Demoulding mechanism of plastic bottle cover mould and implementation method thereof

A demoulding mechanism and bottle cap technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of affecting the processing quality of bottle caps, reducing production efficiency, and high production costs, so as to reduce mold opening and closing strokes and improve Productivity, increasing the effect of setting difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

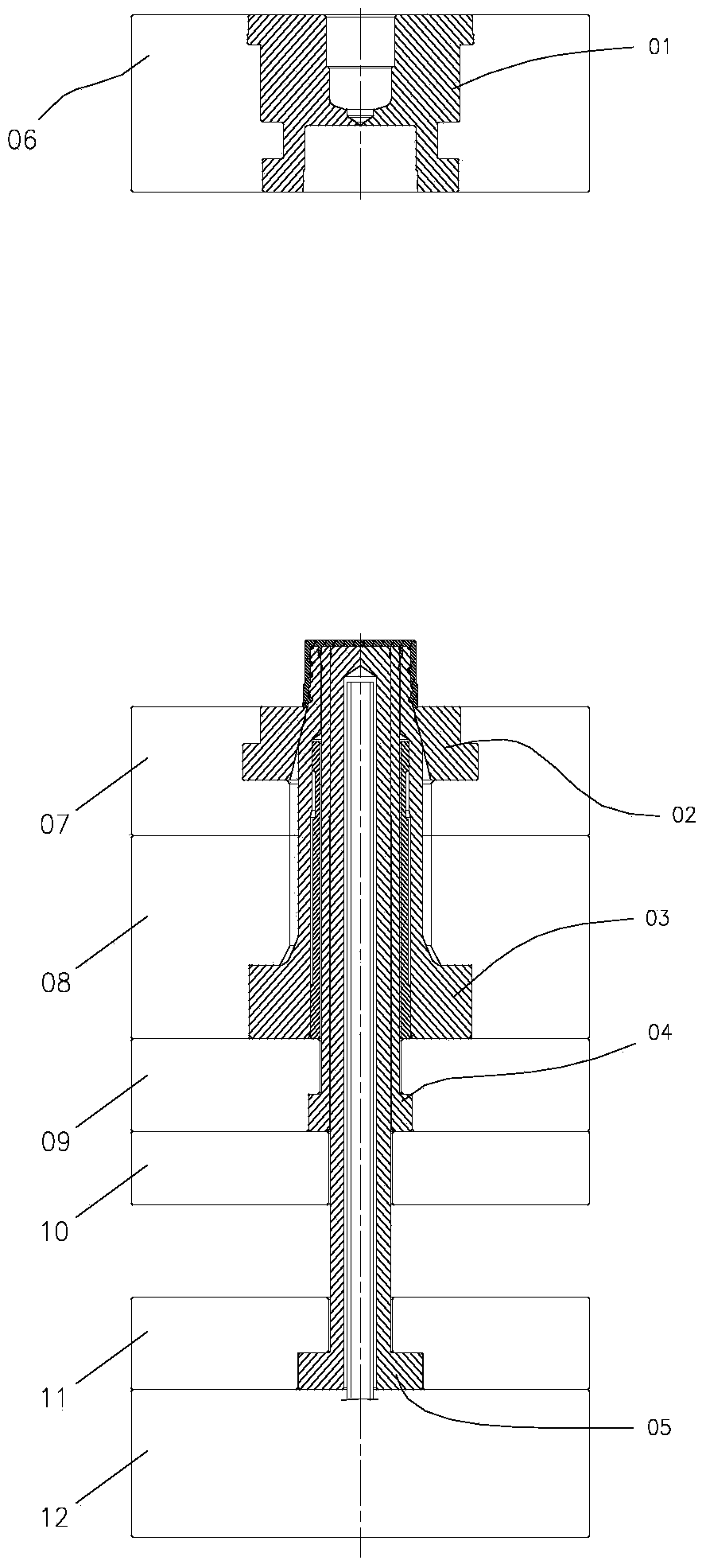

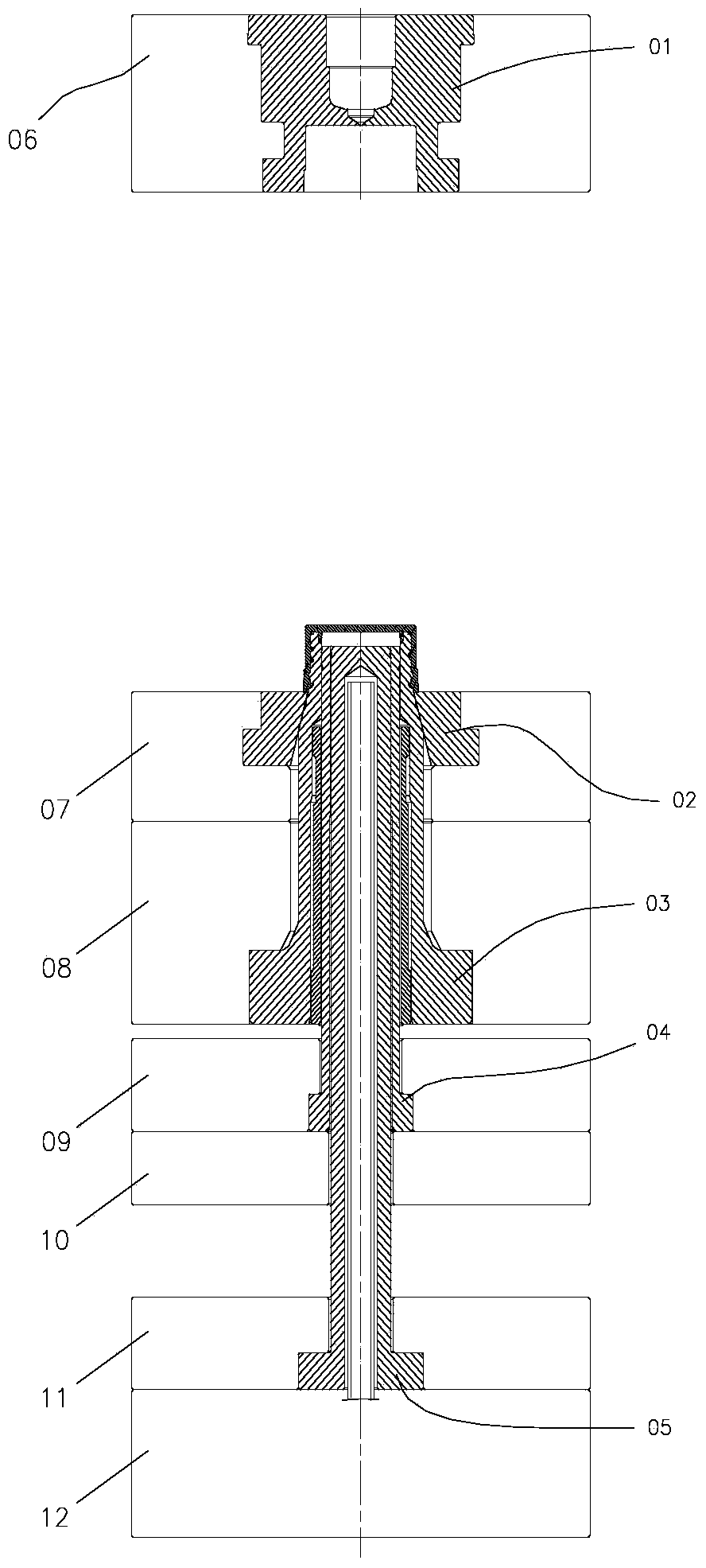

[0034] Figure 5 ~ Figure 10 A specific embodiment of the present invention is shown, by Figure 5 It can be seen that the demoulding mechanism of the plastic bottle cap mold is arranged on the movable mold of the plastic bottle cap mould, including a support and a step-off device, and the support and a step-off device are related to the mold core assembly used for demoulding in the movable mold. Corresponding settings make each mold core assembly fixed at the molding position when the bottle cap is molded, and when the bottle cap is demolded, the mold core assembly is retracted to realize the ejection of the bottle cap.

[0035] The concrete structure of described support and abdication device is: comprise 8 support blocks 20 that are installed on the moving mold and the backing plate 21 that is provided with abdication space 22, described support block 20 is fixed on the back side of formwork 16, formwork 16 The mold core assembly is installed in the front, and the backing ...

