Patents

Literature

56results about How to "Shorter clamping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

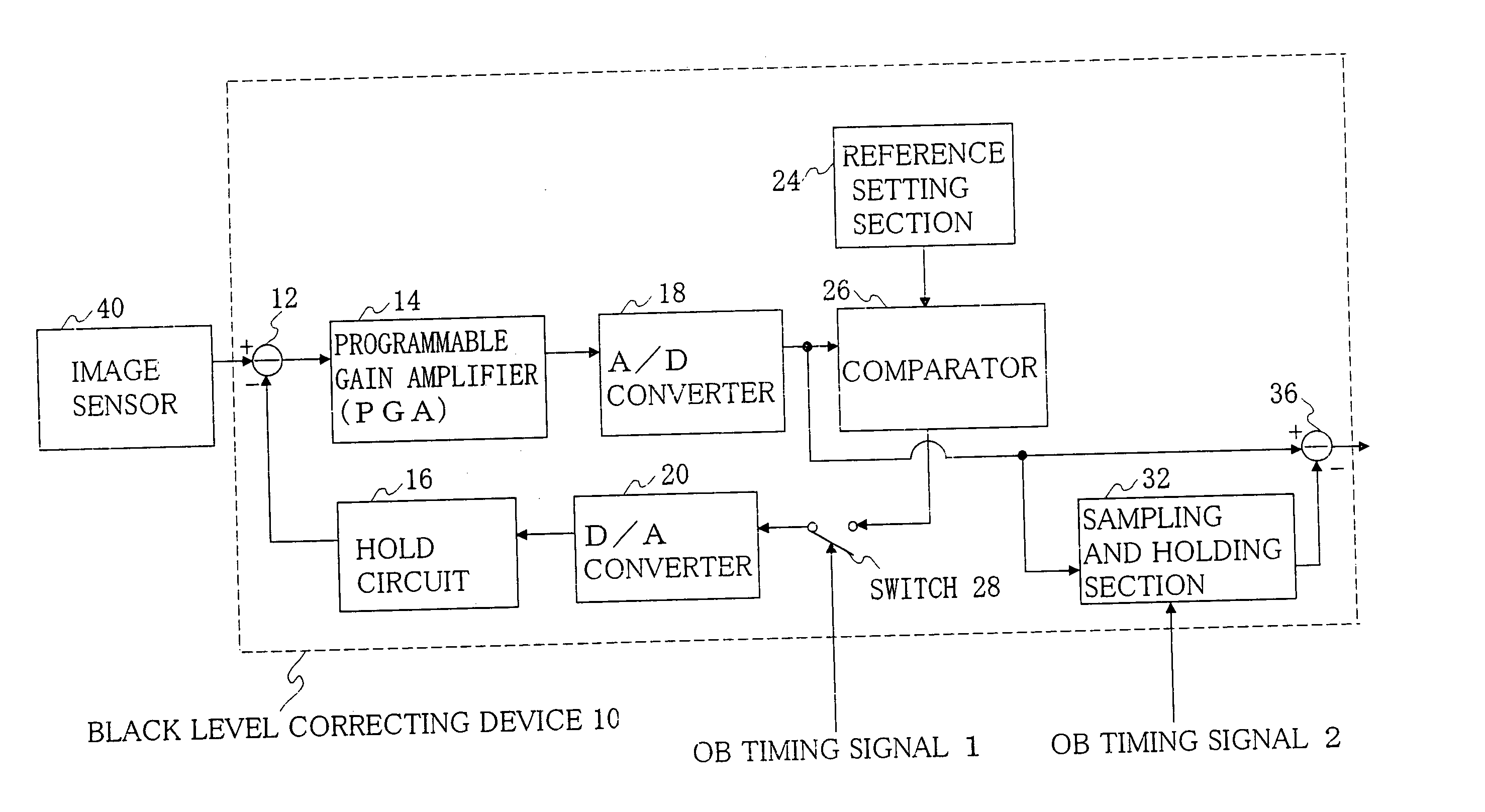

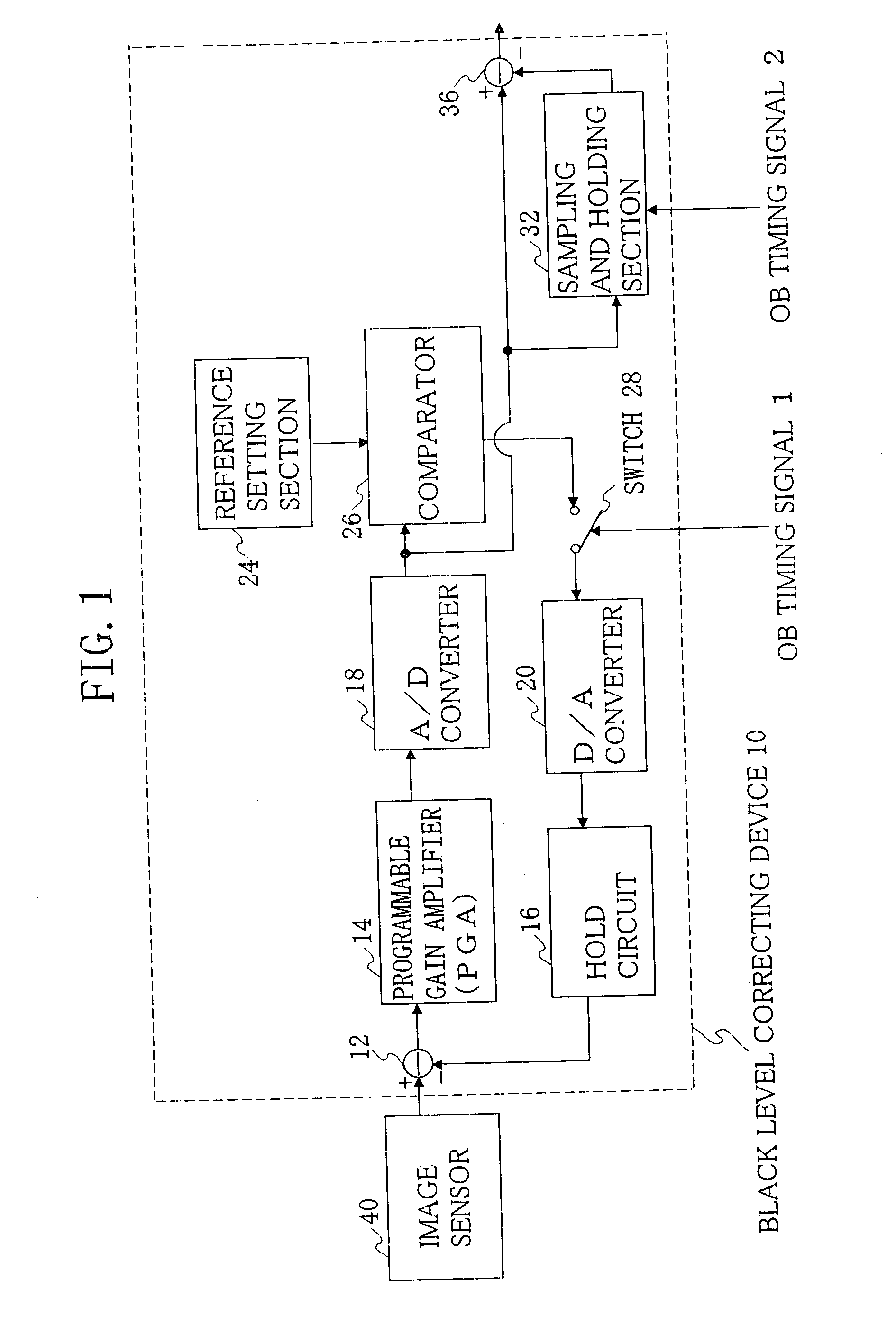

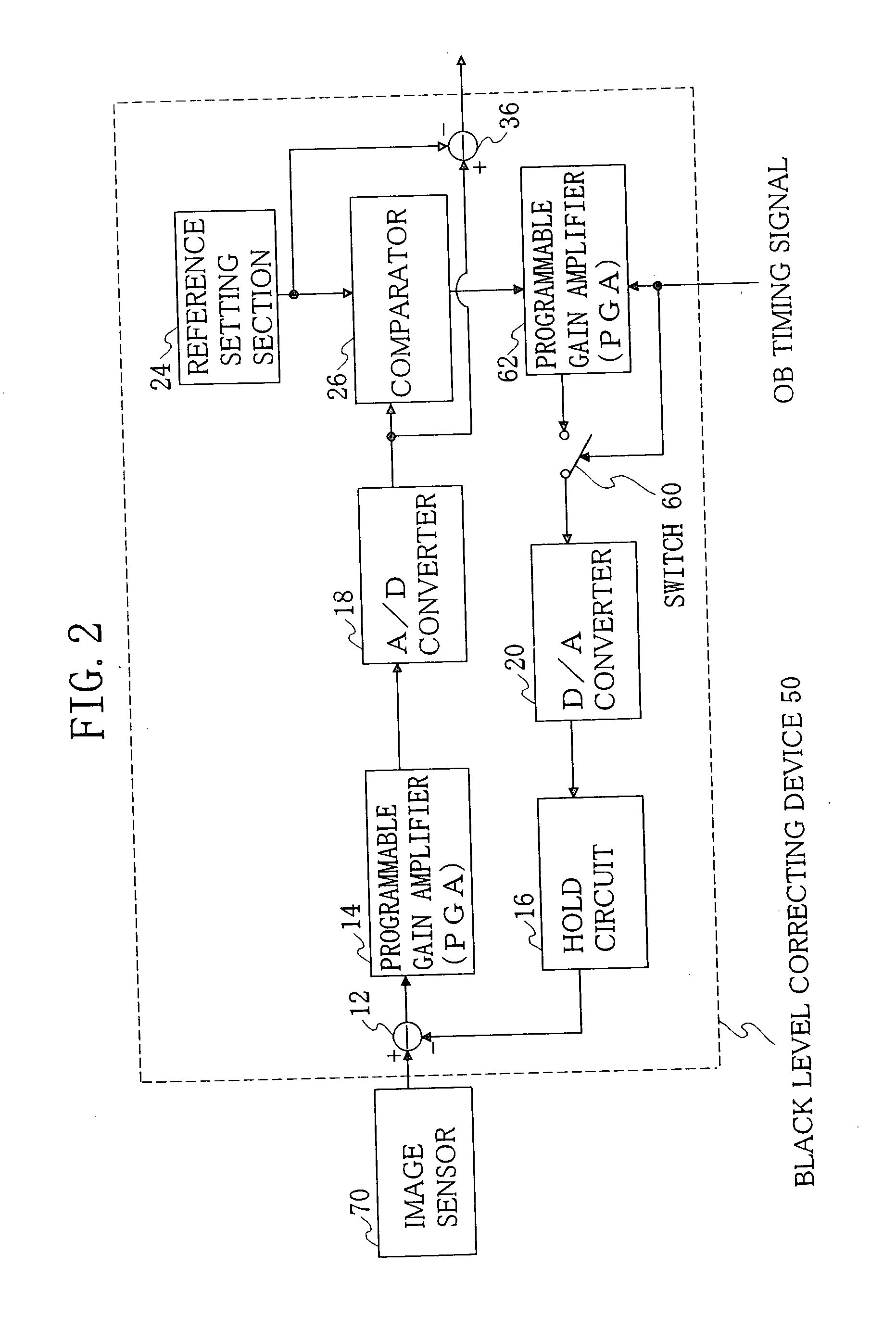

Black level correcting device and electronic camera

InactiveUS7432965B2Reduce saggingSimple structureTelevision system detailsTelevision system scanning detailsEngineeringFeedback control

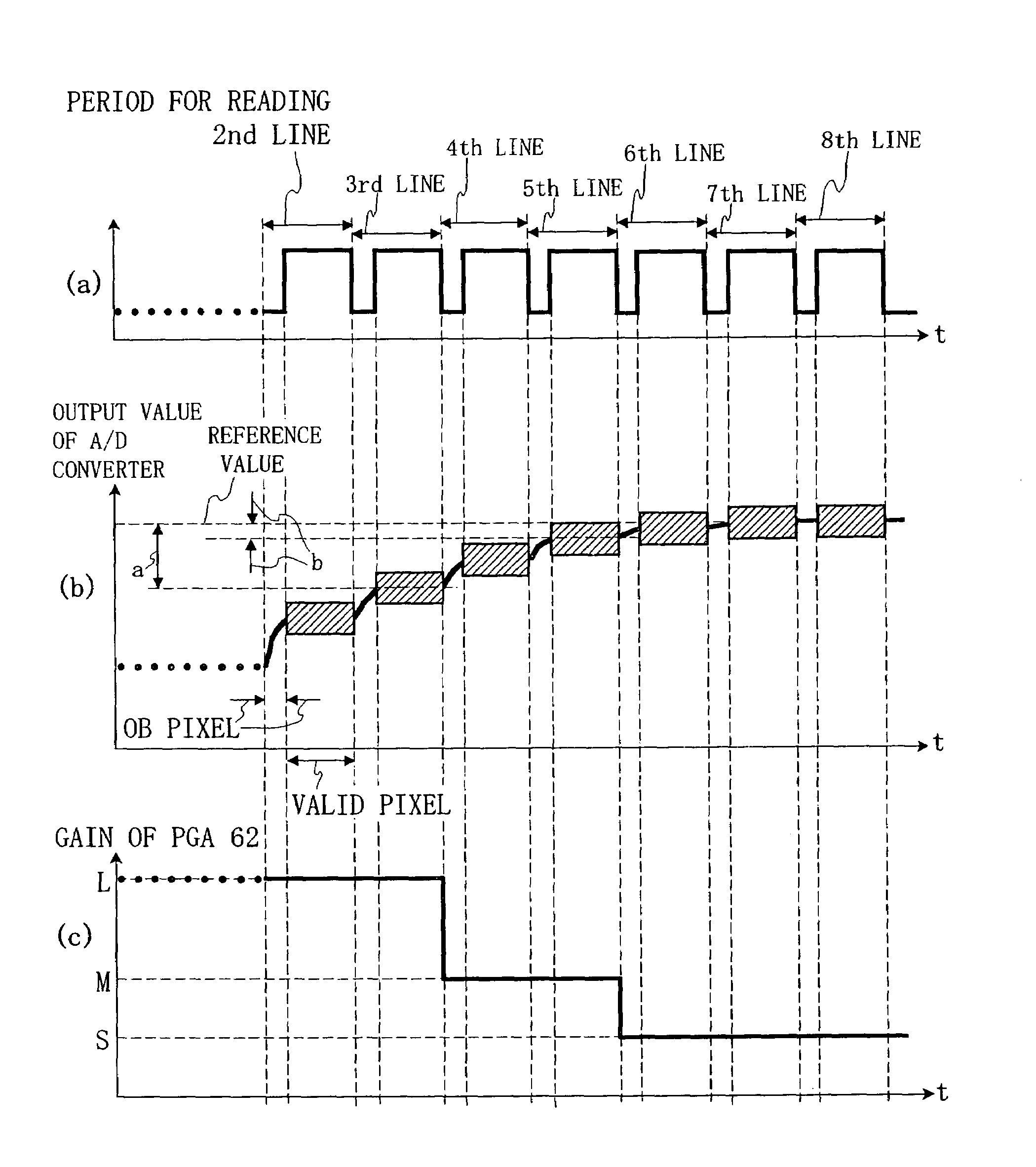

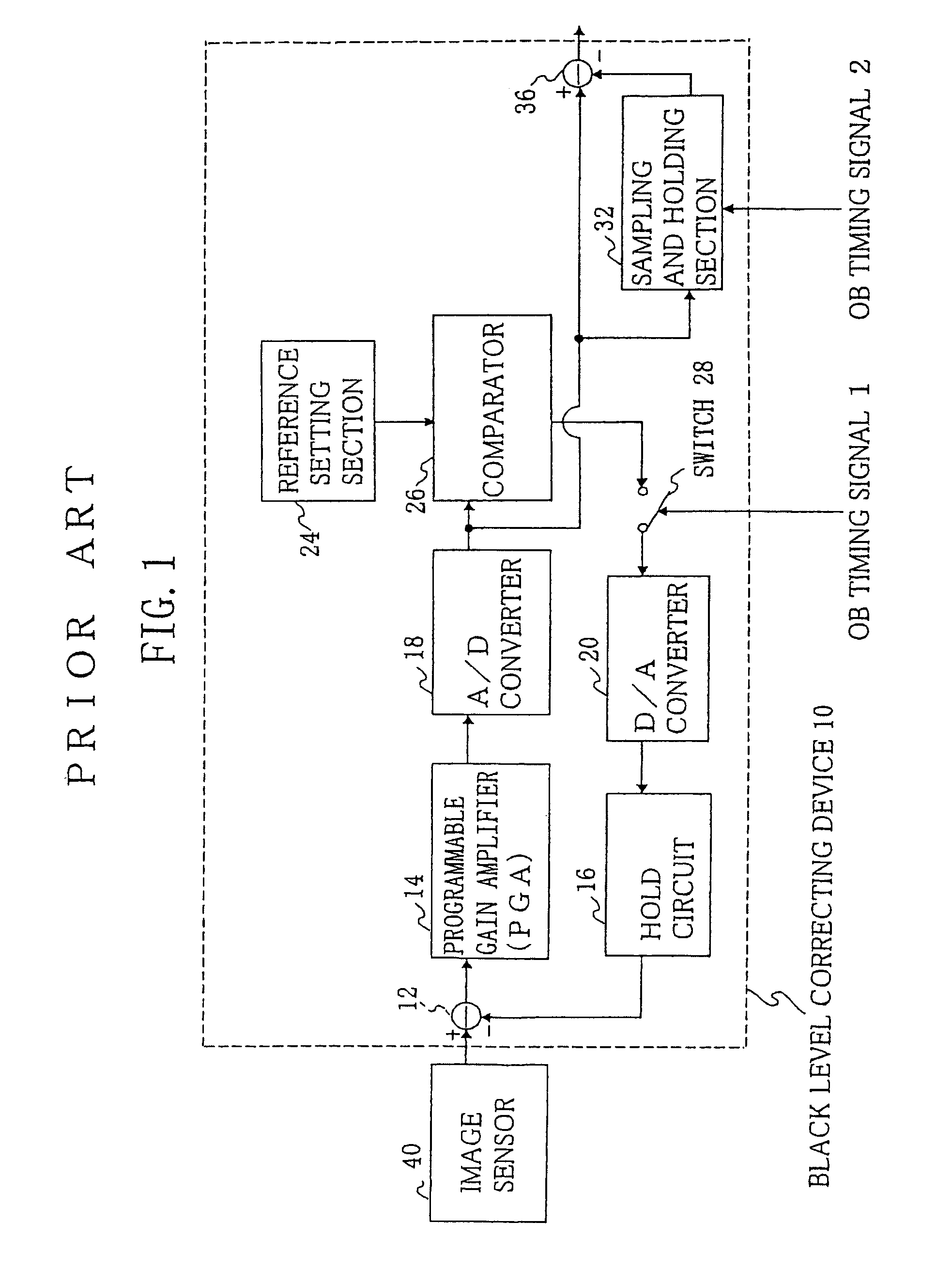

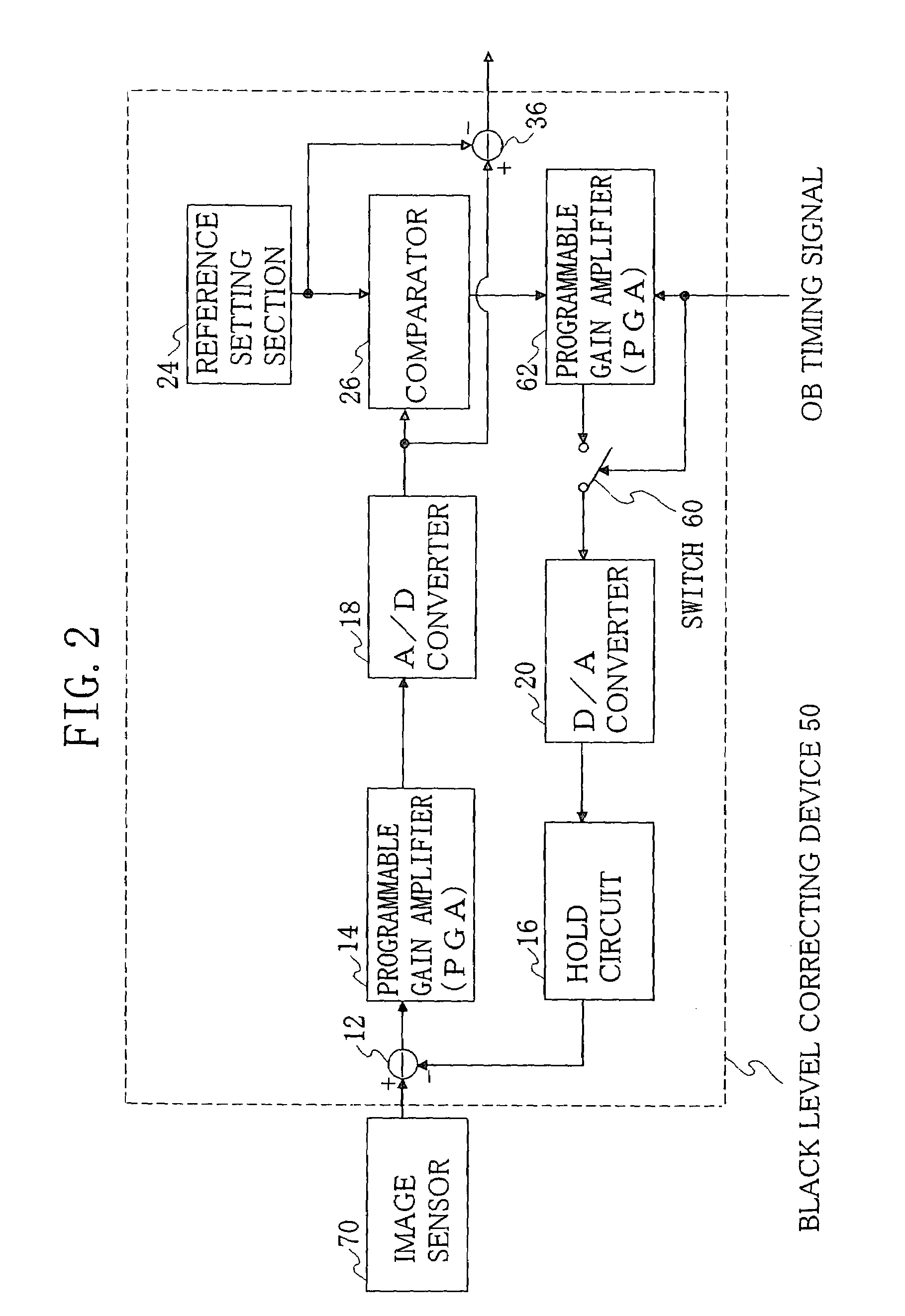

A black level correcting device includes: an A / D converting section converting a result of subtracting a feedback signal from an input pixel signal into a pixel value to be output; and a feedback controlling section generating the feedback signal and having a holding section, a feedback gain adjusting section, etc. The holding section clamps a maintaining level to the level of the feedback signal while pixel signals of OB pixels are output, and maintains and outputs the maintaining level while pixel signals of valid pixels are output. The feedback gain adjusting section multiplies the feedback signal by clamp accelerating gain in synchronization with starting readout of the pixel signals from the OB pixels. Accordingly, clamp time of the holding section is shortened, enabling stabilization of the maintaining level at a convergence level before starting readout of the pixel signals from the valid pixels. Consequently, a sag can be reduced.

