Quick correction device

A proofreading device and fast technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious installation, cumbersome installation process, and easy loss, so as to reduce the clamping time, reduce the disassembly parts, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

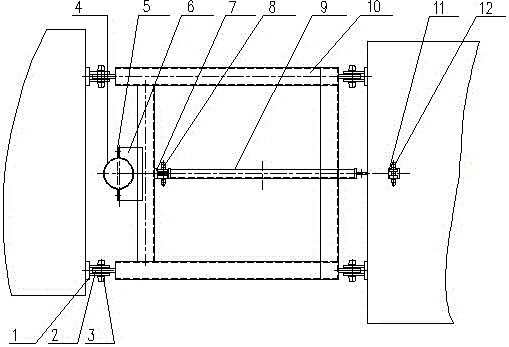

[0009] A quick proofreading device, said quick proofreading device includes a frame-shaped main body 10, a pressure plate 4, a rubber pad 5, an arc-shaped base 6, an ear seat 1, an ear seat 2 7, an ear seat 3 11, and a pin 3 , pin two 8, pin three 12, ear plates 2 and struts 9, the two ends of the two horizontal straight rods of the frame-shaped main body 10 pass through ear seats one 1, ear plates 2 and pin one 3 respectively Connected with the mud pump and the common base, the arc-shaped base 6 is welded on the vertical straight rod on the side of the frame-shaped main body 10 facing the mud pump, and the arc-shaped bottom plate 6 is formed with the pressure plate 4 and the rubber pad 5 The fixing device for fixing the cardan shaft, the said lug 2 7 is welded on the above-mentioned vertical straight bar, and one end of the strut 9 is fixedly connected with the lug 2 7 through the pin 2 8, and the said common base Ear seat 3 11 and pin 3 12 are provided, and the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com