Eccentric shaft machining clamp

An eccentric shaft and fixture technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of long workpiece positioning time, high staff skill requirements, and cumbersome operation process, and achieve simplified fixture structure and versatility. Good, the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

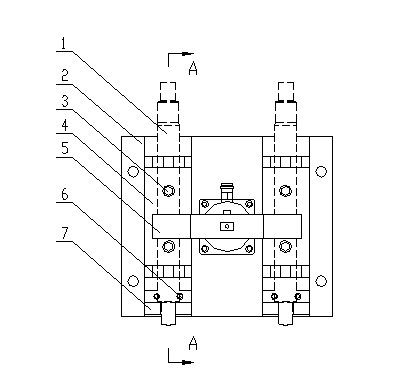

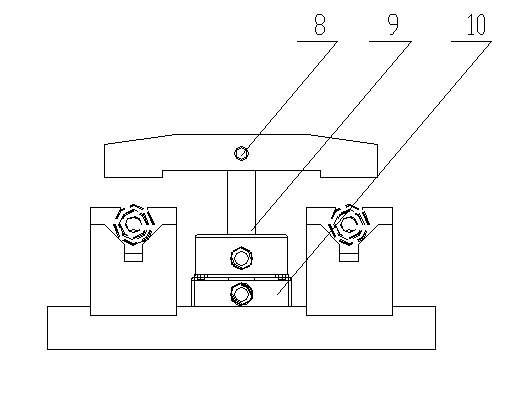

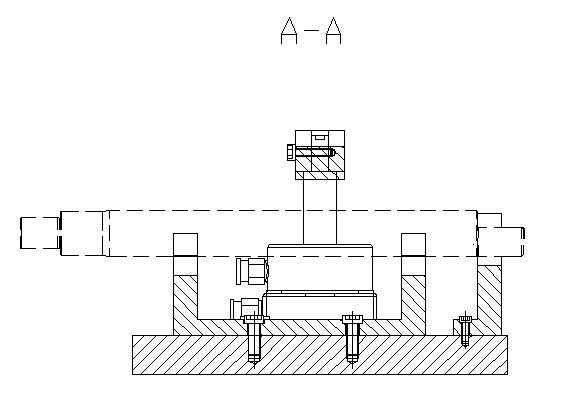

[0017] Referring to accompanying drawings 1, 2, 3 and 4, the eccentric shaft processing jig shown in the embodiment of the present invention mainly consists of a bottom plate 2, a V-shaped module 4 fixed on the bottom plate, a limiting groove 7 fixed on one side of the bottom plate, and a pressing plate 5. The pneumatic device 10 is composed of a guide rod 9 fixed on the bottom plate. The pressure plate 5 is connected with the moving parts of the pneumatic device 10 and moves up and down along the guide rod 9 . When operating, put the workpiece on the V-shaped module 4, adjust the eccentric shaft of the front section of the workpiece to face the limit groove 7 on the limit groove module, push it lightly so that it just inserts into the groove, and at the same time, the end face is close to the limit groove The end face realizes the axial positioning of the workpiece. Press the button of the pneumatic device, and the pressure head, under the action of the moving parts of the pne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com