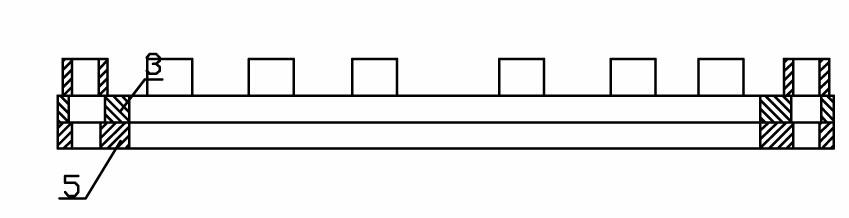

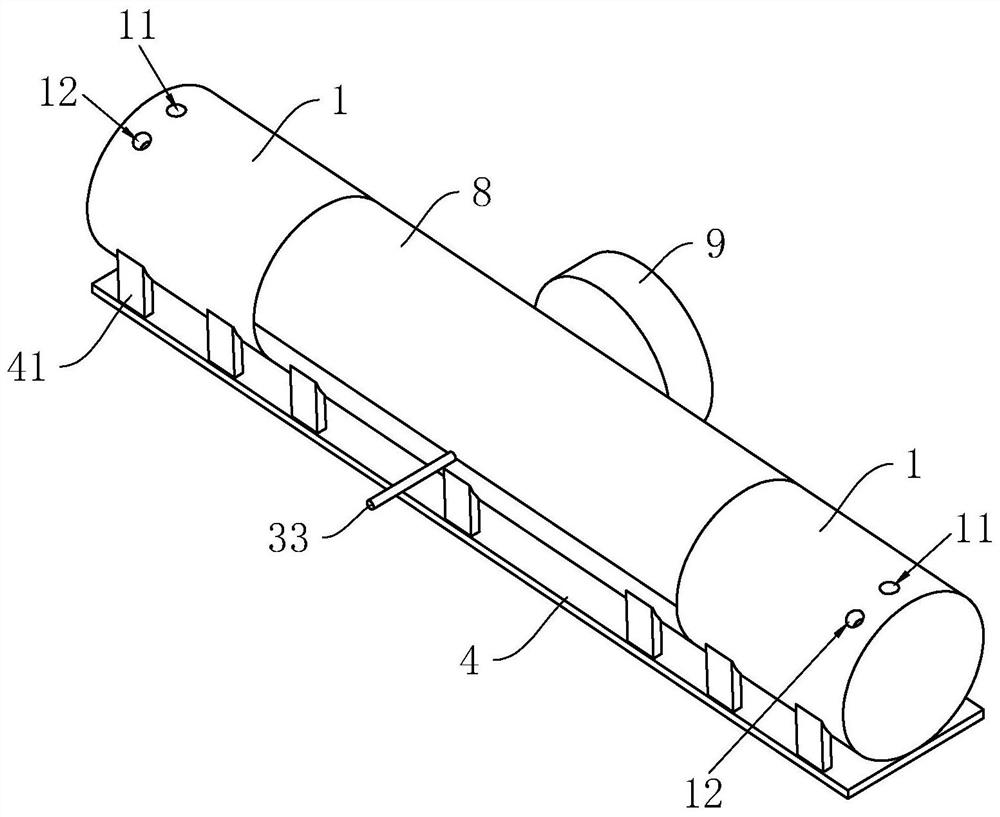

Longitudinal and transverse tandem full-spectrum LED plant lamp

PendingCN114562704APromote growthHeight adjustableLighting support devicesElectrical apparatusEngineeringDiffuse reflection

The invention discloses a longitudinal and transverse tandem full-spectrum LED plant lamp, and belongs to the technical field of LED lamplight illumination. The plant lamp comprises a plurality of sets of plant lamps, a light source is arranged in each set of plant lamp, each set of plant lamp comprises a main lamp body and a series connection lamp body, each main lamp body is provided with a sweeping mechanism, a lifting mechanism and a series connection mechanism, and each series connection lamp body is installed between every two adjacent main lamp bodies through the corresponding series connection mechanism. According to the plant lamp, colored light obtained through diffuse reflection of plants is utilized and converged to the focus through a convex lens, then the light sensor is utilized for detecting the light intensity to judge the height between the main lamp body and vegetation, then the height of the main lamp body is adjusted, and the plant lamp can be conveniently and rapidly cleaned. The problem that the mounting height of the light source cannot be adaptively adjusted along with the growth of the plants is solved, illumination is fully provided for the plants, and the growth of the plants is facilitated.

Owner:ZHEJIANG GESUNG LIGHTING CO LTD

Wave dissipation building blocks forming wave dissipation wall body and formed wall body

InactiveCN101353886BLow costReduce construction proceduresBreakwatersQuaysEngineeringMechanical engineering

