Novel dustproof dispersion machine

A disperser, a new type of technology, applied in mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve the problems of polluting the environment of mixing tanks and affecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

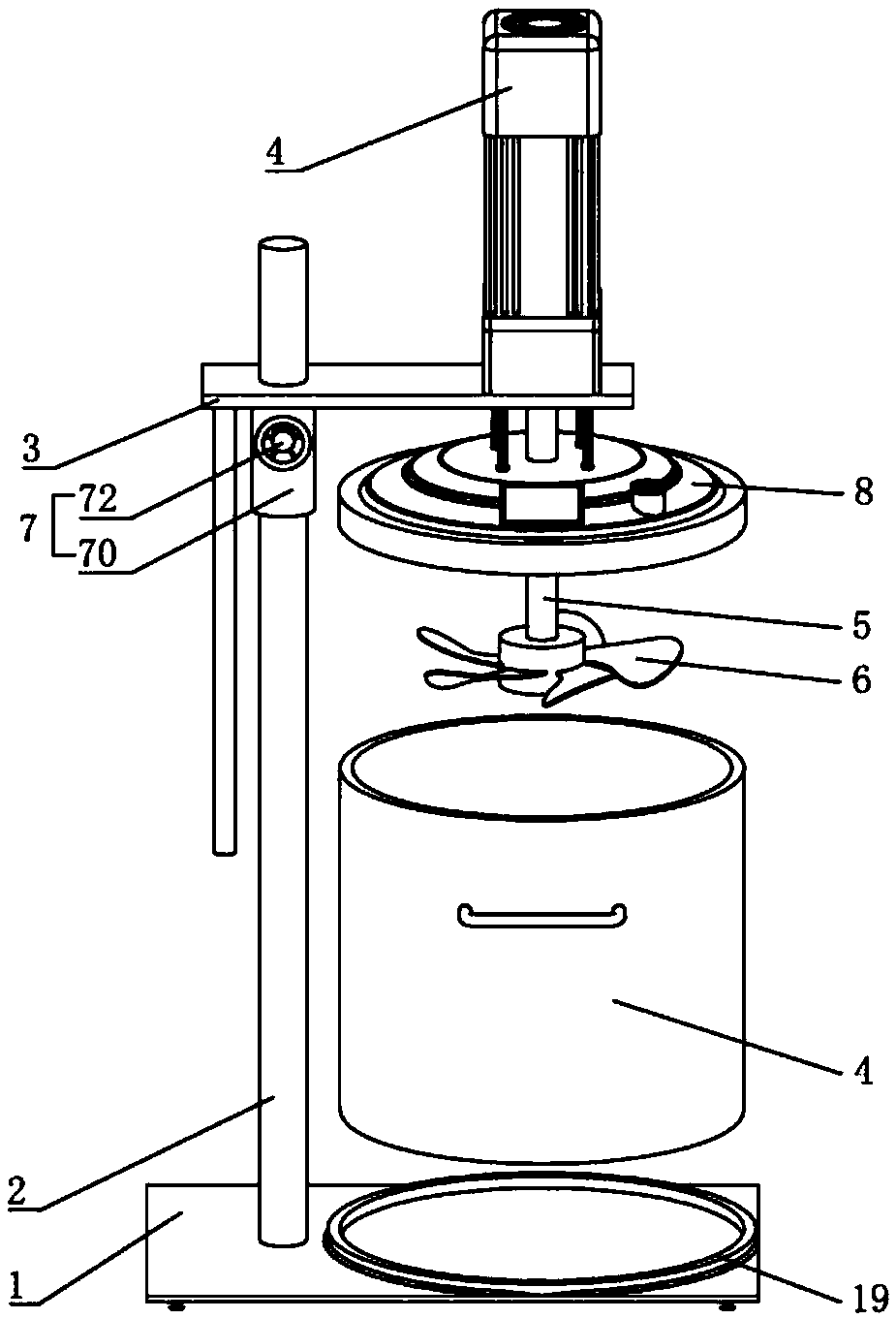

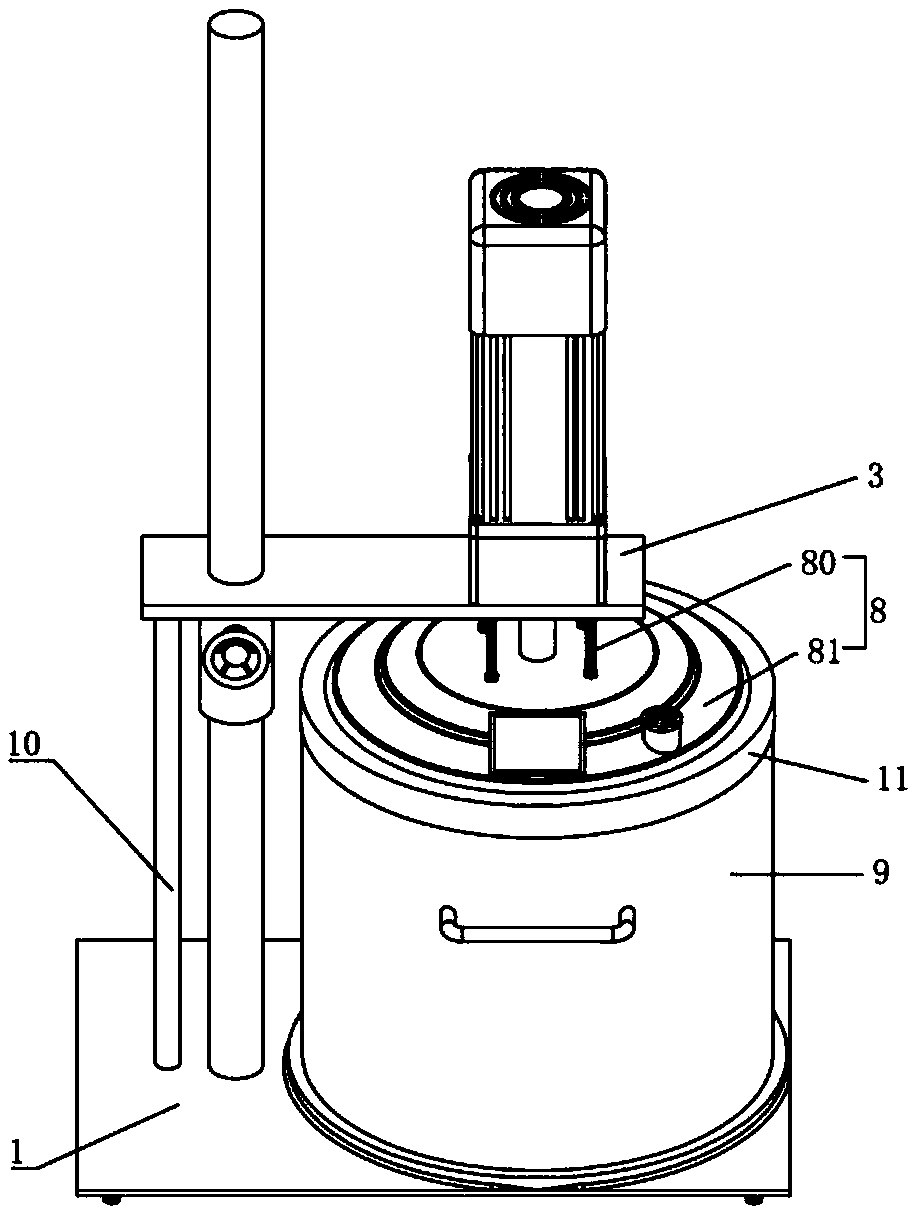

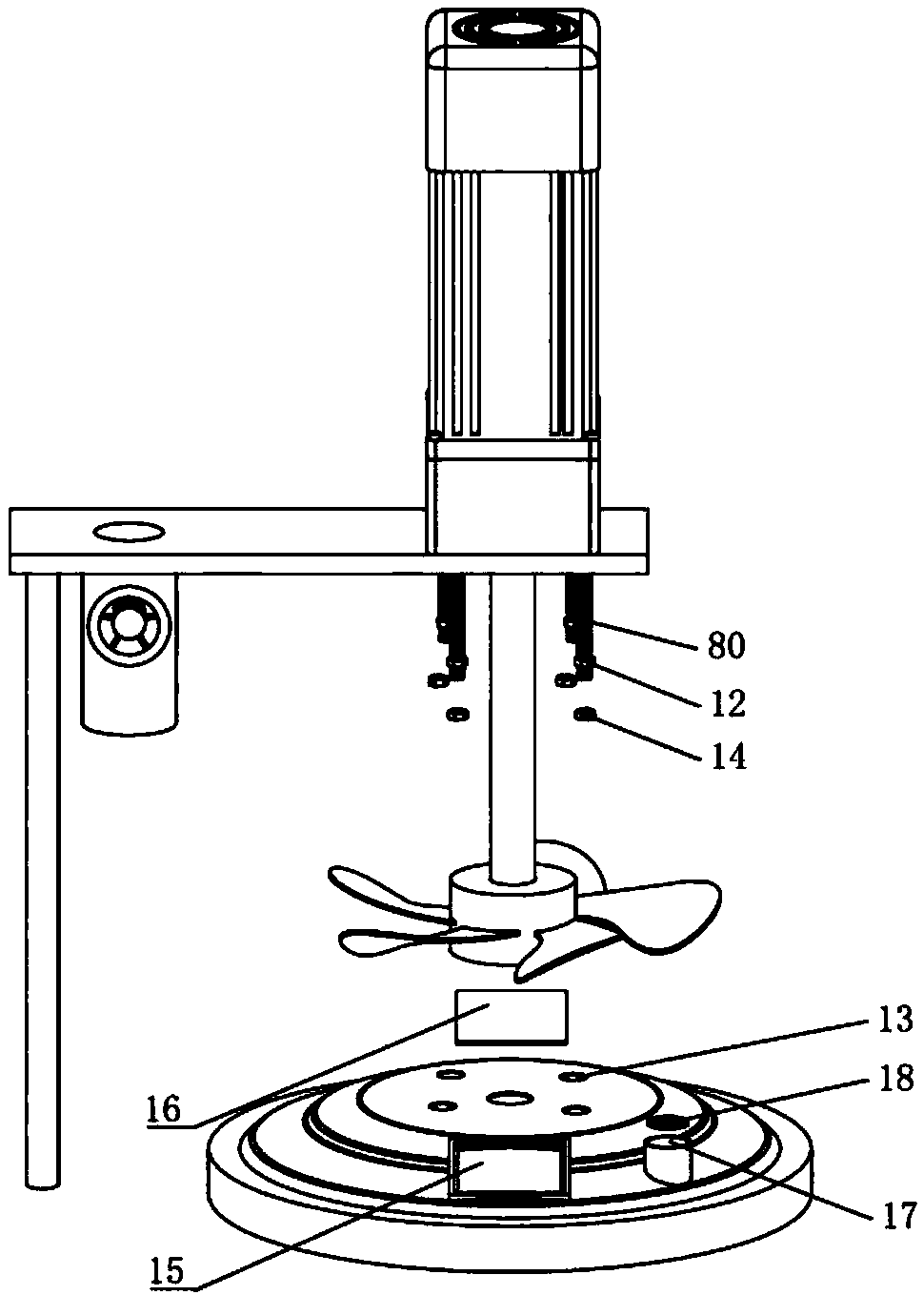

[0034] Embodiment: a kind of novel dust-proof dispersion machine, with reference to figure 1 , including a base 1 set on the ground, a support column 2 vertically welded on the base 1, a mounting seat 3 sleeved on the support column 2, a stirring motor 4 arranged on the mounting seat 3, and a stirring motor 4 connected to the The rotating shaft 5 facing the side of the base 1, the blade 6 connected to the lower end of the rotating shaft 5, and the stopper 7 used to limit the sliding position of the mounting base 3 on the support column 2, the stopper 7 here includes sleeved and fixed The sleeve 70 connected to the mounting base 3 , the threaded hole opened on the sleeve 70 , the bolt 71 matched with the threaded hole and the end abutted on the support column 2 .

[0035]The paint dispersing machine also includes a mixing bucket unit 9 arranged on the base 1 and a dust-proof assembly 8 arranged on the mounting base 3. Here, the mixing bucket unit 9 refers to a mixing bucket ded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com