Single Cup Injection Mold

An injection mold, single-cup technology, applied in household appliances, other household appliances, household components, etc., can solve problems such as low production efficiency, improve efficiency, and facilitate product release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

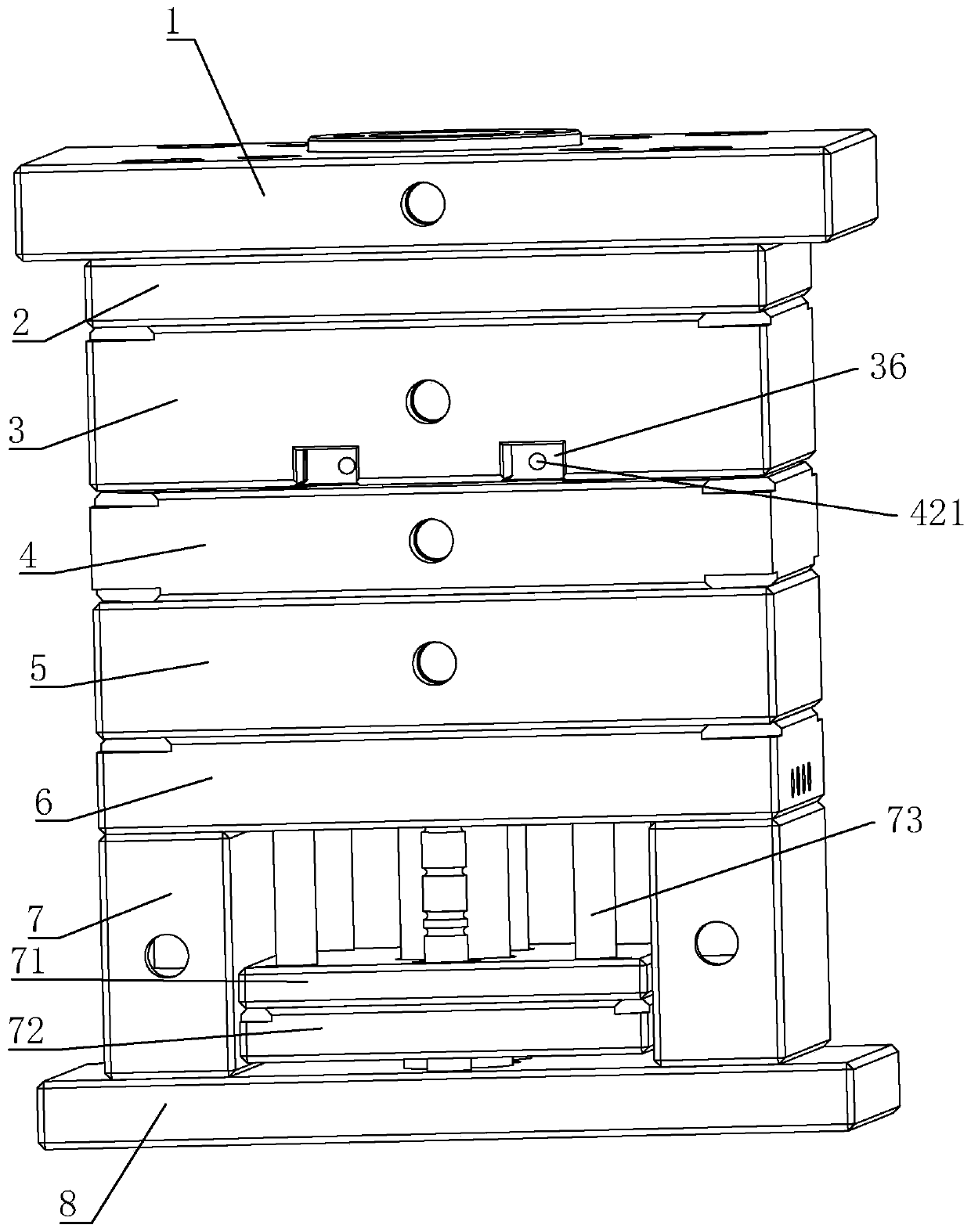

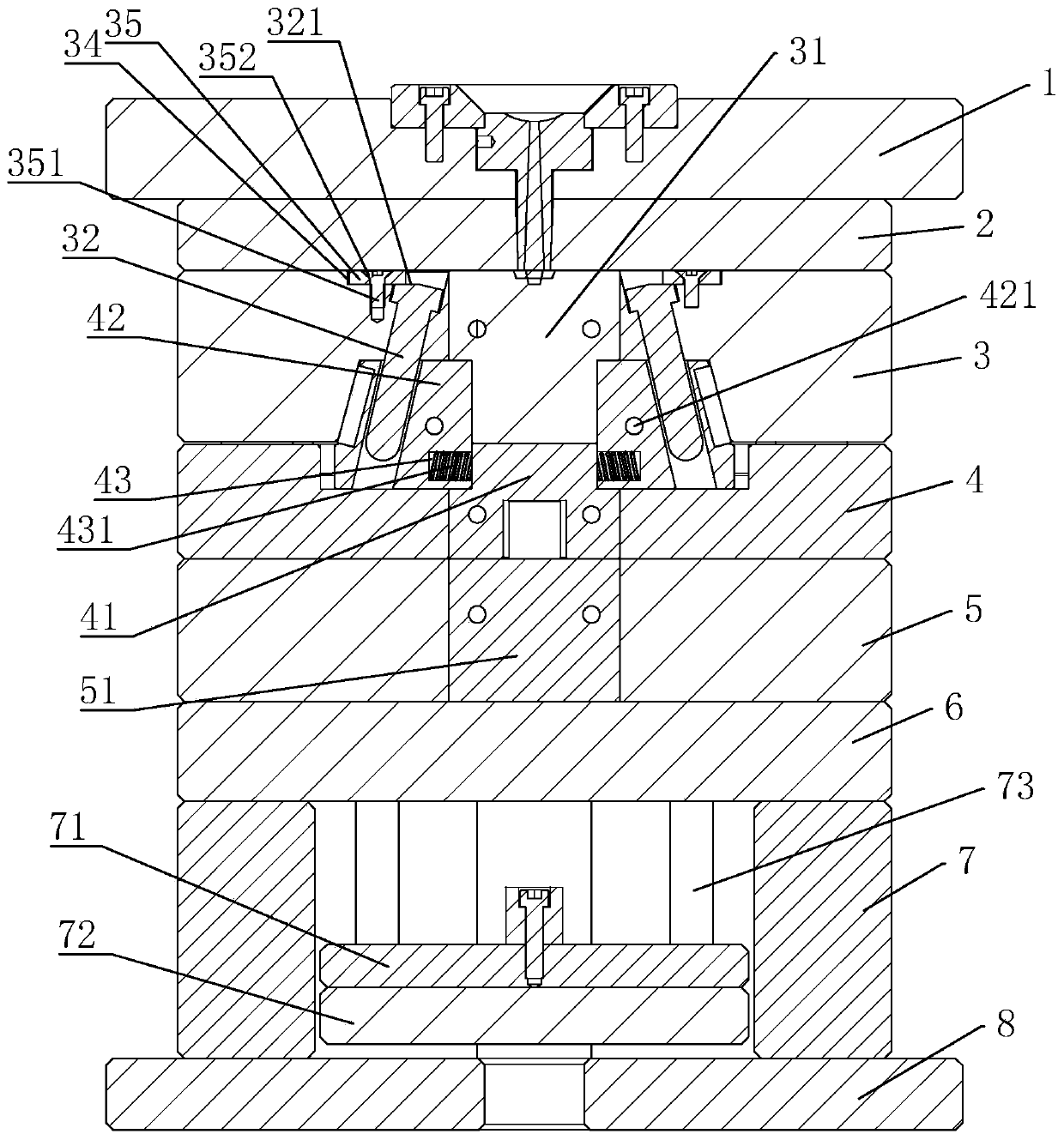

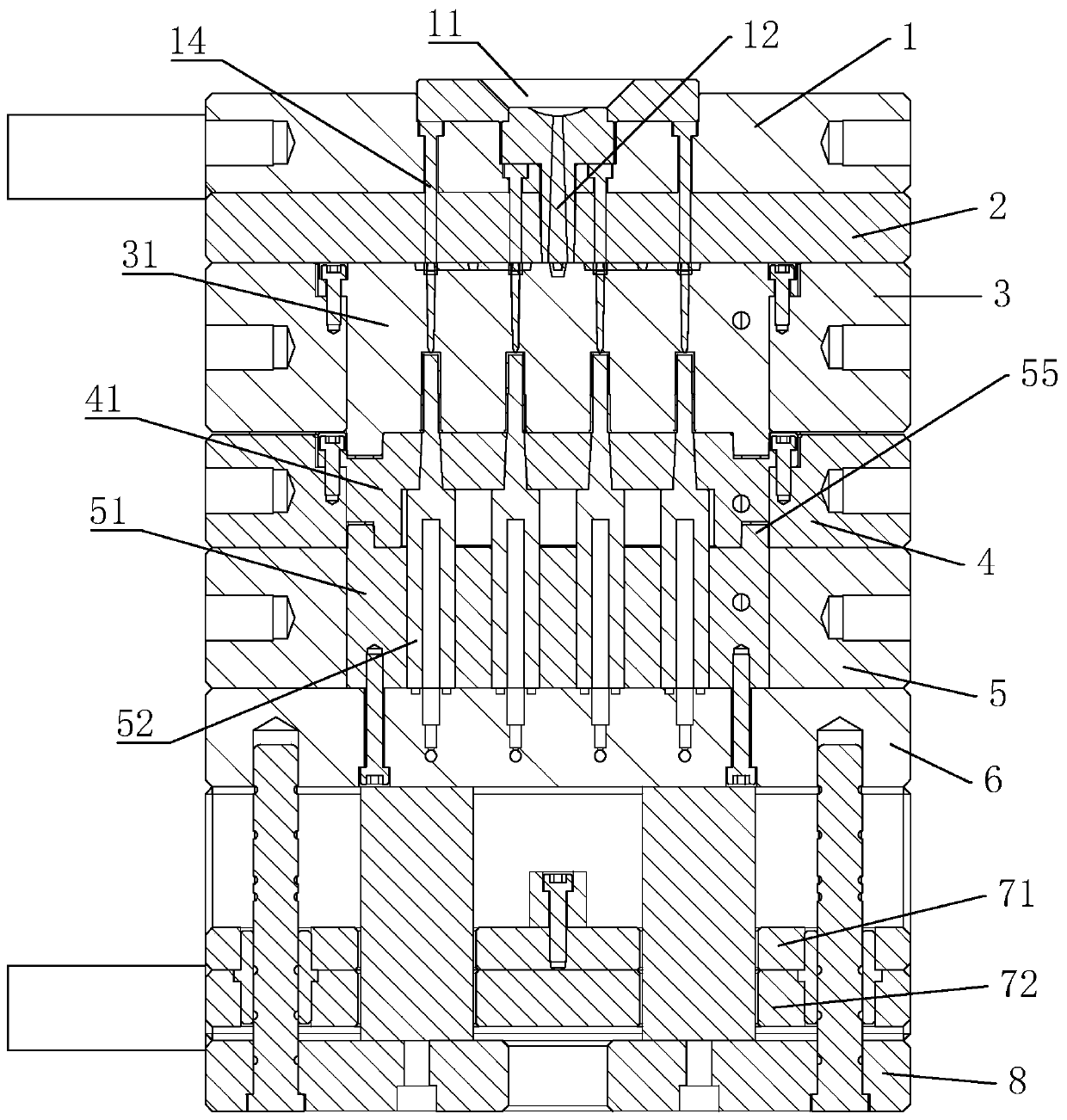

[0027] A single-cup injection mold, such as figure 1 , including: upper fixed plate 1, nozzle plate 2, A plate 3, unloading plate 4, B plate 5, placement plate 6, two support plates 7 supporting the placement plate 6, two support plates located on top to bottom 7 between the push rod fixed plate 71 and the first push plate 72, the lower fixed plate 8 connecting the two support plates 7, as figure 2 , A plate 3 is embedded with a front mold core 31, a second push plate 41 corresponding to the front mold core 31 is embedded in the stripping plate 4, and a rear mold corresponding to the front mold core 31 is embedded in the B plate 5 Kernel 51, the rear mold kernel 51 is provided with a positioning block 55 stretching into the second push plate 41 (such as image 3 ), which is conducive to the accuracy of the movement of the rear mold core 51 and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com