Owner:汪荣勋

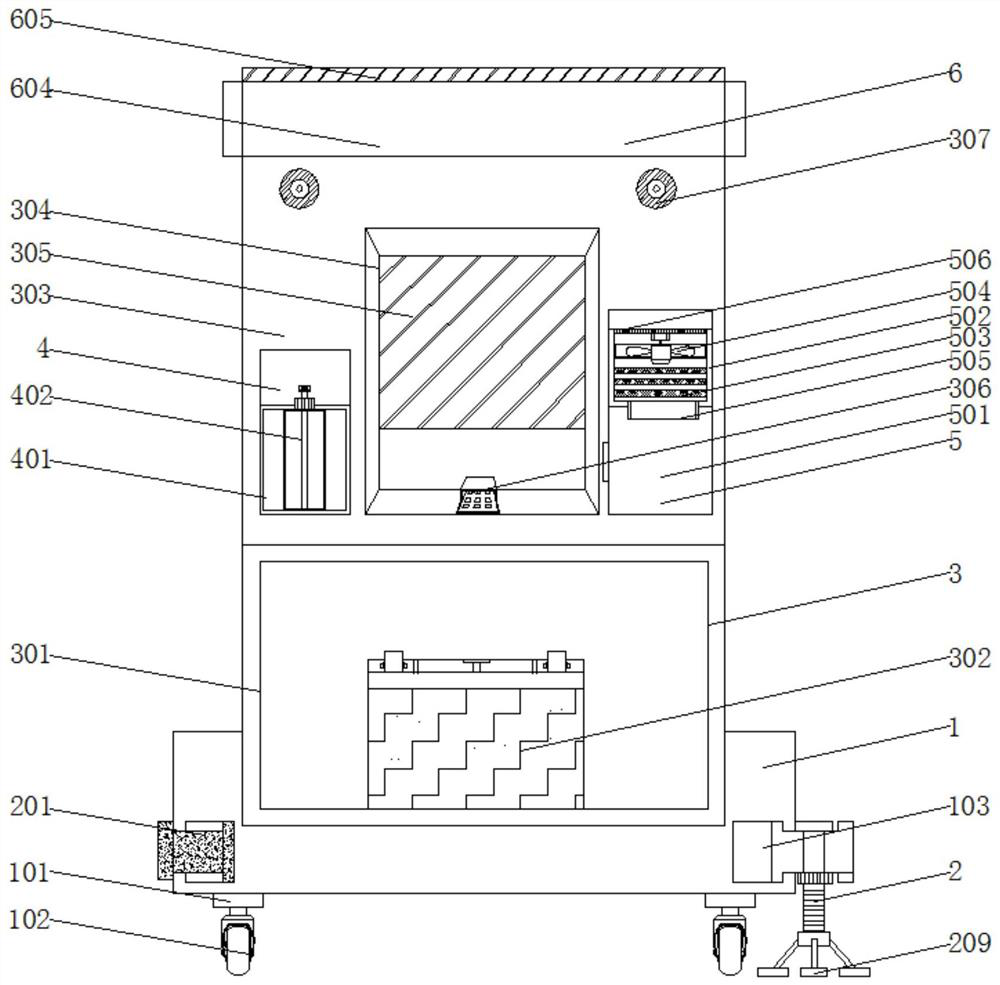

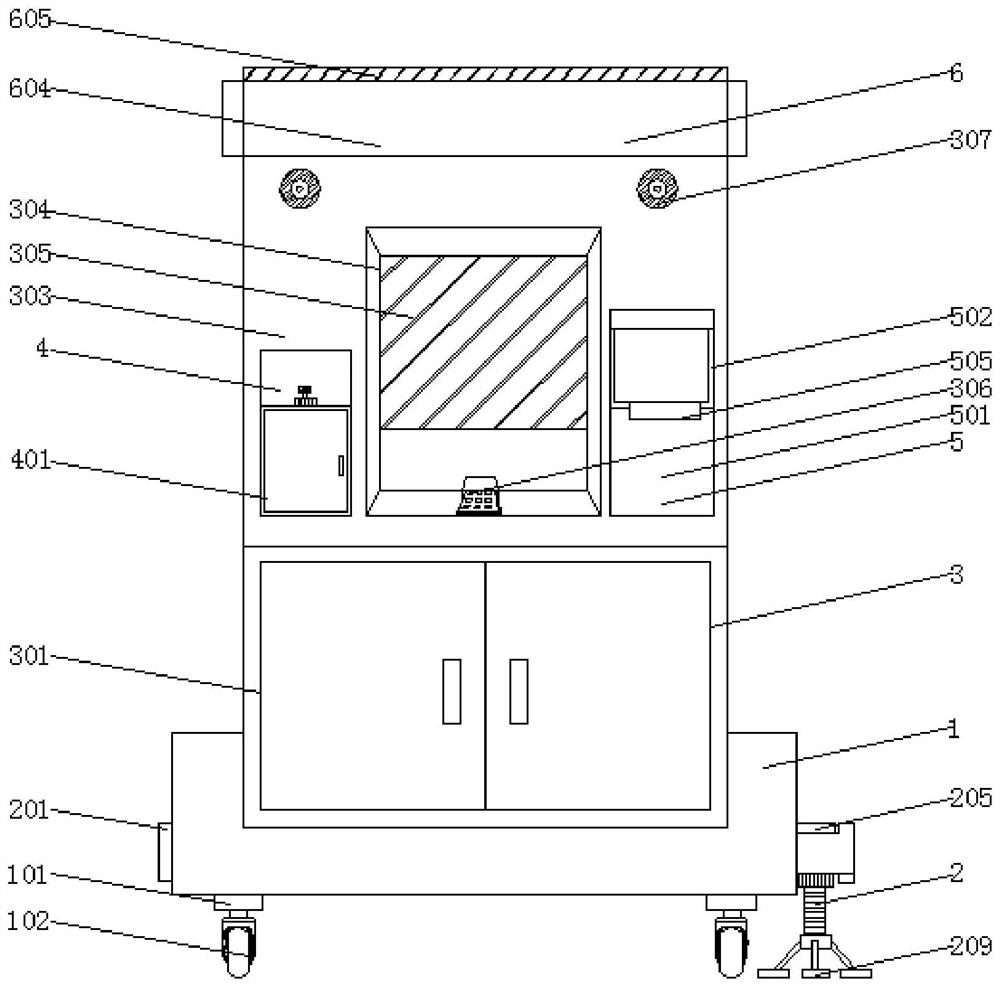

Automobile reservation service device

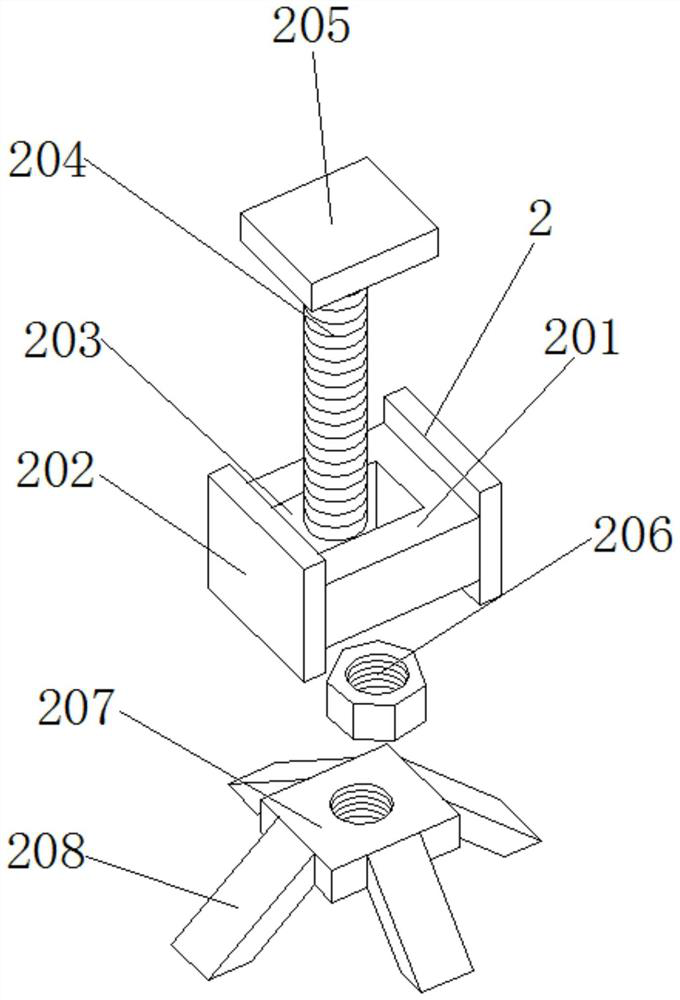

InactiveCN112650415AEasy to installResidue reductionPharmaceutical containersMedical packagingMachineBottle

The automobile reservation service device comprises a base, a stabilizing structure and a machine body. Multiple sets of movable grooves are formed in the outer walls of the two sides of the base, the stabilizing structure is installed in the movable grooves, one end of the stabilizing structure extends out of the base, and the machine body is installed at the top of the base; a containing groove is formed in the front face of the machine body, a drying structure is installed on the front face of the machine body and located on one side of the containing groove, and a top box is installed at the top of the machine body. Hands of a user can be disinfected by pressing the disinfectant bottle, then disinfectant on the hand of the user can be rapidly air-dried through the drying structure, so that appointment operation can be conveniently carried out; the sliding function is added to the device through the sliding wheels and the stability of the whole device can be improved through the stable structure, so that under the condition that the limited pulley is accidentally touched, the device is prevented from deviating and falling laterally, and the device is prevented from being damaged.

