Symmetrical internal combustion engine

An internal combustion engine, symmetrical technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as output shaft jamming, achieve the effects of prolonging service life, reducing consumption, and enhancing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

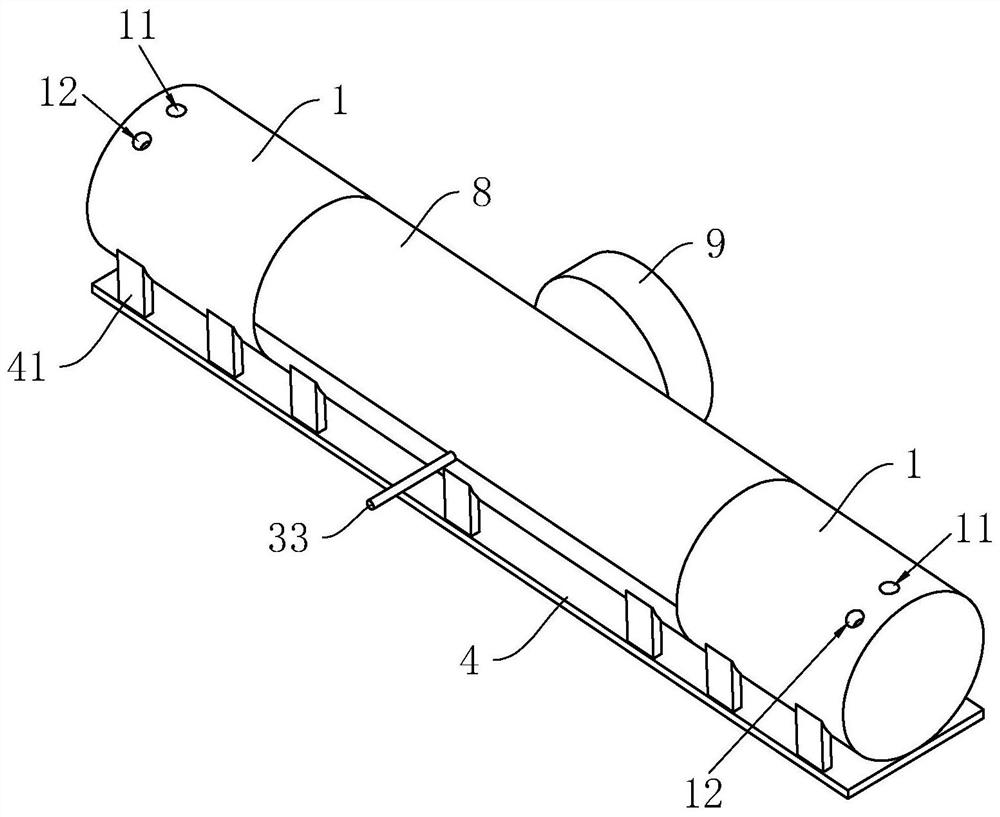

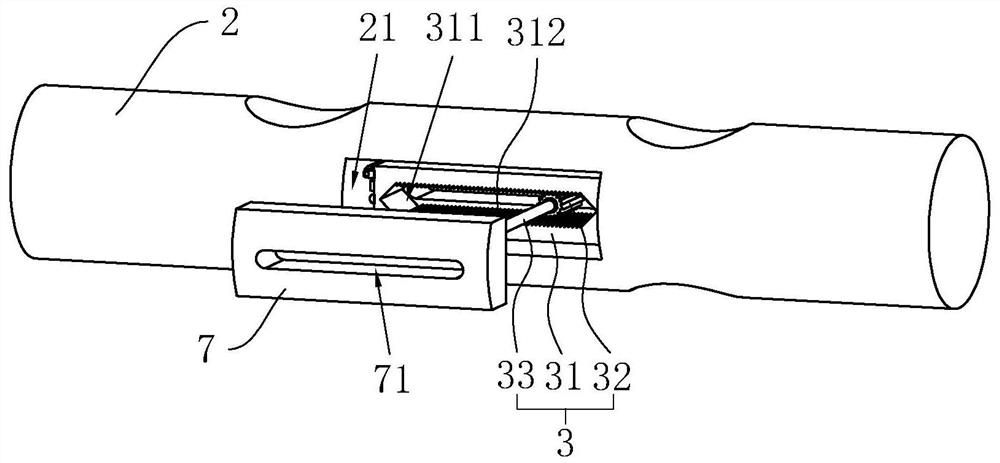

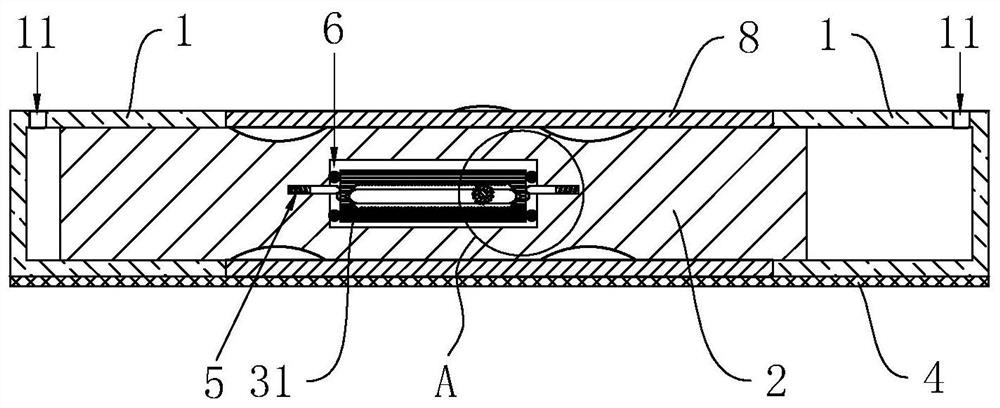

[0038] A symmetrical internal combustion engine, referring to Figure 1-Figure 4 , including at least two symmetrically arranged combustion chambers 1, a piston rod 2 slidingly arranged between the two symmetrically arranged combustion chambers 1, a kinetic energy conversion mechanism 3 slidingly arranged on the piston rod 2, and a fixed combustion chamber for installation Mount 4 for chamber 1. Using the kinetic energy conversion mechanism 3 of the internal combustion engine to convert the reciprocating motion of the piston rod 2 into a circumferential motion, the possibility of the components of the internal combustion engine being stuck can be eliminated, and the reliability of the internal combustion engine is improved.

[0039] The mounting base 4 is a flat member, the mounting base 4 can be made of steel plate, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com