Embodiment 2

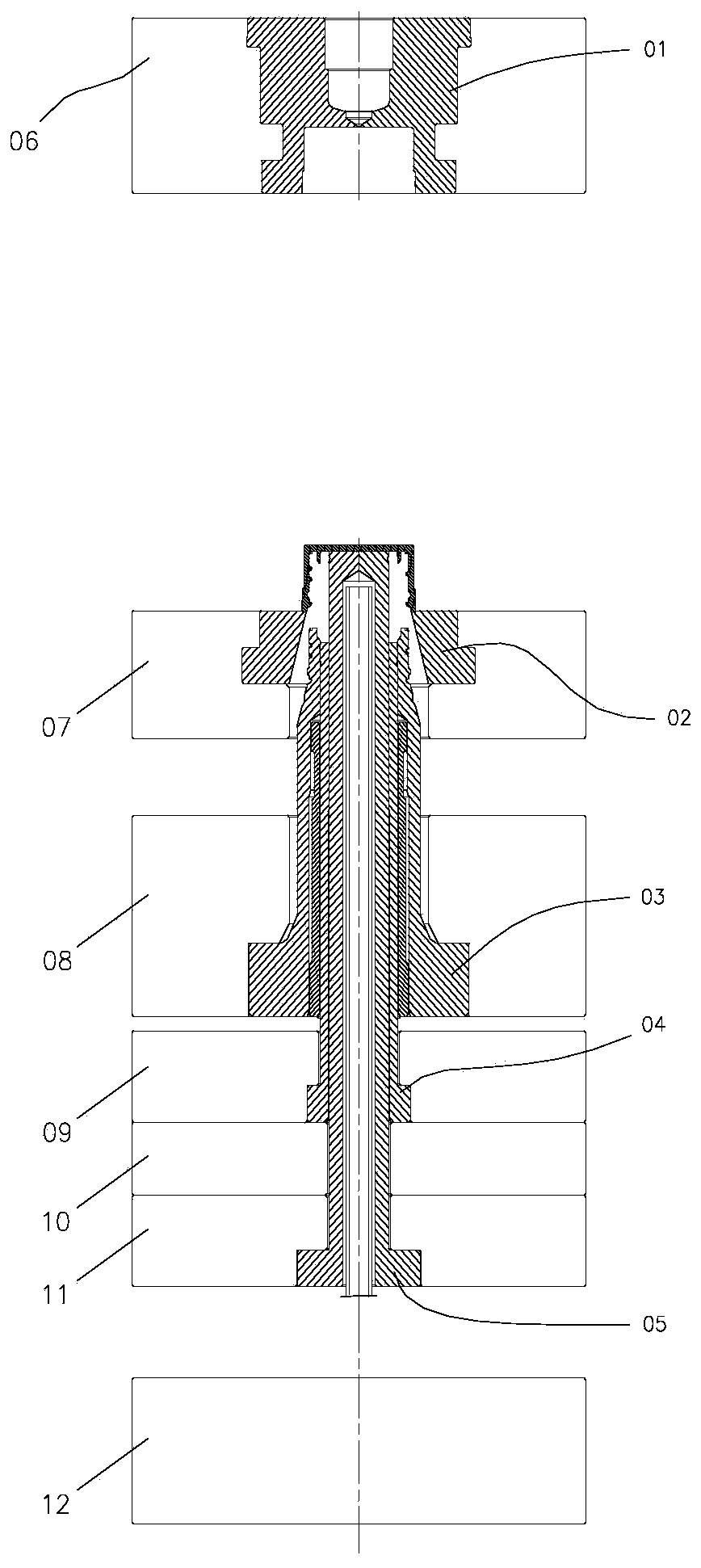

[0045] Figure 11 to Figure 14 Another specific embodiment of the present invention is shown; as Figure 11 As shown, in this specific embodiment, when the mold is in the forming state, there is a space between the template 16 and the template 17 . The template 16 is forced by the oil cylinder 19 (multiple oil cylinders can act at the same time), and can still keep the mold core assembly 03, 04, 05 in the correct molding position during injection, and move backward without being affected by the injection pressure. After the molding is completed, the pressure of the oil cylinder 19 can be removed, and then the oil cylinder 18 pushes the templates 14, 15, 16 to make the mold core assembly retreat backwards. By the same principle as in embodiment 1, the bottle cap demoulding effect is realized.

Embodiment 3

[0047] Figure 15 ~ Figure 20 Another specific embodiment of the present invention is shown; this specific embodiment is the same as embodiment 1 except the following features: Figure 15 and Figure 16 Shown support block 20 and Figure 19 , Figure 20 The abdication spaces 22 shown are all distributed in a straight line and parallel direction; the backing plate 21 is driven by a cylinder, an oil cylinder or an electric motor, so that the backing plate 21 can be in a supporting station ( Figure 15 ) and give way ( Figure 16 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com