Owner:SUZHOU JINHUA ENTERPRISE SERVICES CO LTD

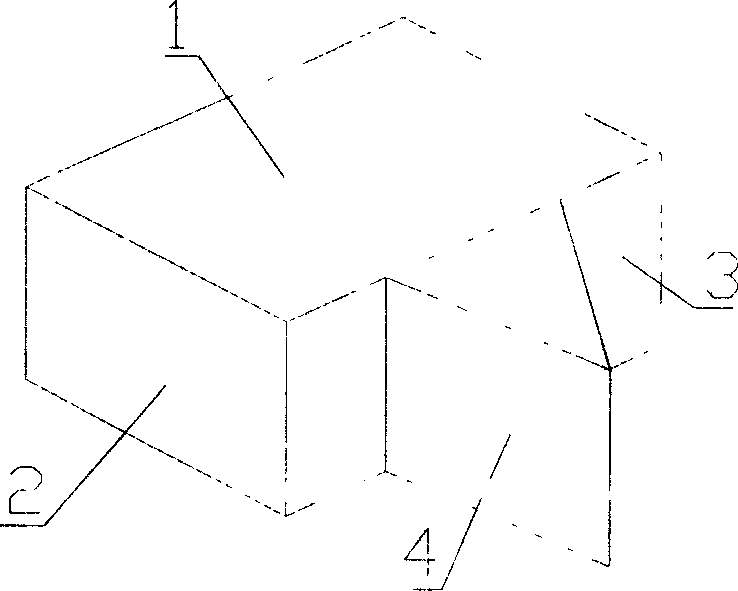

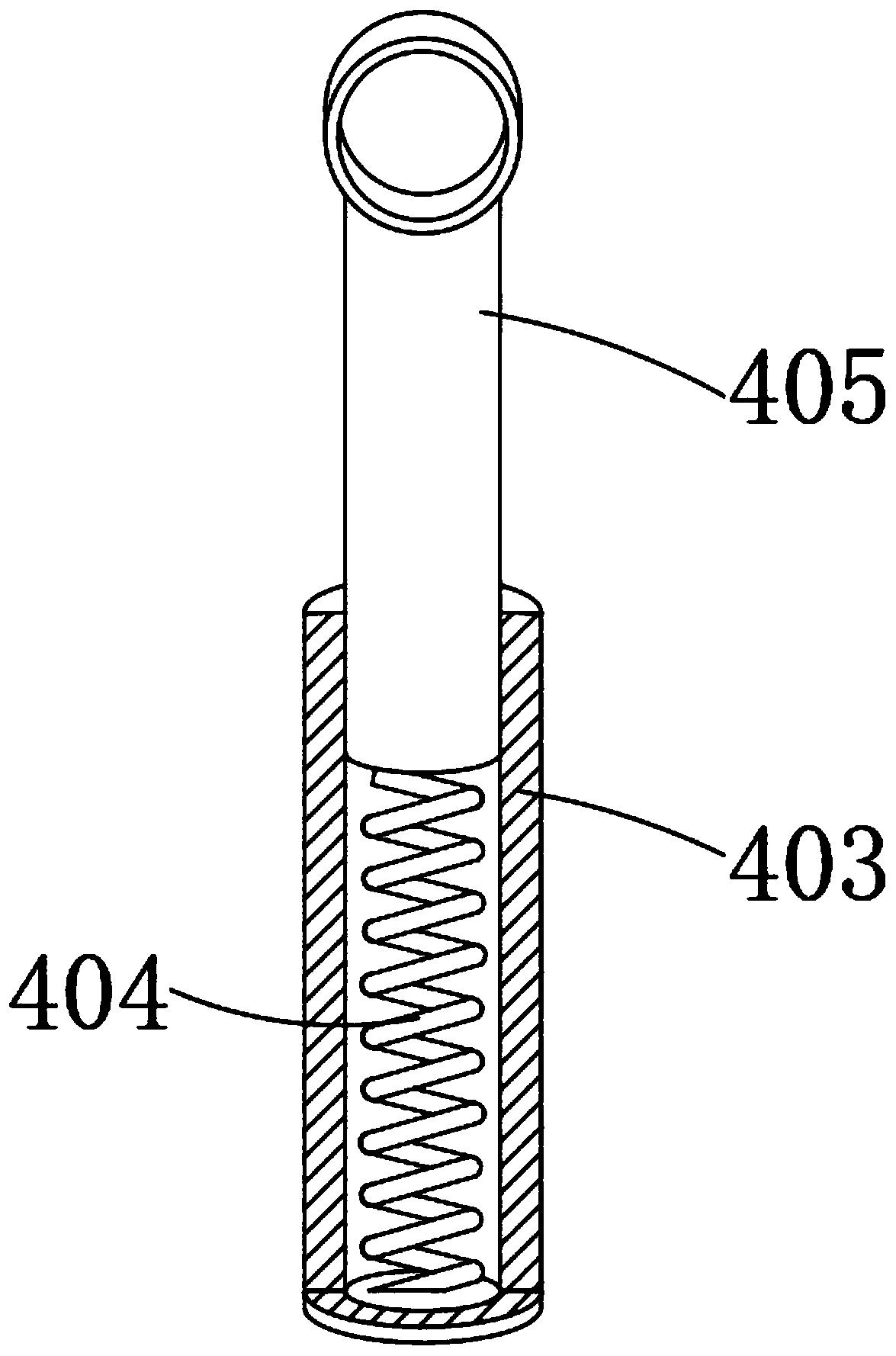

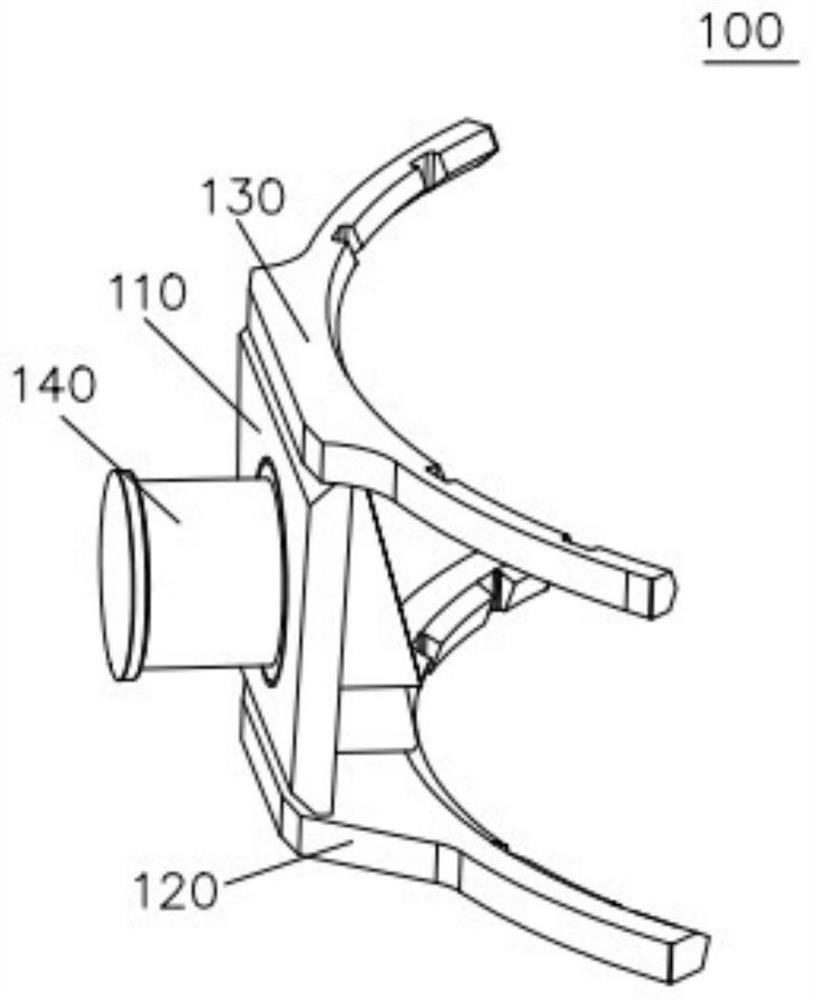

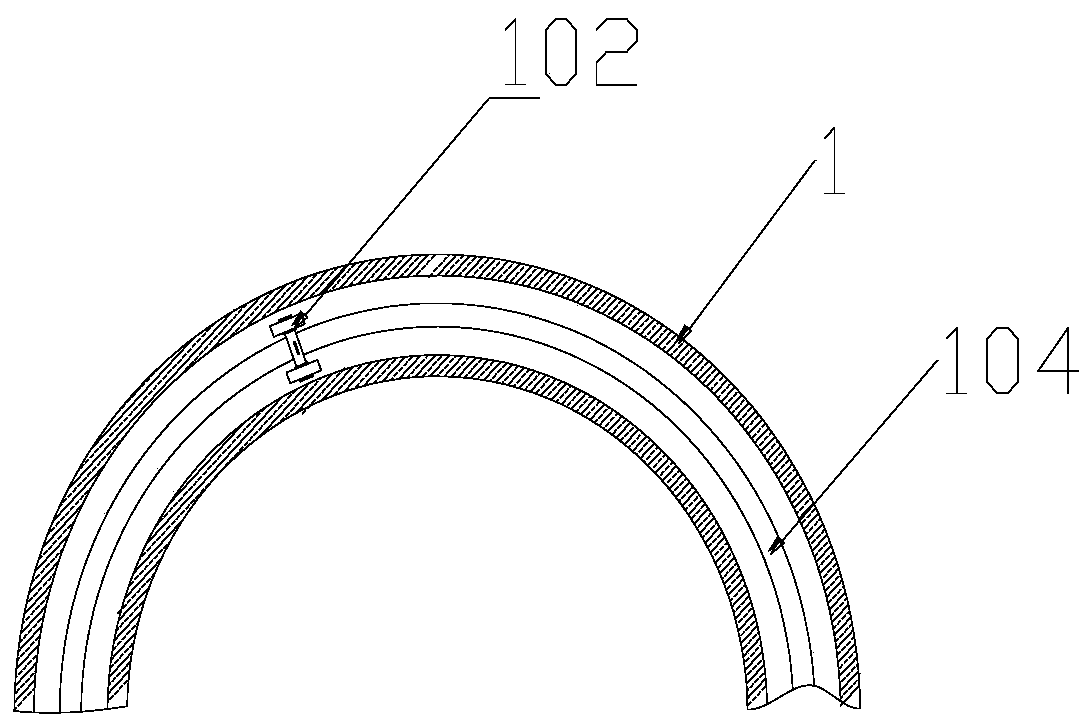

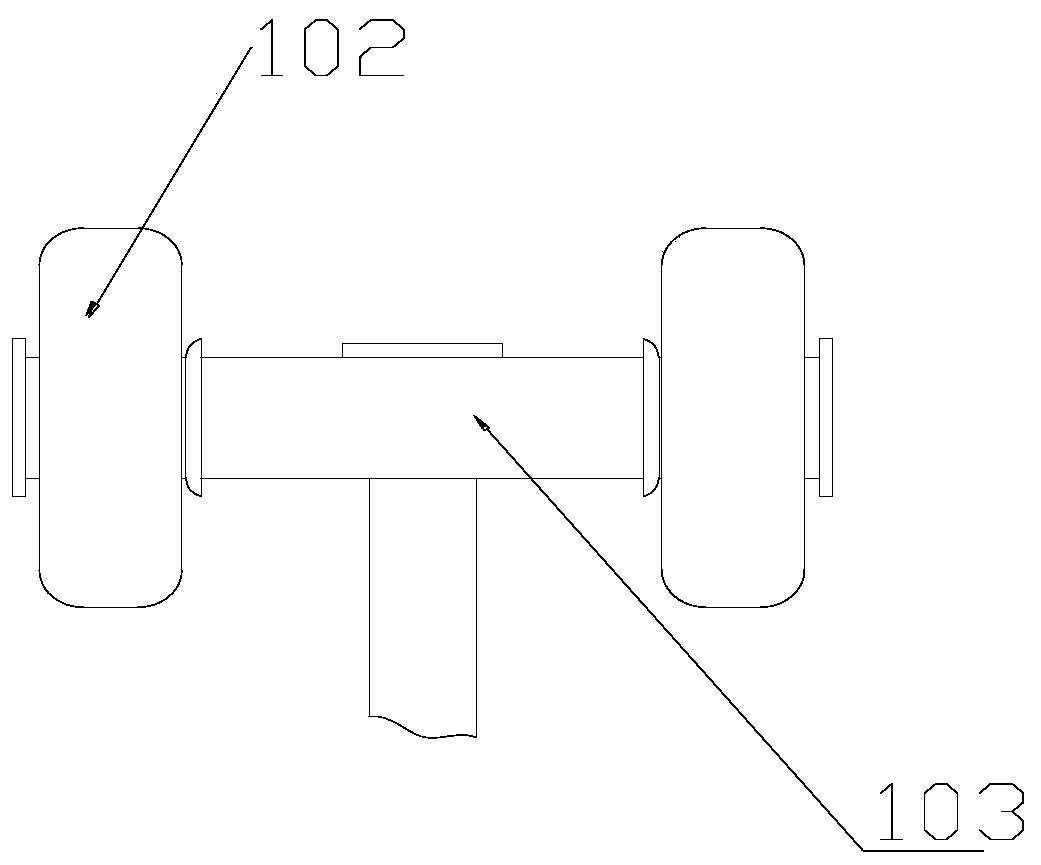

Hanging ventilation type anti-radiation system

PendingCN110522467AReduce weightReduce the burden of surgeryRadiation safety meansEngineeringRadiation

The invention discloses a hanging ventilation type anti-radiation system. The hanging ventilation type anti-radiation system comprises a guide rail mechanism (1) and hook mechanisms (3). The hanging ventilation type anti-radiation system is characterized by also comprising balance regulators (2) and anti-radiation clothes (4), wherein the first connecting end of each balance regulator (2) is in rolling connection with the guide rail mechanism (1); the second connecting end of each balance regulator (2) is connected with the first connecting end of the corresponding hook mechanism (3); and thehook end of each hook mechanism (3) is detachably connected with the corresponding anti-radiation clothes (4). The hanging ventilation type anti-radiation system disclosed by the invention has the advantage of alleviating the weight of protective clothes, and the flexibility of medical personnel can also not be influenced; besides, the hanging ventilation type anti-radiation system can be used bya plurality of people simultaneously, so that resources are saved, and the medical personnel can also conveniently and quickly exchange positions; and the medical personnel can bow or bend the waist,so that the burden in an operation of a doctor is alleviated, and the doctor can more easily complete intervening operative procedures.