Owner:NIKON CORP

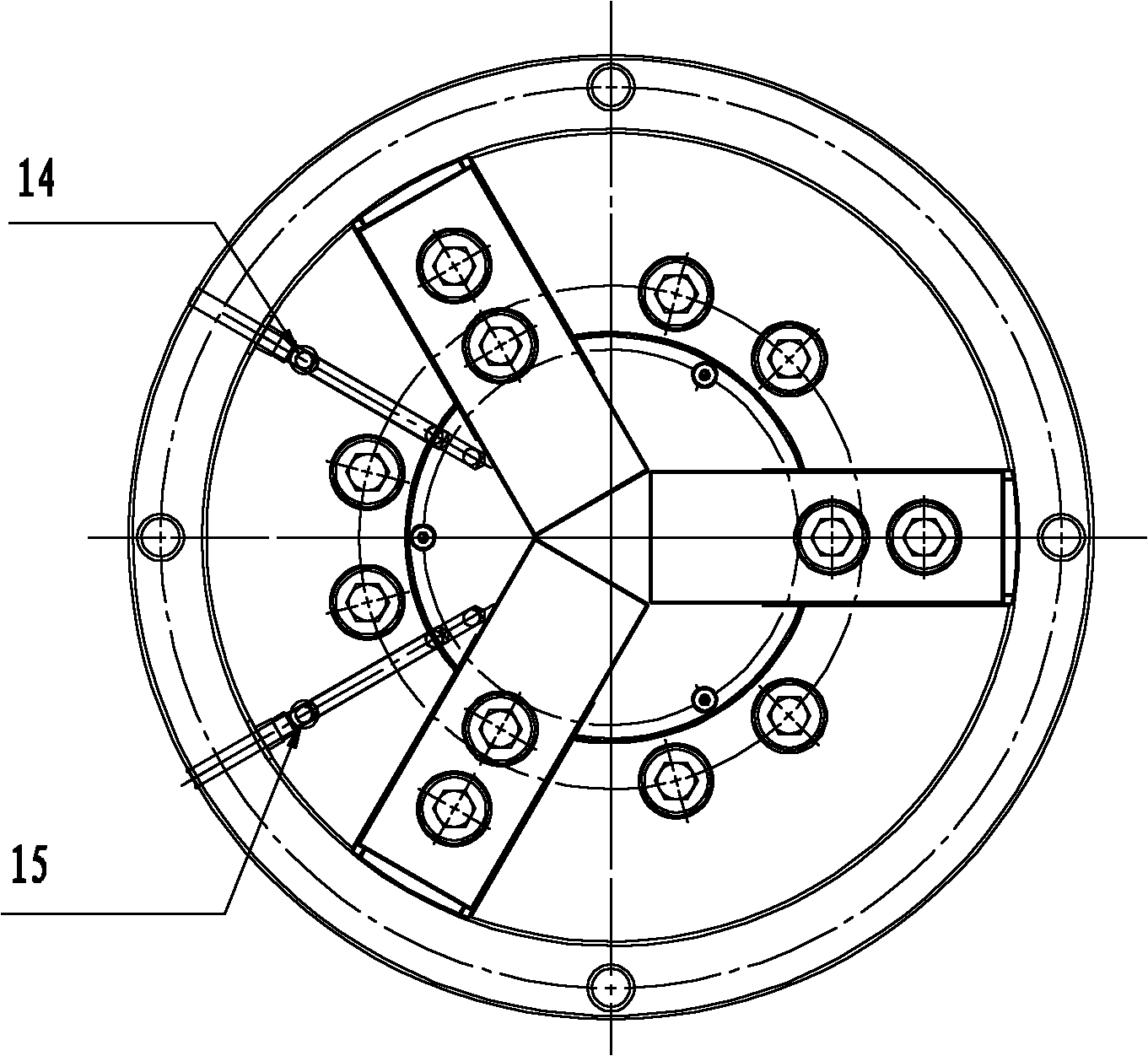

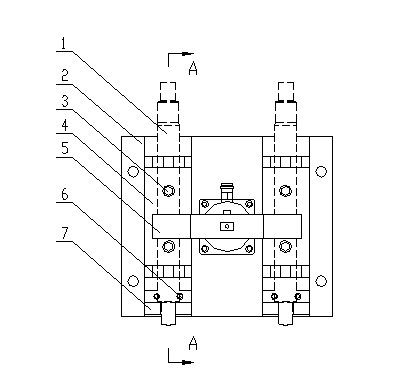

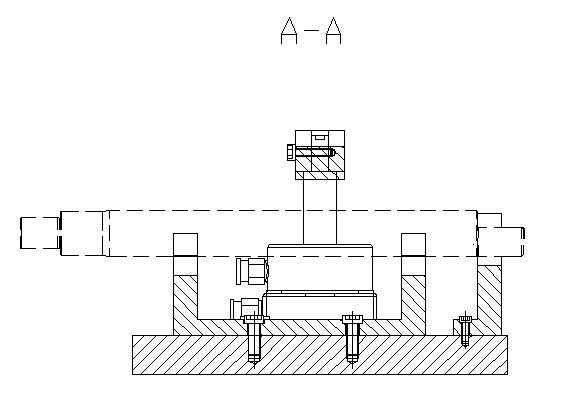

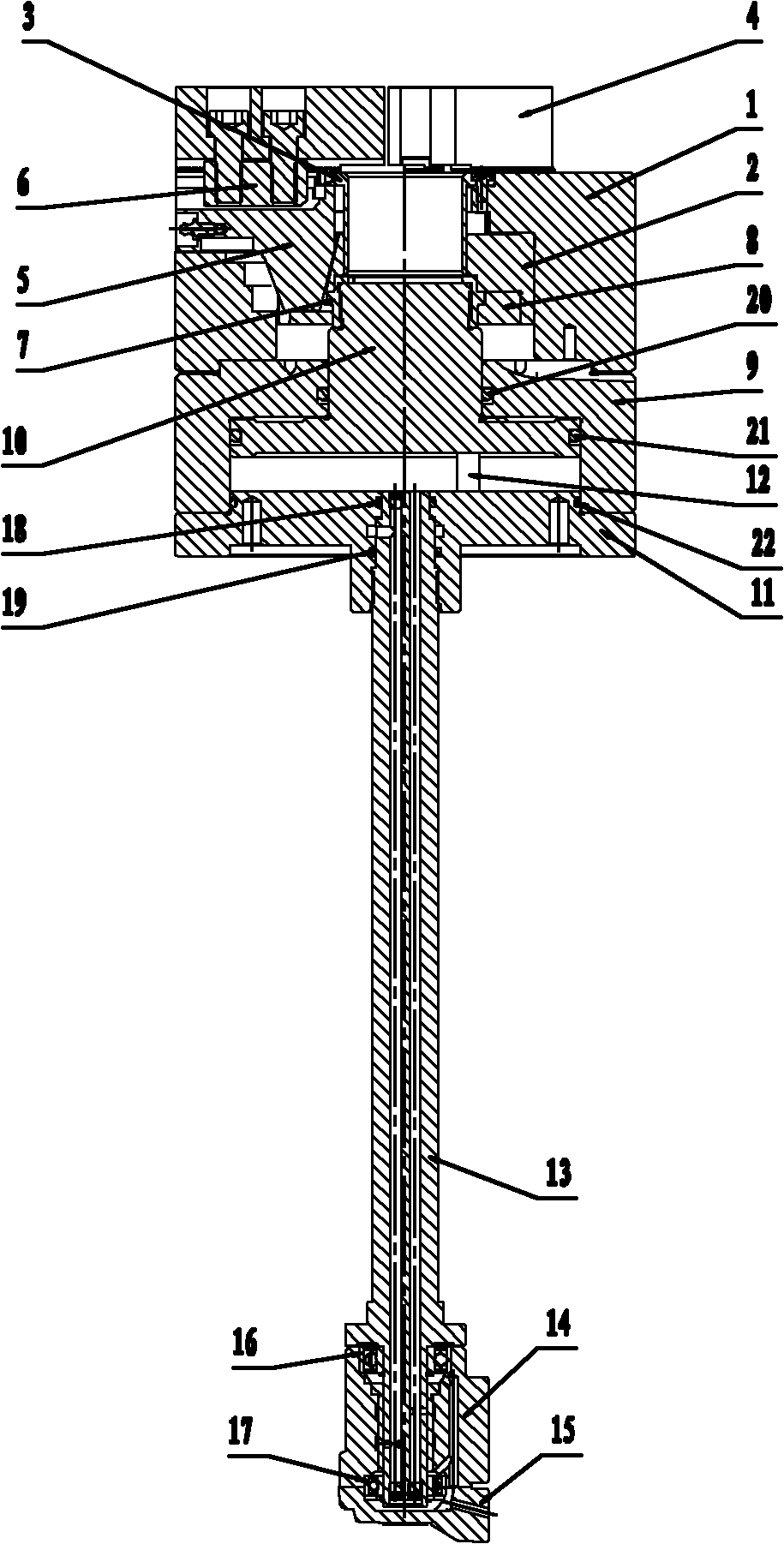

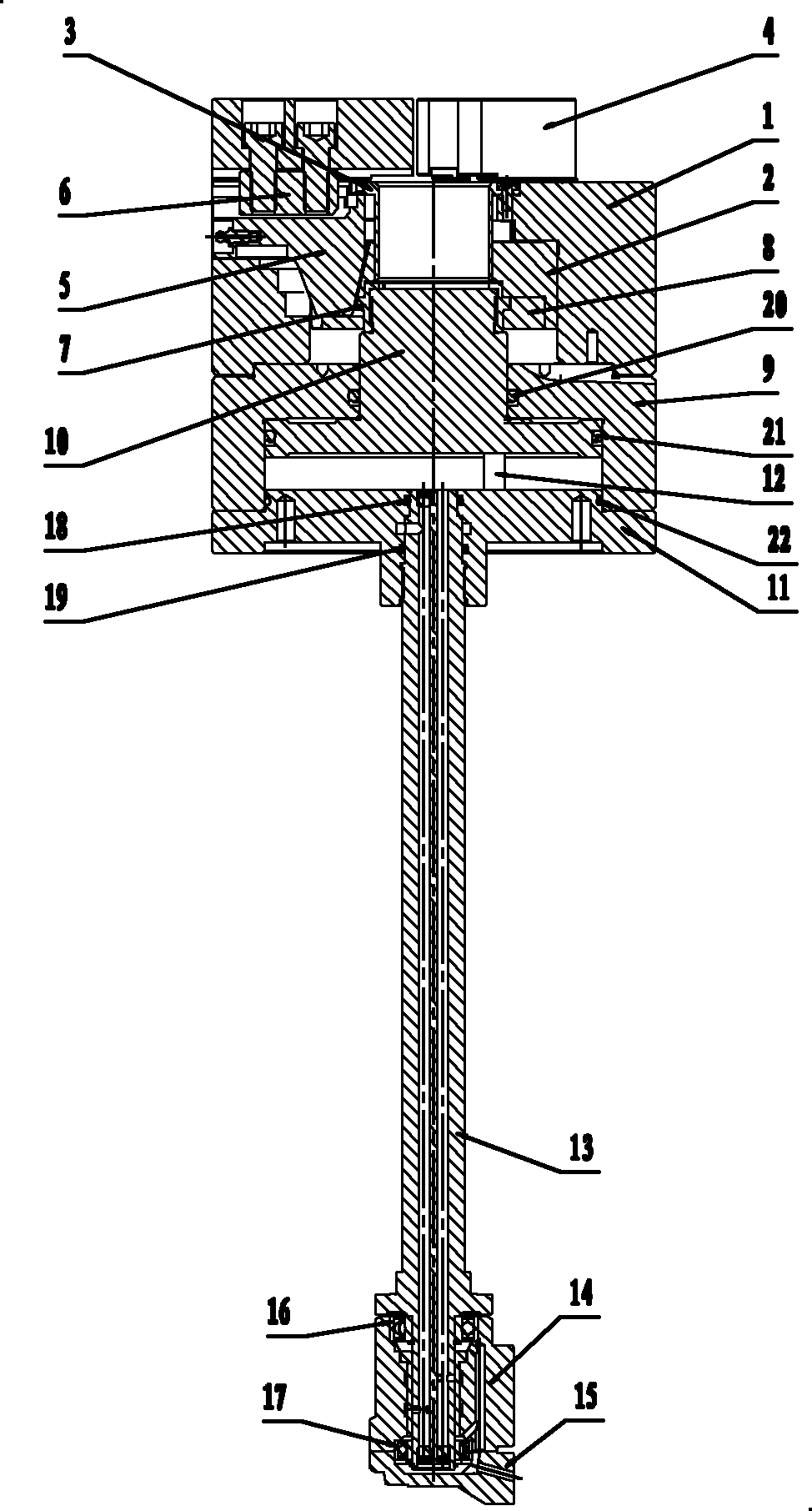

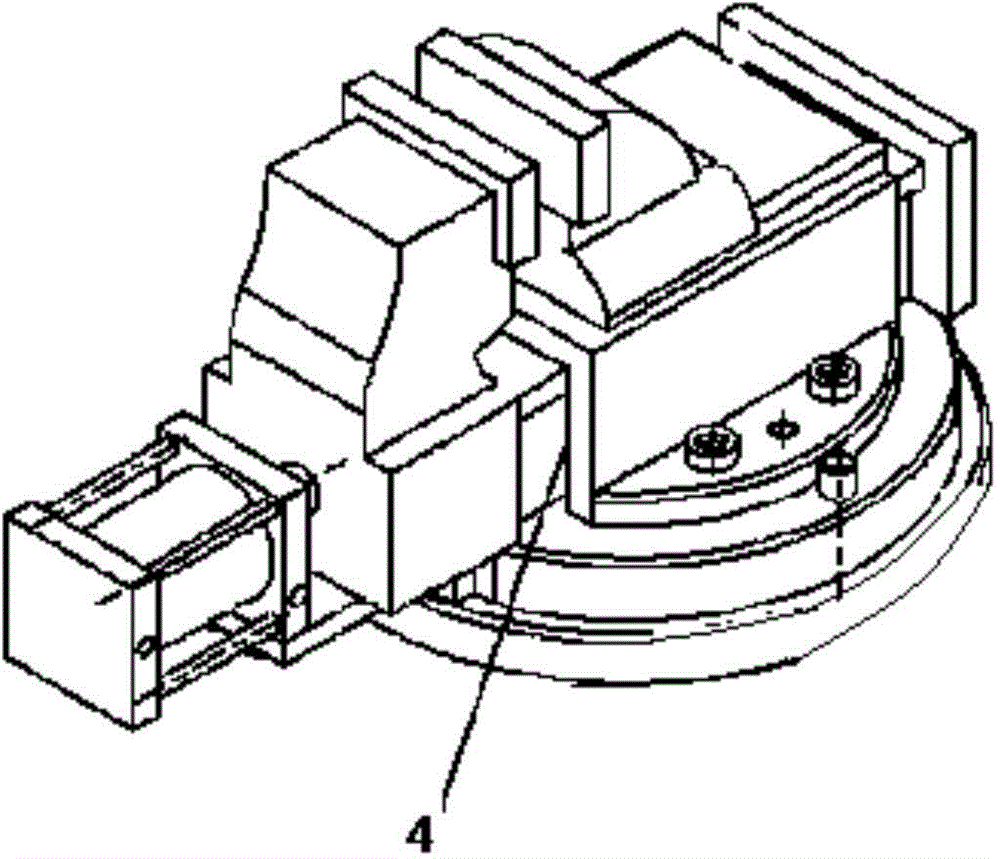

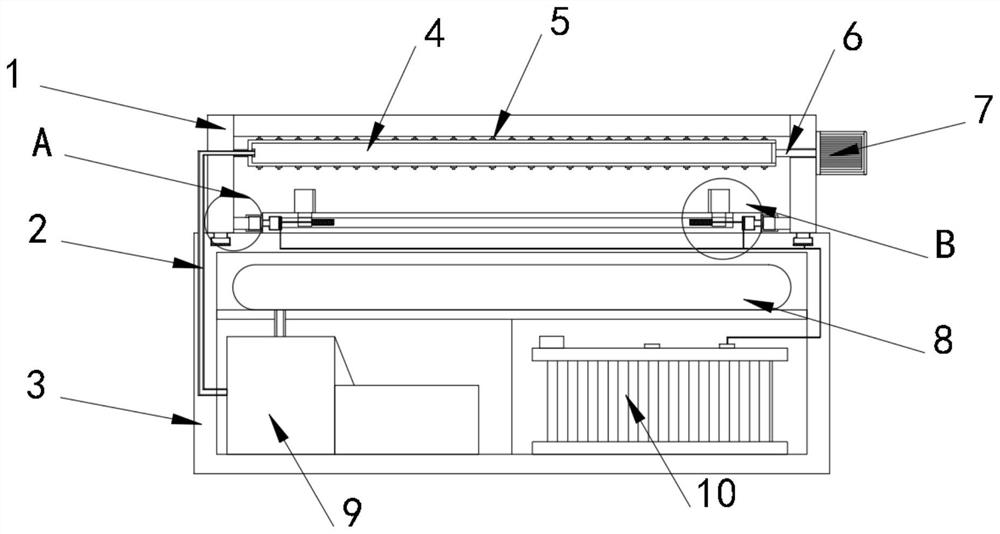

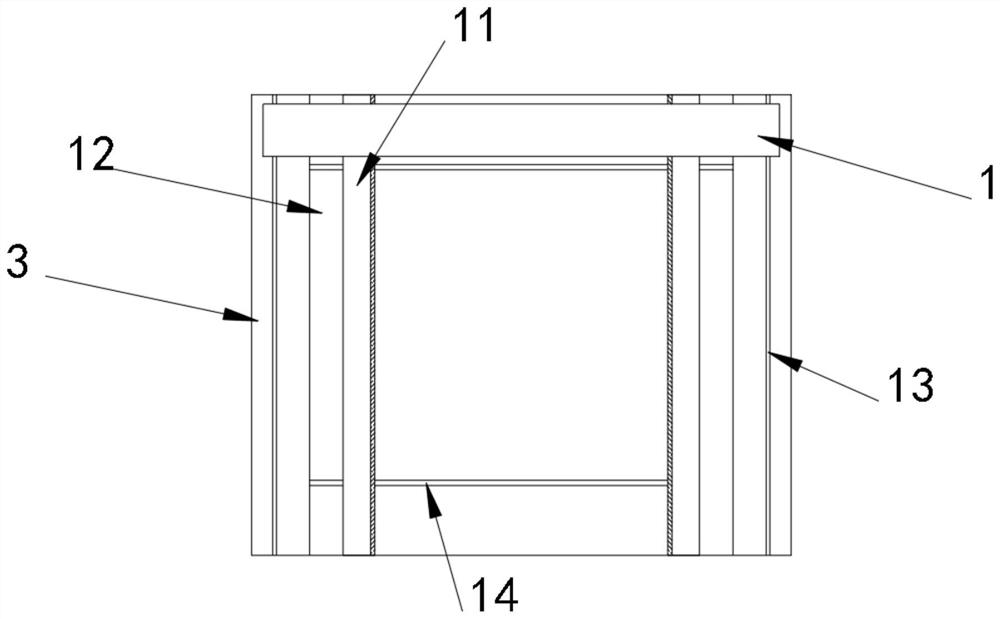

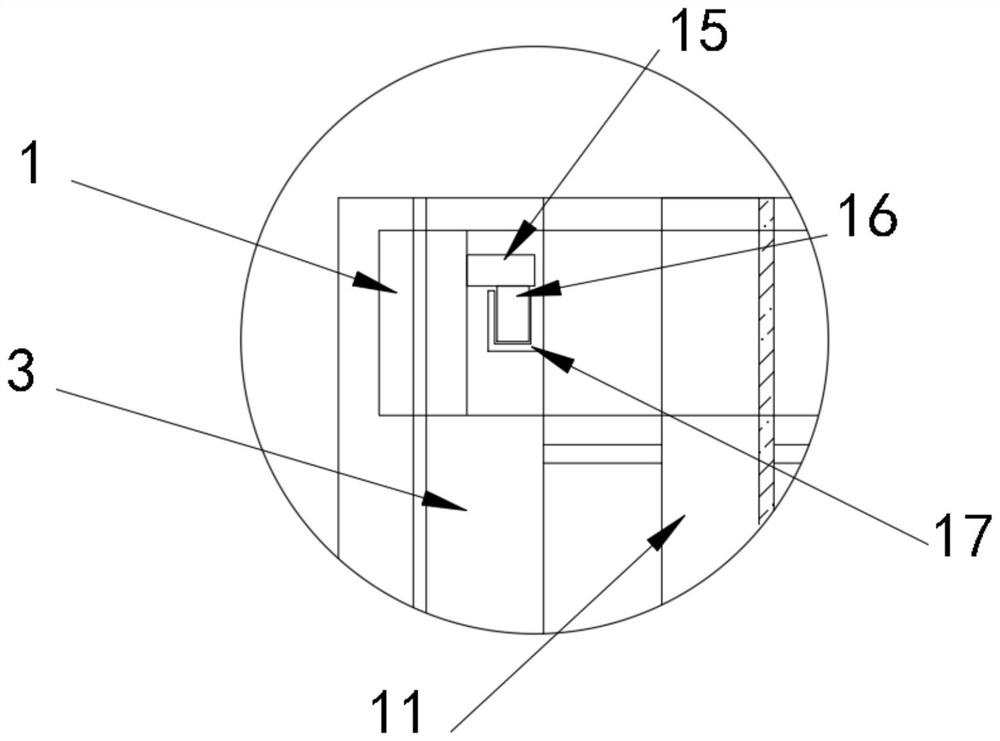

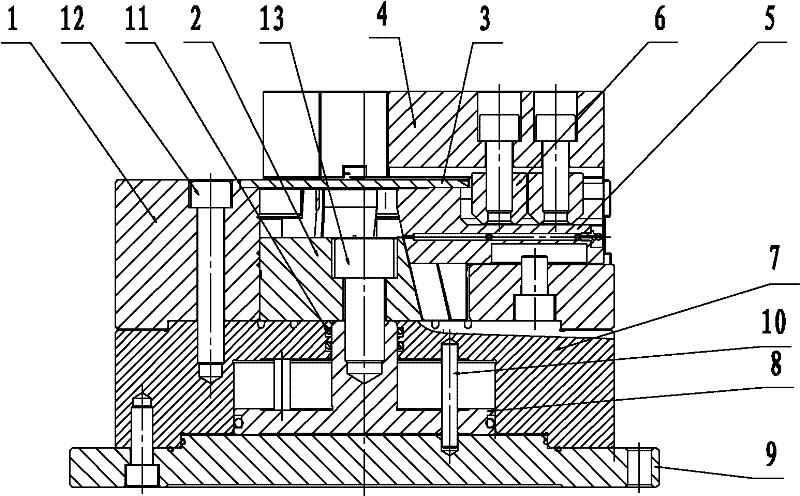

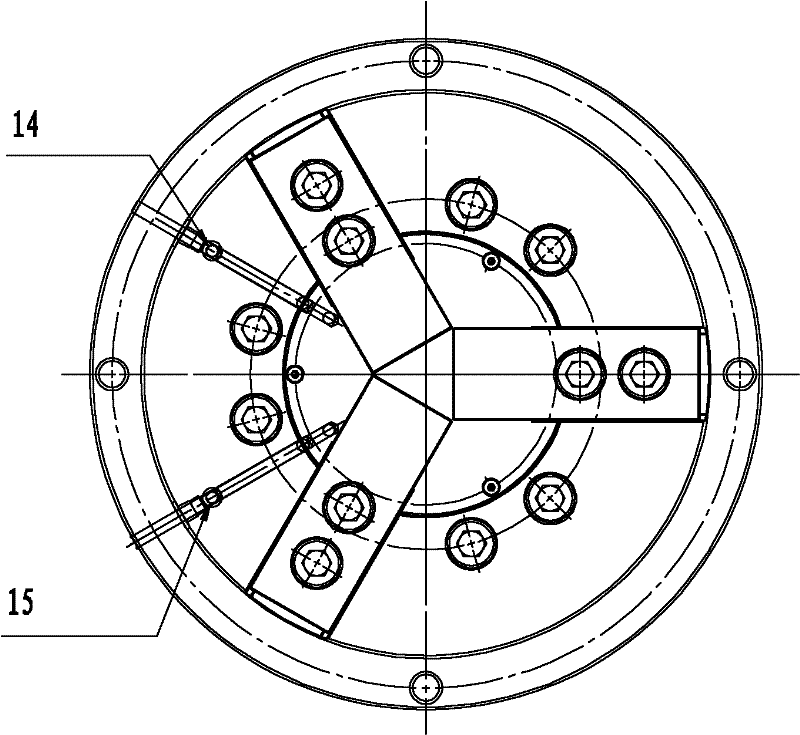

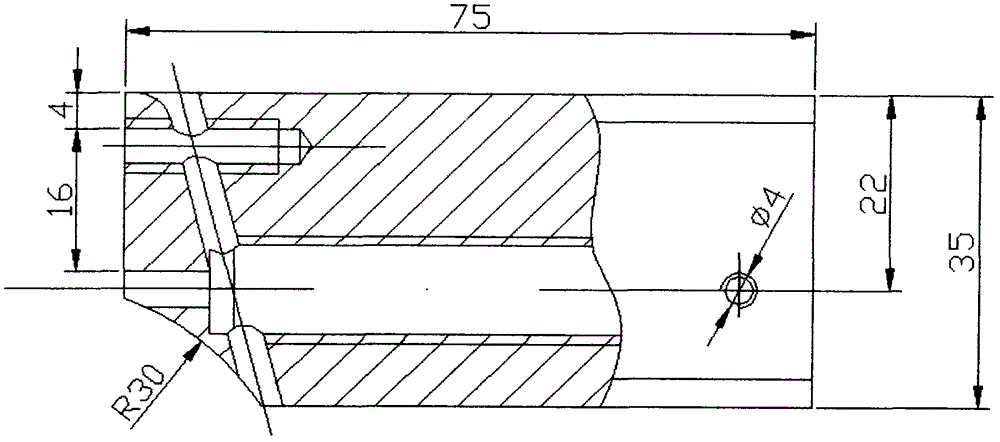

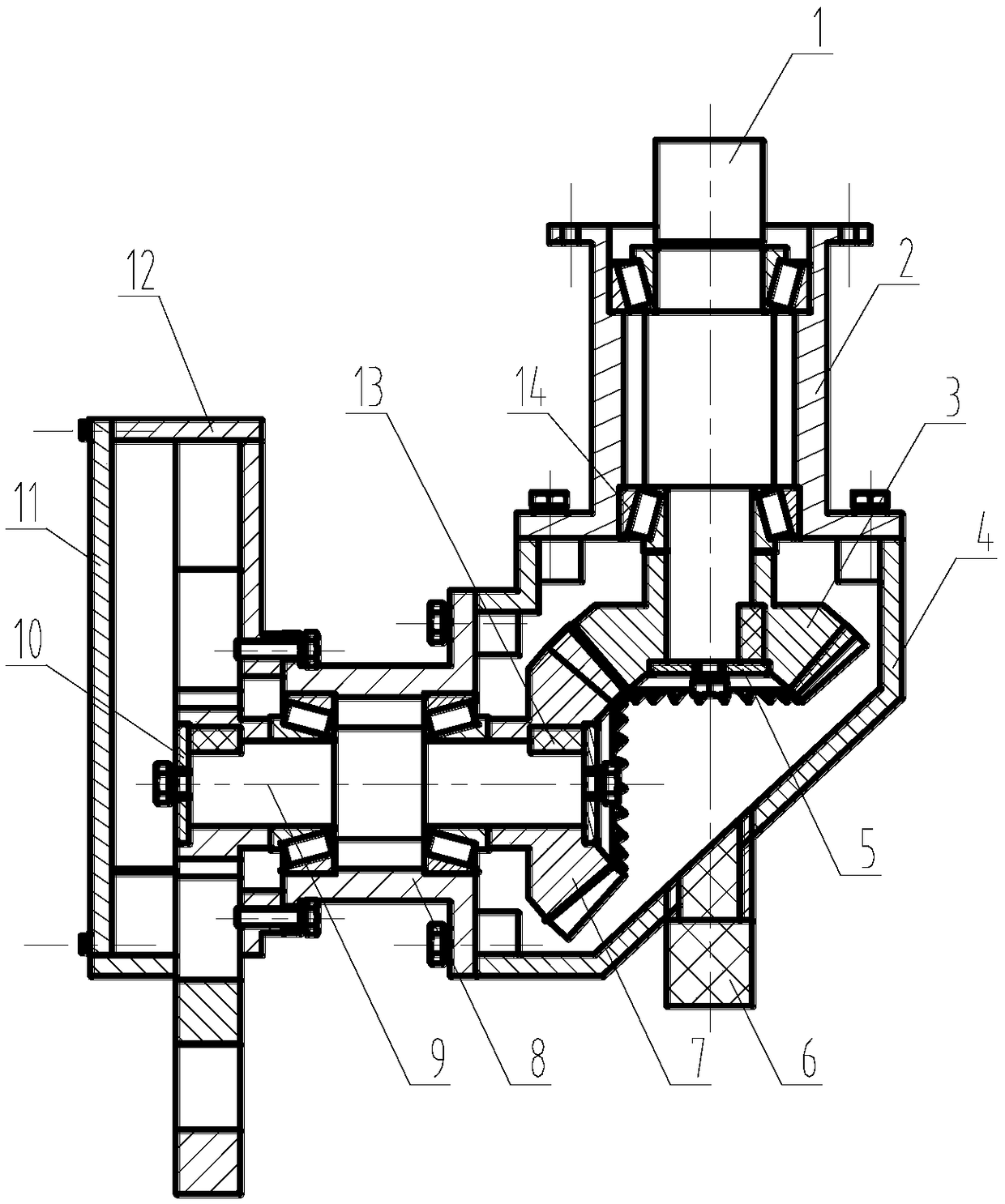

Vertical type fixed hydraulic power chuck

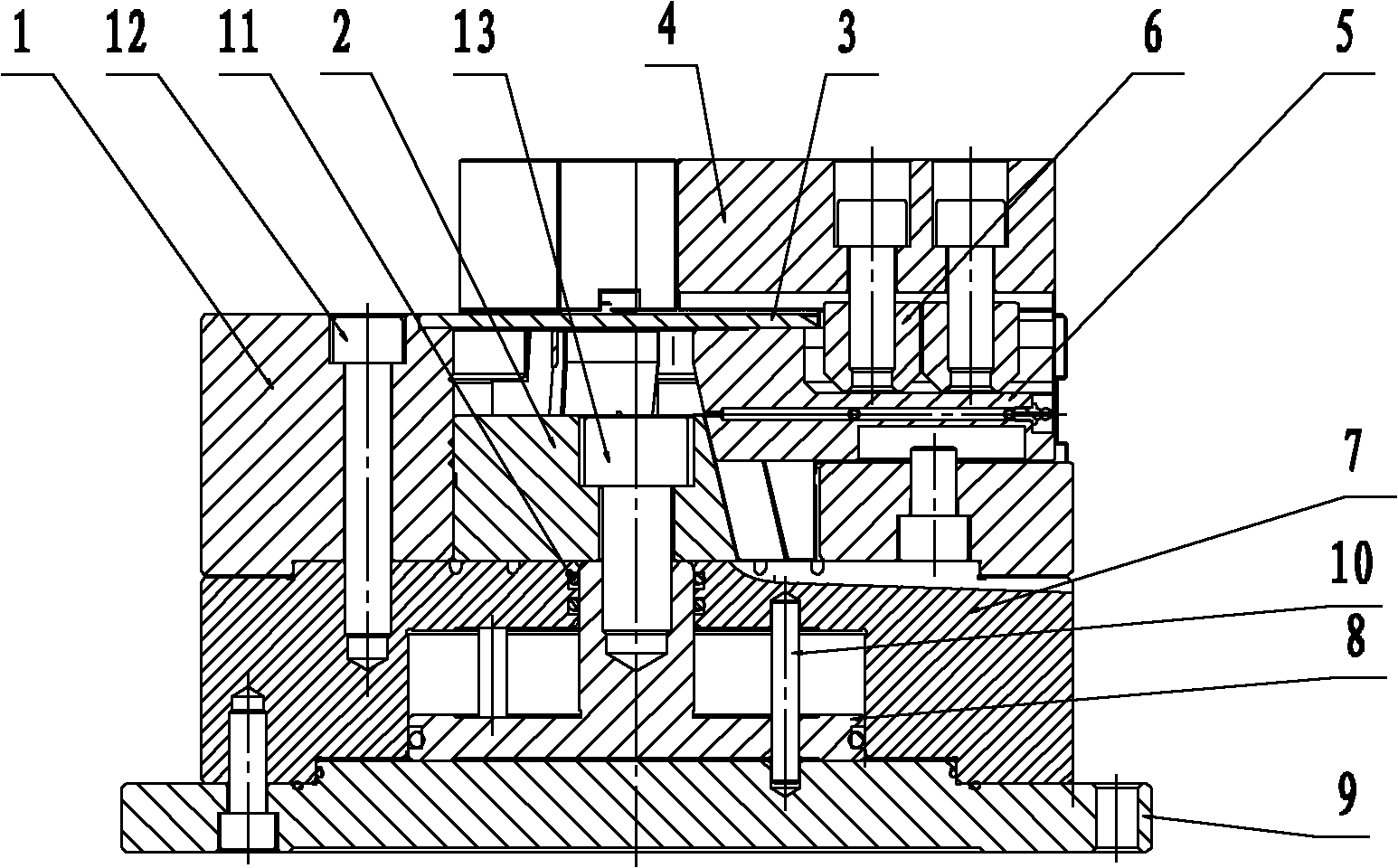

The invention relates to a vertical type fixed hydraulic power chuck which comprises a chuck body, a wedge catch system, a blocking cover, three claws, three slide carriages and six T-shaped blocks, and is characterized in that an oil cylinder body and a base form an oil cylinder main body; a piston is installed in the oil cylinder body and slides in the oil cylinder body along the direction of a guiding shaft; an upper oil chamber and a lower oil chamber are formed above and below the piston; the control hydraulic oil of the upper oil chamber and the lower oil chamber is controlled by a left oil inlet and outlet hole or a right oil inlet and outlet hole; the piston is connected with the wedge catch system by a driving connecting screw; under the driving of the piston, the wedge catch system slides up and down in the chuck body; and the chuck body is connected seamlessly and fixedly with the oil cylinder body by a connecting bolt. The structure of the invention is simple, compact and reasonable, the vertical type fixed hydraulic power chuck connects the cylinder body and the chuck integrally and is loaded on a work bench, a workpiece can be loaded and clamped conveniently, and quick die changing can be realized, thereby greatly lightening the labor intensity, shortening the clamping time, improving the productivity, having adjustable clamping force, and being suitable for matching with a numerical control machining center.

