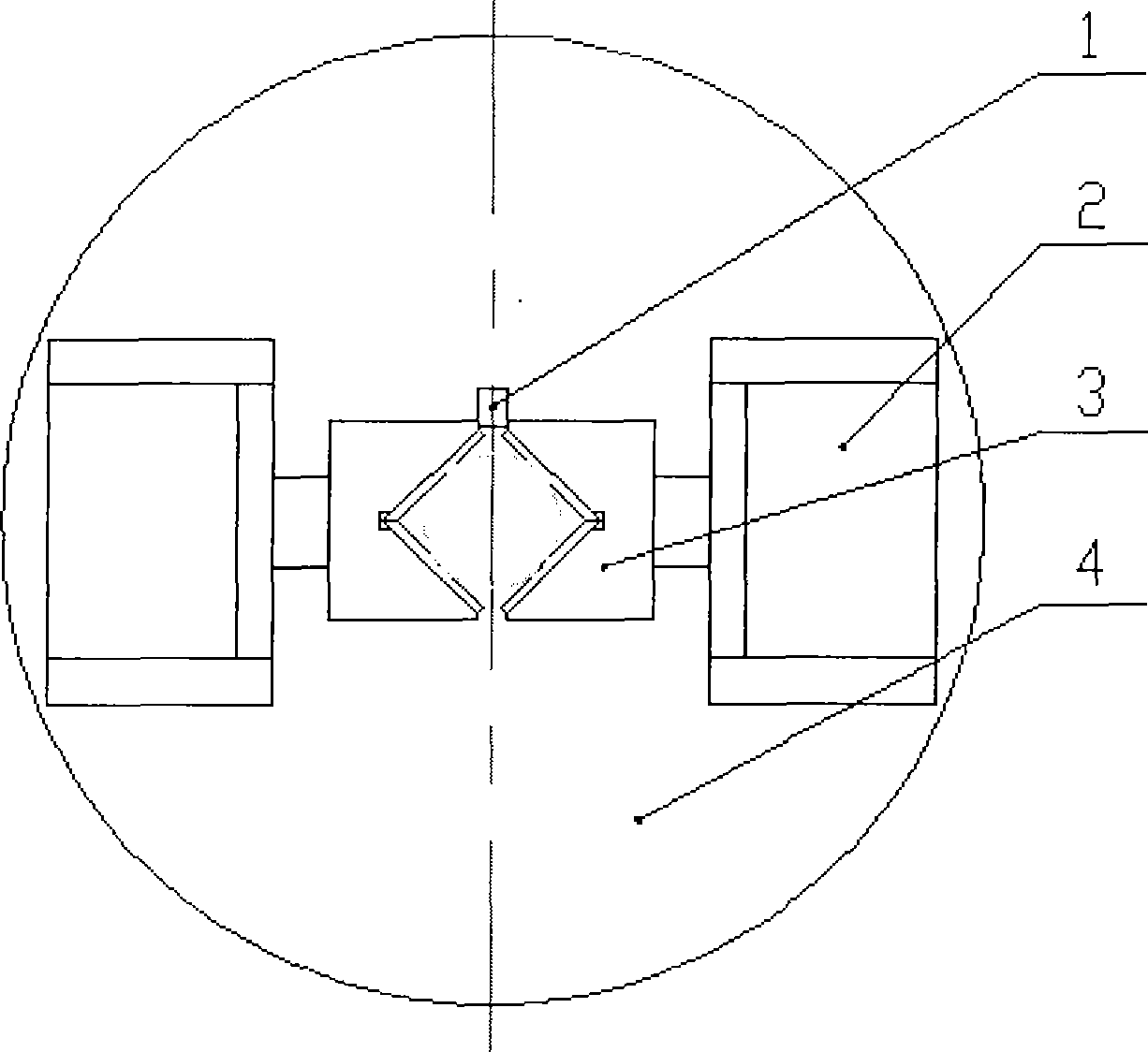

Linkage rod type air chuck for laser pipe cutter

A technology of pneumatic chuck and pipe cutting machine, which is applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc. It can solve the problems of inaccurate centering, less suitable pipe diameter, and large influence of pipe diameter tolerance. Realize the effect of automatic control of loose clamp and adjustable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