Owner:THE FIRST AFFILIATED HOSPITAL OF CHONGQING MEDICAL UNIVERSITY

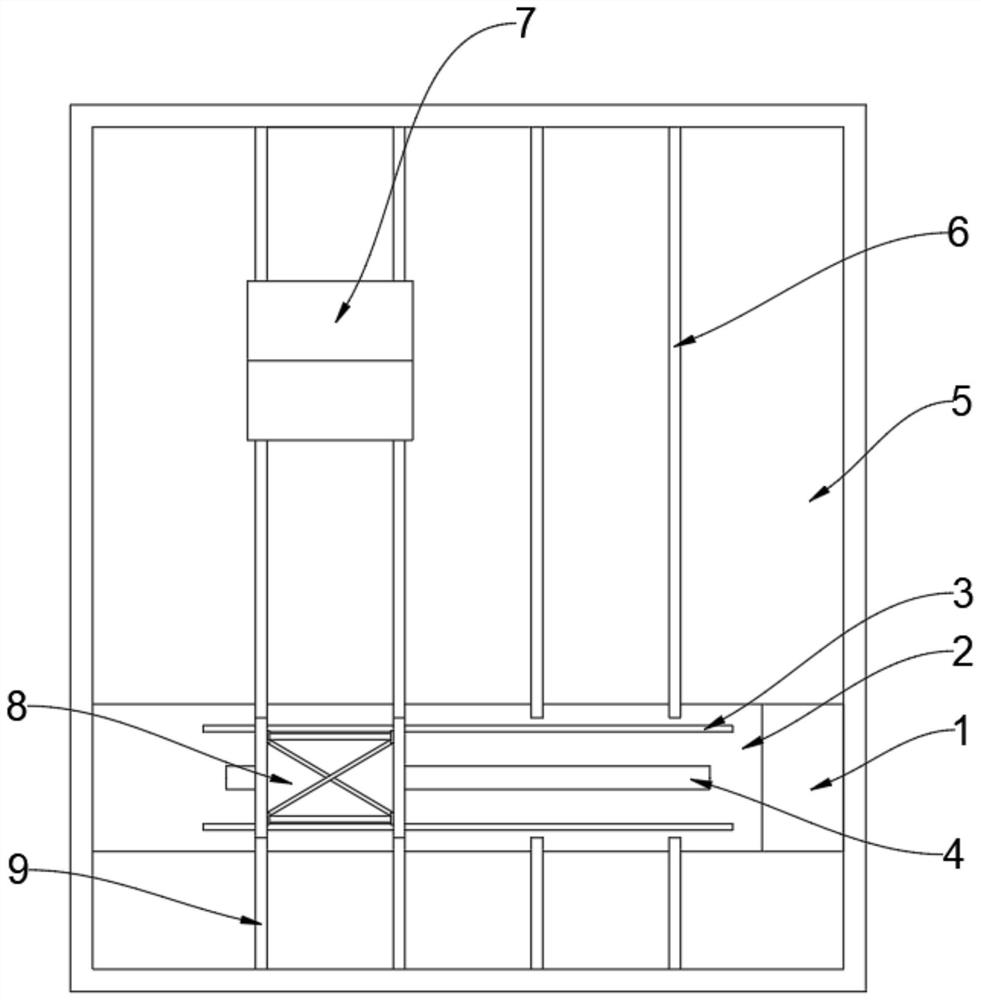

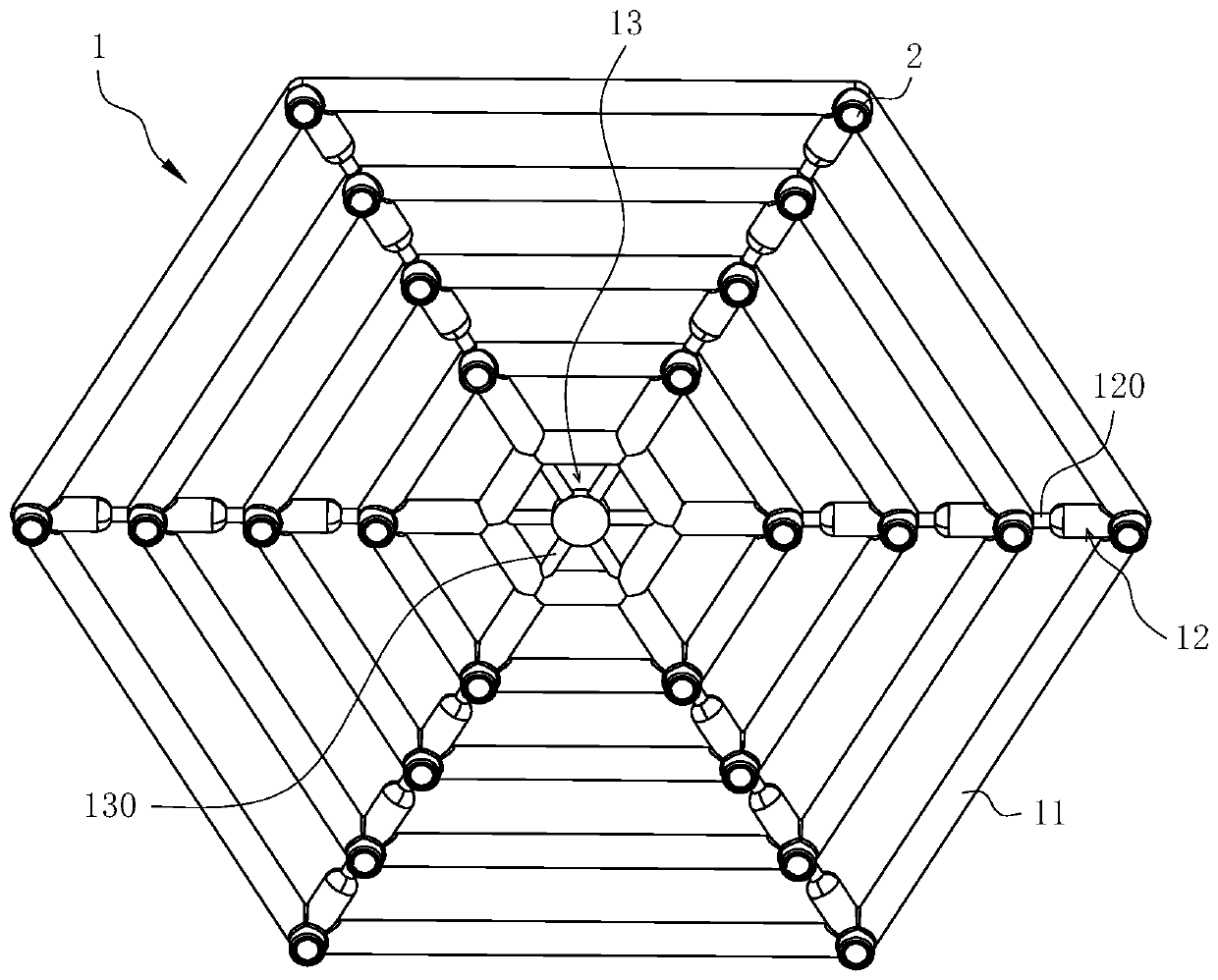

A lotus seed picking platform

ActiveCN112840853BEasy to pullEasy to changePicking devicesHeadersAgricultural scienceAgricultural engineering

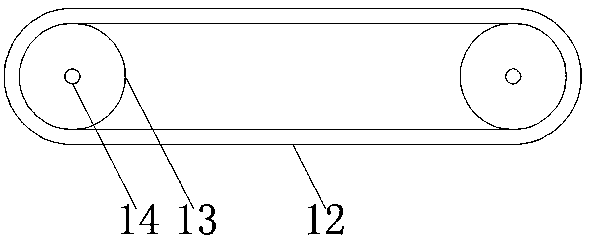

The invention discloses a lotus seed picking platform, which includes a picking pool. Four long I-shaped steels and four short I-shaped steels corresponding to the four long I-shaped steels are evenly arranged in parallel inside the picking pool. The long I-shaped steels and The bottom surface of the short I-shaped steel and the bottom surface of the picking pool are fixedly connected by a long column, and a picking studio is slidingly connected above the two long I-shaped steels; the picking studio includes a bottom plate and a ceiling, and the bottom plate includes leisure. area and lotus picking area, the upper end of the leisure area is fixed with four fixed limit columns and three side guardrails, the outer side of the top of the fixed limit column is sleeved with a support sleeve rod, and the middle position of the bottom plate The two sides of both sides are all connected with driving belt pulley by rotating shaft. On the one hand, the lotus seed picking platform of the present invention provides a brand-new mechanized operation method for manual picking of lotus pods, and on the other hand, it also develops the lotus seed leisure tourism industry, and has broad application prospects.

Owner:武汉明春莲联科技有限公司

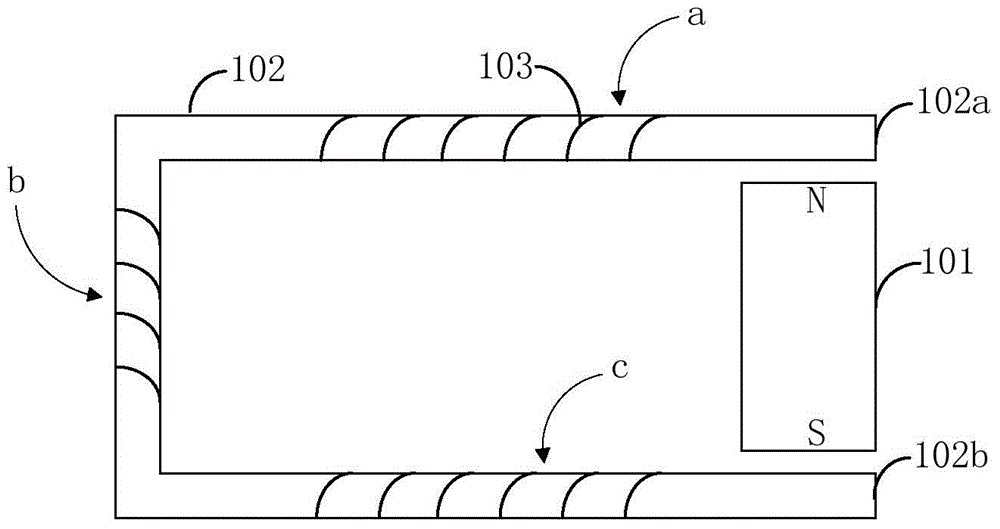

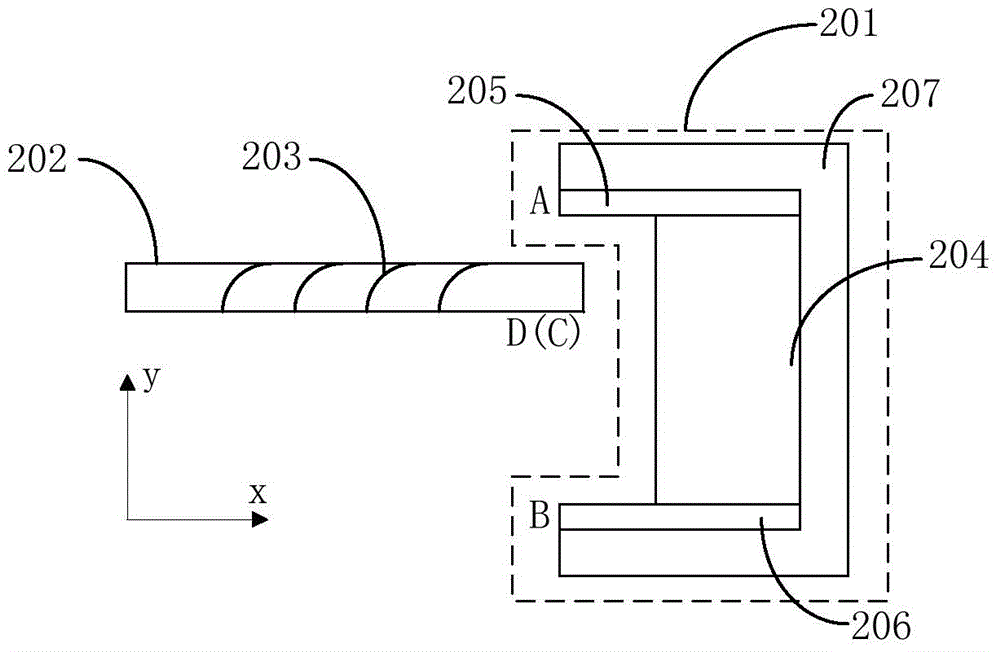

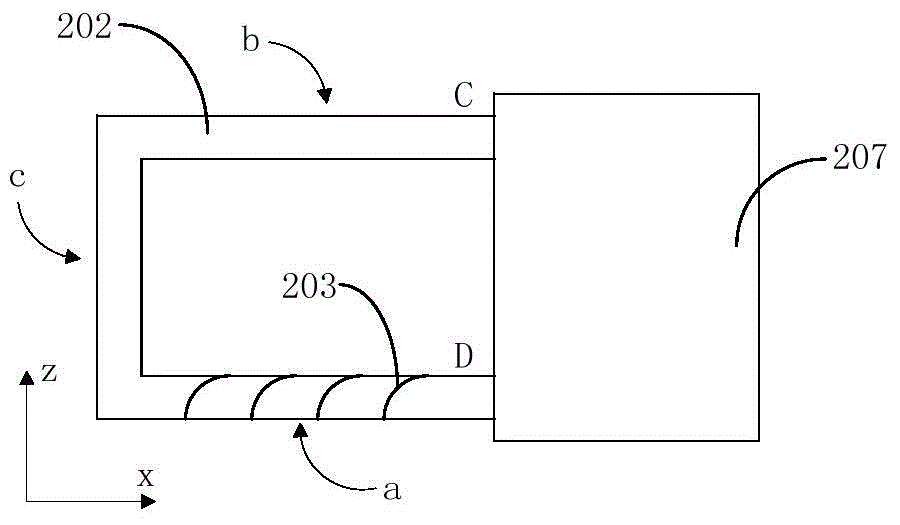

Power generating device, controller and switching system

The invention discloses a power generating device, a controller and a switching system. The power generating device comprises a magnet component for generating a magnetic field and a magnetizer wound with a generating coil. When the magnetizer and the magnet component move relatively, the magnetic flux of the generating coil changes to generate electric energy. The power generating device is not provided with a rotor and a stator; and thus compared with the existing generating device with many coils and complicated structure, the provided power generating device has a simpler structure and is provided with a few coils. Therefore, the power generating device has a smaller size and thus can meet various application requirements, especially one for a small size of a generating device.