Owner:江苏无锡建华机床附件集团有限公司

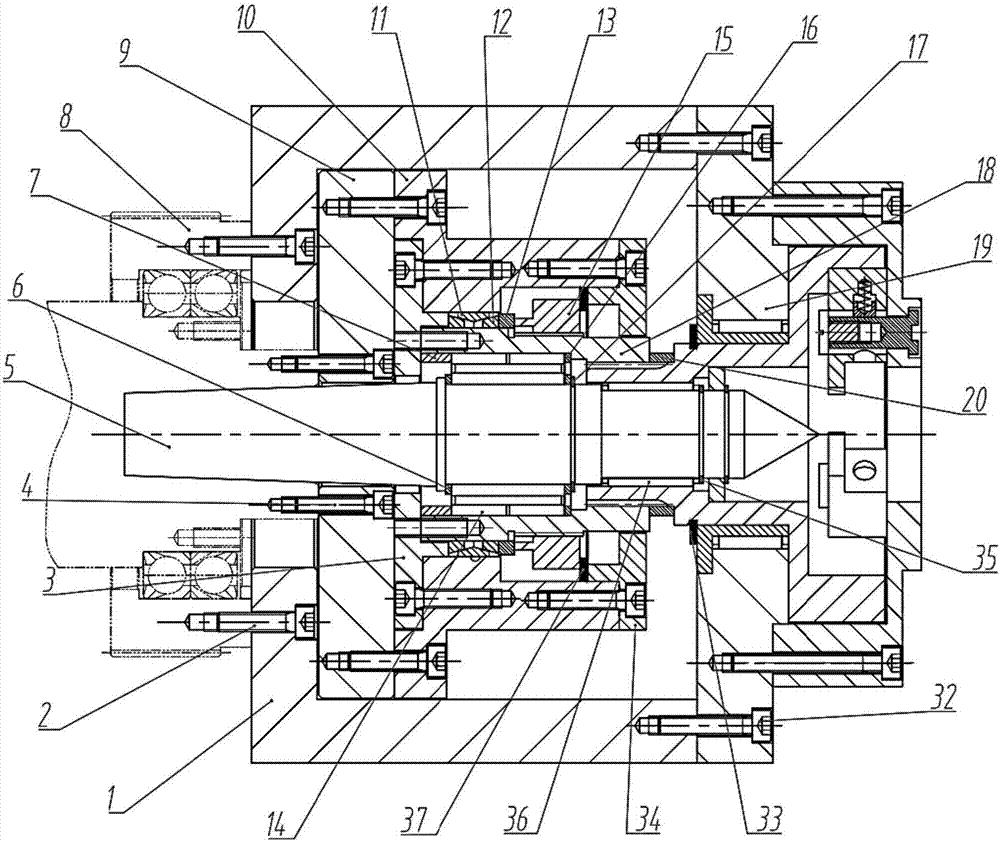

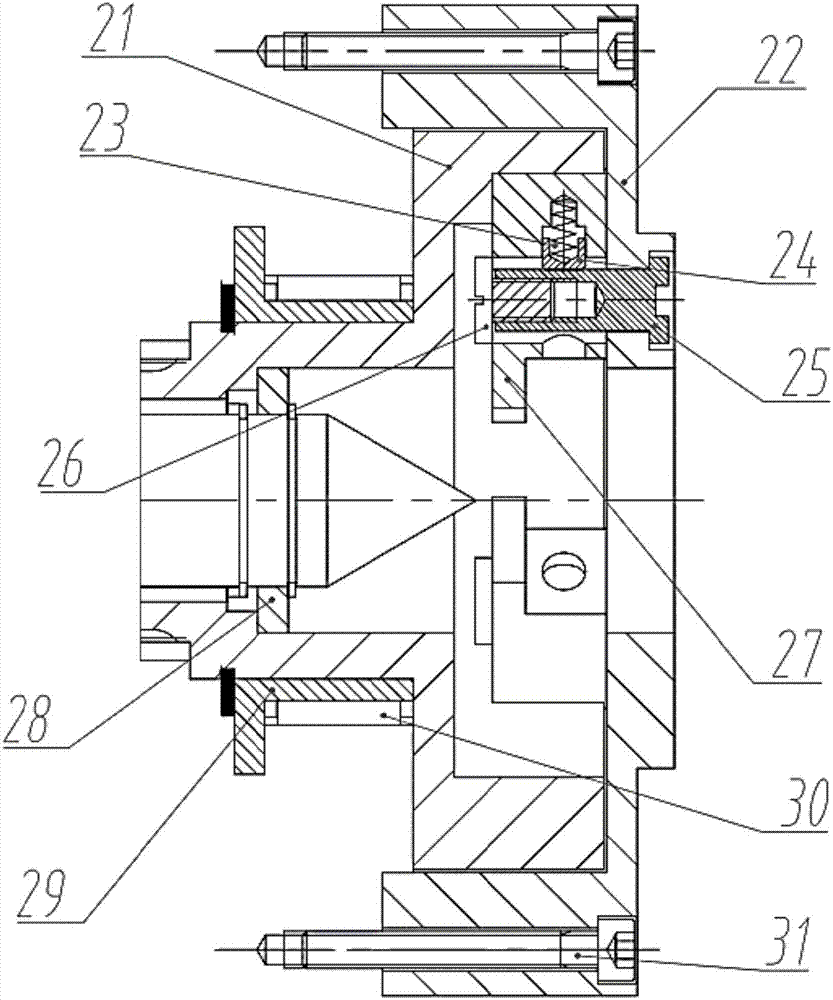

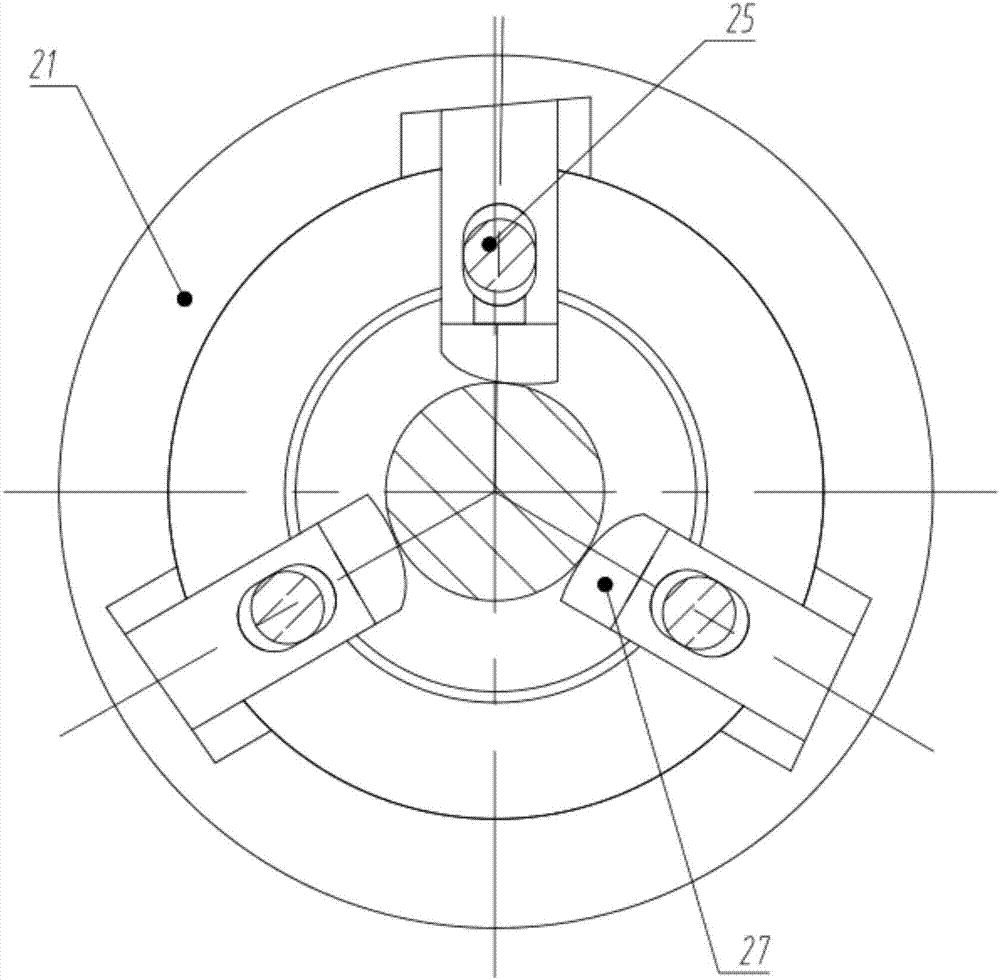

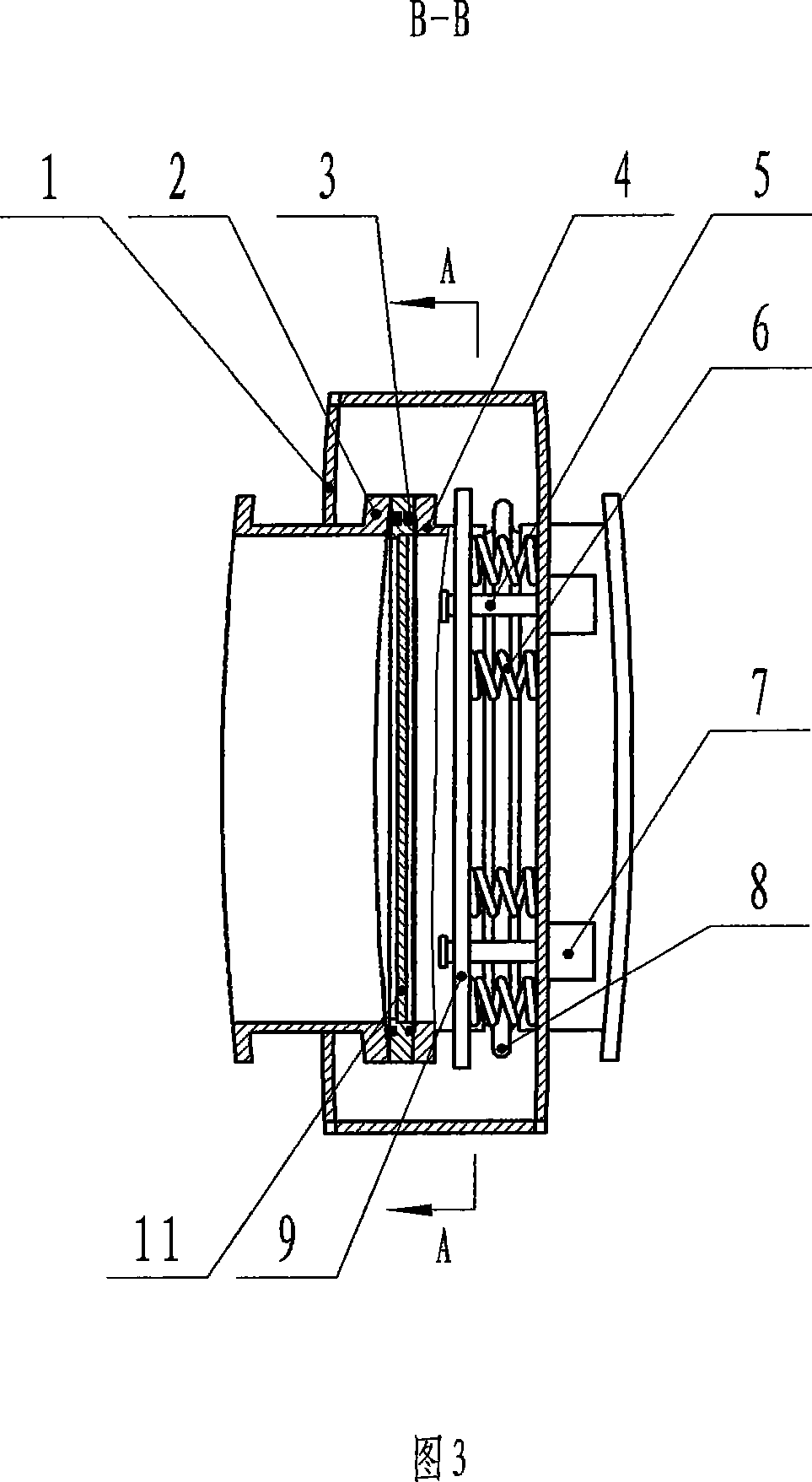

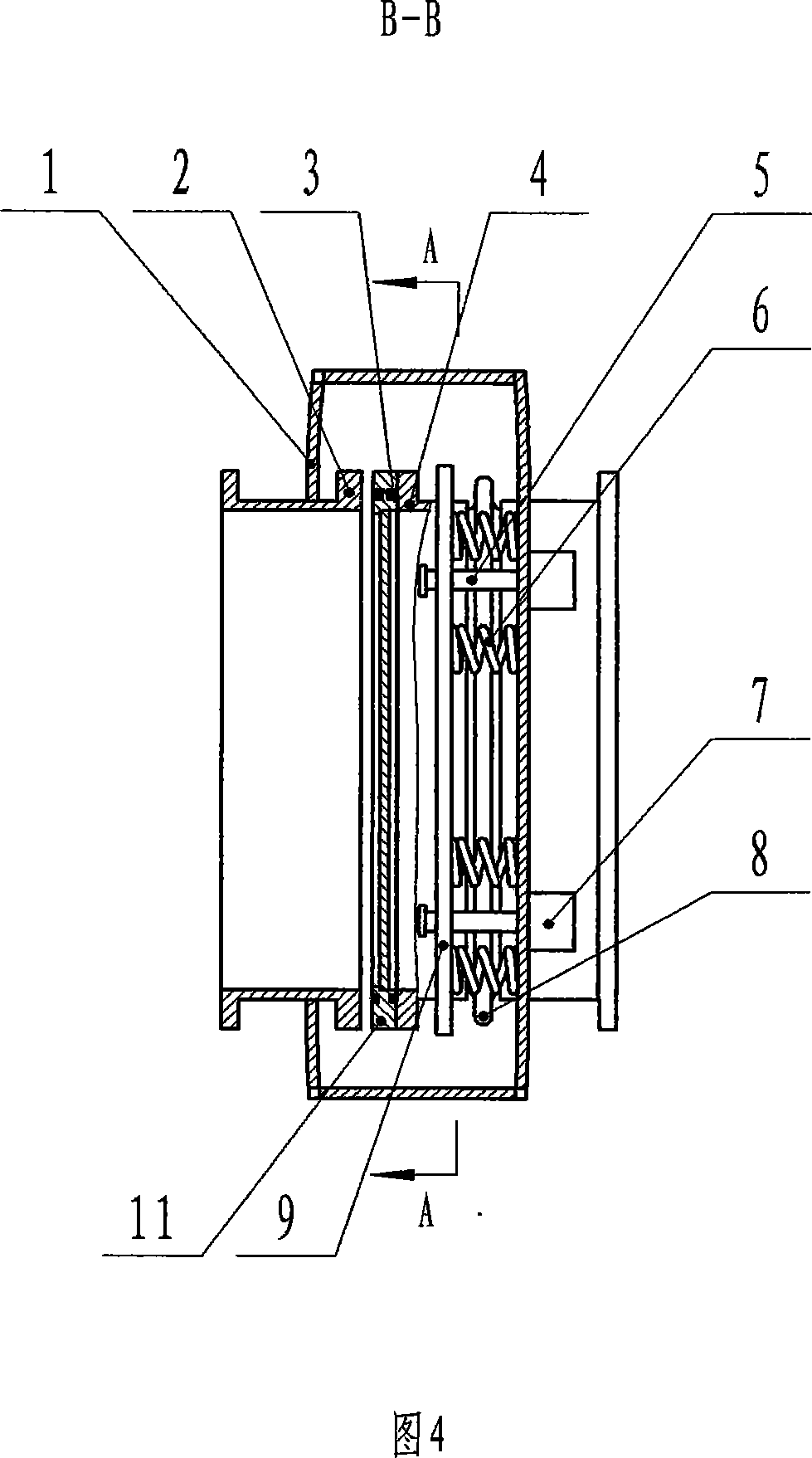

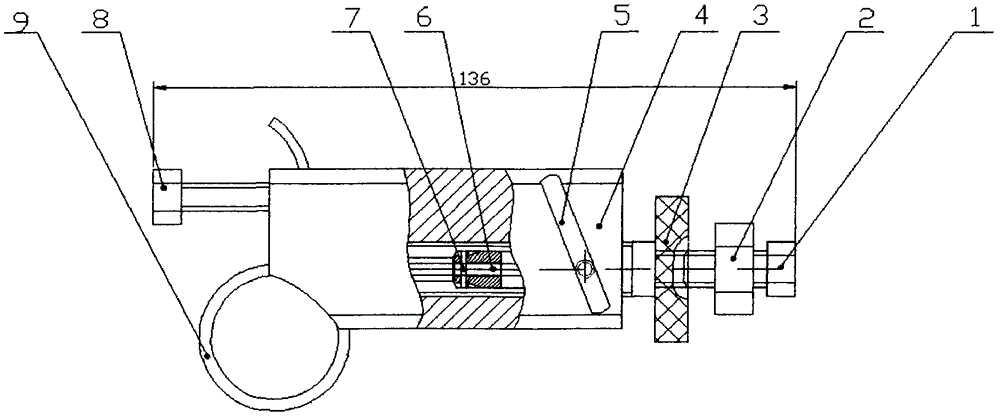

Friction wedge type automatic clamp for cylindrical grinding and application method thereof

ActiveCN106965087AGuaranteed coaxialityRealize automatic clampingGrinding work supportsNeedle roller bearingGear wheel

The invention discloses a friction wedge type automatic clamp for cylindrical grinding and an application method thereof. The friction wedge type automatic clamp for cylindrical grinding comprises a connecting flange, a left end cover, a head rack tip, a positioning flange, an intermediate sleeve, a hexagonal nut, a spline inner sleeve, a supporting ring, a wedge ring, a shifting ring, wedges, a supporting ring positioning sleeve, a needle bearing and a right end cover, wherein the connecting flange is mounted onto a gear of a head rack through a screw; the connecting flange, the supporting ring and the shifting ring are sequentially fixed through the screws; the shifting ring is connected with three wedges through three uniformly-distributed shifting pins; the three wedges are correspondingly embedded into three bevel grooves of the wedge ring; the positioning flange is fixed to a machine body of the head rack and is fixedly connected with the intermediate sleeve; the spline inner sleeve is connected with the wedge ring; a pre-tensioned inner conical spring and a pre-tensioned outer conical spring are mounted between the intermediate sleeve and the spline inner sleeve. According to the friction wedge type automatic clamp for the cylindrical grinding, an automatic wedge clamping manner is used for replacing an existing general manual chuck and a hydraulic driving chuck, so that the structure is simplified, and meanwhile, the automatic clamping function is achieved; in addition, the grinding precision is ensured.

Owner:QUZHOU COLLEGE OF TECH

Demoulding mechanism of plastic bottle cover mould and implementation method thereof

ActiveCN103737868ADon't worry about damageIncreased setup difficultyDomestic articlesBottle capMold removal

The invention provides a demoulding mechanism of a plastic bottle cover mould. The demoulding mechanism is arranged on a moving mould of the plastic bottle cover mould and comprises a support and an abdication device, wherein the support and the abdication device are correspondingly arranged with demoulding mould core assemblies in the moving mould, each mould core assembly is fixed on a forming position when the bottle cover is formed, when the bottle cover is demoulded, the retraction of the mold core assembly is realized, and the emersion of the bottle cover is realized. The invention simultaneously provides a demoulding method for realizing the demoulding mechanism by using the plastic bottle cover mould. The demoulding mechanism provided by the invention has the advantages that the structure is reasonable and compact, the volume is small, the production efficiency is high, and the quality of a bottle cover product is processed.

Owner:EVERFINEST PRECISION MACHINERY SHENZHEN

Manufacture method of automobile air duct

The invention provides a manufacture method of an automobile air duct. The manufacture method comprises the following steps: opening an upper mould and a lower mould of a mould, and heating and cleaning the moulds; coating and polishing; measuring a temperature; starting a vacuum pump for sucking gas on the inner surface of the lower mould, laying leather on the inner surface of the lower mould; sealing the space between the surrounding of the leather and the lower mould to form a vacuum state by a packing tape; laying a glass fiber felt which is as large as the leather on the inner surface of the upper mould and fixing; casting a rigid polyurethane foamed material on the leather in the middle of the lower mould, and casting two ends of the lower mould, and then closing the moulds; and opening the upper mould after 15-21 min, closing the vacuum pump, unsealing the packing tape and then taking the foamed air duct out from the lower mould. The manufacture method provided by the invention is simple in manufacture process, less in procedures, and high in production efficiency; the whole production of each product is 30+ / -3 min, and is reduced by about 70 percent in comparison with the conventional production time, the weight is reduced by 62.5 percent, and the production cost is lowered.

Owner:安徽金诚汽车装饰设计开发有限公司

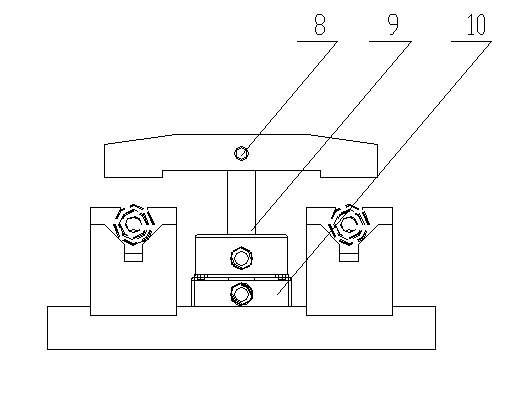

Eccentric shaft machining clamp

InactiveCN103419031AAchieve axial positioningRealize circumferential compression positioningPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to an eccentric shaft machining clamp which is mainly composed of a base plate, a shaft sleeve positioning device fixed on the base plate and a pressing plate. The eccentric shaft machining clamp is characterized by further comprising a pneumatic device and a guide rod fixed on the base plate. The pressing plate is connected with a moving part of the pneumatic device and moves up and down along the guide rod. When the eccentric shaft machining clamp is operated, a workpiece is placed in the shaft sleeve positioning device on the base plate and axial positioning of the workpiece is achieved. A pneumatic device button is pressed and a pressing head presses till a workpiece rod body portion along the guide rod through the action of the moving part of the pneumatic device. Circumferential pressing and positioning of the workpiece are achieved, and the whole pressing process is easy to operate, short in time, efficient, good in universality as workpieces of the same series can be positioned and clamped through the clamp and capable of greatly meeting the production requirement.

Owner:JIANGSU GANGYANG

Black level correcting device and electronic camera

InactiveUS20050094009A1Reduce saggingSimple structureTelevision system detailsTelevision system scanning detailsElectrical and Electronics engineeringVideo camera

A black level correcting device includes: an A / D converting section converting a result of subtracting a feedback signal from an input pixel signal into a pixel value to be output; and a feedback controlling section generating the feedback signal and having a holding section, a feedback gain adjusting section, etc. The holding section clamps a maintaining level to the level of the feedback signal while pixel signals of OB pixels are output, and maintains and outputs the maintaining level while pixel signals of valid pixels are output. The feedback gain adjusting section multiplies the feedback signal by clamp accelerating gain in synchronization with starting readout of the pixel signals from the OB pixels. Accordingly, clamp time of the holding section is shortened, enabling stabilization of the maintaining level at a convergence level before starting readout of the pixel signals from the valid pixels. Consequently, a sag can be reduced.

Owner:NIKON CORP

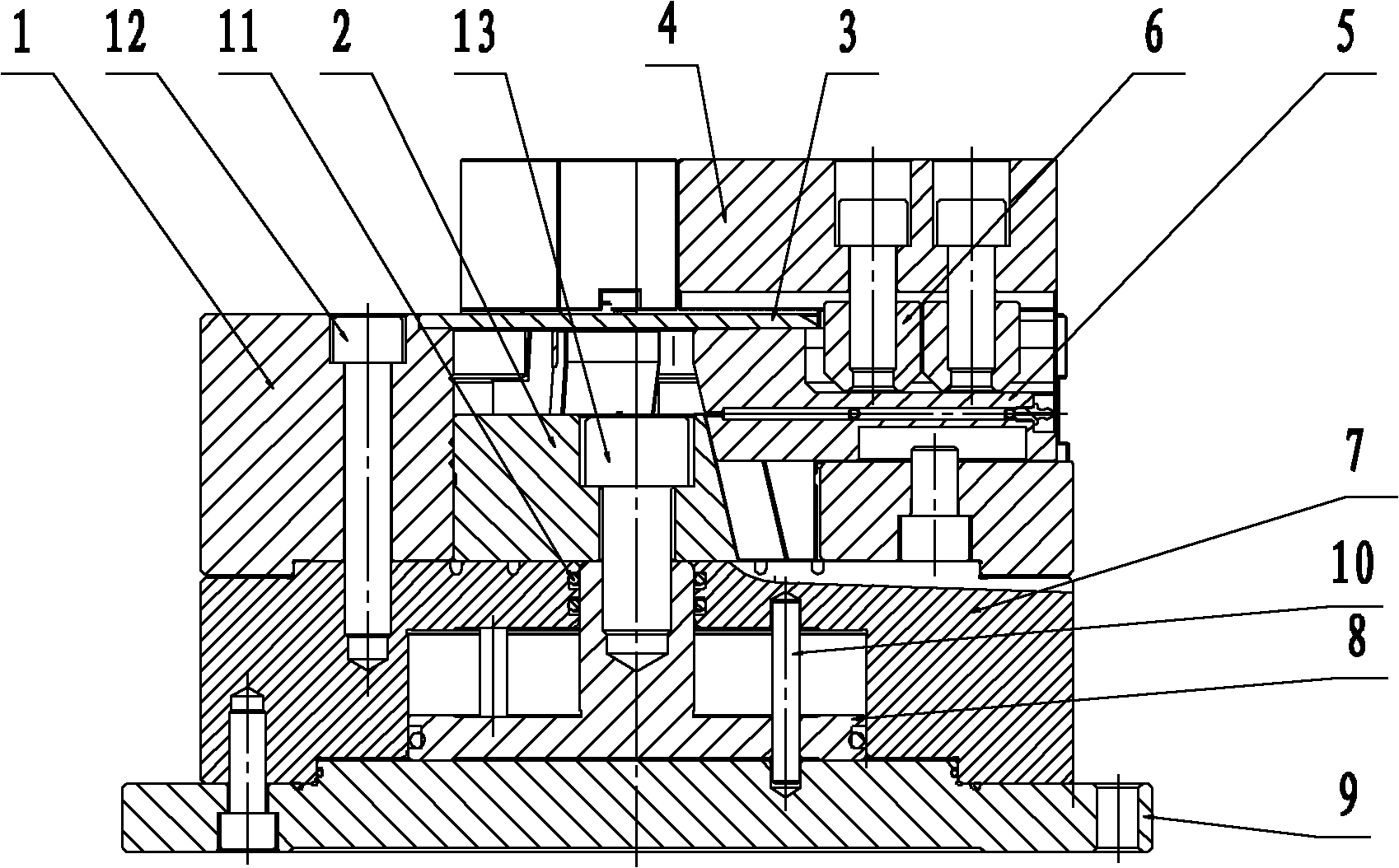

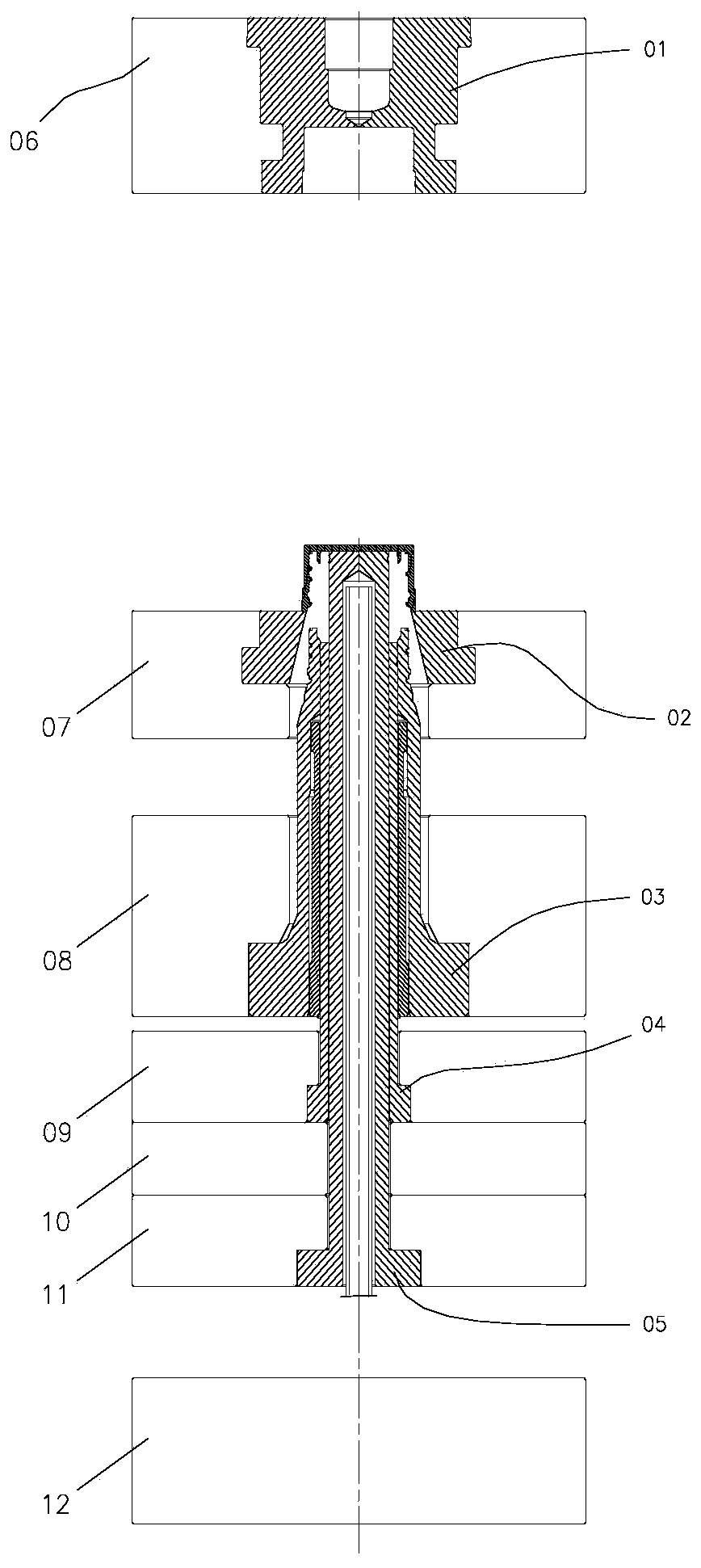

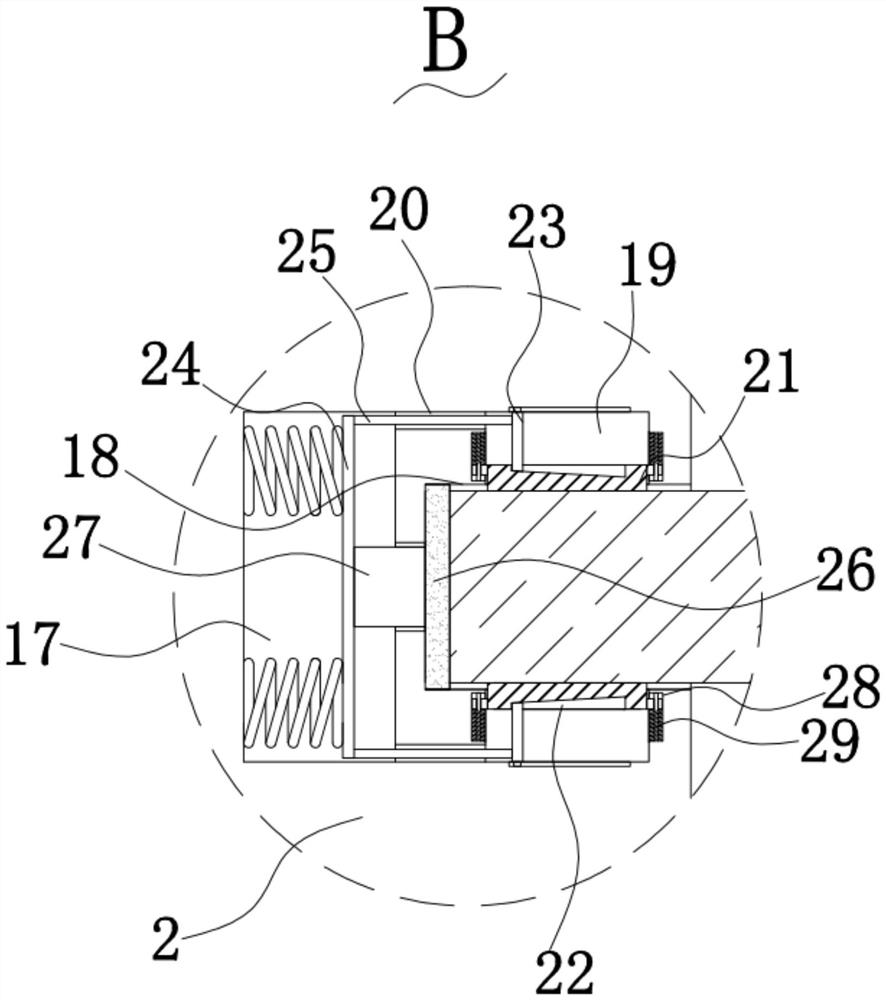

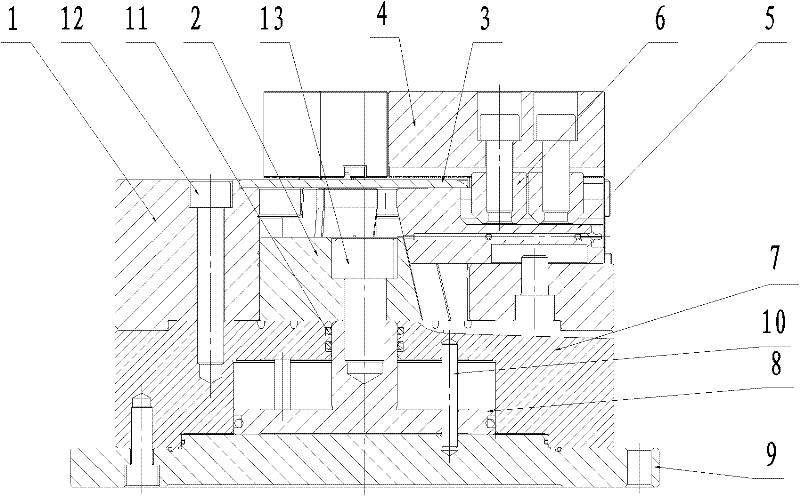

Back distribution type front pneumatic chuck

The invention relates to a back distribution type front pneumatic chuck which comprises a chuck body, a wedge core sleeve, a retaining cap, three jaws, three sliding bases and three T shaped blocks. The back distribution type front pneumatic chuck is characterized in that an air cylinder body is connected with a base to forma an air cylinder main body, a piston is installed in the air cylinder body and connected with the wedge core sleeve through a push-pull sleeve and a push-pull ring, the wedge core sleeve slides up and down in the chuck body under the driving of the piston, an upper air chamber and a lower air chamber are formed above and below the piston, the base is fixedly connected with an extended valve rod in a thread screwing way, the valve rod and a valve body are connected through a bearing and can rotate relatively at a high speed, and a valve cap is connected with the valve body through a screw. The back distribution type front pneumatic chuck has simple, compact and reasonable structure; since the air cylinder body and the chuck body are connected into a whole and a distributing valve is arranged at the rear part independently, the back distribution type front pneumatic chuck can be successfully installed in a narrow space at the tail part of a machine tool, thereby greatly reducing the labor intensity, shortening clamping time and improving productivity; and in addition, since the clamping force is adjustable, the back distribution type front pneumatic chuck can be matched with numerical control equipment which needs air distribution at the tail part of the machine tool and has limited space at the tail part.

