Back distribution type front pneumatic chuck

A technology of pneumatic chucks and chucks, applied in the direction of chucks, etc., can solve the problems of difficult installation of rotary cylinders, inability to realize equipment automation, limited tail space, etc., and achieve the effects of improving productivity, shortening clamping time, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

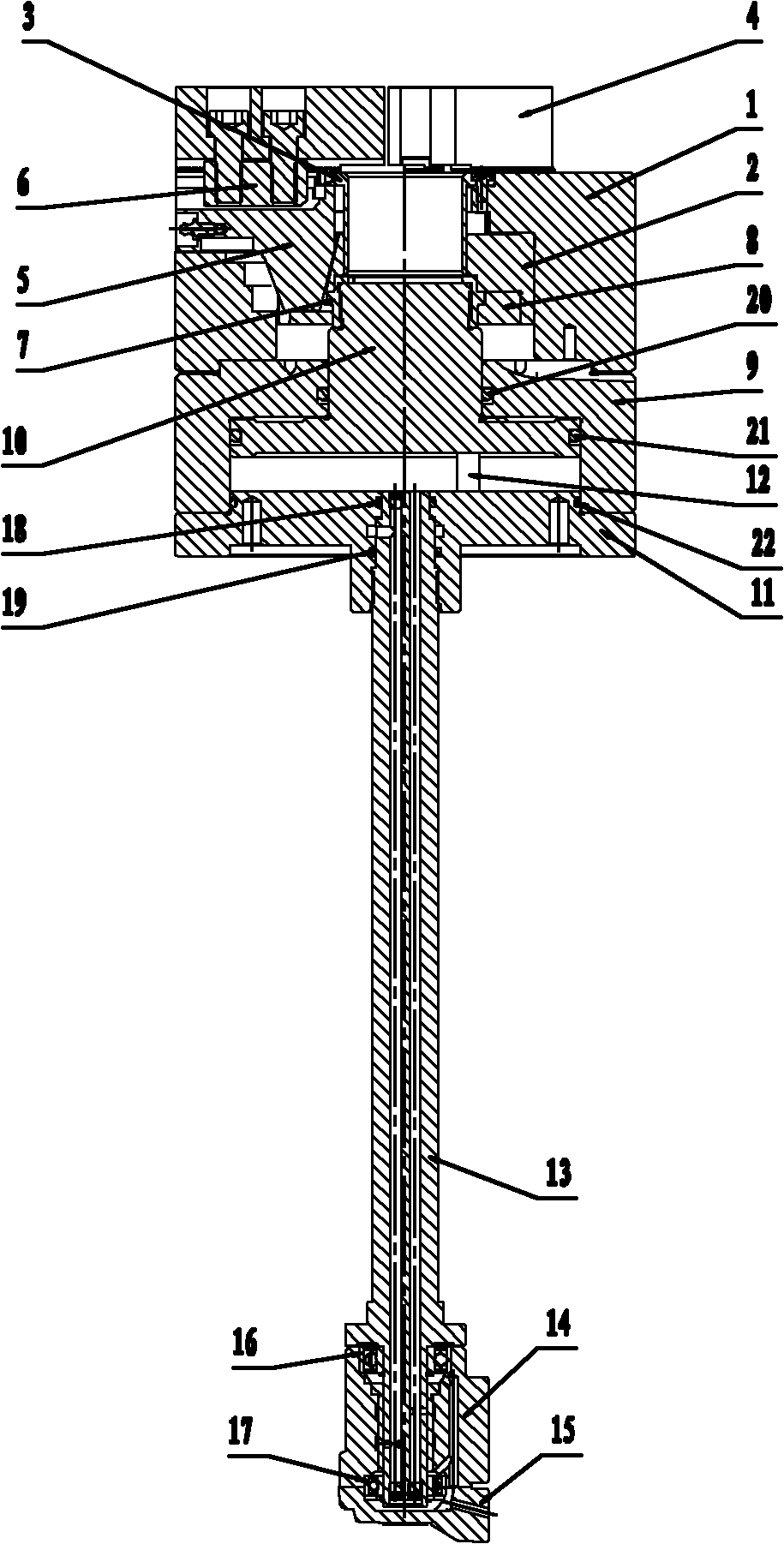

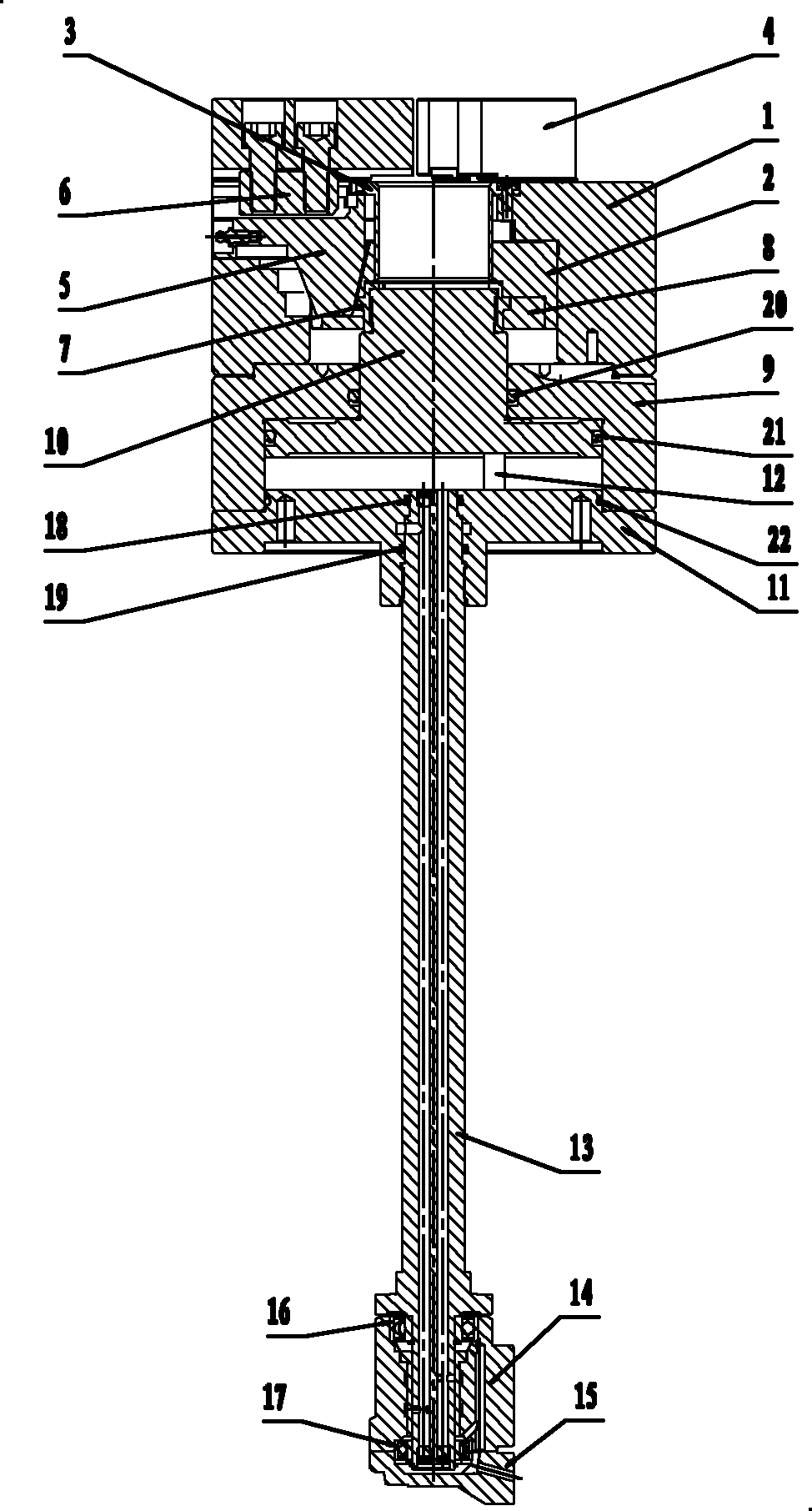

[0011] Such as figure 1 As shown, it includes chuck body 1, wedge sleeve 2, cover 3, three claws 4, three sliding seats 5, three T-blocks 6, push-pull sleeve 7, push-pull ring 8, cylinder body 9, piston 10. Base 11, guide shaft 12, valve stem 13, valve body 14, valve cover 15, bearings 16~17, first sealing ring 18, second sealing ring 19, third sealing ring 20, fourth sealing ring 21, The fifth sealing ring 22 .

[0012] In the present invention, the chuck body 1 and the cover 3 are connected to form the chuck main body, and three straight grooves are provided at the front end of the chuck body 1, and three sliding seats 5 are installed in the three straight grooves, and the three sliding seats 5 pass through the chute and the wedge The heart sleeve 2 is connected, and the three sliding seats 5 are connected with the three claws 4 through the comb te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com