Owner:邢志伟

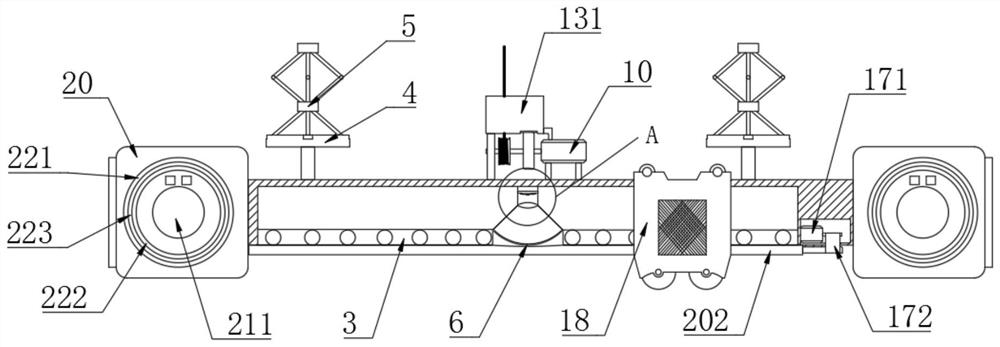

Head fixing device for tumor radiotherapy

InactiveCN113134170AEasy to change positionAvoid forgettingDevices for pressing relfex pointsX-ray/gamma-ray/particle-irradiation therapyCushionMedical physics

A head fixing device for tumor radiotherapy disclosed by the present invention comprises a bed board, a connecting frame is installed on one side of the bed board through bolts, a pillow plate is installed on the end portion of the connecting frame through bolts, supports are installed on the two sides of the pillow plate through bolts, and limiting rods are installed on the inner sides of the supports through screws. Locking screws are installed on the surfaces of one sides of the supports through reserved threaded holes, fixing frames are installed at the ends of the locking screws through bolts, connecting rods are installed on one sides of the fixing frames through screws, rubber cushions are installed at the ends of the connecting rods through screws, and a pillow is installed on the top of the pillow plate through screws. Lower fixing grooves are formed in the two ends of the top of the bed board through opening grooves, sleeve rods are installed on the two sides of the bottom of the bed board through bolts, and the bottoms of the sleeve rods are sleeved with sleeves. The head fixing device for tumor radiotherapy is practical in function, convenient to operate, convenient to use by workers and suitable for being widely popularized and used.

Owner:魏莉莉

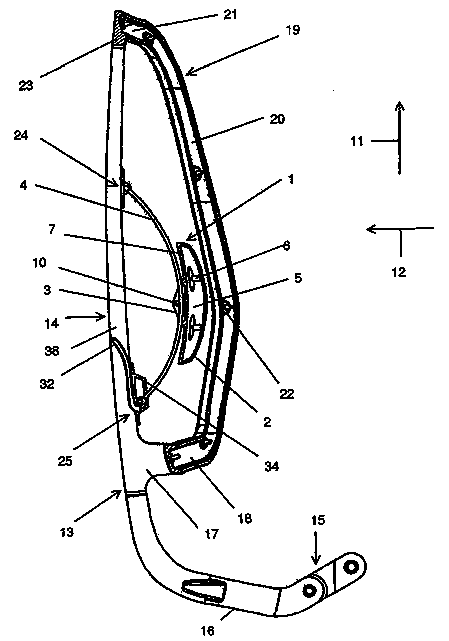

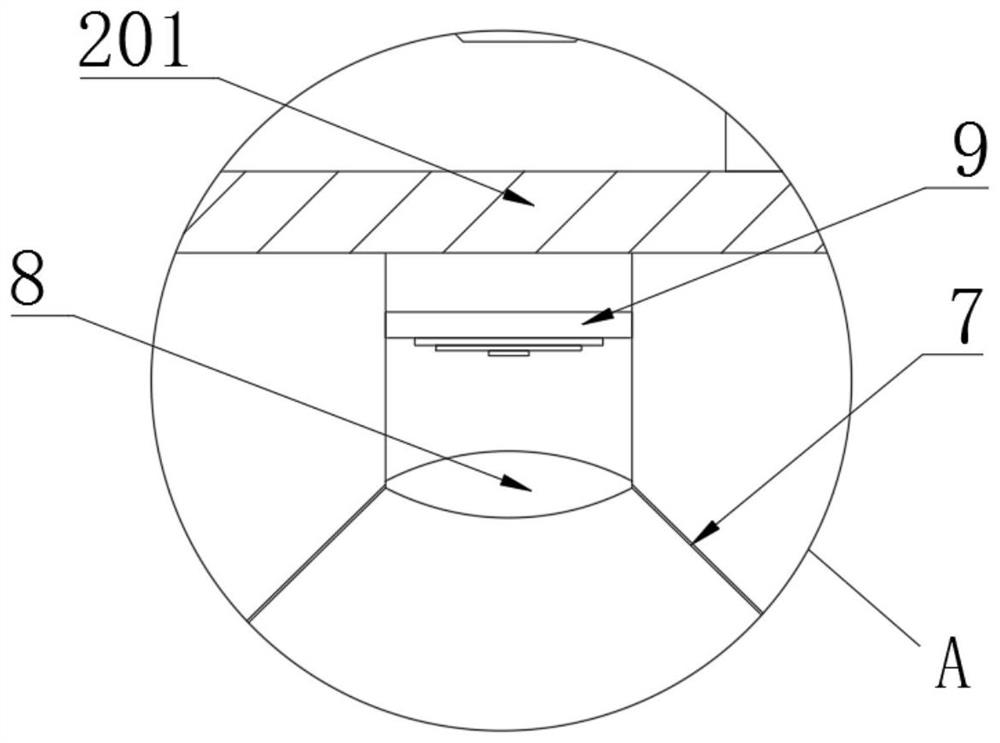

Mandibular condylar process detecting hook

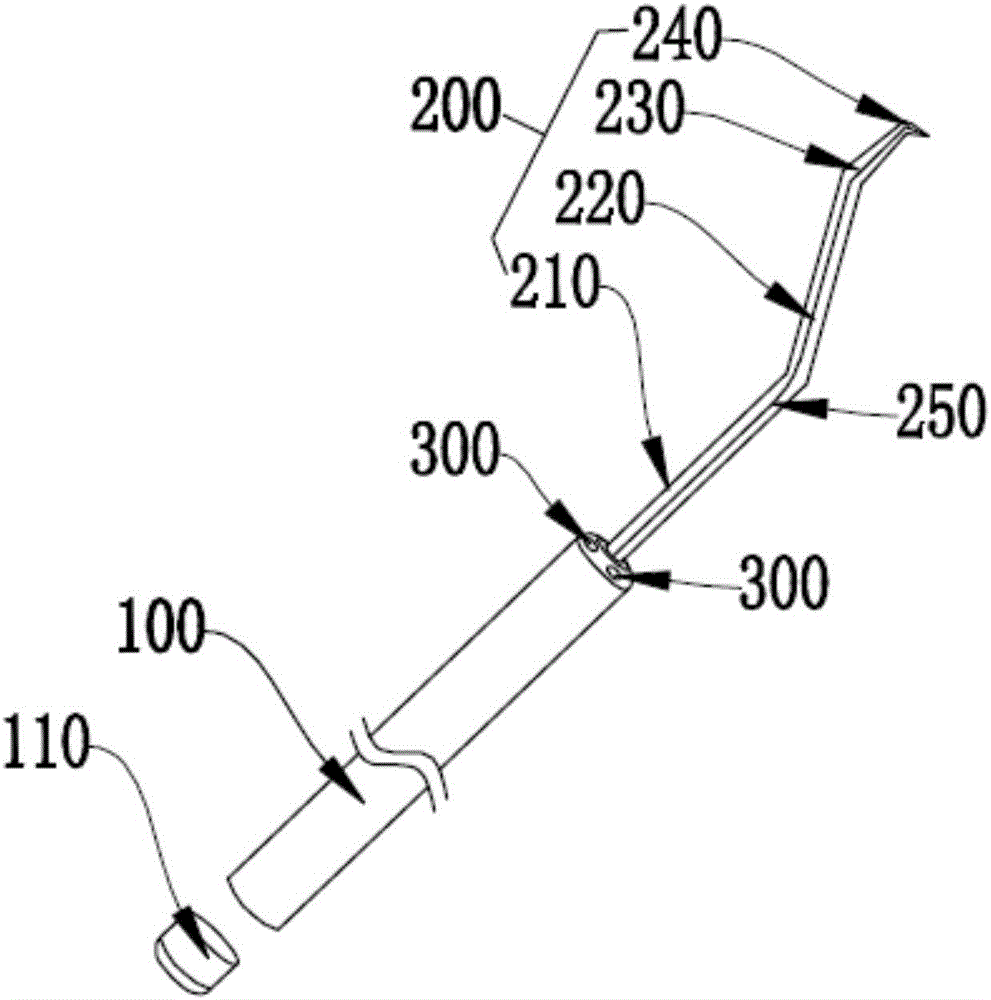

InactiveCN106510780AAvoid interferenceEasy to change positionSurgical field illuminationBody of mandibleDisplay device

The invention relates to the field of medical apparatus and instruments and particularly relates to a mandibular condylar process detecting hook comprising a handle and a detecting hook fixedly arranged at the end of the handle; the detecting hook sequentially comprises a first detecting hook section, a second detecting hook section and a third detecting hook section from bottom to top; the included angle between the first detecting hook section and the second detecting hook section is 140-160 DEG, and the included angle between the second detecting hook section and the third detecting hook section is 140-160 DEG; the third detecting hook section is provided with a pointed cone, and the included angle between the pointed cone and the third detecting hook section is 110-120 DEG; the handle is of a cylinder and is 8-15 CM long; the first detecting hook section is 5-8 CM long; the second detecting hook section is 5-8 CM long; the third detecting hook section is 1-3 CM long; and the pointed cone is 0.5-1.5 CM long. The device is provided with a position display device, so that the position of the detecting hook can be clearly displayed under an environment with a poor visual condition.