Owner:江苏无锡建华机床附件集团有限公司

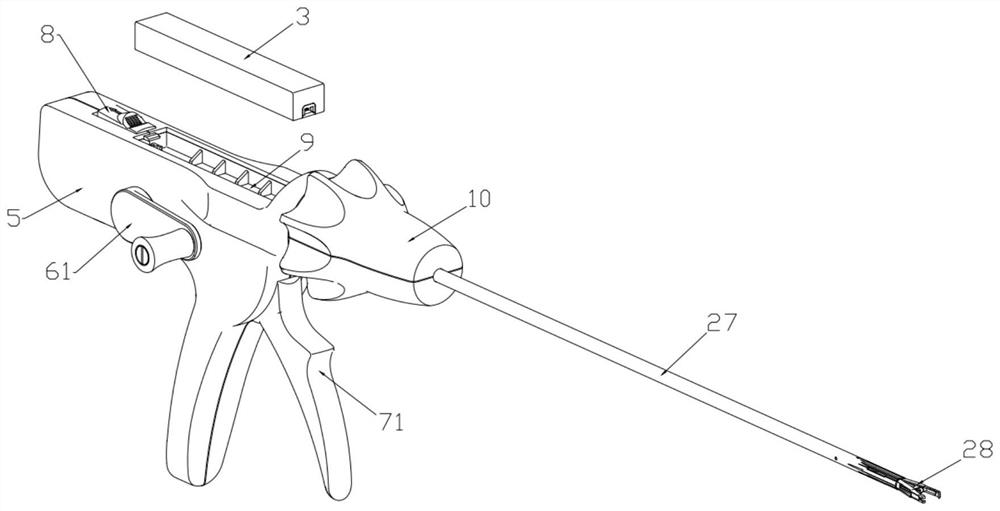

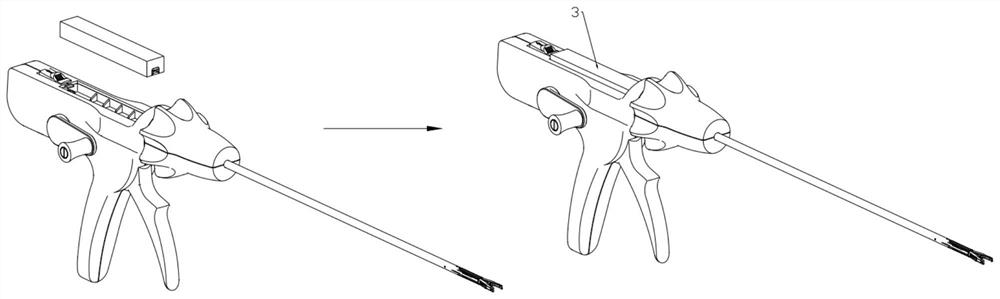

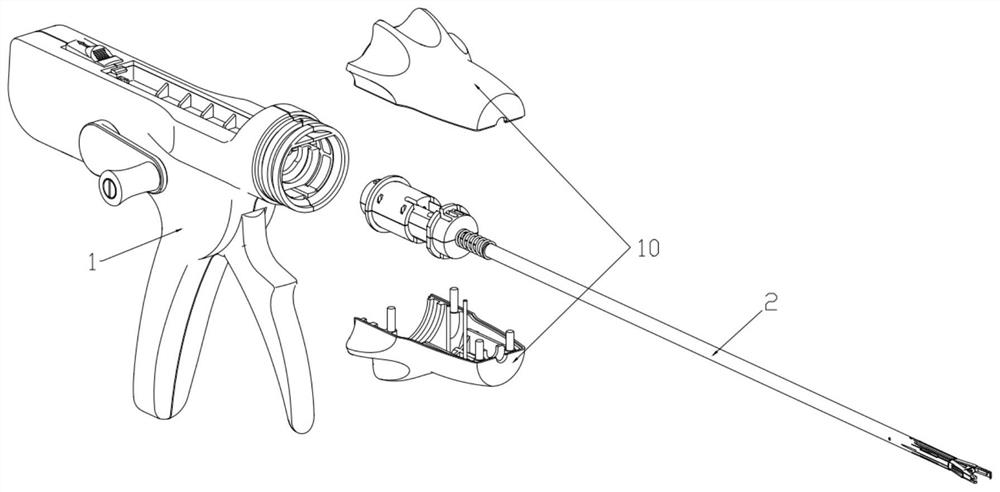

Ligation clip continuous shooting clip applier and use method thereof

The invention provides a ligation clip continuous shooting clip applier and a using method thereof. The ligation clip continuous shooting clip applier comprises a gun body assembly used for holding and shooting and composed of a left shell, a right shell, a clip feeding assembly, a shooting assembly and a clip bin loading and unloading button, a gun barrel assembly is movably installed at one end of the gun body assembly, an upper connecting pipe and a lower connecting pipe are connected by buckles, an annular cavity structure formed by an upper shooting connecting ring and a lower shooting connecting ring is movably arranged on the outer side of the upper connecting pipe and the outer side of the lower connecting pipe in a sleeving mode and axially moves outside the upper connecting pipe and the lower connecting pipe, and barbs are arranged at the front end of a pushing clamping plate and the front end of a clamping storage groove; and the ligation clip continuous shooting clip applier further comprises a clip bin assembly used for loading and unloading the ligation clip, the clip bin assembly can be replaced, the ligation clip can be quickly supplemented after being used up in the operation process, the clip applying time is shortened, meanwhile, the ligation clip is basically in a natural state in the clip bin assembly, the failure rate of the ligation clip is greatly reduced, and the gun body assembly and the gun barrel assembly can be repeatedly used in the same operation, so that the economic burden of a patient is reduced.

Owner:常州缤纷智造科技有限公司

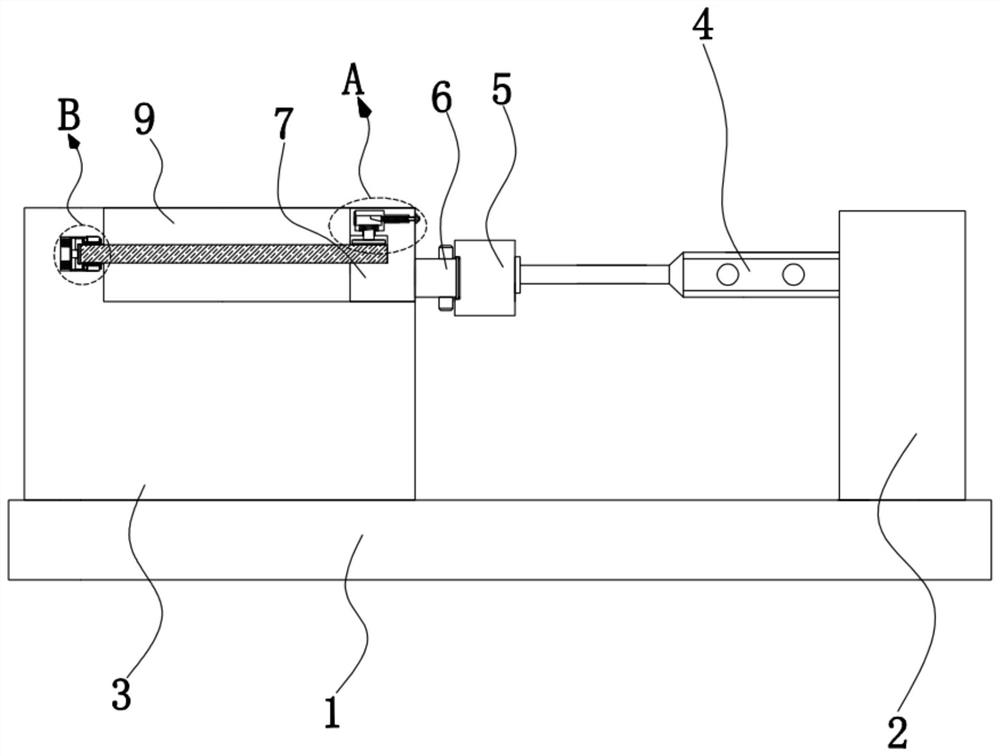

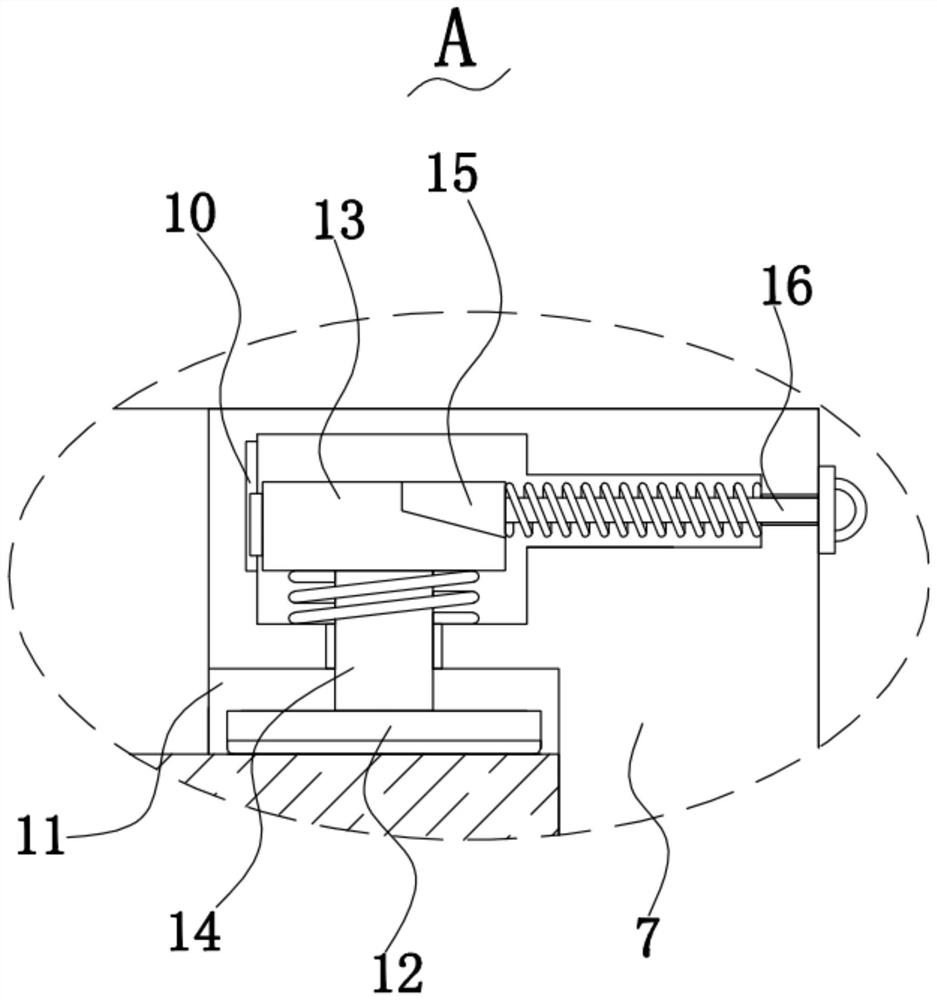

Bench vice

InactiveCN104084823ALabor savingShorter clamping timeWork clamping meansPositioning apparatusPneumatic cylinderPneumatic pressure

The invention relates to a bench vice. The bench vice comprises a rotating disc, a vice jaw mounting base, a first vice jaw, a sliding groove, a guide rail, a second vice jaw, a fixed plate and a pneumatic cylinder, wherein the vice jaw mounting base is mounted on the rotating disc; the first vice jaw is mounted on the vice jaw mounting base; the sliding groove is formed in the cavity of the vice jaw mounting base; the guide rail is arranged on the sliding groove; the second vice jaw is mounted on the guide rail; the second vice jaw can slide along the guide rail along the sliding grieve; the fixed plate is fixedly mounted on the rotating disc; the pneumatic cylinder is mounted on the fixed plate. The bench vice can reduce the labor force of workers, shorten the time for clamping work pieces, and also guarantee the surface quality of the work pieces.

Owner:李星

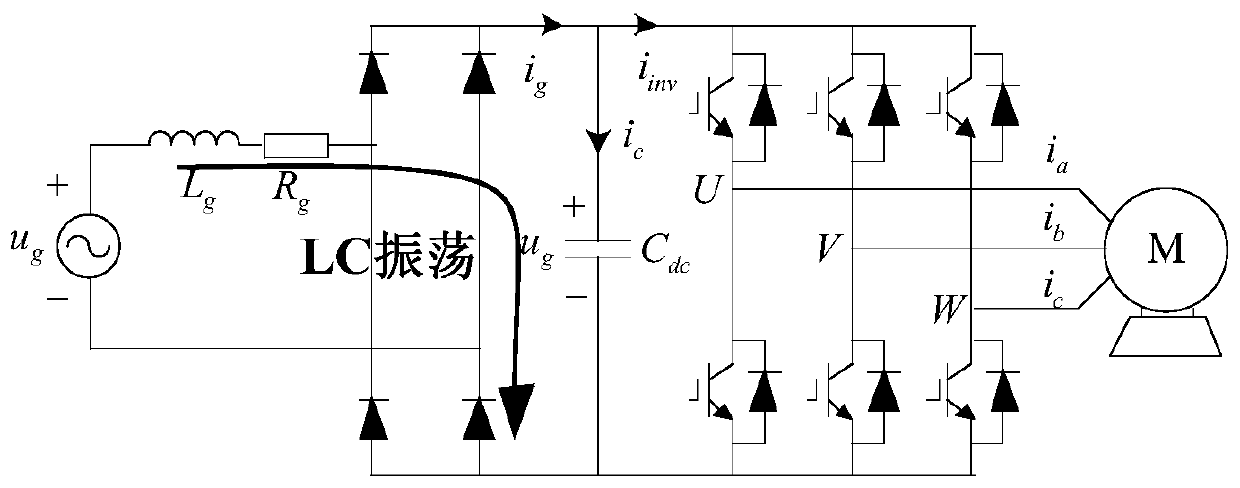

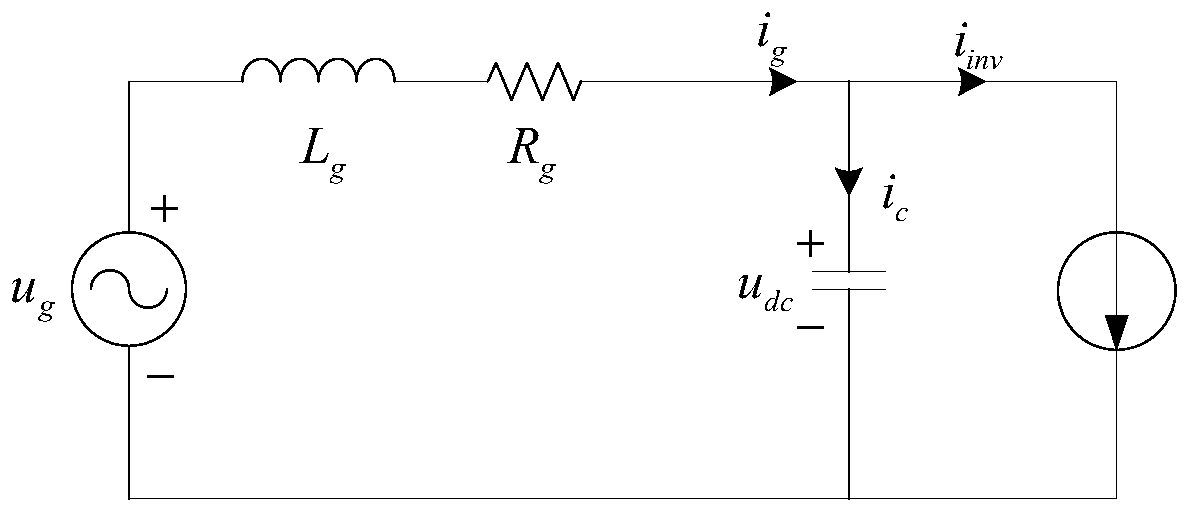

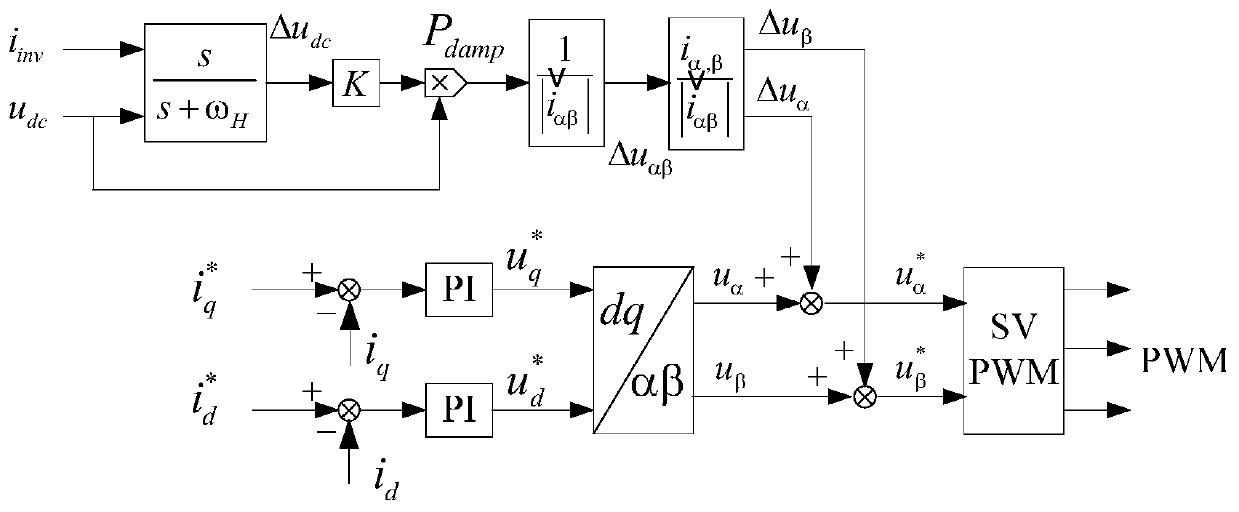

Resonance suppression method and system for electrolytic-capacitor-free variable-frequency driving system

ActiveCN111342731AShorter clamping timeImprove power factorElectronic commutation motor controlAC motor controlPower factorElectric machine

The invention discloses a resonance suppression method and system for an electrolytic-capacitor-free variable-frequency drive system, and belongs to the field of drive control of permanent magnet synchronous motors. The method comprises the steps: multiplying a bus voltage resonance component by the feedback proportional gain to obtain a damping current of the system; multiplying a damping currentby a current bus voltage to obtain equivalent damping power of the input side of an inverter, and converting LC oscillation of the input side of a driving system to the output side of the inverter; dividing the equivalent damping power of the input side of the inverter by the current output current of the inverter to obtain the equivalent damping output voltage of the inverter, and superposing the equivalent damping output voltage to the damping voltage of the alpha axis and the damping voltage of the beta axis according to the current of the alpha axis and the beta axis of the motor, so thatresonance components are absorbed by the current of the motor, and LC resonance suppression is realized. According to the invention, the LC resonance in the driving system can be effectively suppressed, the power factor of the driving system without the electrolytic capacitor can be improved, the calculation is simple, and the digital realization is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

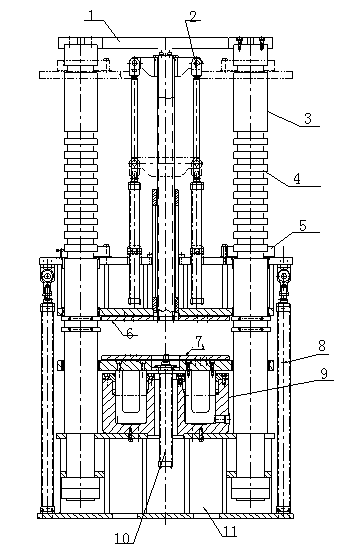

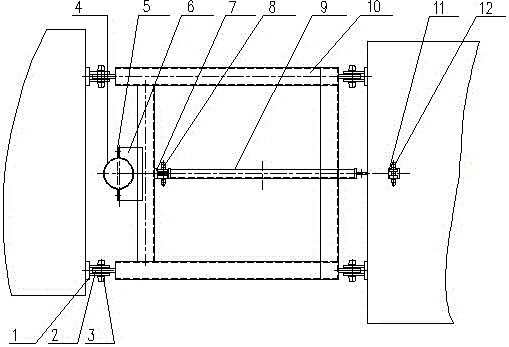

Die assembly mechanism for injection molding machine

The invention discloses a die assembly mechanism for an injection molding machine. The mechanism comprises a first fixing plate, a second fixing plate, an oil cylinder assembly, a drag link and a carrying plate used for carrying the applied force of the oil cylinder assembly, wherein the oil cylinder assembly is used for driving the first fixing plate and the second fixing plate to move, so that the first fixing plate and the second fixing plate move relatively or oppositely to realize die assembly and die disassembly; the oil cylinder assembly comprises a driving oil cylinder and a driven oil cylinder having the same moving track, and the driving oil cylinder is used for driving the die assembly mechanism to realize die assembly and die disassembly movement; during die disassembly, the driven oil cylinder is moved passively; during die assembly, the main journey of the driven oil cylinder makes passive movement, the driven oil cylinder actively makes effort to realize die assembly with larger pressure clamping force after die assembly is about to complete or is completed. According to the die assembly mechanism, the advantages of quick movement of small-diameter driving oil cylinder and large pressure of driven oil cylinder can be sufficiently achieved due to the oil cylinder assembly formed by the driving oil cylinder and the driven oil cylinder, and the time for assembling and disassembling die can be shortened, on the premise that high-pressure die assembling and die locking is sufficiently guaranteed.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

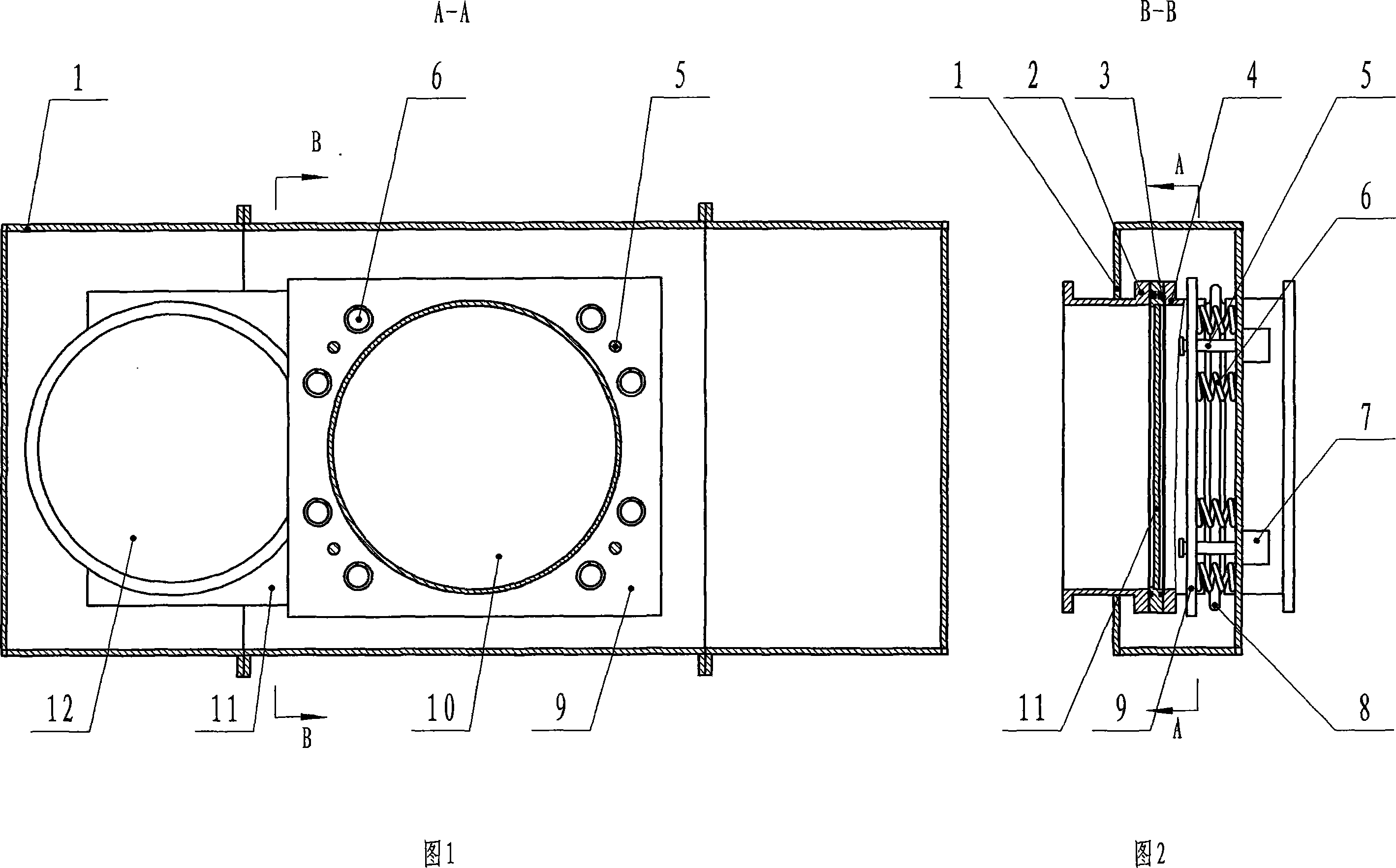

Automatically compensating clamping sealing device of glasses valve

The invention relates a kind of auto compensation fasten device of the glass valve. It is consisted of an inside auto compensation fasten structure, a power structure and a draw link. The inside auto compensation fasten structure is consisted of the offset fasten springs at the two sides of the pipe direct-axis; one end of the fasten spring contacts with the side wall of movable valve base drawplate and the other end of it contacts with the inside wall of the valve body; the power structure is installed on the outer side of valve body; one end of the brace connects with the power output part of power structure and the other end of it goes through hole on the movable valve base drawplate; at the head of brace sets up a spacing step and the distance between the spacing step and the movable valve base drawplate is 5-15mm when the valve is opening. The favorable effectiveness of the invention is that the mount of fasten spring's add-and-subtract accords to the requirement of seal and isn't limited by the amount of brace and it can increase the mount of fasten spring singly at the state of do not increase the mount of brace in order to enhance the seal performance; and can compensate the bow distortion and gap distortion produced after the valve bearing.

Owner:SHIJIAZHUANG NO 1 VALVE FACTORY

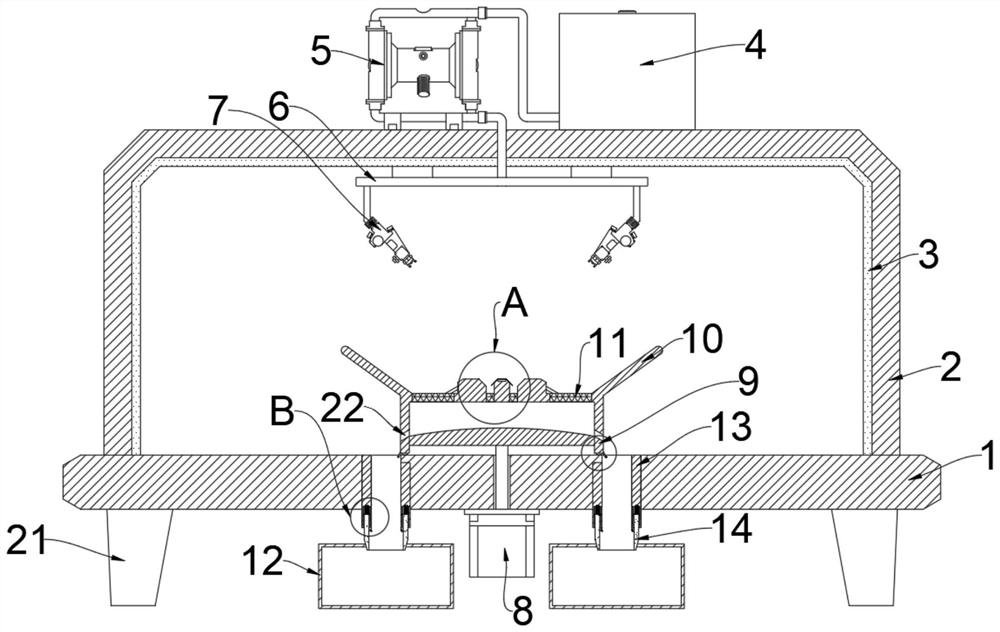

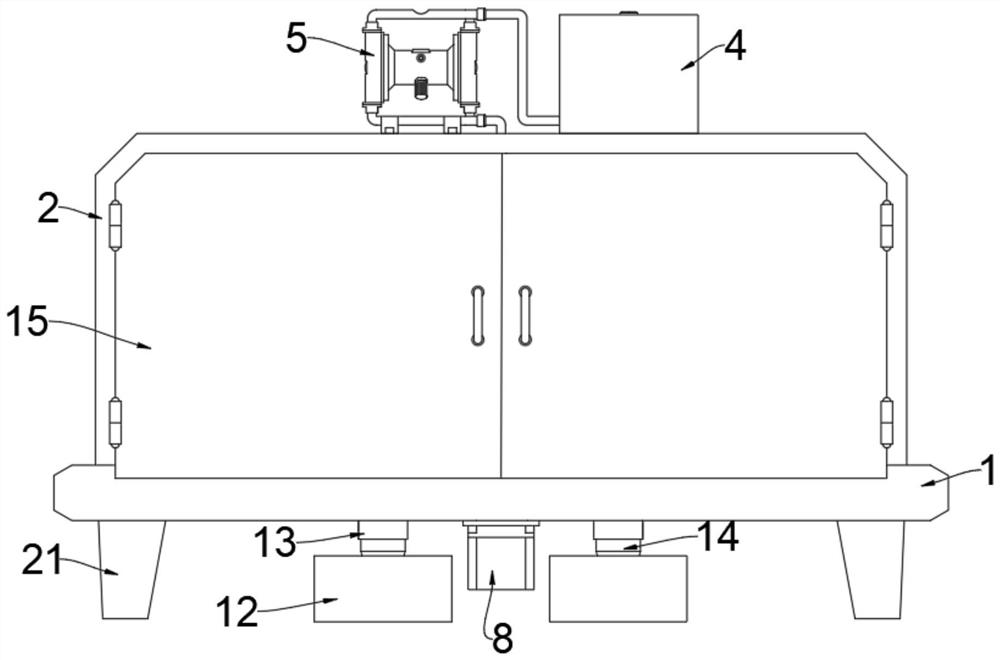

Paint spraying device for automobile maintenance

The invention discloses a paint spraying device for automobile maintenance. The paint spraying device comprises a workbench; a rotating shaft table is installed at the upper end of the workbench and is connected with the workbench through a bearing; and a first flow guide plate is installed on the outer side of the upper end of the rotating shaft table and is fixedly connected with the rotating shaft table. According to the paint spraying device for automobile maintenance, paint can be guided to flow into the rotating shaft table through installation of a second flow guide plate, the practicability of the device is improved, the device can recover the paint more conveniently, and paint waste is avoided; and a sealing spring can be installed to jack a second recovering pipeline downwards, the second recovering pipeline makes close contact with a paint recovering box, the situations that the paint volatilizes unpleasant smell pollutes the environment are avoided, the practicability of the device is improved, workers can conveniently and rapidly mount and dismount the paint recovering box, the practicability of the device is improved, the use difficulty of the device is reduced, and the device is more user-friendly.

