Fixing device for plastic pipes for bridge

A technology for fixing devices and plastic pipes, which is applied in the direction of pipe brackets, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems affecting the convenience and reliability of operation, applicability and practical limitations, and achieve convenient maintenance and Change the position, ensure the stability and reliability of the installation, and the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

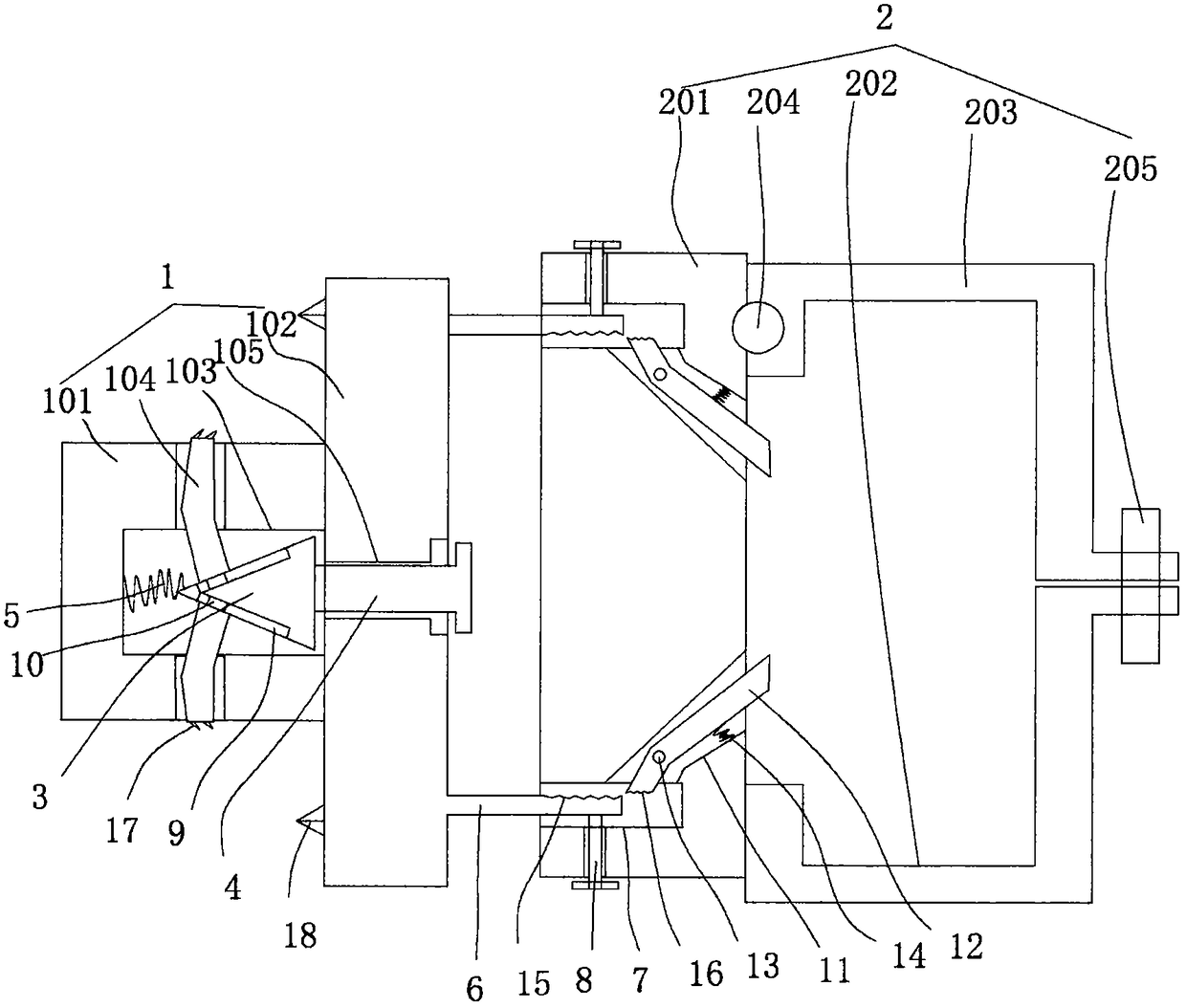

[0015] figure 1 A specific embodiment of the present invention is shown, wherein figure 1 It is a schematic diagram of the structure of the present invention.

[0016] see figure 1 , A plastic pipe fixing device for a bridge, comprising a mounting base 1 and a fixing structure 2 arranged on the mounting base 1. The mounting base 1 includes a plug-in column 101 and a pressure panel fixed on the outer end of the plug-in column 101 102. A cavity 103 is provided in the plug-in cylinder 101, and a pressing tooth 104 communicating with the cavity 103 is uniformly fixed on the side wall of the plug-in cylinder 101. The center of the panel 102 is fixed with a screw hole 105 communicating with the cavity 103, a conical abutment block 3 is arranged in the cavity 103, and a screw 4 is arranged in the screw hole 105. The inner end is pressed against the big end of the cone block 3, the inner side of the pressing tooth 104 is pressed against the surface of the cone block 3, and the cone ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com