Owner:彭国光 +4

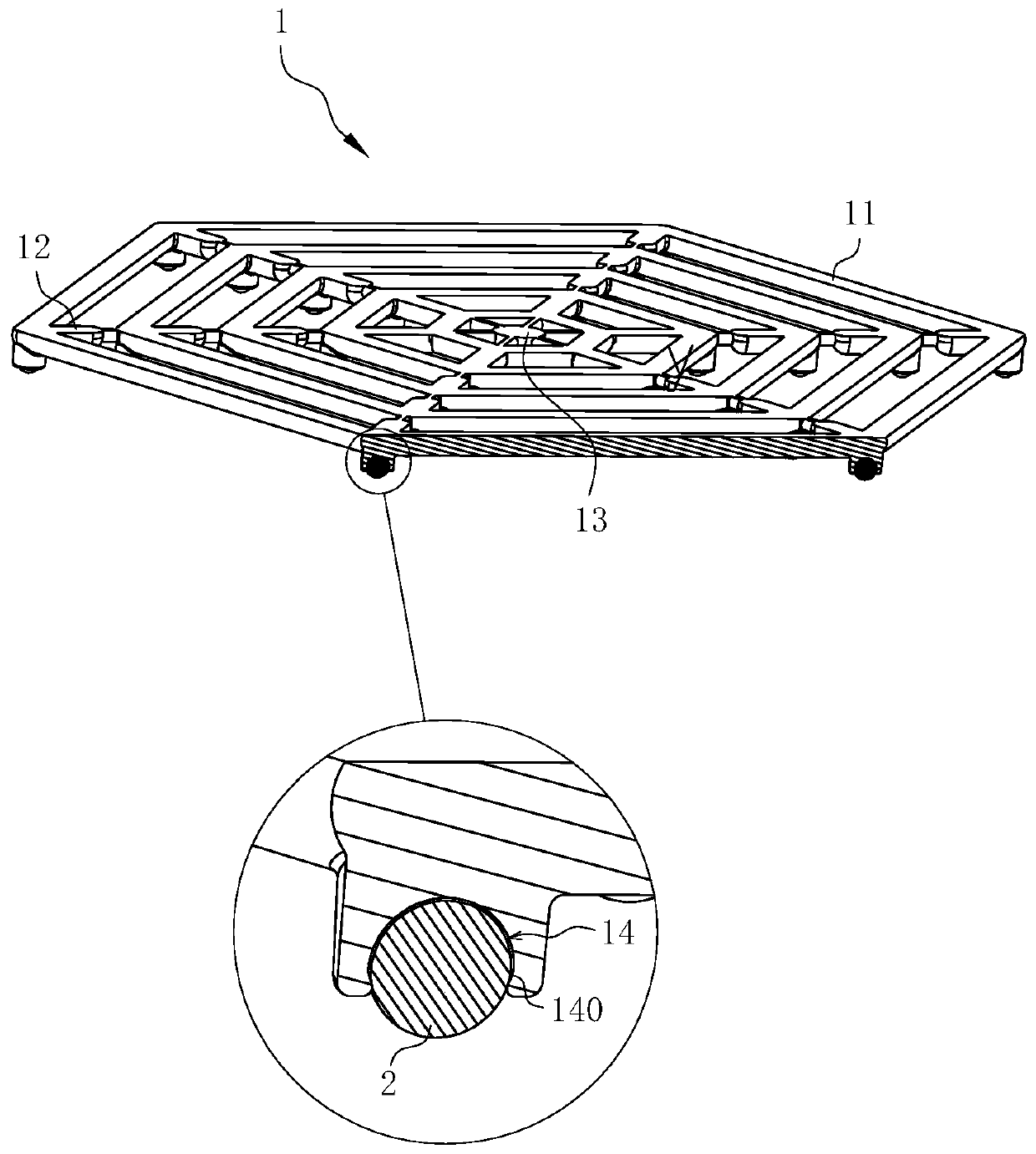

Vase pad

PendingCN110584403AEasy to change positionSimplify the assembly processFlower holdersBiomedical engineeringSupport surface

The invention discloses a vase pad. The vase pad comprises a pad body, and is characterized in that a plurality of rolling bodies capable of rolling on a supporting surface to drive the pad body to move are arranged at the bottom of the pad body. According to the vase pad, the vase pad can be moved to drive a vase to move, so that the position of the vase is convenient to change.

Owner:CIXI HUAZHIJIE PLASTIC PROD

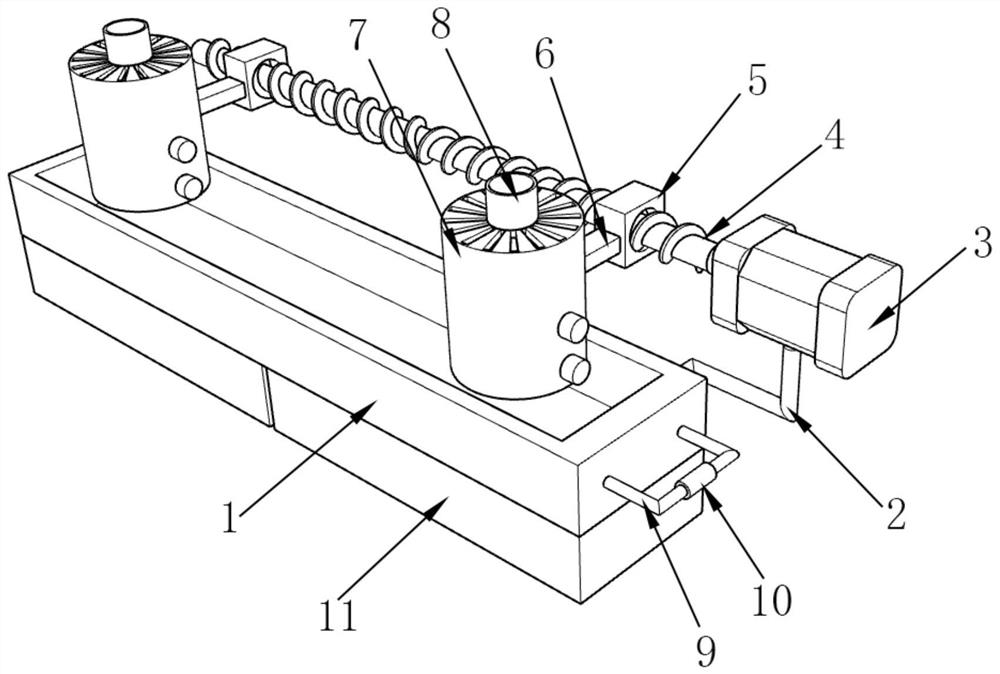

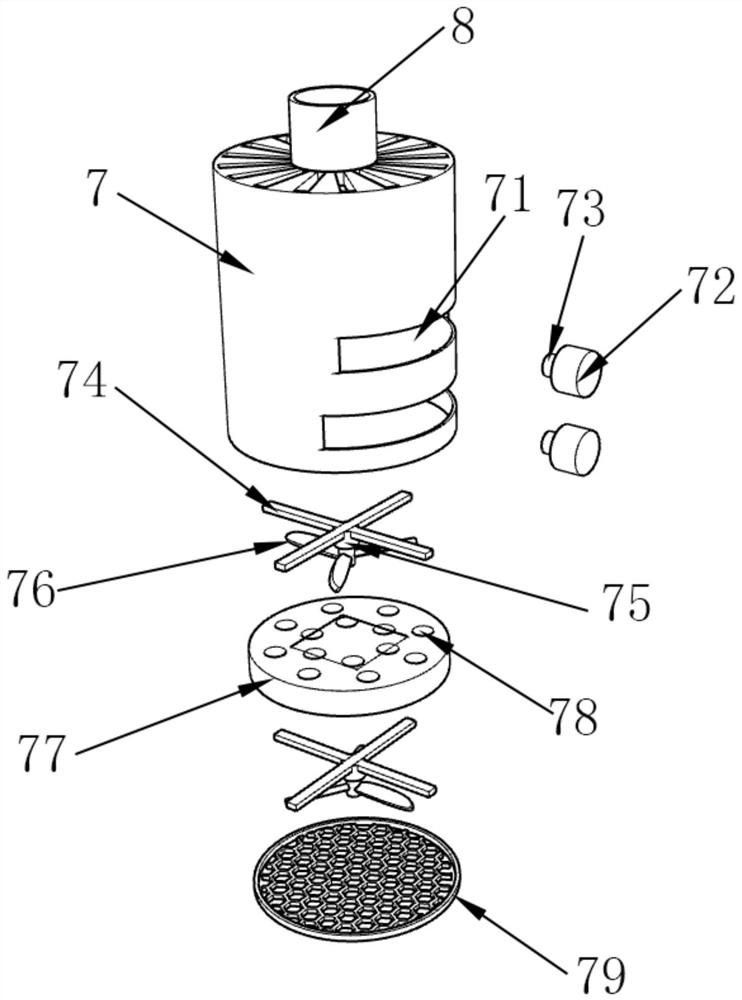

Gravel sub-packaging treatment equipment for building stones and use method of gravel sub-packaging treatment equipment

PendingCN114850024AHigh precisionImprove the effect of building constructionSievingScreeningSlide plateCrushed stone

The invention discloses gravel sub-packaging treatment equipment for building stones and a using method thereof.The gravel sub-packaging treatment equipment comprises a sub-packaging collecting plate, a welding frame is welded to the back face of the sub-packaging collecting plate, a motor is fixedly connected to the top of the motor, a two-way screw rod is fixedly connected to the side face of the motor, and the left side and the right side of the outer surface of the two-way screw rod are movably sleeved with sliding plates; the side face of the sliding plate is fixedly connected with a connecting block, and one end of the connecting block is fixedly connected with a classification tank. According to the equipment, by means of mutual cooperation of the classification tank and devices inside the classification tank, the sizes of different stone materials can be evenly subdivided, so that the stone materials are subpackaged, by means of a multi-layer classification structure, the stone material using accuracy and the building construction effect can be improved, potential safety hazards are reduced, and by means of mutual cooperation of the adjusting movable bottom plate and devices inside the adjusting movable bottom plate, the construction efficiency is improved. And the position of the equipment can be conveniently replaced or moved, so that the equipment can be conveniently used in work, meanwhile, manpower loss and harmfulness are reduced, and the working efficiency of the equipment is improved.