Owner:广州米粒科技有限公司

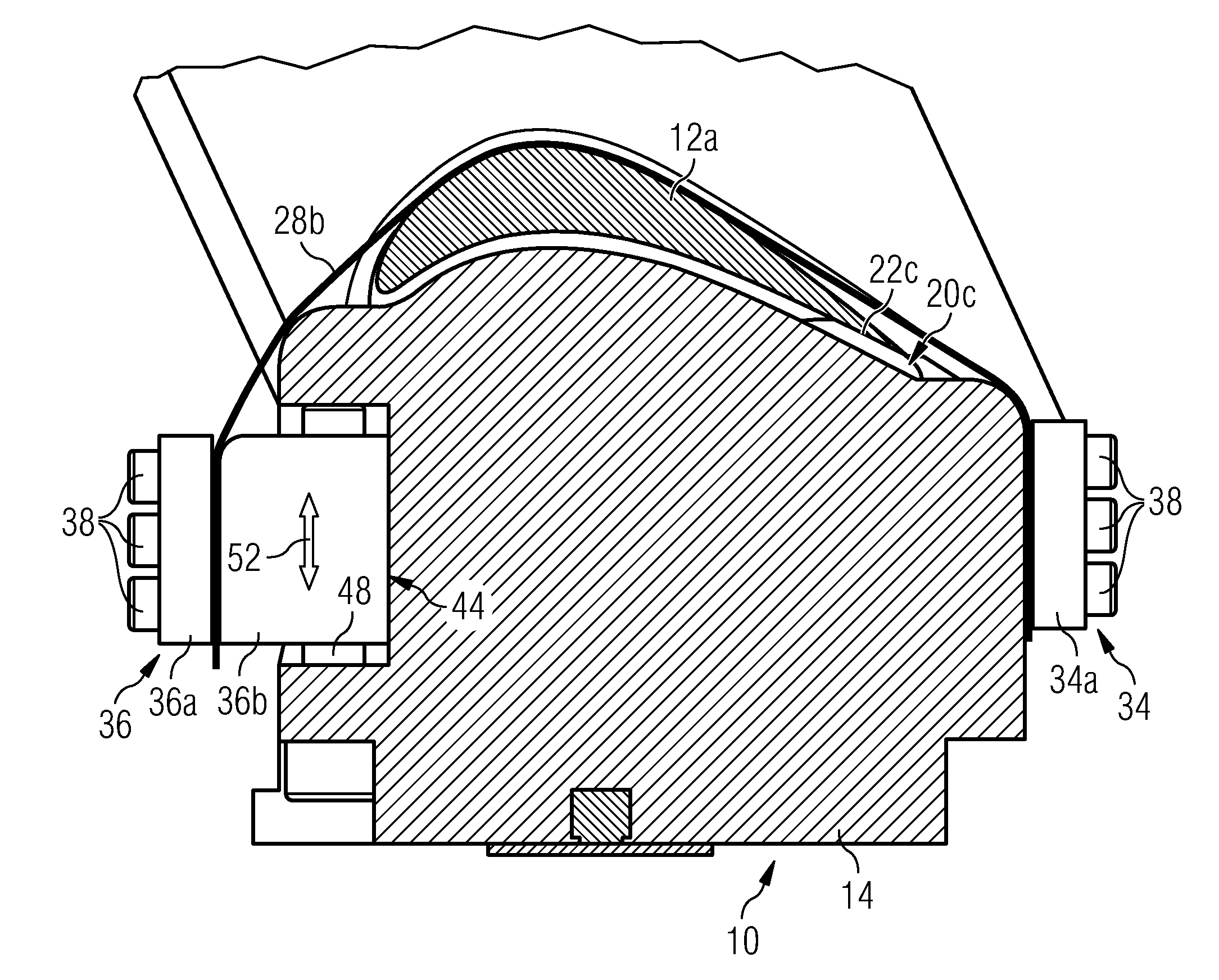

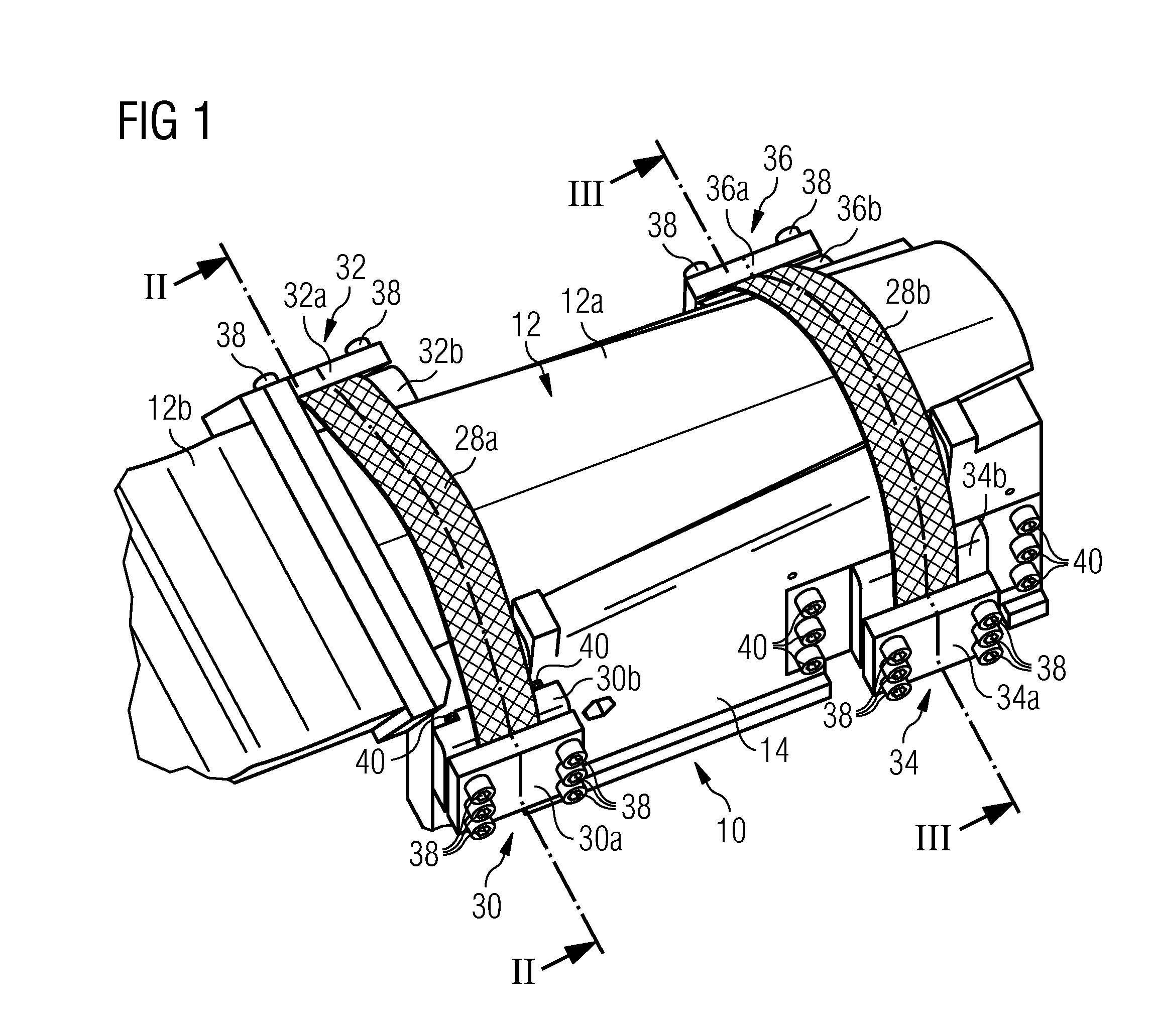

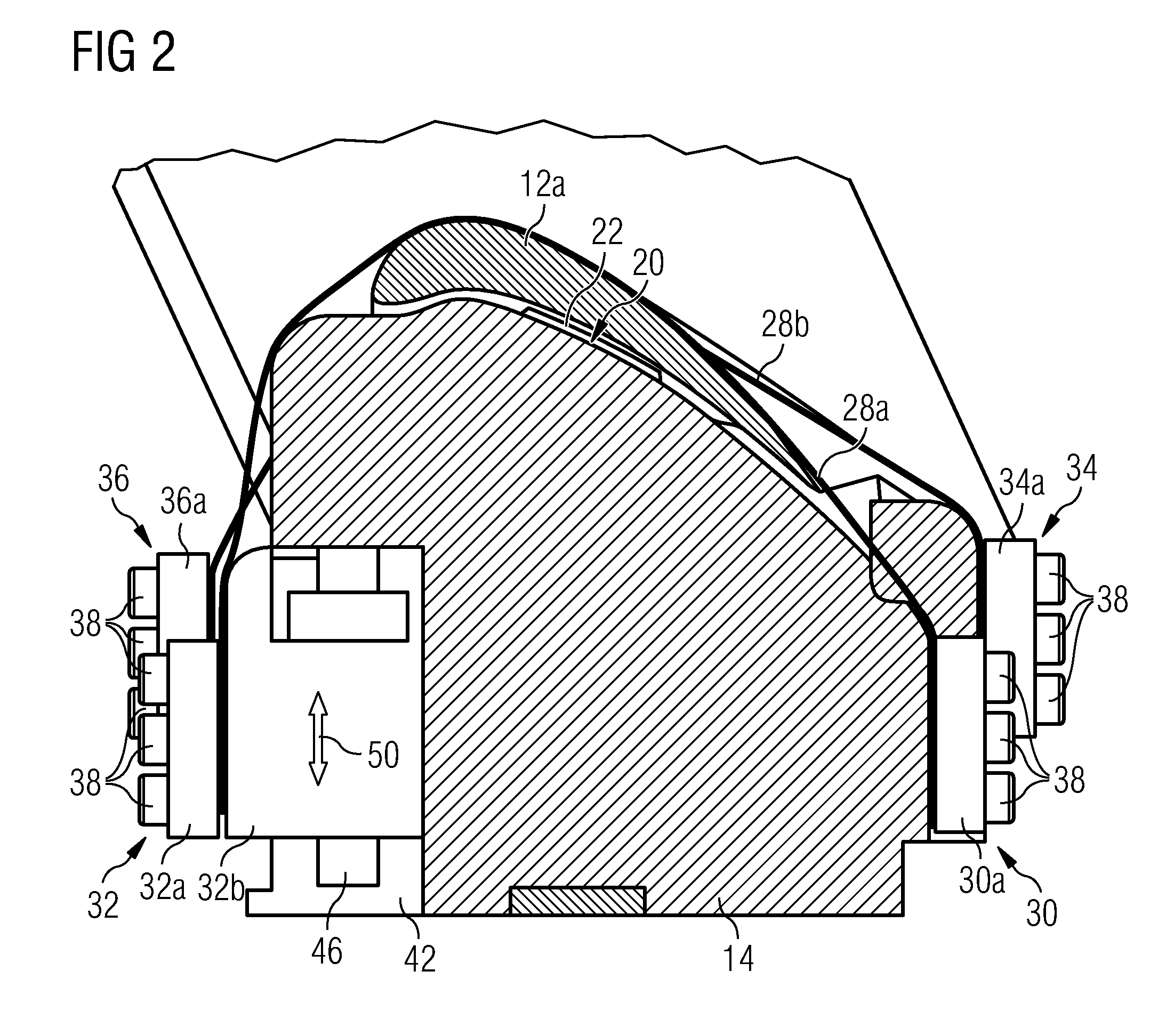

Workpiece clamping device

InactiveUS20100230883A1Short clamping timeGood accessibilityPositioning apparatusVicesTurbine bladeMachining

A workpiece clamping device for clamping a workpiece during machining is provided. The workpiece may be a turbine blade in the region of the blade airfoil. The workpiece clamping device includes a basic body with a workpiece seat, wherein provision is made for at least one clamping strap for clamping the workpiece.

Owner:SIEMENS AG

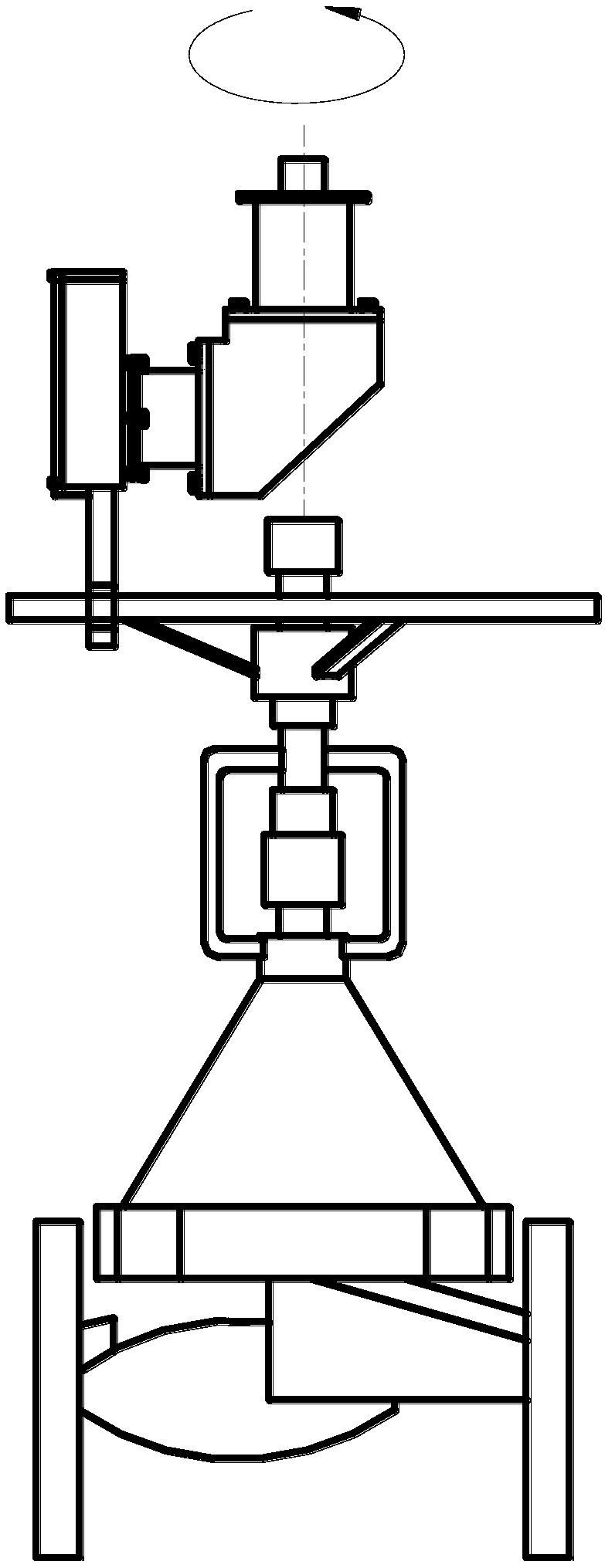

Fire-fighting robot for closing valve in case of fire

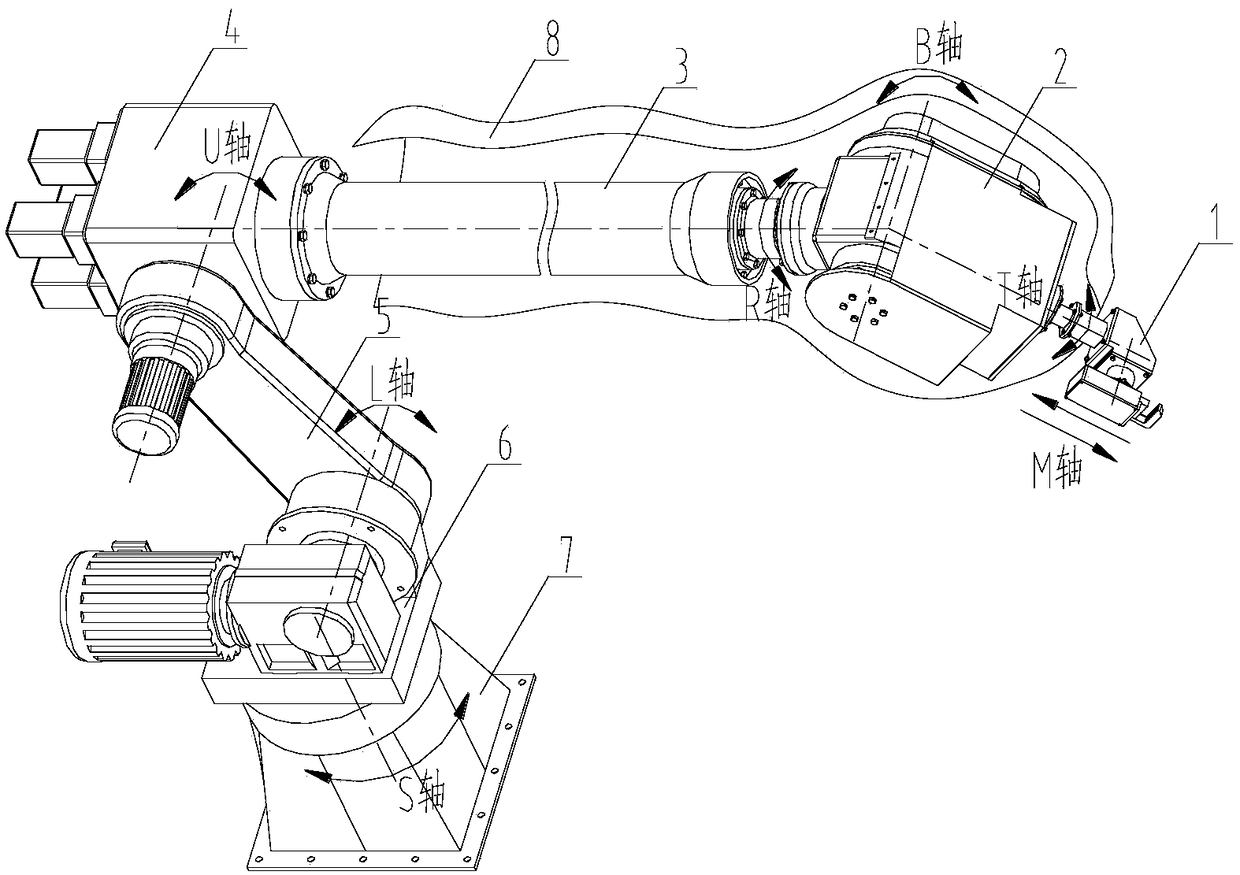

ActiveCN109318238AGood fire and explosion-proof performanceIncrease freedomArmsDrive motorEngineering

The invention discloses a fire-fighting robot for closing a valve in case of fire. The fire-fighting robot for closing the valve in case of fire comprises an end effector, a wrist unit, an upper arm unit, an upper arm drive unit, a lower arm unit, a waist unit, a base, and high-temperature-resistant protection clothing, wherein the end effector is used for opening and closing the valve through clamping a handle of the valve and rotating around the center of the valve; the wrist unit is connected with the upper arm unit through a spline and a bolt; and the upper arm unit plays a role in transmitting the movement of the end effector and the wrist unit. According to the fire-fighting robot for closing the valve in case of fire provided by the invention, all components adopt mechanical drivingand have excellent fire-proof and explosion-proof performances; driving motors at the working part are placed behind the upper arm drive unit located under the indoor temperature state, so that the whole machine has a reliable performance; and when the fire happened, the robot can directly fulfil the task of closing the valve at short range, and people can operate at the safety position, so thatthe problem that the inflammable and explosive pipeline valve cannot be closed when the fire happened can be effectively solved.