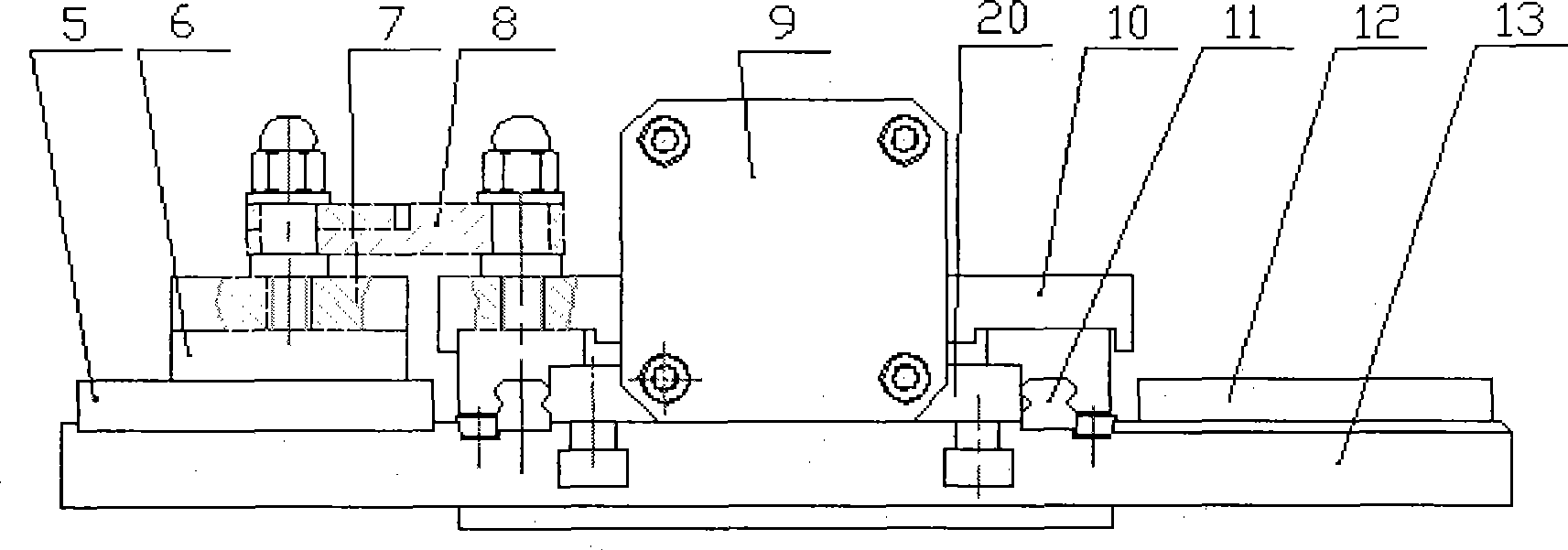

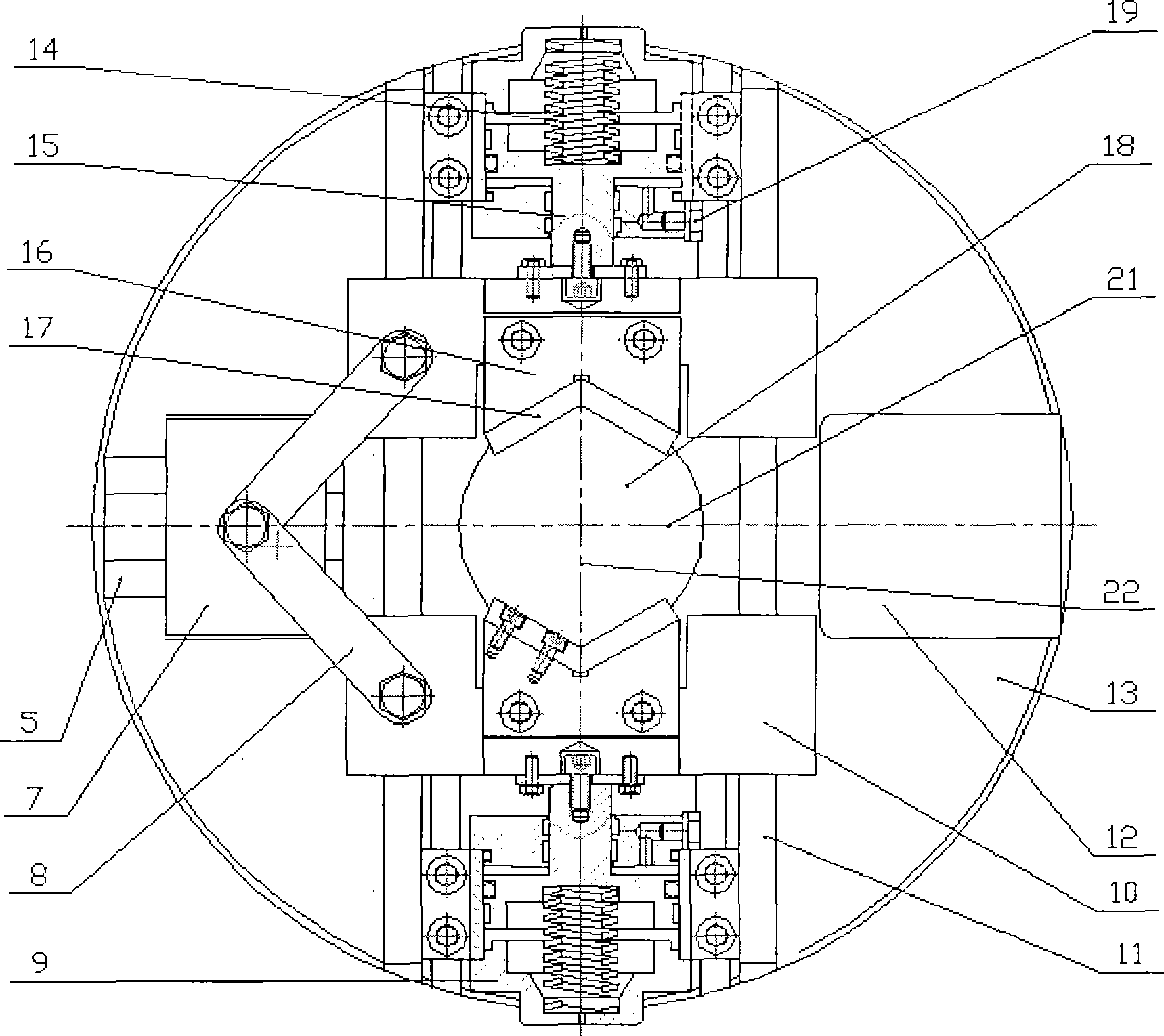

[0010] The invention according to figure 2 , image 3 The structure shown is implemented, wherein the horizontal transverse guide rail 5 and the horizontal longitudinal guide rail 11 are linear rolling guide rails produced by Dalian Hanyi Seiko Enterprise Co., Ltd. (the models are respectively BRH15B2L360HZ1 II and BRH15B2L98HZ1 II), and the spring 14 is adopted from Japan Co., Ltd. Tokyo The mold spring produced by the clockwork factory (model is TM27×050), the disc body seat 13, the weight block 12 adopts Q235, the gasket 17 adopts T10, and the remaining parts are connecting rod 8, cylinder 9, cylinder connecting seat 20, piston 15. Clamp block 16, horizontal vertical slide plate 10, horizontal horizontal slide plate 7, and slide block 6 are all made of 45# steel. The size of the entire chuck is designed according to the diameter of the processed pipe, and the size of each component involved is based on the size of the chuck. The size of the disk is designed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com