Owner:湖南恒信伟业建材有限公司

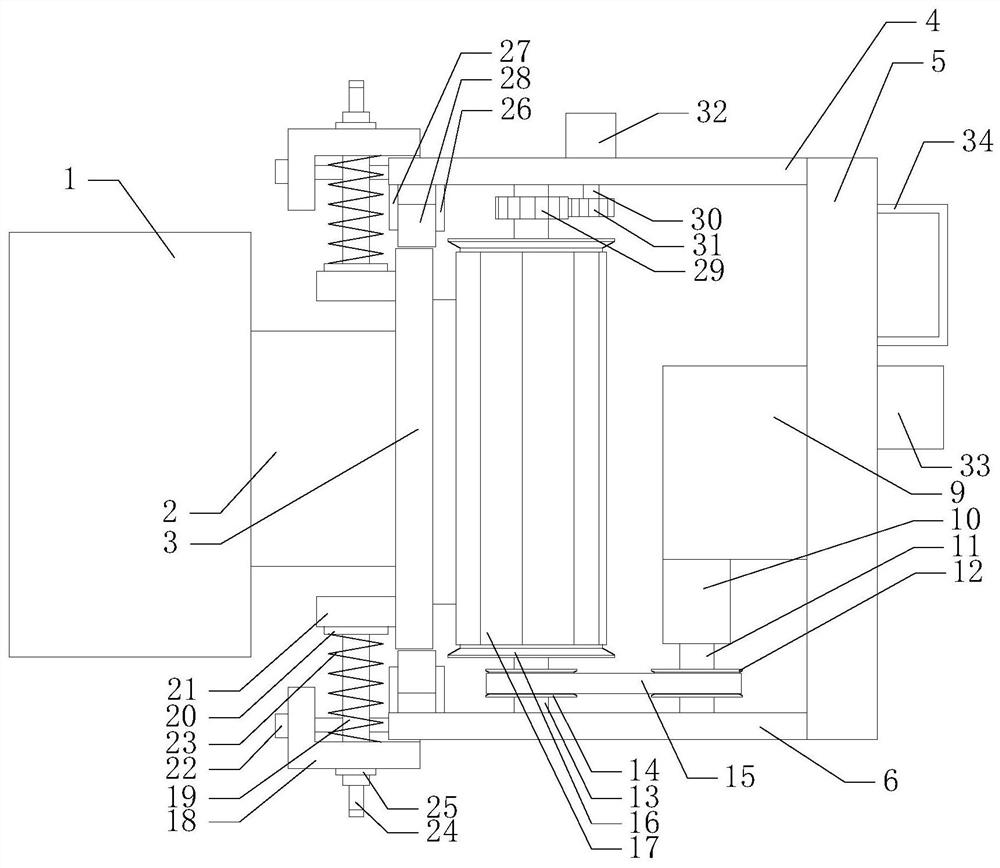

Symmetrical internal combustion engine

ActiveCN113356995AImprove structural stabilityReduce consumptionInternal combustion piston enginesPhysicsPiston

The invention provides a symmetrical internal combustion engine and relates to the technical field of internal combustion engines. The symmetrical internal combustion engine comprises at least two combustion chambers symmetrically arranged at intervals, a piston column, a kinetic energy conversion mechanism and a mounting seat. The piston column is a long-rod-shaped component, the two ends of the piston column are located in the two combustion chambers correspondingly, and the piston column is in sliding connection with the combustion chambers. The kinetic energy conversion mechanism comprises a tooth tool box, a ratchet wheel and an output shaft, the tooth tool box is installed on the piston column in a sliding manner, and the sliding direction of the tooth tool box is perpendicular to the length direction of the piston column. A hollow cavity is formed in the middle of the tooth tool box, ratchets are arranged at the top and the bottom of the cavity in the length direction of the piston column correspondingly, and the ratchets on the two sides face opposite directions. The distance between the ratchets on the two sides is larger than the diameter of the ratchet wheel. The ratchet wheel is matched with the ratchets, and the output shaft is coaxially installed on the ratchet wheel. The mounting seat is used for mounting the combustion chambers and the output shaft, and the output shaft is rotationally mounted on the mounting seat. The symmetrical internal combustion engine has the advantage of preventing the output shaft from being stuck.

Owner:唐显著

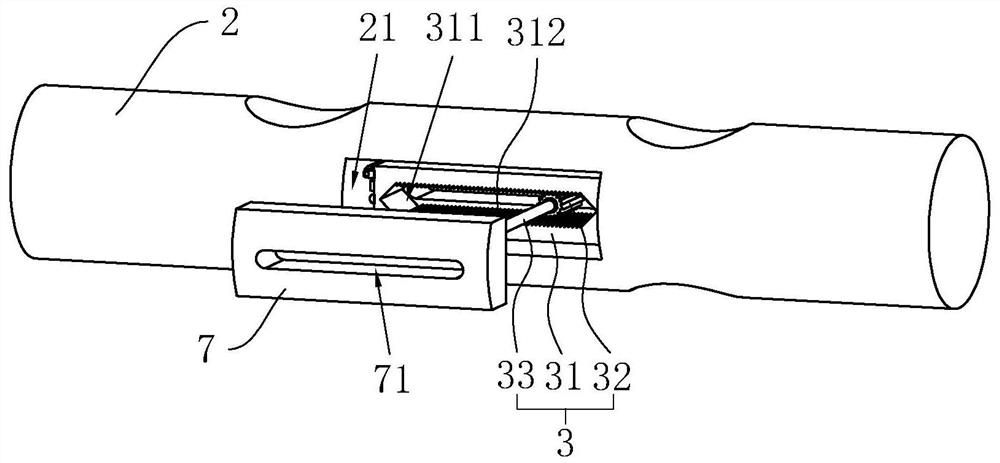

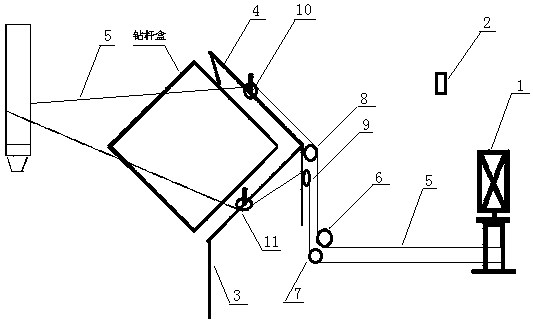

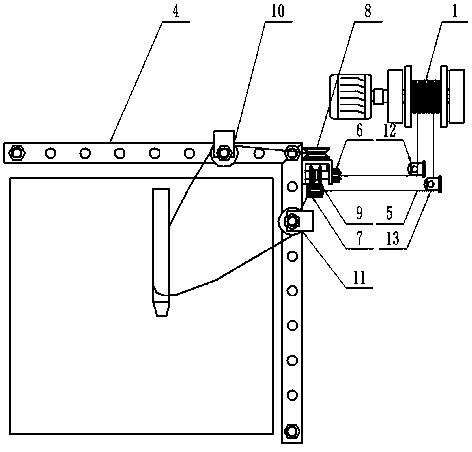

Electric remote control drill tool pulling and sending device and using method thereof

PendingCN110700769AAccess controlReduce security risksDrilling rodsDrilling casingsPull forceBraced frame

The invention relates to an electric remote control drill tool pulling and sending device and a using method thereof. According to the device, a remote control positive and negative rotation motor isused as a power source, a steel wire rope, a turning pulley block and a support frame are matched to form a turning mechanism, tensile force needed for pulling a drill tool is transmitted to a stand column support from a remote control motor roller through the steel wire rope, an operator does not need to carry the drilling tool and support the drilling tool with the hands, the drilling tool can be safely and smoothly controlled to exit from and enter a drill stem box, and therefore the safety risk and the labor strength are greatly reduced; and the electric remote control drill tool pulling and sending device is simple in structure and accurate in positioning, the labor intensity for pushing and pulling the drilling tool to exit form and enter the drilling stem box when a well drilling worker removes the drilling tool can be greatly reduced, and the advantages of safe and convenient operation, labor saving and high efficiency are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