Owner:NANYANG NORMAL UNIV

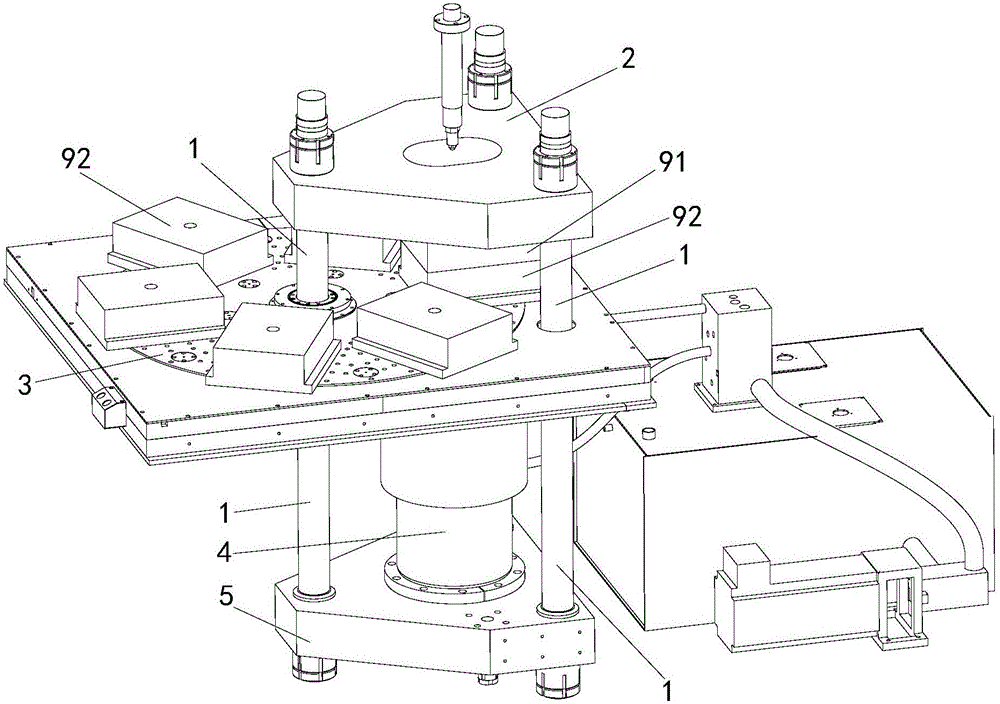

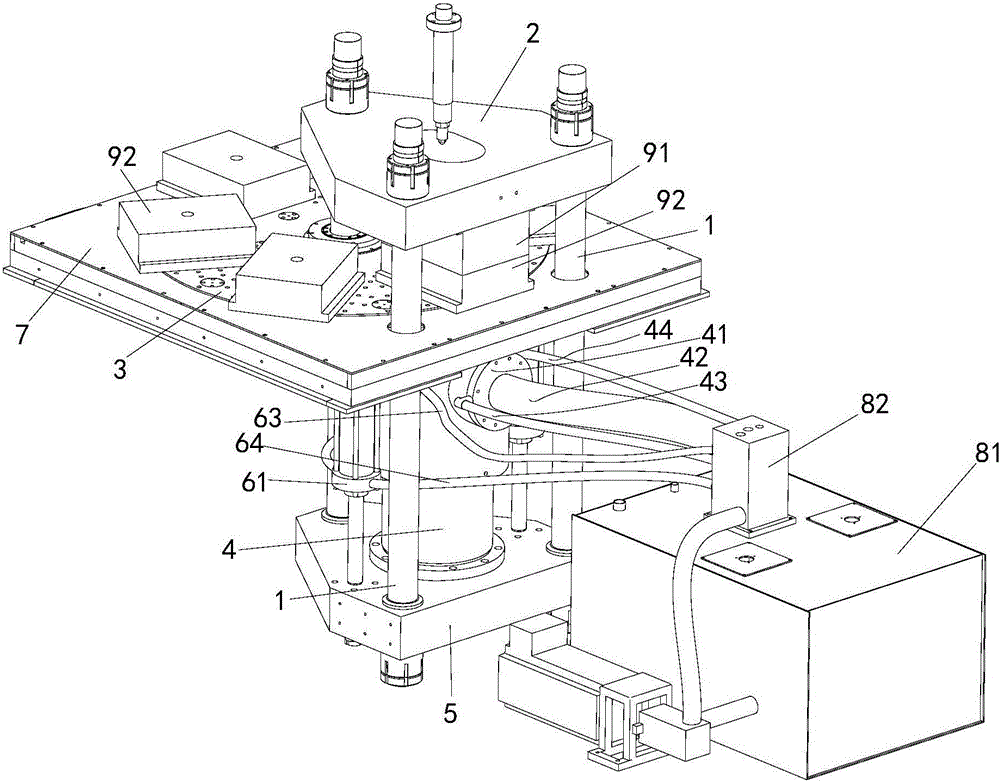

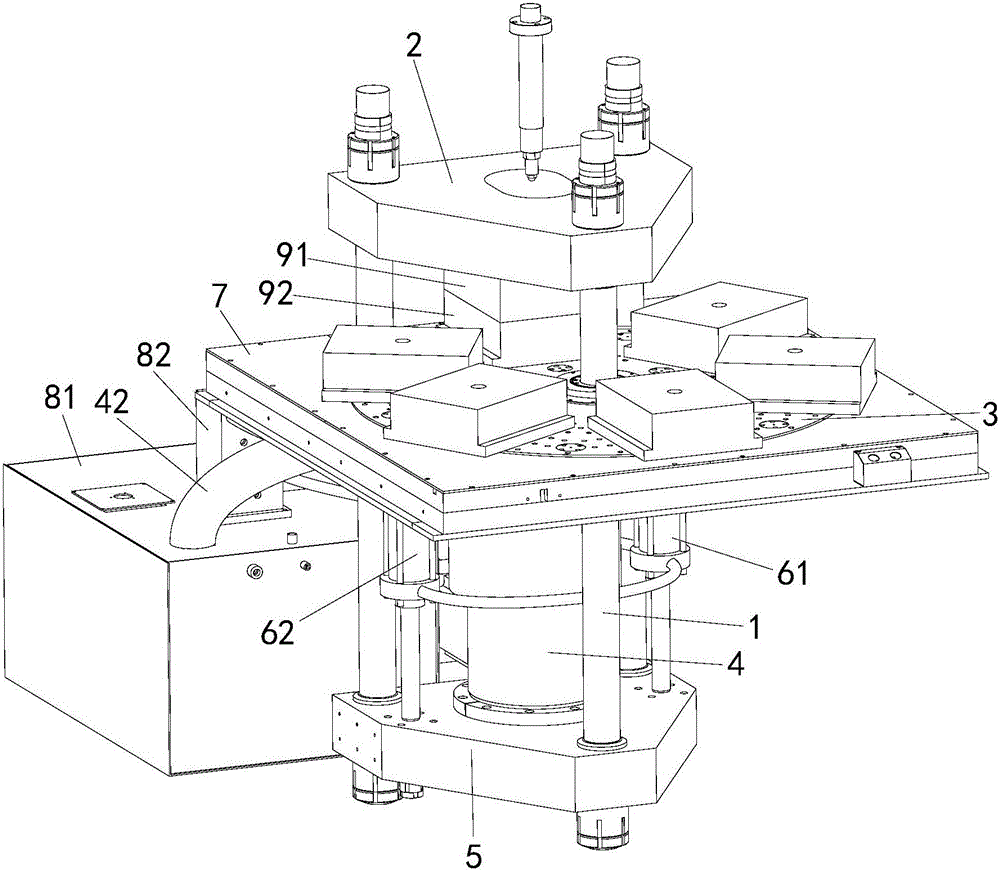

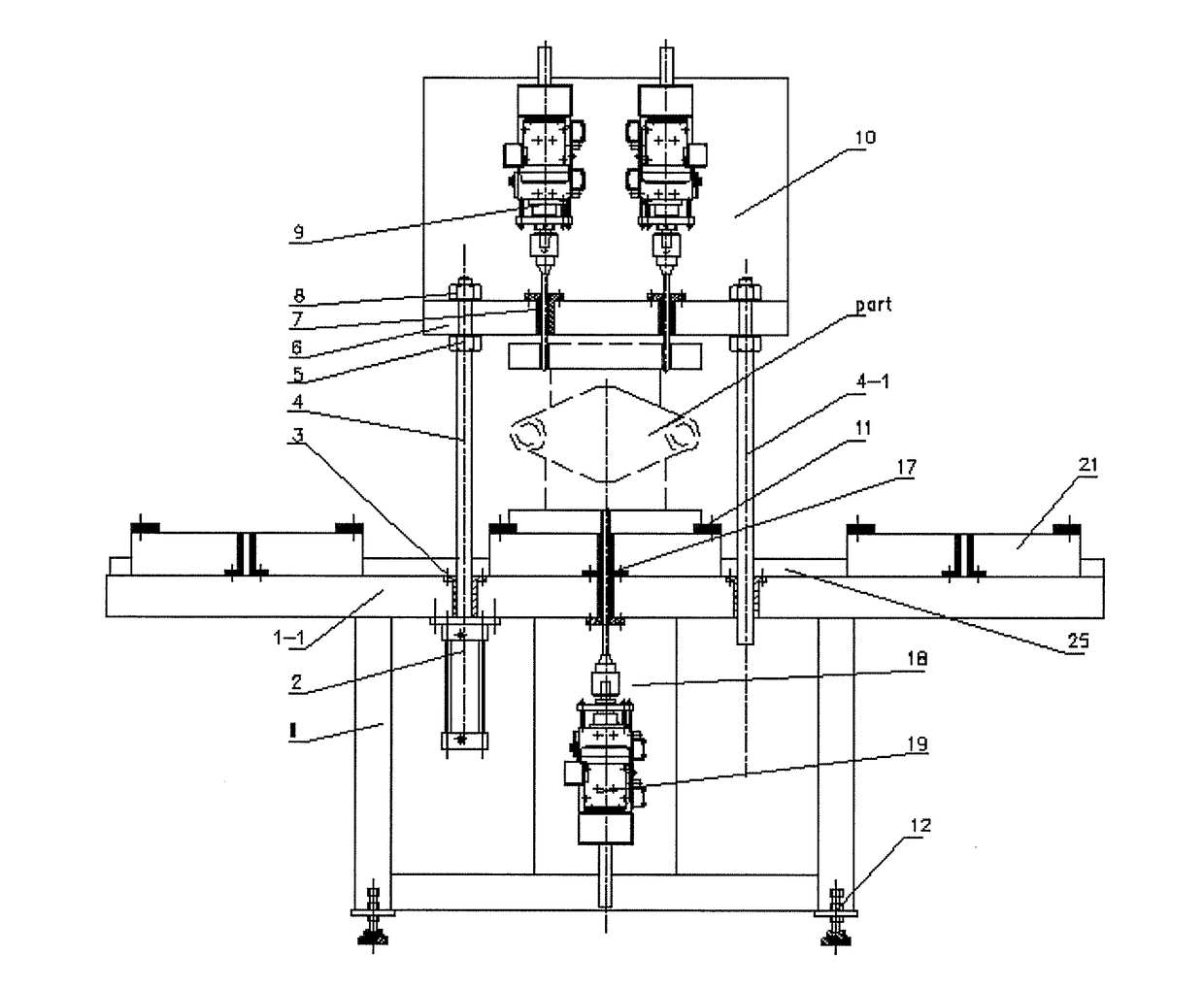

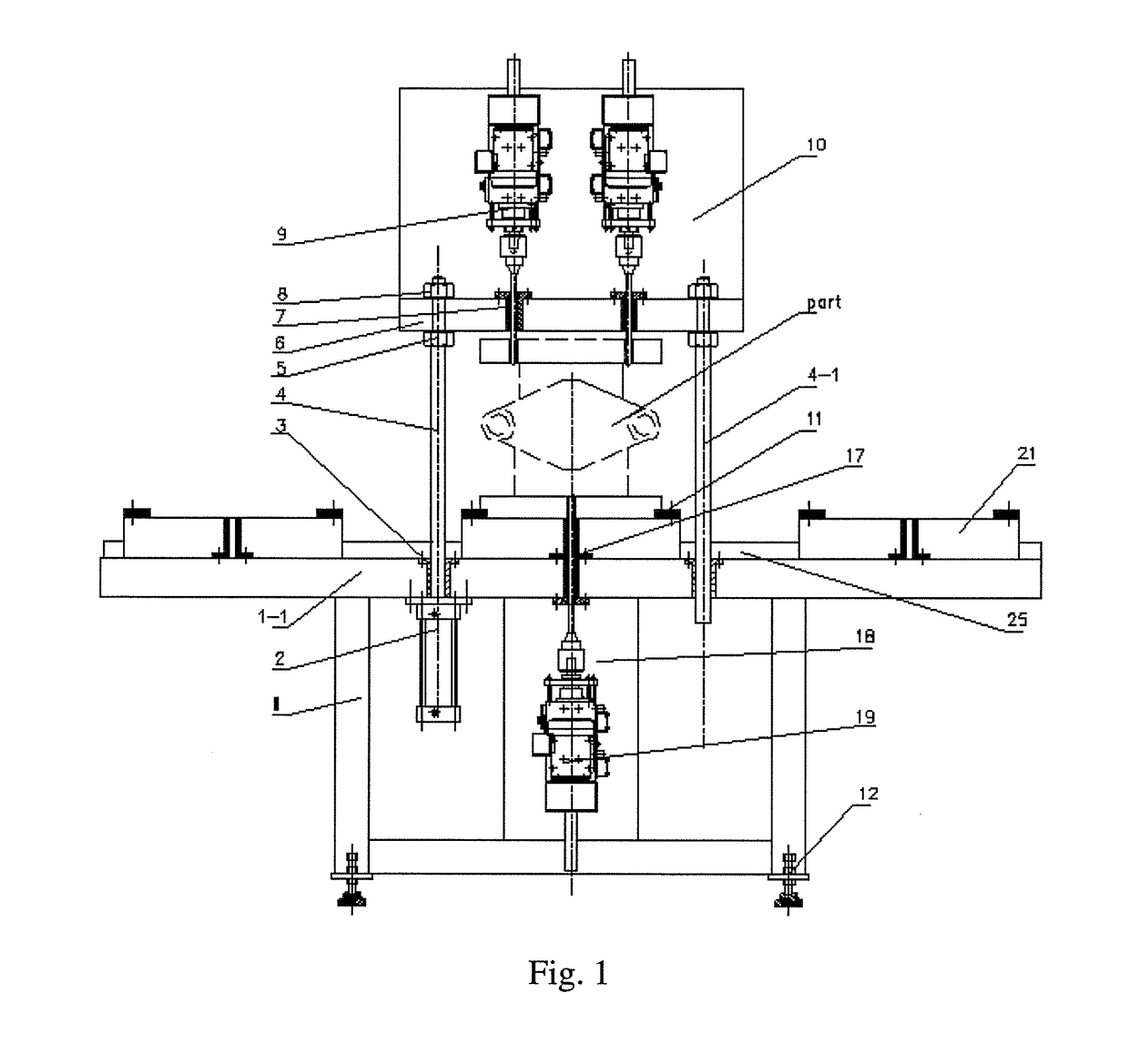

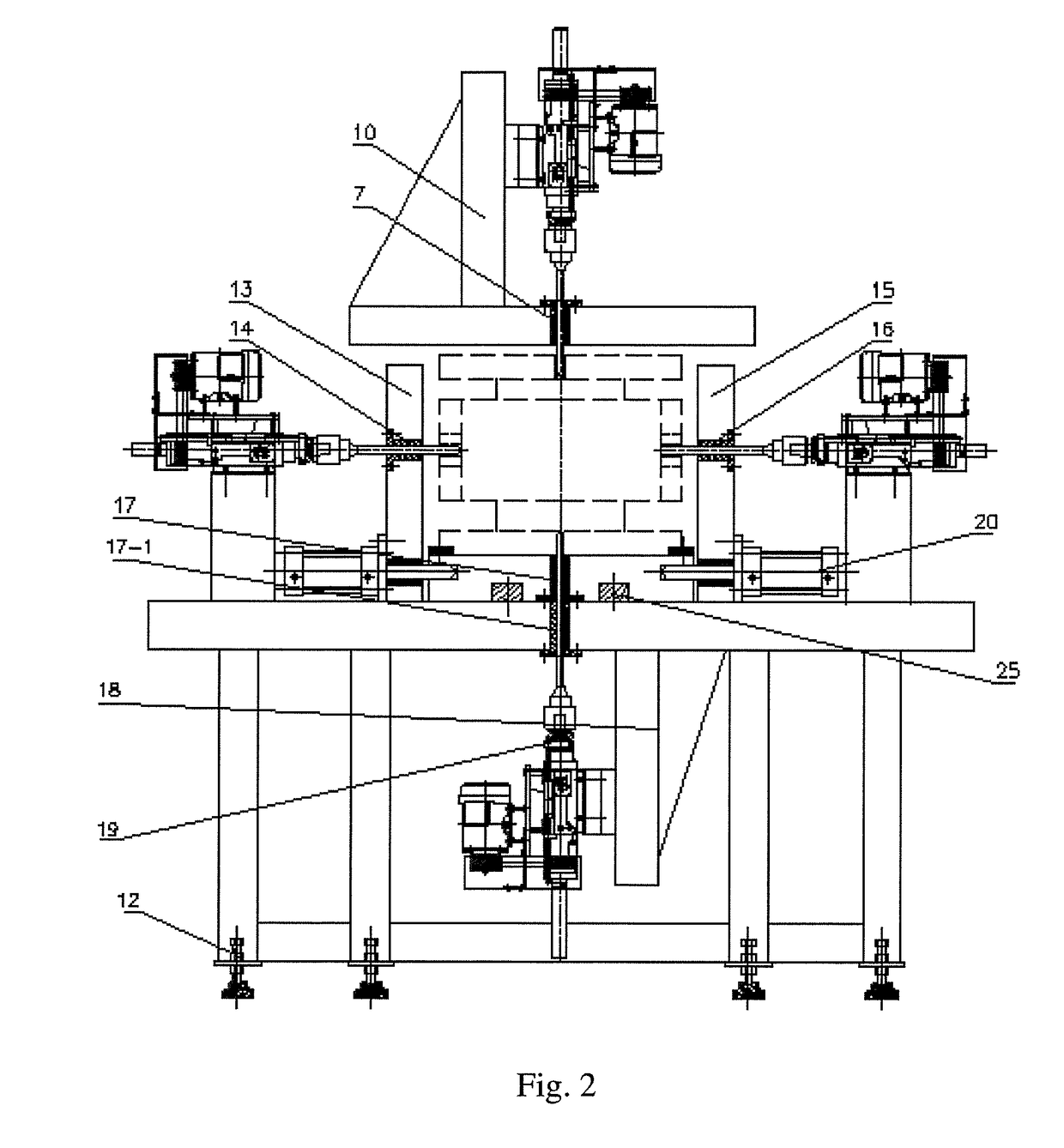

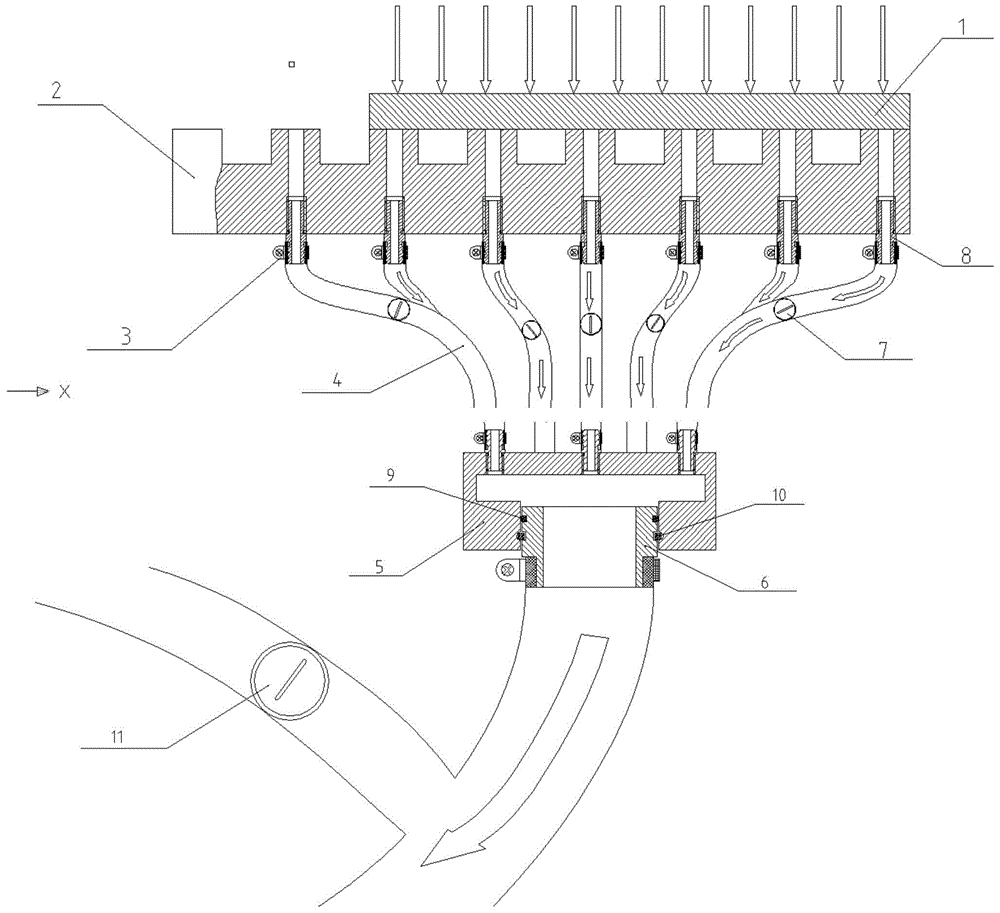

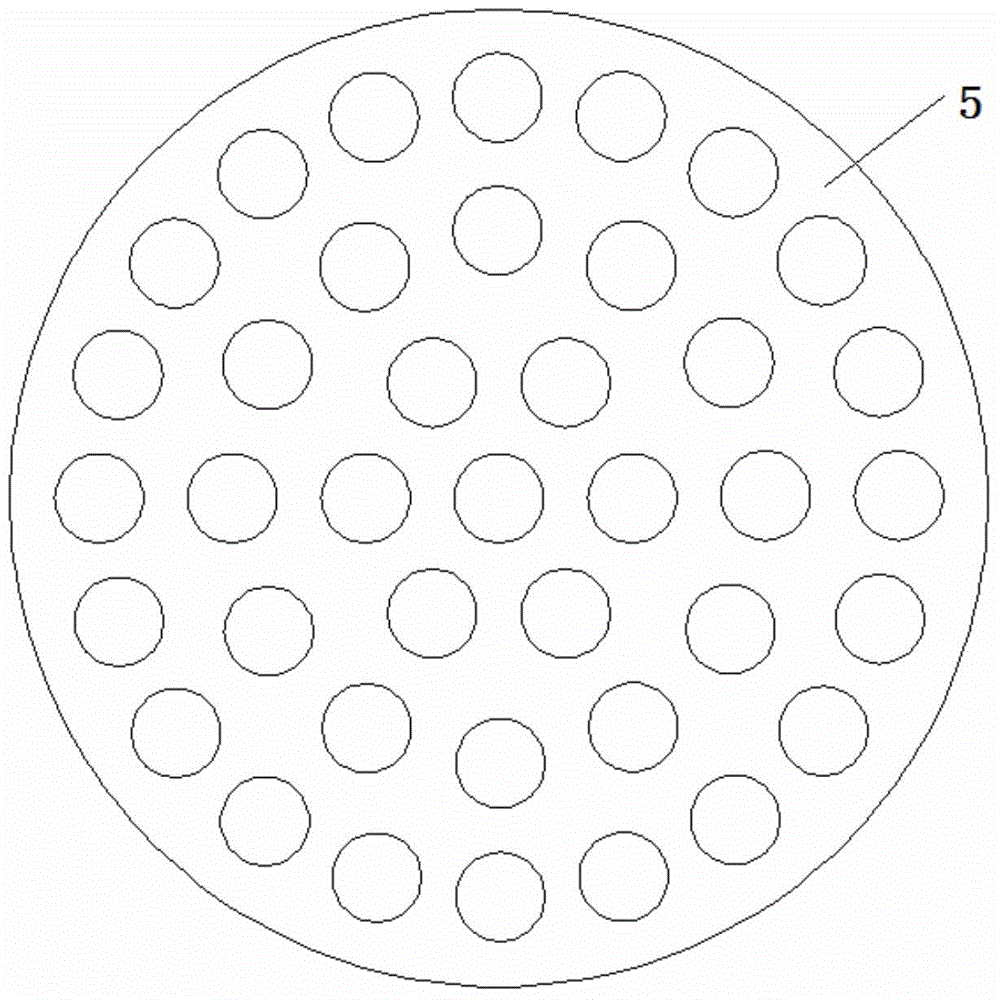

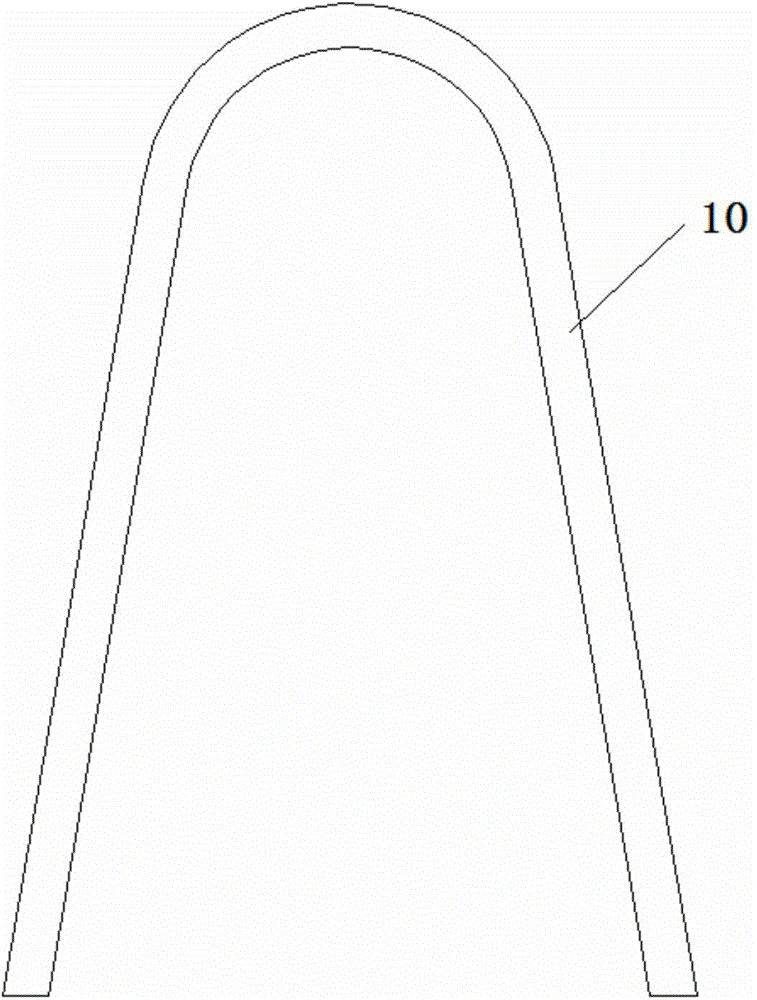

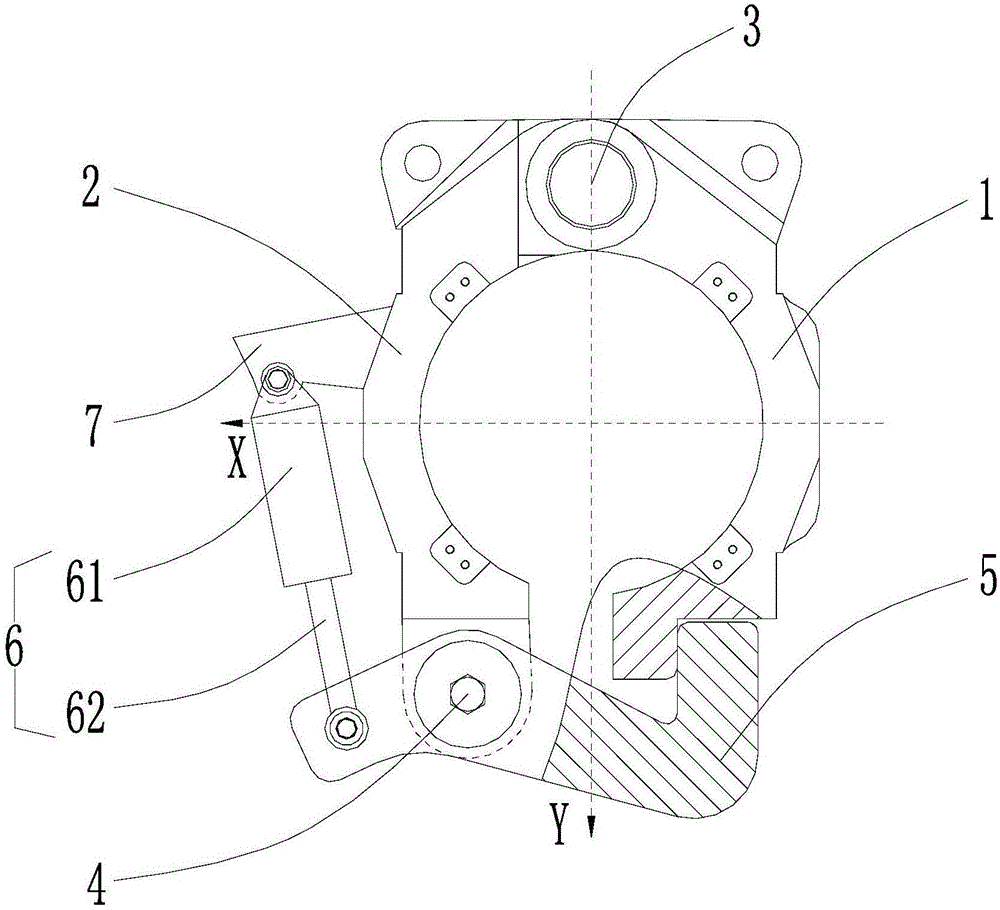

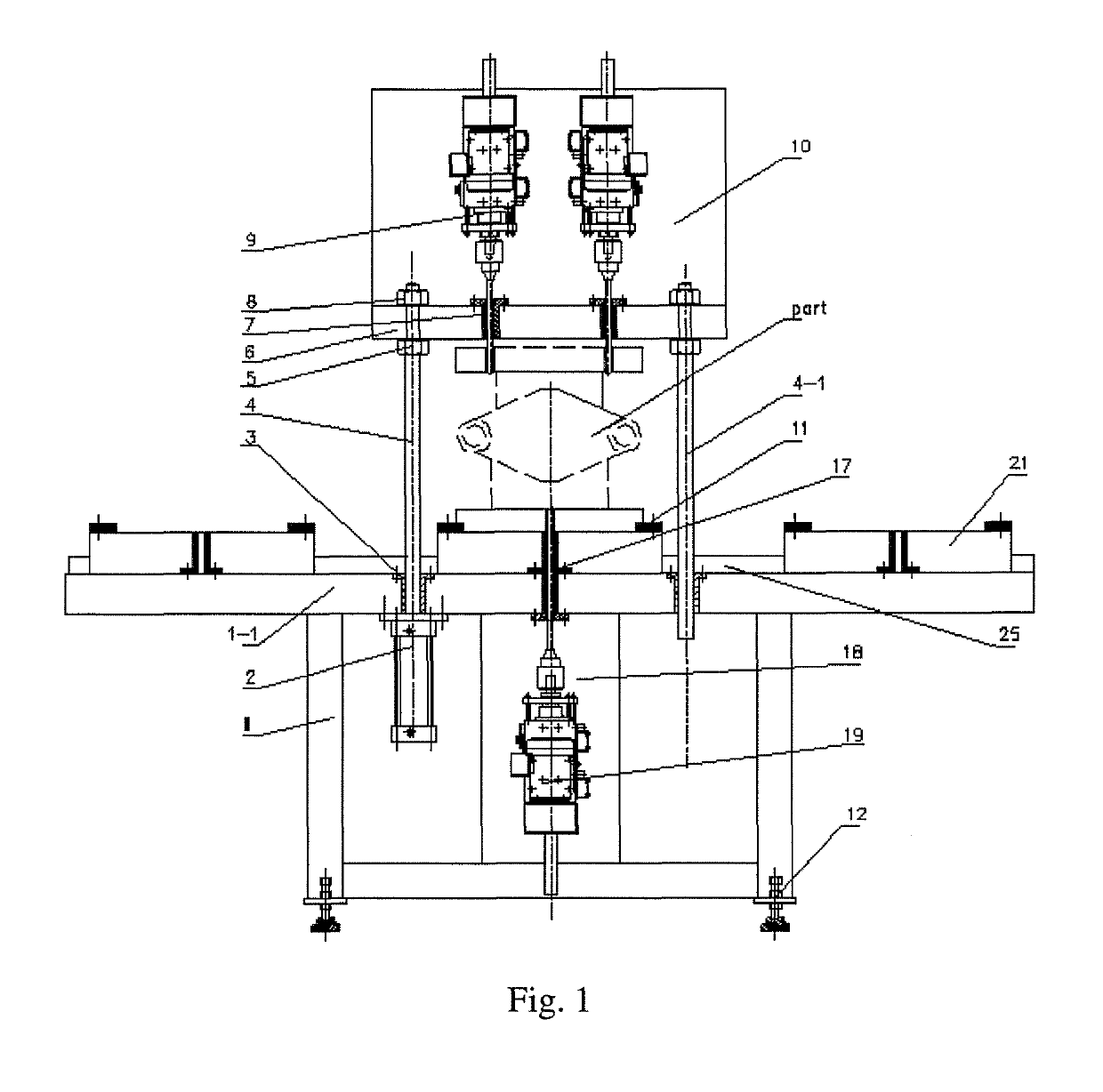

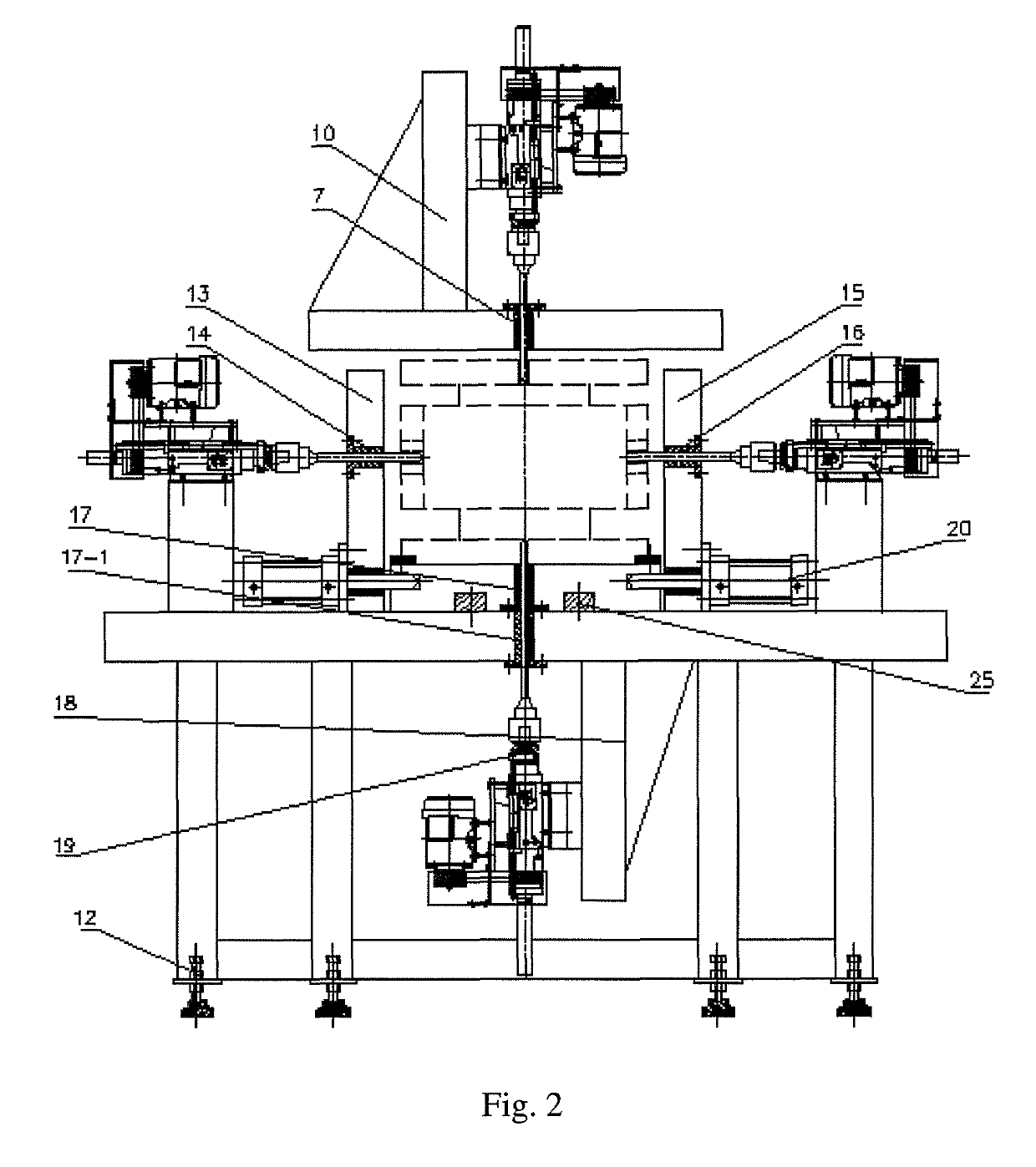

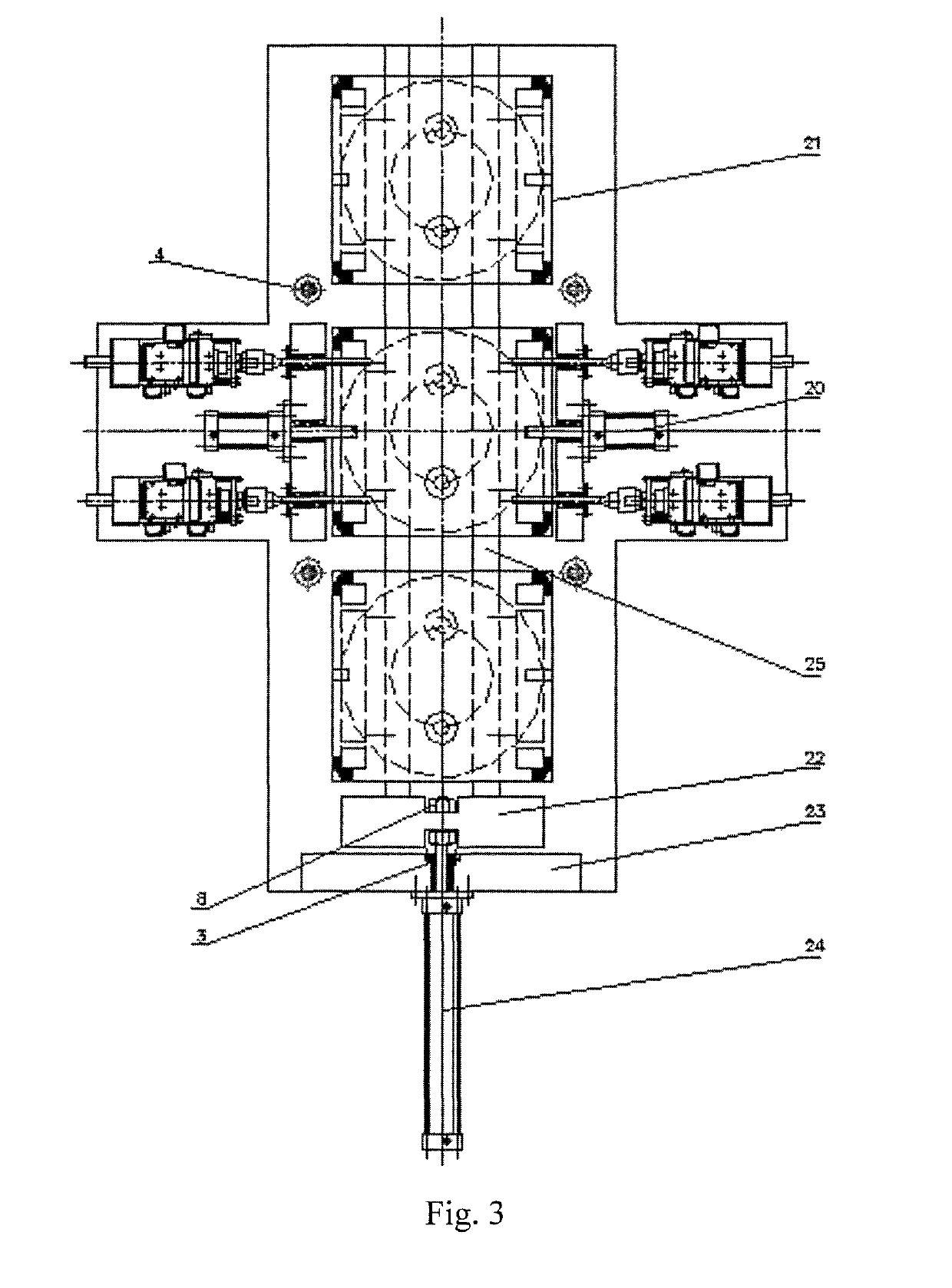

Four-directional drilling machine

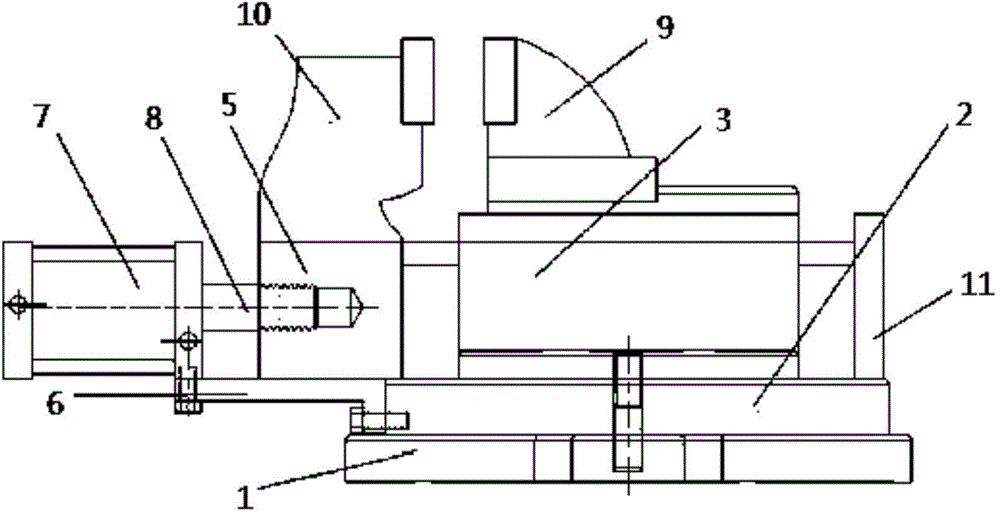

ActiveUS20180333788A1Shorter clamping timeReasonable and compact in clampingMetal working apparatusBoring/drilling machinesHydraulic cylinderPiston rod

The present application discloses a four-directional drilling machine, comprising a main frame, a main machine platform, flange-type hydraulic cylinders, linear bearings, hydraulic piston rods, guide rods, nuts A, an upper pressure plate, drill bushings A, nuts B, monoblock drilling machines A, an upper supporting plate, positioning stop blocks, adjustable base assemblies, a left supporting plate, a drill bushing B, a right supporting plate and the like.

