Electric remote control drill tool pulling and sending device and using method thereof

A drilling tool and electric technology, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of occupying drill floor area, injury of wellhead personnel, and large swing range of drill pipe, so as to reduce safety risks and labor intensity. The effect of reducing labor intensity and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

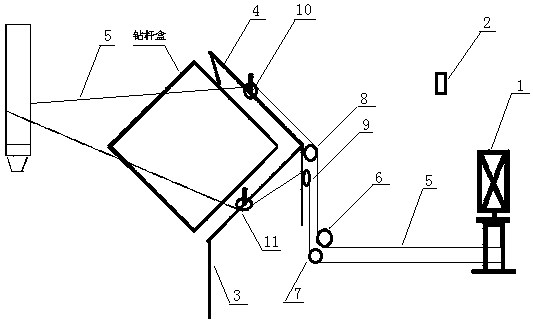

[0036] The first embodiment of the present invention relates to an electric remote control drilling tool pulling device, such as figure 1 As shown, it includes a remote control motor 1, a support frame, a first fixed pulley block, a second fixed pulley block and a steel wire rope 5. The support frame is fixed on the drill floor outside the drill rod box, and the first diverting pulley block is fixed on the support frame. and the second diverting pulley block, the first fixed pulley block and the second fixed pulley block are fixed on the drill floor; one end of the steel wire rope 5 is wound on the drum of the remote control motor 1, and the other end of the steel wire rope 5 passes through the first fixed pulley block in sequence , the first deflection pulley block, the second deflection pulley block and the second fixed pulley block are wound back on the cylinder of the remote control motor 1, and the steel wire rope 5 between the first deflection pulley block and the second ...

no. 2 approach

[0046] This embodiment relates to an electric remote control drilling tool pulling device, such as figure 1 As shown, it includes a remote control motor 1, a support frame, a first fixed pulley block, a second fixed pulley block and a steel wire rope 5. The support frame is fixed on the drill floor outside the drill rod box, and the first diverting pulley block is fixed on the support frame. and the second steering pulley block, the first fixed pulley block and the second fixed pulley block are fixed on the drill floor; further, the support frame is composed of three column supports 3 and two beams 4, and the three column supports 3 are vertically parallel set, and its upper end is vertically connected by two beams 4 to form a right-angled frame structure, and the right-angled diagonal of the right-angled frame structure is aligned with the wellhead;

[0047] The first deflection pulley set includes the first deflection pulley 10 and pulley three 8, the second deflection pulle...

no. 3 approach

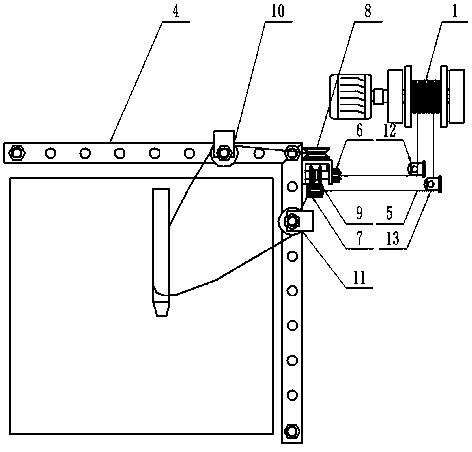

[0059] This embodiment relates to an electric remote control drilling tool pulling device, such as figure 2 As shown, it includes a remote control motor 1, a remote control 2, a support frame, a first fixed pulley block, a second fixed pulley block and a wire rope 5. The remote control motor 1 is installed on the farthest corner of the drill floor, and the remote control 2 can be Control the forward or reverse rotation of the remote control motor 1, the support frame is fixed on the drill floor surface outside the drill rod box, the first steering pulley block and the second steering pulley block are fixed on the support frame, the first fixed pulley block and the second The two fixed pulley blocks are all fixed on the drill floor; further, the support frame is composed of three column supports 3 and two beams 4, and the three column supports 3 are vertically arranged in parallel, and their upper ends are vertically connected by two beams 4 to form a right angle Shaped frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com