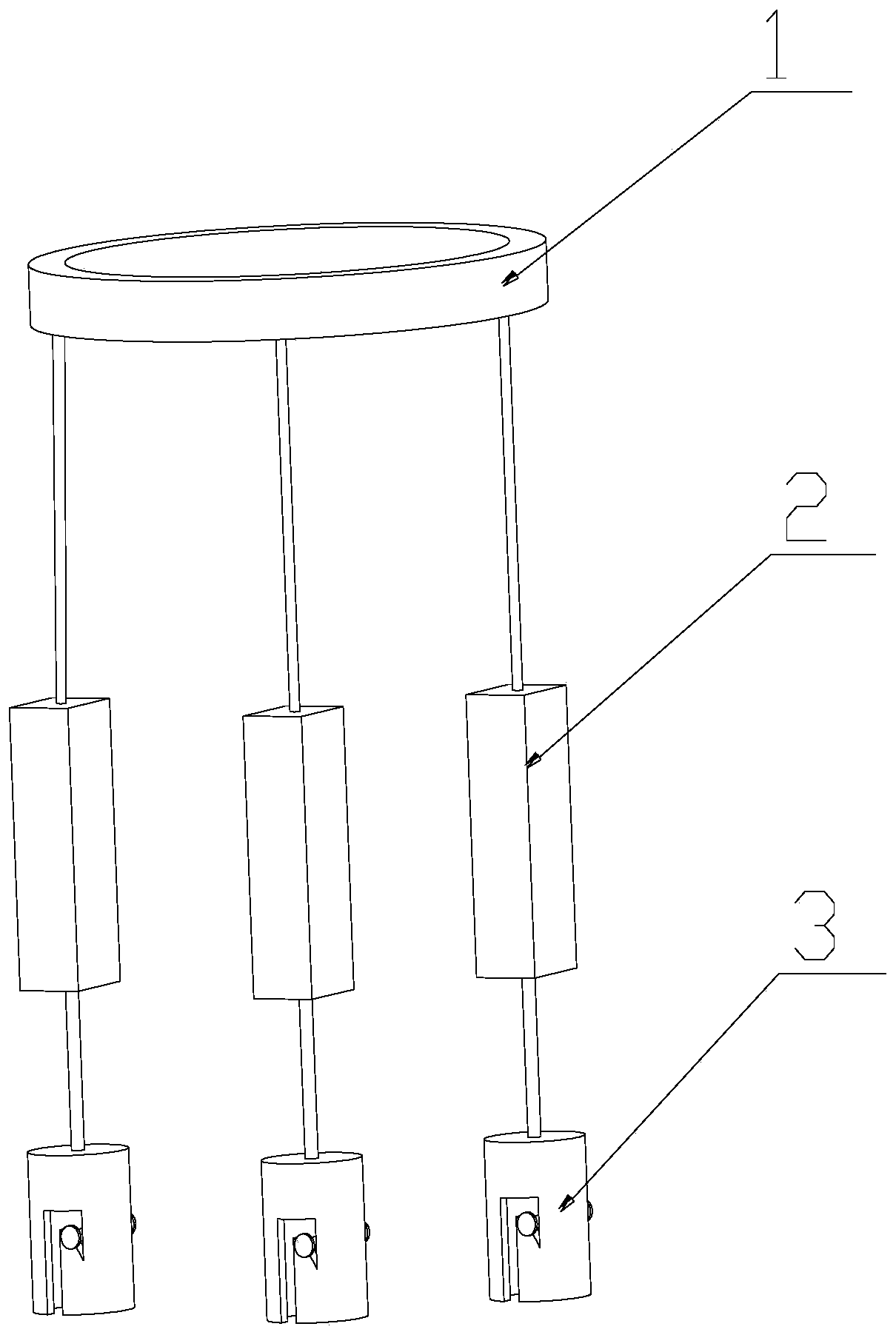

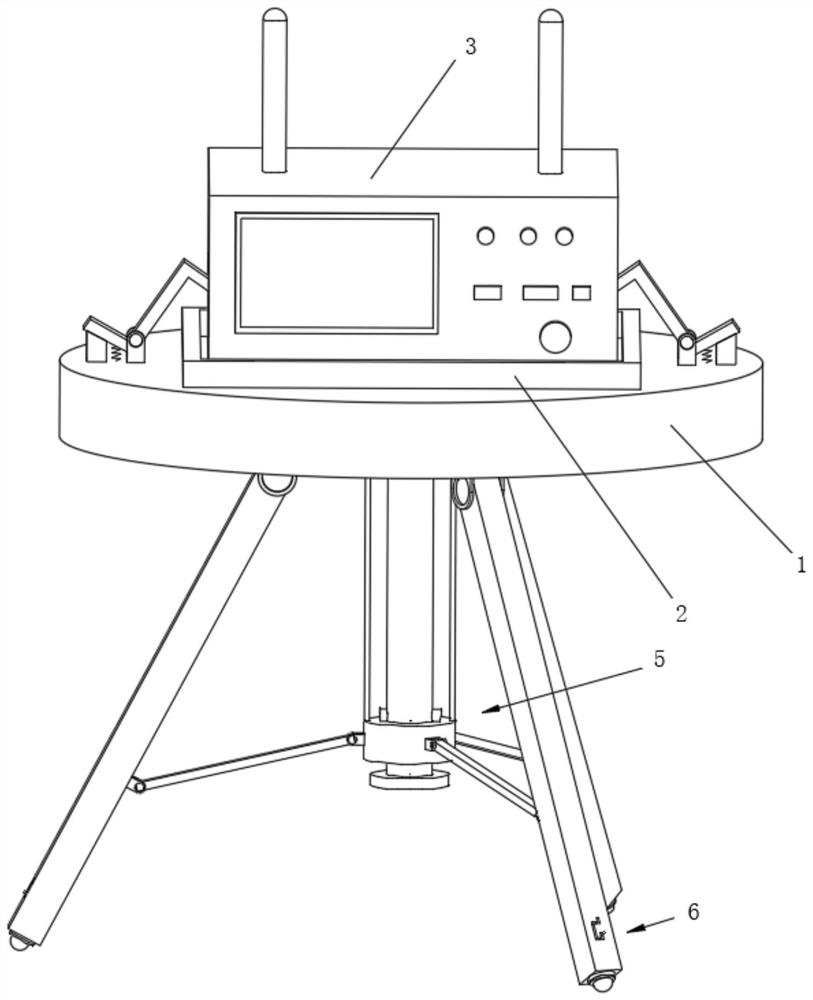

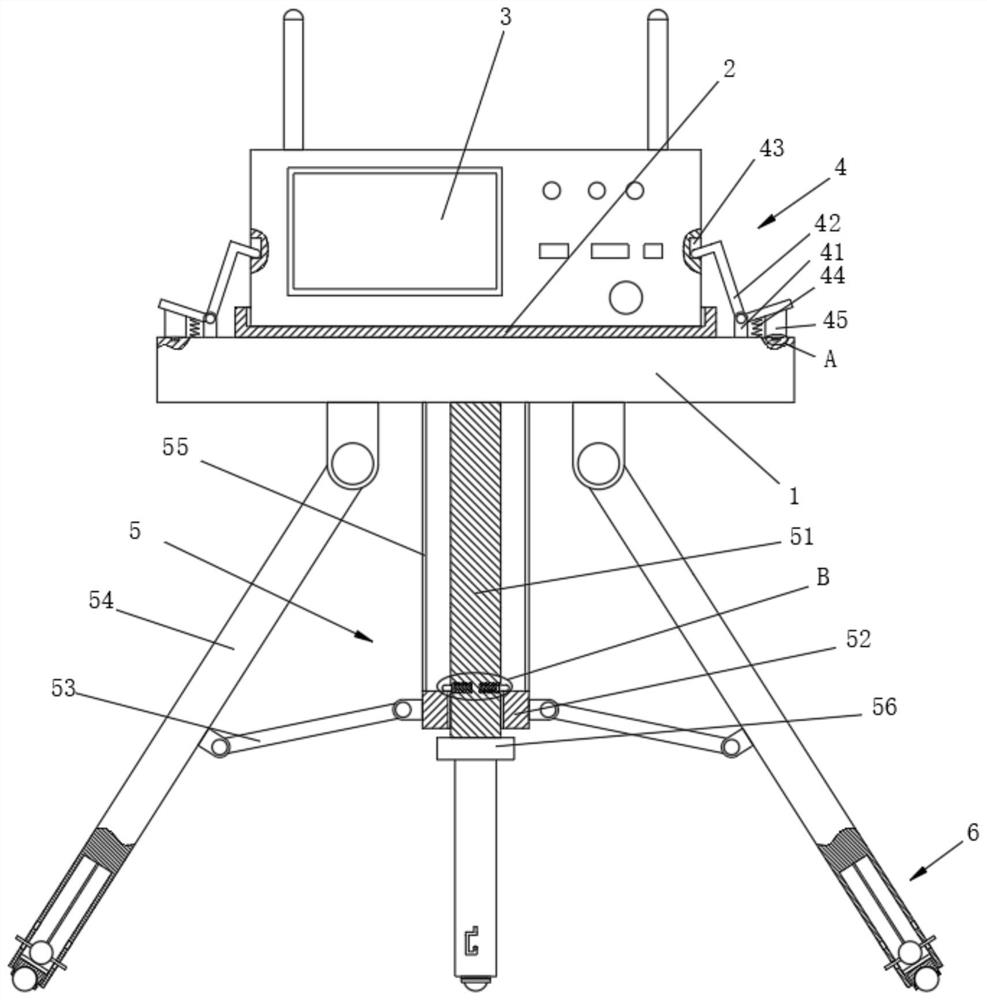

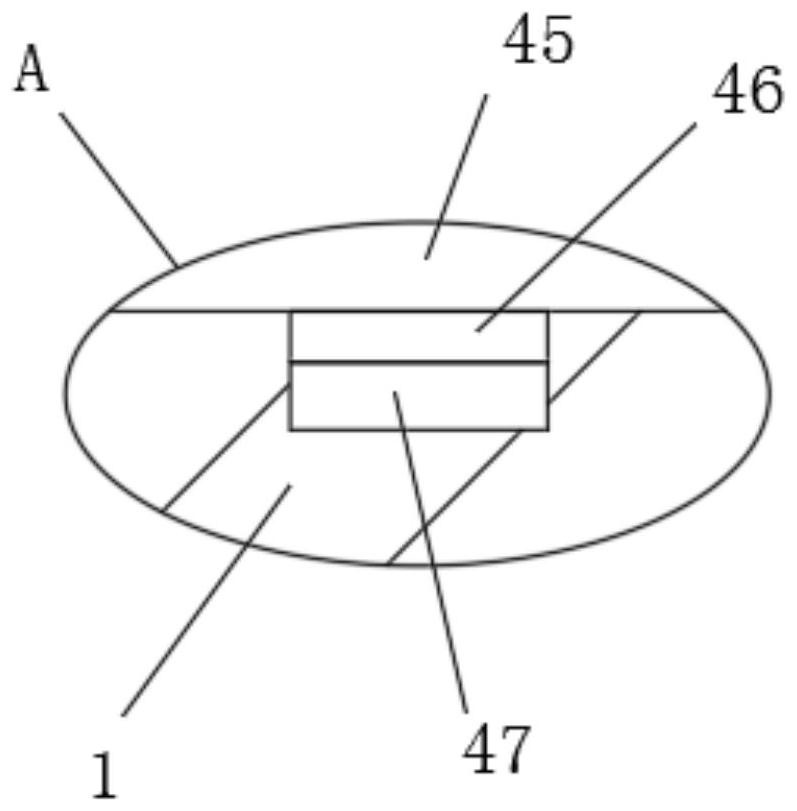

Emergency monitoring system based on cloud computing of Internet of Things

InactiveCN114352864AStable supportAvoid influenceMeasurement apparatus componentsStands/trestlesEnvironmental monitorMonitoring system

The invention discloses an emergency monitoring system based on Internet of Things cloud computing, which comprises a fixed seat, a limiting sleeve, an environment monitor, a limiting mechanism, a supporting mechanism and a moving mechanism, and is characterized in that the fixed seat is fixedly connected with the limiting sleeve, the limiting sleeve is rectangular, and the environment monitor is slidably connected in the limiting sleeve; two symmetrically distributed limiting mechanisms are arranged on the fixed seat, the limiting mechanisms are clamped with the environment monitor, a supporting mechanism is arranged at the bottom of the fixed seat, and a moving mechanism is arranged at the bottom of the supporting mechanism. The invention relates to an emergency monitoring system based on Internet of Things cloud computing. The emergency monitoring system has the advantages of being stable in supporting and convenient to change positions.

Owner:深圳市子元工业技术有限公司

Fixing device for plastic pipes for bridge

InactiveCN108266574AEnsure stable and reliable installationImprove stabilityPipe supportsEngineeringSurface plate

The invention discloses a fixing device for plastic pipes for a bridge. The fixing device comprises a mounting seat and a fixing structure, wherein the fixing structure is arranged on the mounting seat. The mounting seat comprises an insertion column body and an abutting panel, wherein the abutting panel is fixed to the outer side end of the insertion column body. The insertion column body is internally provided with a cavity. Abutting clamping teeth are uniformly fixed to the side wall of the insertion column body, wherein the abutting clamping teeth communicate with the cavity. A screw holeis fixedly formed in the center of the abutting panel, wherein the screw hole communicates with the cavity. The cavity is internally provided with a conical abutting block. The screw hole is internally provided with a screw rod. Column bodies are uniformly fixed to the outer side face of the abutting panel. The fixing structure comprises a fixing seat, a U-shaped clamping block and an n-shaped buckling block, wherein the U-shaped clamping block and the n-shaped buckling block are arranged on the fixing seat. Insertion holes are fixedly formed in the side face of the fixing seat, wherein the insertion holes are matched with the column bodies. Locking position screw rods are fixed to the side wall of the fixing seat, wherein the locking position screw rods are matched with the insertion holes. The fixing device is reasonable in structural arrangement; the mounting seat can be separated from the fixing structure; it can be guaranteed that the mounting seat is mounted stably and reliably;and the fixing device is convenient and fast to operate, good in use stability and great in adaptability.

Owner:王恒标

mobility aids

ActiveCN111917050BEasy to change positionImprove securityApparatus for overhead lines/cablesReduction driveElectric machinery

The invention provides a mobile auxiliary device suitable for assisting movement on a power transmission line iron tower, which includes a fixing part, a slideway, a frame, a driving device, a guiding device and a connecting part. The fixing part fixedly connects the slideway to the iron tower, and the slideway is provided with racks of teeth and is located on one side of the frame. The driving device includes a motor, a speed reducer, a first rotating shaft, a second rotating shaft, a first pulley, a second pulley, a first belt, a running wheel and a toothed belt. Two sets of guides are respectively located at the top and bottom of the slideway. The connecting part includes a connecting piece and a hanging rope, and the connecting piece connects the frame with one end of the hanging rope. The mobile auxiliary equipment provided by the embodiment of the present invention can drive the human body to move, which is convenient for workers to change positions on the iron tower, saves the physical strength and time of bare-handed movement, improves the safety of workers working on the iron tower, and enables the monitoring and maintenance of the transmission line iron tower Work more convenient and efficient, improve work efficiency.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com