Owner:CITIC DICASTAL

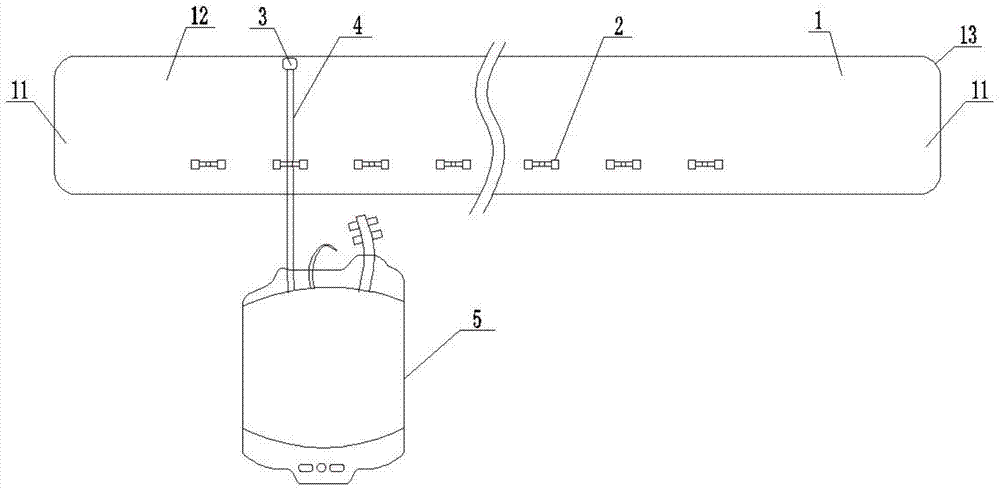

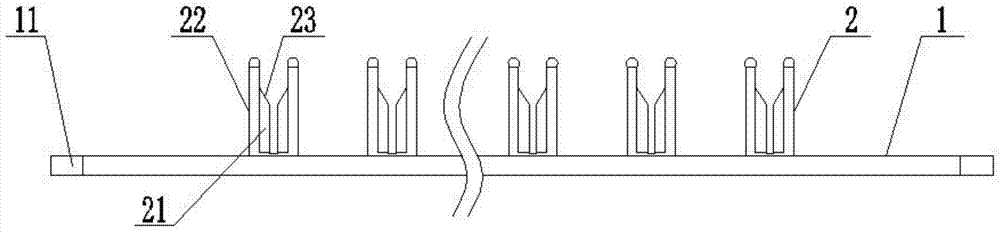

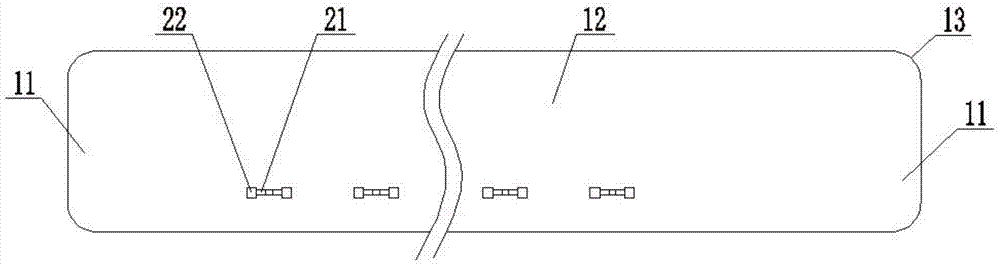

Auxiliary jig for PCB thin plate production

PendingCN112130055AShorter clamping timeImprove detection efficiencyPrinted circuit testingMeasurement instrument housingHydraulic cylinderElectric machinery

The invention provides an auxiliary jig for PCB thin plate production. The auxiliary jig for PCB thin plate production comprises a base, a first fixing seat which is fixedly mounted at the top of thebase, a second fixing seat which is fixedly mounted at the top of the base, a hydraulic cylinder which is fixedly mounted on the outer wall of one side of the first fixing seat, a connecting block which is fixedly mounted on a telescopic shaft of the hydraulic cylinder, a rotating rod which is rotationally mounted on the outer wall of one side of the connecting block, a clamping block which is fixedly mounted at one end, far away from the connecting block, of the rotating rod, and a motor which is fixedly mounted on the outer wall of one side of the connecting block. The auxiliary jig for PCBthin plate production has the advantages of being convenient to use, high in clamping speed and capable of improving the detection efficiency.

Owner:AOSHIKANG TECH CO LTD

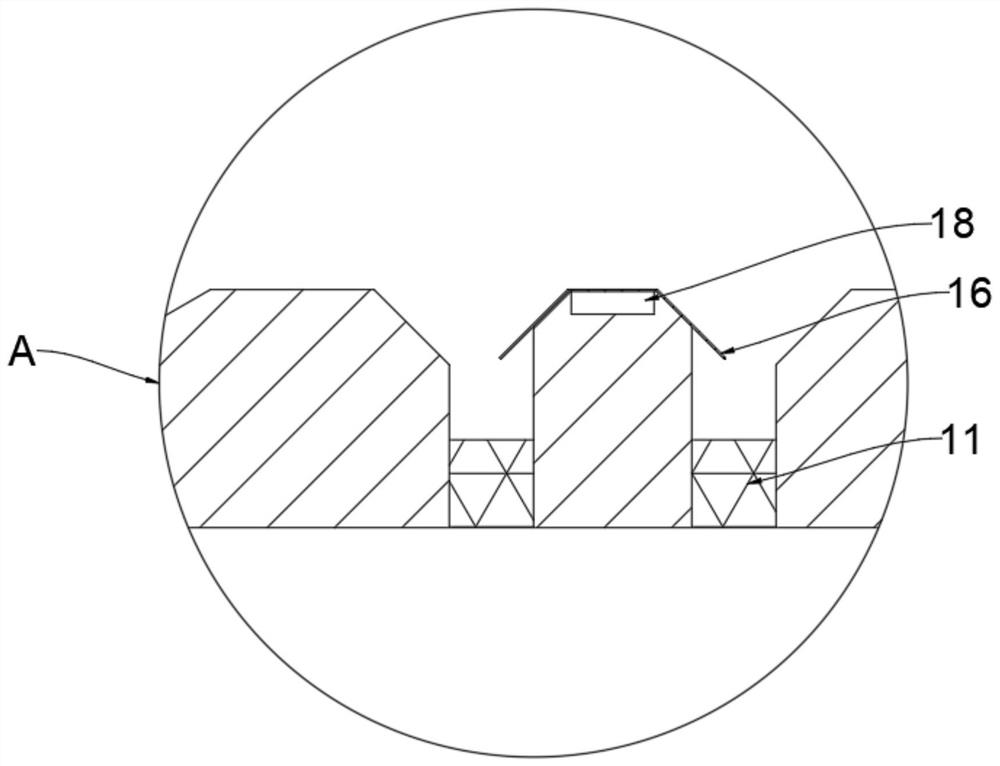

Air pressure large force suction cup

InactiveCN104589080ASimple structureDon't worry about magnetizationWork clamping meansPositioning apparatusEngineeringAir compressor

An air pressure large force suction cup comprises a clamping platform, and a plurality of same square tables are milled on the clamping platform; through holes are punched in the square tables, and threads are arranged at the bottoms of the through holes; a plurality of high-pressure air pipes are connected with the through holes through air pipe joints inserted into the bottoms of the through holes; and air valves are arranged on the high-pressure air pipes. A round cake joint is further included, and is of a round cake cavity structure, and a plurality of same screw holes are evenly distributed in the upper surface of the round cake joint; and the other ends of the high-pressure air pipes are connected with the round cake joint through the air pipe joints inserted into the screw holes. An opening in the lower portion of a cavity of the round cake joint is matched with an air pipe chuck through an O-shaped ring, and is limited through a spring clamping strip, and the other end of the air pipe chuck is connected with an air compressor pipe; and a pressure relief valve is arranged on a branch of the air compressor pipe. The air pressure large force suction cup has the advantages of being convenient, easy to operate, efficient and low in cost.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

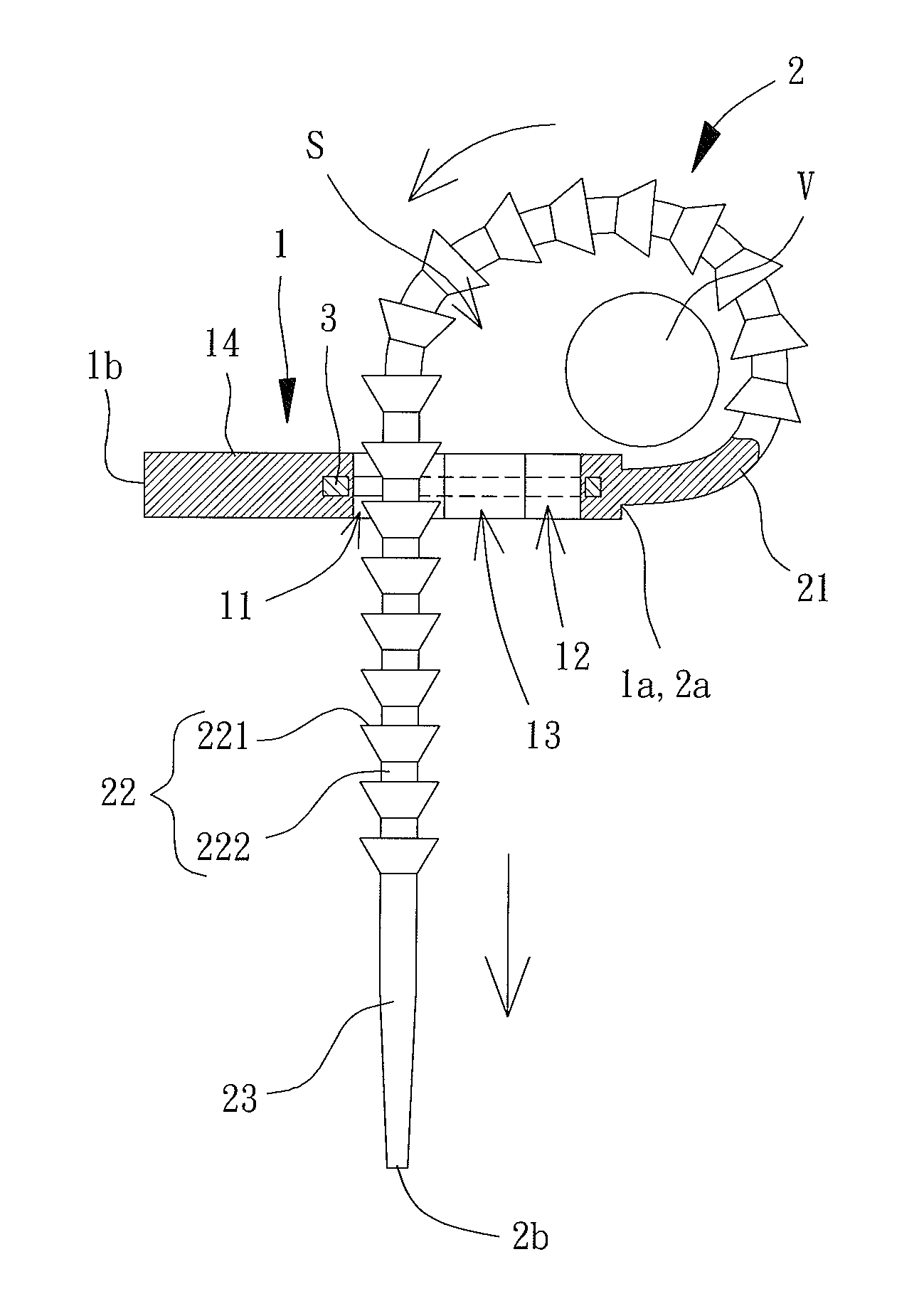

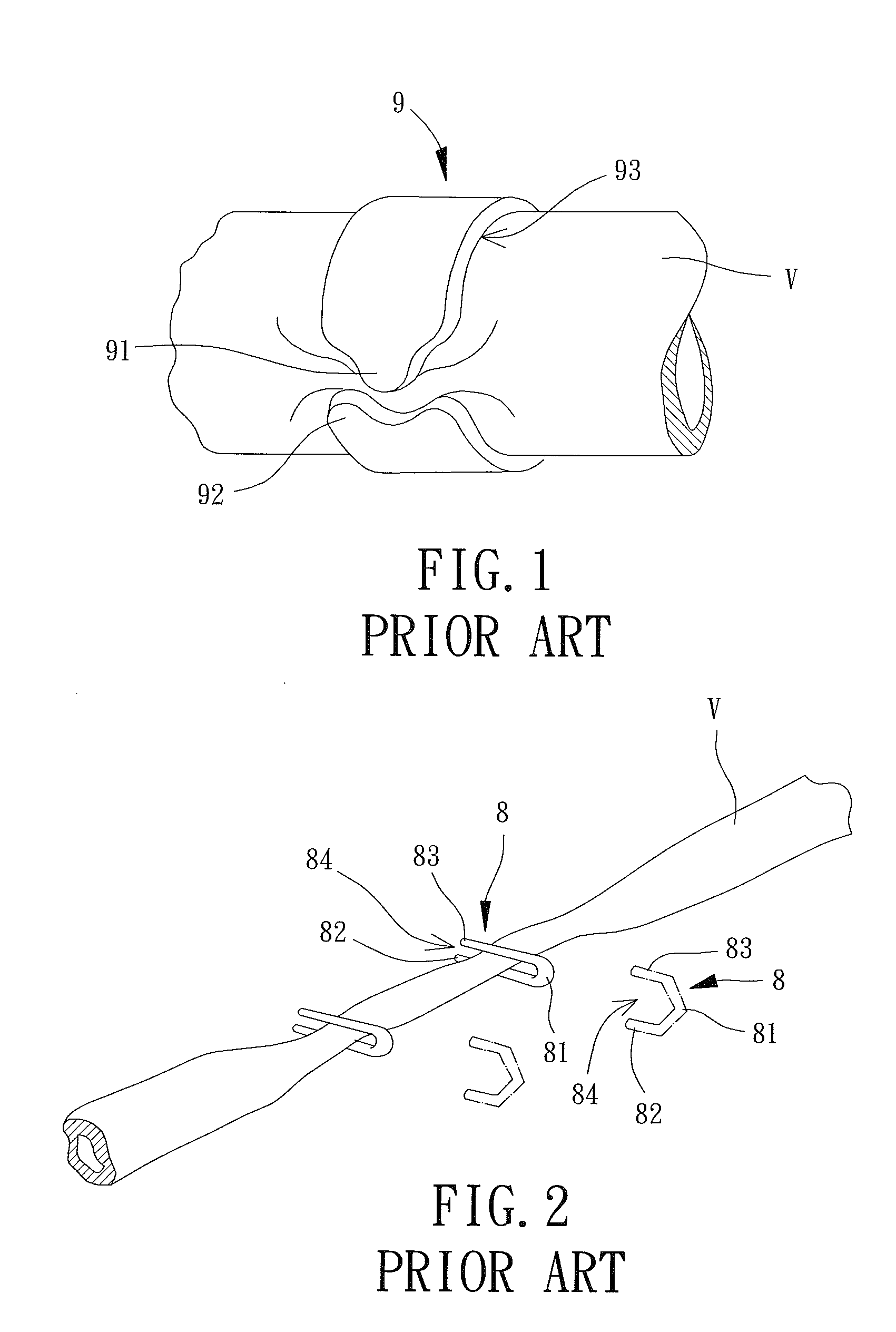

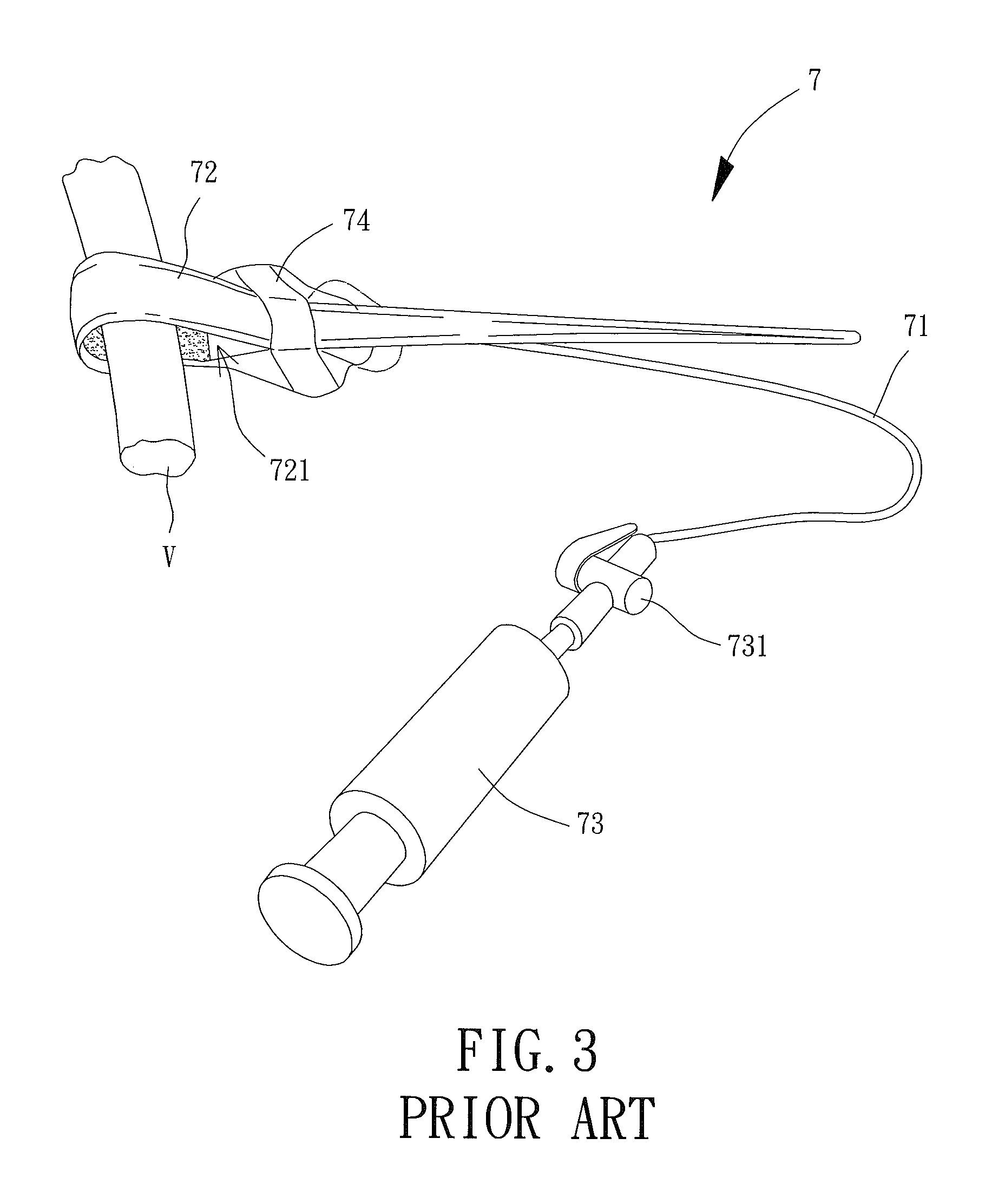

Vascular Clamp for Use in Minimally Invasive Surgery

InactiveUS20160151067A1Improve efficiencyShorter clamping timeWound clampsLess invasive surgeryVascular clamp

A vascular clamp for use in minimally invasive surgery includes a positioning member having a first side and a second side opposite to the first side and looping / tightening member and a reinforcing member. The positioning member includes a through-hole, a positioning hole, and a connection gap intercommunicating the through-hole with the positioning hole. Each of the through-hole, the positioning hole, and the connection gap extends from the first side through the second side of the positioning member. The looping / tightening member includes a connection end and a free end. The connection end is connected to the positioning member. The looping / tightening member includes a positioning section having a plurality of engagement blocks. A neck is interconnected between two adjacent engagement blocks. One of the engagement blocks is selectively and removably engaged in the positioning hole. The reinforcing member is mounted between the first and second sides of the positioning member.

Owner:METAL INDS RES & DEV CENT

Mold locking device for bottle blowing machine

PendingCN106477853AImprove blowing efficiencyFew partsGlass blowing apparatusGlass productionEngineeringBottle

The invention discloses a mold locking device for a bottle blowing machine. The bottle blowing machine comprises a fixed mold base and a movable mold base, wherein one end of the movable mold base is rotatablely arranged on one end of the fixed mold base, and the movable mold base is used for cooperating with the fixed mold base to open or close the mold. The mold locking device comprises a mold locking shaft arranged on the other end of the movable mold base, and a mold locking arm which rotates around the mold locking shaft and is sheathed on the mold locking shaft, wherein one end of the mold locking arm adjacent to the fixed mold base is used for performing collision along the first direction and locking the other end of the fixed mold base. The mold locking device also comprises a driving mechanism which is arranged on the movable mold base and used for driving the mold locking arm to rotate around the mold locking shaft, wherein the driving mechanism is used for driving one end of the mold locking arm to approach or deviate from the other end of the fixed mold base along the line of the second direction so as to lock or unlock the mold; and the first direction is perpendicular to the second direction. By setting the first direction to be perpendicular to the second direction, no matter how huge the power in the first direction is used for opening the mold base, the force component in the second direction is always zero, thereby failing to push the mold locking arm to move; and only one fixed cylinder is needed.

Owner:JIANGSU NEWAMSTAR LIQUID PACKAGING ENG TECH RES CENT CO LTD

Computer hardware maintenance and detection device

InactiveCN111679947ASpeed up cleaningImprove cleaning efficiencyDetecting faulty computer hardwareAir pumpEngineering

The invention provides a computer hardware maintenance and detection device, wherein a fixed base is fixedly mounted on the upper surface of the worktable; a storage battery is mounted in the worktable; an air pump is arranged on the left side of the storage battery in the workbench; an air storage tank is arranged above the storage battery and the air pump in the workbench; first mounting slidinggrooves are formed in the left side and the right side of the upper surface of the workbench correspondingly. And second mounting sliding grooves are formed in the front portion and the rear portionof the upper surface of the fixing base correspondingly, second connecting sliding blocks are slidably connected to the interiors of the left side and the right side of the fixing base correspondingly, first connecting sliding blocks are slidably connected to the interiors of the first mounting sliding grooves, and first sliding resistors are embedded into the lower ends of the first mounting sliding grooves. According to the computer hardware cleaning device, the cleaning speed of computer hardware can be increased, directional flowing airflow is formed in the cleaning cylinder cover throughthe connecting air pipe and the spray head, dust on the surface of the computer hardware is stripped, the cleaning efficiency is improved, the two sides of the computer hardware are fixed while cleaning is conducted, and the clamping time is saved while labor force is saved.

Owner:宜昌力天科技有限公司

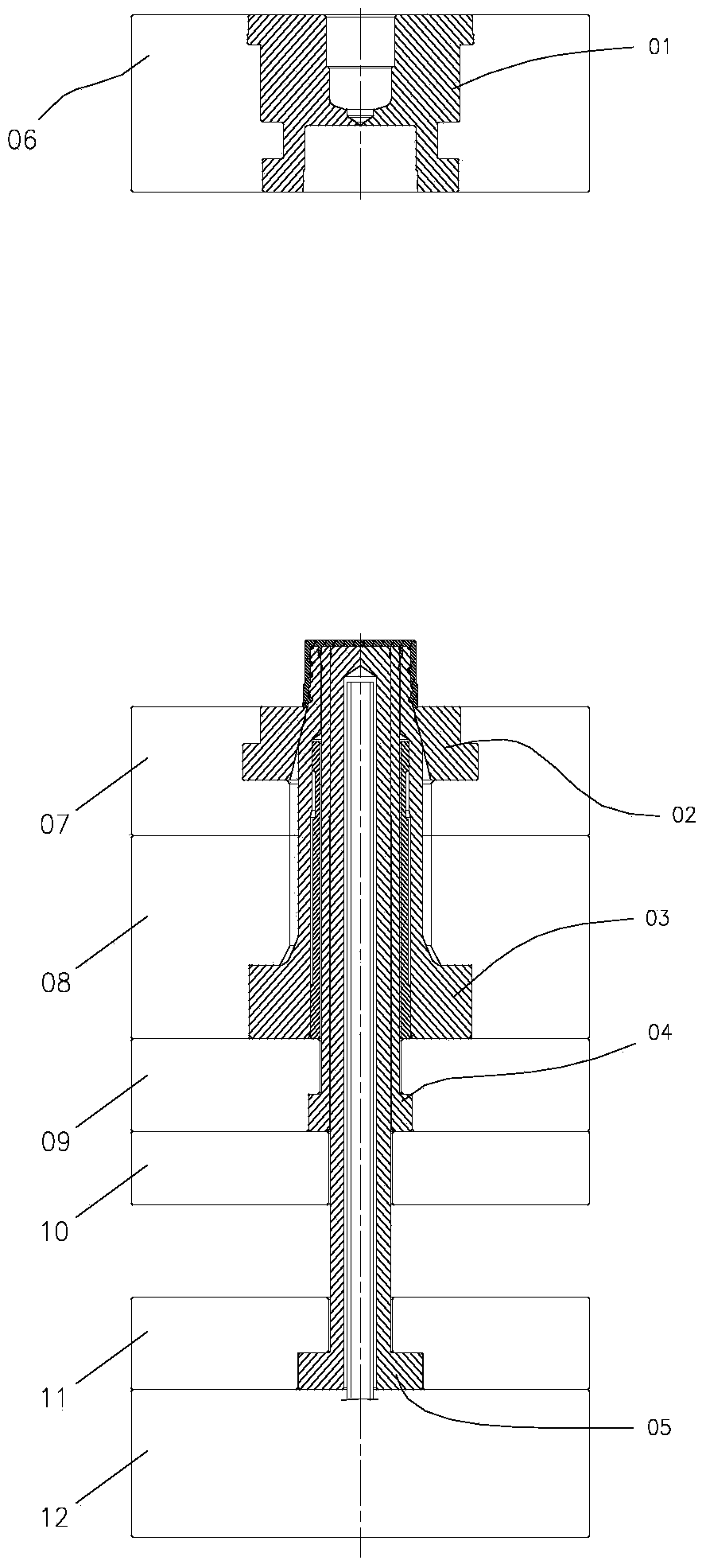

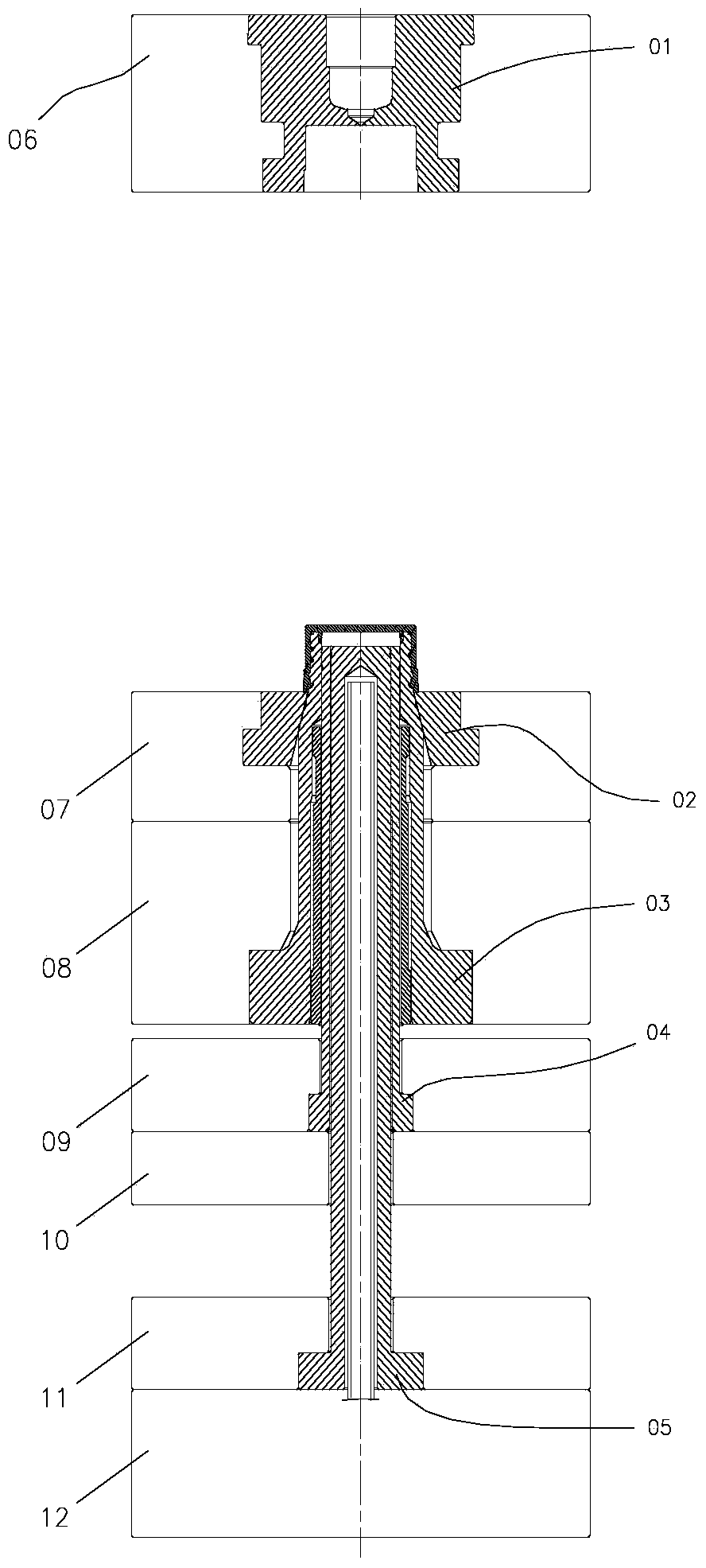

Vertical type fixed hydraulic power chuck

InactiveCN101920350BEasy clampingSimple structureChucksPositioning apparatusProduction rateNumerical control

The invention relates to a vertical type fixed hydraulic power chuck which comprises a chuck body, a wedge catch system, a blocking cover, three claws, three slide carriages and six T-shaped blocks, and is characterized in that an oil cylinder body and a base form an oil cylinder main body; a piston is installed in the oil cylinder body and slides in the oil cylinder body along the direction of aguiding shaft; an upper oil chamber and a lower oil chamber are formed above and below the piston; the control hydraulic oil of the upper oil chamber and the lower oil chamber is controlled by a leftoil inlet and outlet hole or a right oil inlet and outlet hole; the piston is connected with the wedge catch system by a driving connecting screw; under the driving of the piston, the wedge catch system slides up and down in the chuck body; and the chuck body is connected seamlessly and fixedly with the oil cylinder body by a connecting bolt. The structure of the invention is simple, compact and reasonable, the vertical type fixed hydraulic power chuck connects the cylinder body and the chuck integrally and is loaded on a work bench, a workpiece can be loaded and clamped conveniently, and quick die changing can be realized, thereby greatly lightening the labor intensity, shortening the clamping time, improving the productivity, having adjustable clamping force, and being suitable for matching with a numerical control machining center.

Owner:江苏无锡建华机床附件集团有限公司

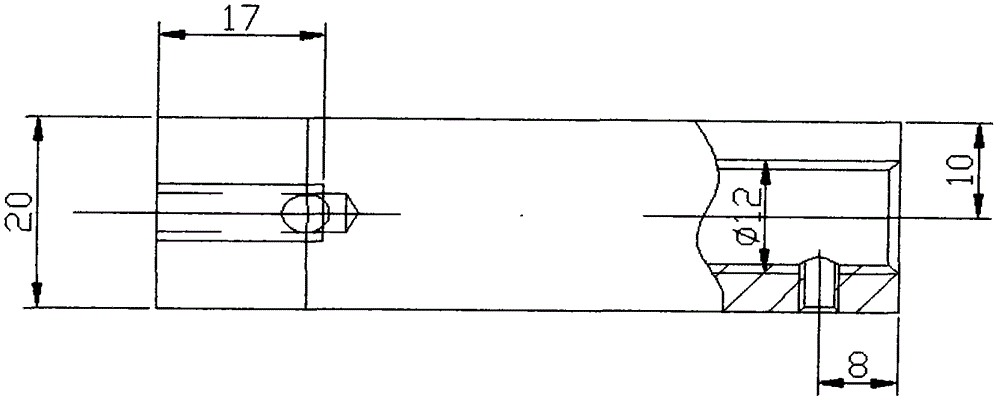

Round tube shaped object rapid clamping device, application method and application thereof

InactiveCN102626909BLarge diameter rangeEasy clampingEngine testingWork holdersEngineeringScrew thread

The invention discloses a round tube shaped object rapid clamping device. The round tube shaped object rapid clamping device comprises a block shaped main piece, a bolt stud, a bolt stud, a locking bolt, a fastener and a steel wire, wherein the block shaped main piece is provided with an internal thread; the bolt stud is provided with an external thread and the internal thread; the bolt stud is only provided with an external thread; the bolt stud with the external thread and the internal thread rotationally enters a threaded hole formed by the internal thread of the block shaped main piece; and by rotating the bolt stud with the external thread and the internal thread, the steel wire can be tightened so that a round tube shaped object is clamped. Compared with shortcomings of a strip shaped clamp for clamping the round tube shaped water tube in the automobile mechanical production in the prior art, the advantages of the round tube shaped object rapid clamping device disclosed by the invention are capability of achieving the need of rapidly clamping the round tube shaped object in the production, good clamping performance, large diameter range of the clamped tubular body, durability, convenience in operation, clamping time conservation, good repeated use resistance, uneasiness for damaging and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Four-directional drilling machine

ActiveUS10286457B2Reasonable and compact in clamping and pushingShorter clamping timeMetal working apparatusBoring/drilling machinesHydraulic cylinderDrill bushing

The present application discloses a four-directional drilling machine, comprising a main frame, a main machine platform, flange-type hydraulic cylinders, linear bearings, hydraulic piston rods, guide rods, nuts A, an upper pressure plate, drill bushings A, nuts B, monoblock drilling machines A, an upper supporting plate, positioning stop blocks, adjustable base assemblies, a left supporting plate, a drill bushing B, a right supporting plate and the like.

Owner:CITIC DICASTAL

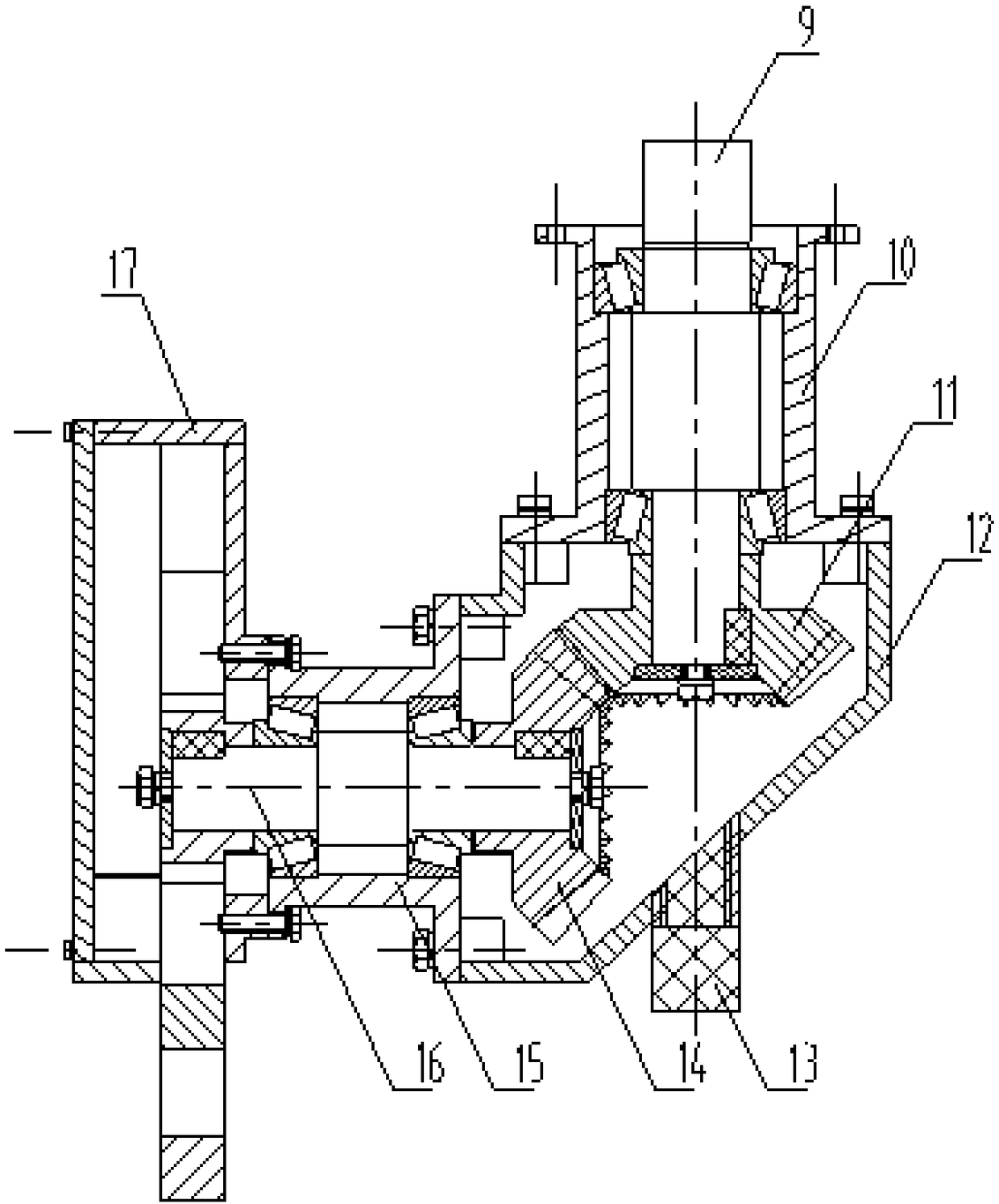

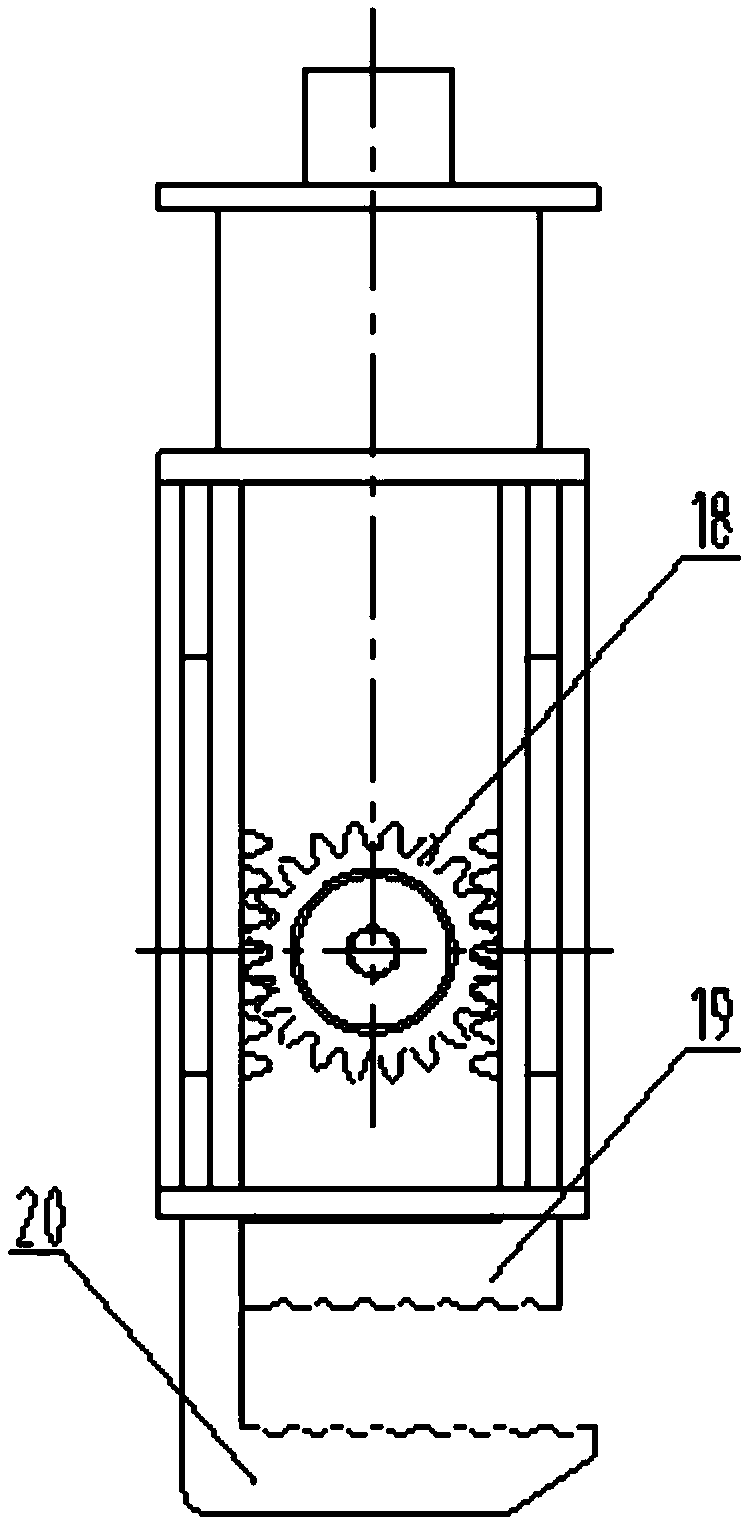

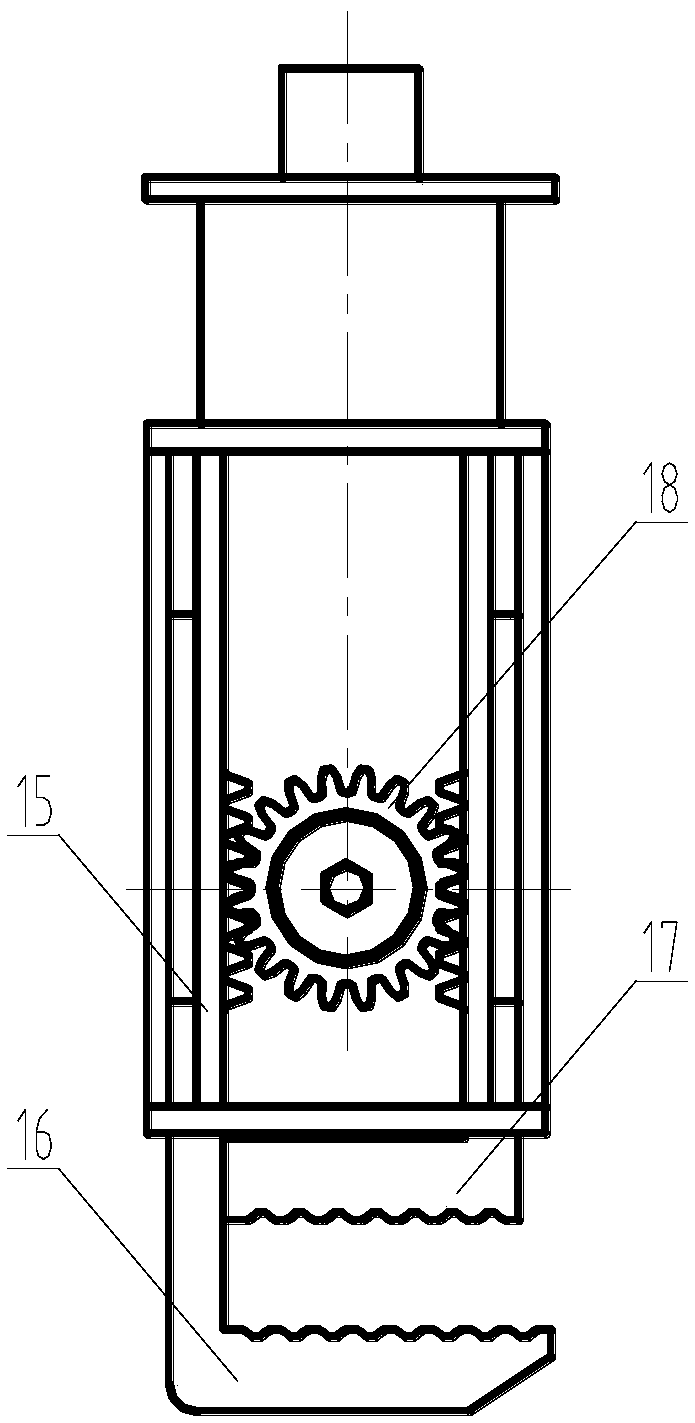

End effector of fire-fighting robot used for fire valve closing

ActiveCN109114295AImprove fire and explosion-proof performanceImprove performanceOperating means/releasing devices for valvesGripping headsRobot end effectorEngineering

The invention discloses an end effector of a fire-fighting robot used for fire valve closing. An input conic gear is engaged with an output conic gear, and the input conic gear and the output conic gear are connected with an input shaft and an output shaft through keys correspondingly. A gear is connected to the other end of the output shaft through a key. A lower clamp body and an upper clamp body are each in an L shape, and racks are machined on the upper portions of the lower clamp body and the upper clamp body to engaged with the left side and the right side of the gear correspondingly. Ahigh temperature resisting camera is in threaded connection to a connecting body. The end effector clamps a valve handle and rotates around the center of a valve so as to open and close the valve, theend effector is used in cooperation with the robot, can achieve stereoscopic dead-angle-free motion and is wide in applicability and suitable for ball valves, butterfly valves, stop valves and othercommon valves; the upper clamp body and the lower clamp body do opposite motion so that the clamping time can be shortened by one time; and the problem that inflammable and flammable pipeline valves cannot be closed when fires happen can be effectively solved.

Owner:NANYANG NORMAL UNIV

Radial tire molding curing bladder molding device

The invention discloses a radial tire molding curing bladder molding device. The device comprises a base, a body, supporting columns, an upper workbench, a lower workbench, an upper core ejector mechanism, a lower core ejector mechanism, a lifting cylinder and a hydraulic oil cylinder, the upper core ejector mechanism is arranged on the body, the ejector head at the bottom of the upper core ejector mechanism is adapted to the bladder ejector port of the upper workbench, the lower core ejector mechanism is arranged on the base, the ejector head at the top of the lower core ejector mechanism is adapted to the bladder ejector port of the lower workbench, the top end of the weightlifting rod of the lifting cylinder is connected with the upper workbench, and the weightlifting member of the hydraulic oil cylinder is connected with the lower workbench. A technical problem of the division of the device working operation is solved by the radial tire molding curing bladder molding device. The radial tire molding curing bladder molding device has the advantages of effective reduction of the loss of the hydraulic oil cylinder, prolongation of the service life, die locking time reduction, reduction of the time for the rubber scorching in the die locking process, rubber safety ensure, production cost reduction, and production efficiency improvement.

Owner:NANJING YATONG RUBBER PLASTIC

Quick correction device

The invention relates to a quick proofreading device. The described fast school team device comprises a frame-shaped main body, a pressing plate, a rubber pad, an arc-shaped base, lugs one, two, three, pins one, two, three, ear plates and struts, and the frame-shaped main body The two ends of the two horizontal straight rods are respectively connected to the mud pump and the common base through the ear seat 1, the ear plate and the pin 1 respectively. On the bar, the arc-shaped bottom plate, the pressure plate, and the rubber pad constitute a fixing device for fixing the cardan shaft. The second ear seat is welded on the above-mentioned vertical straight bar, and one end of the support bar is connected to the ear by pin two. The seat two is fixedly connected, the common base is provided with the ear seat three and the pin three, and the other end of the strut is detachably connected to the common base through the ear seat three and the pin three. The present invention can realize fast calibration and alignment when the hydraulic coupler is connected with the mud pump, and at the same time, the single-machine pump set can be transported as a whole without dismantling each component.

Owner:JIANGSU SINOPETRO SUPERBSKILL MACHINE

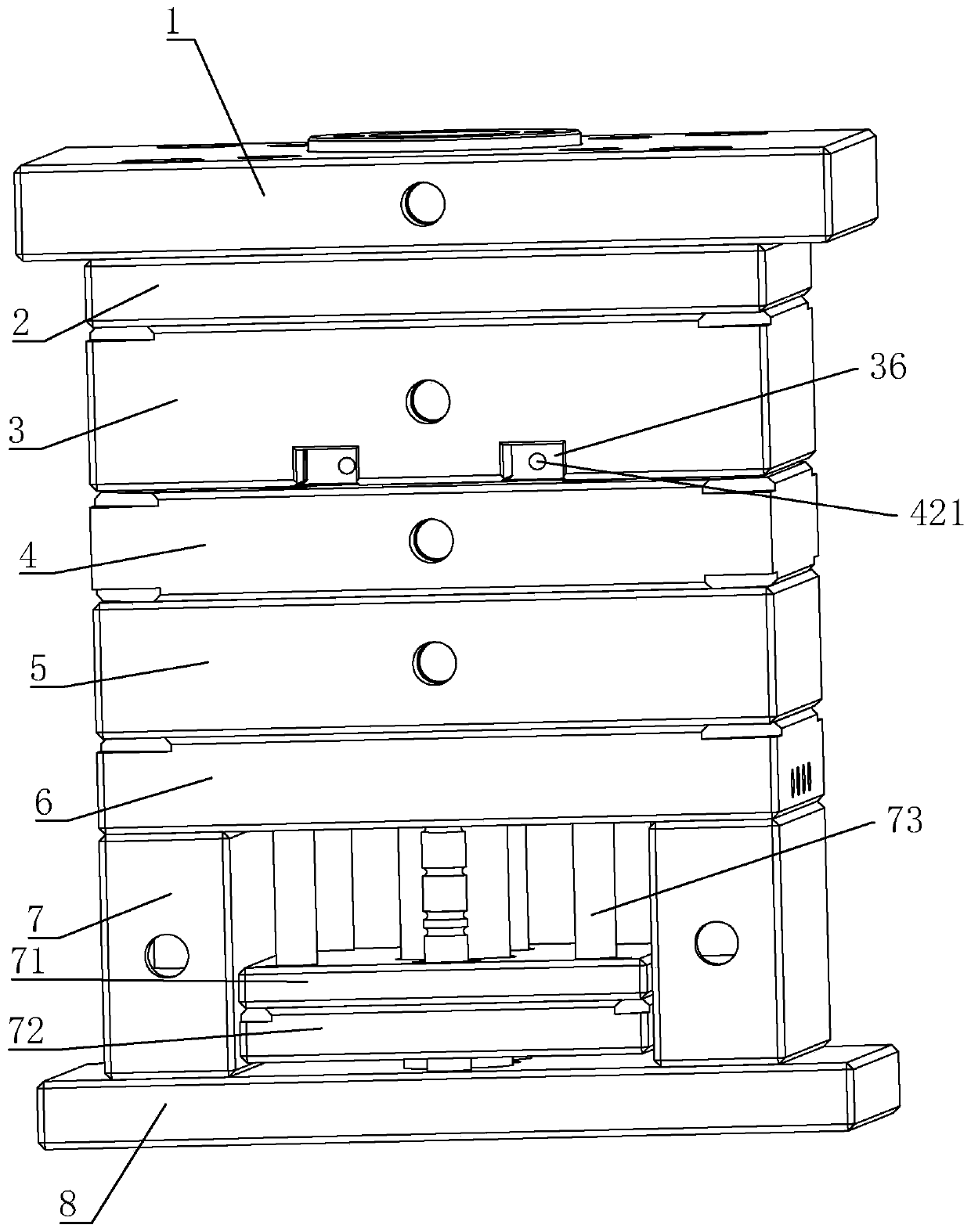

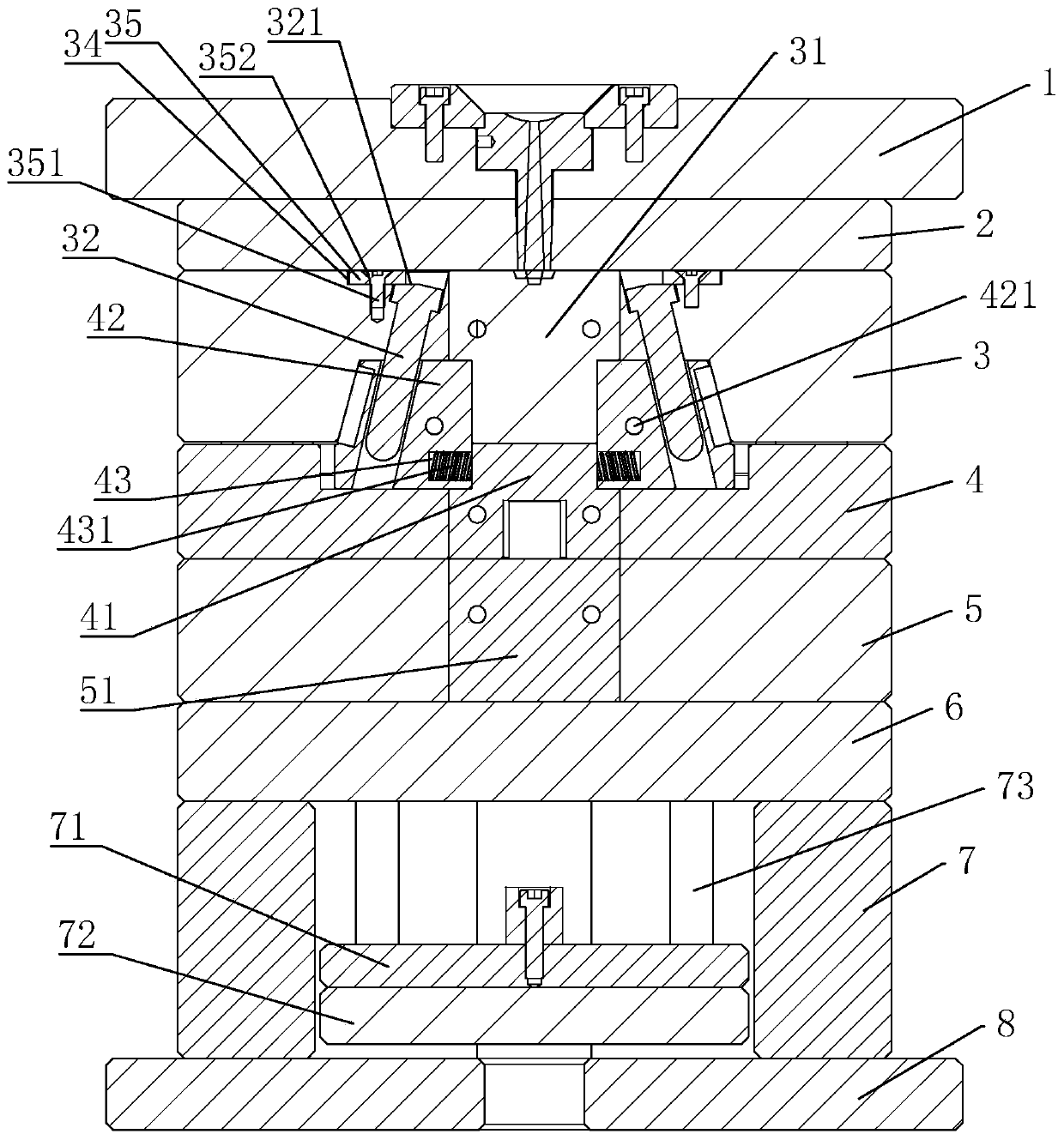

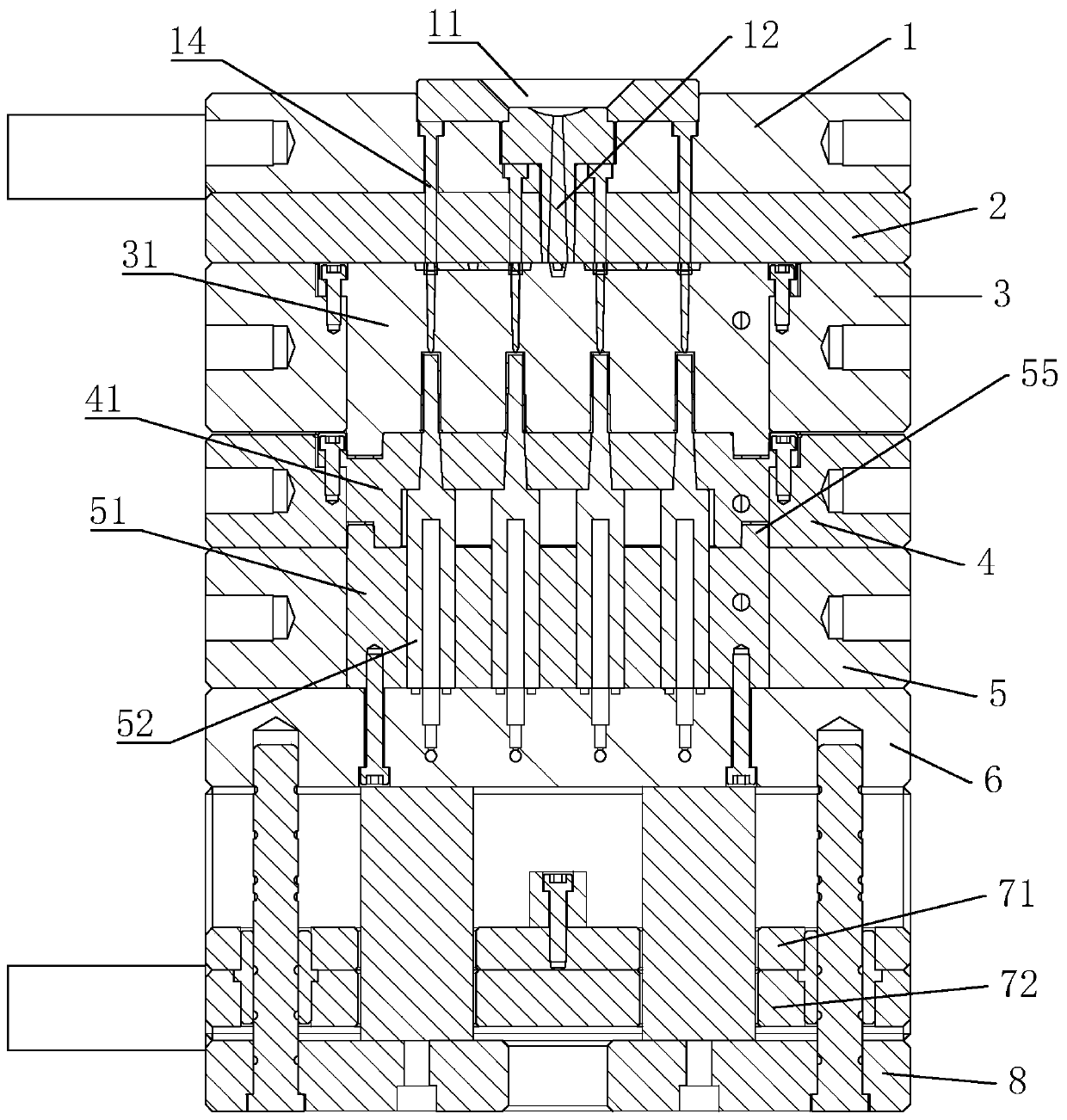

Single Cup Injection Mold

Owner:南京益昌模具有限公司

A heat sealing method for liquid filling bag filling tube

ActiveCN105196613BFree from burnsReduce labor costsBag making operationsPaper-makingEngineeringMechanical engineering

Owner:SICHUAN NIGALE BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com