Manipulator based on automatic control

A technology of automatic control and manipulators, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of high production cost, difficulty in the strength of the manipulator arm, unfavorable repair and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

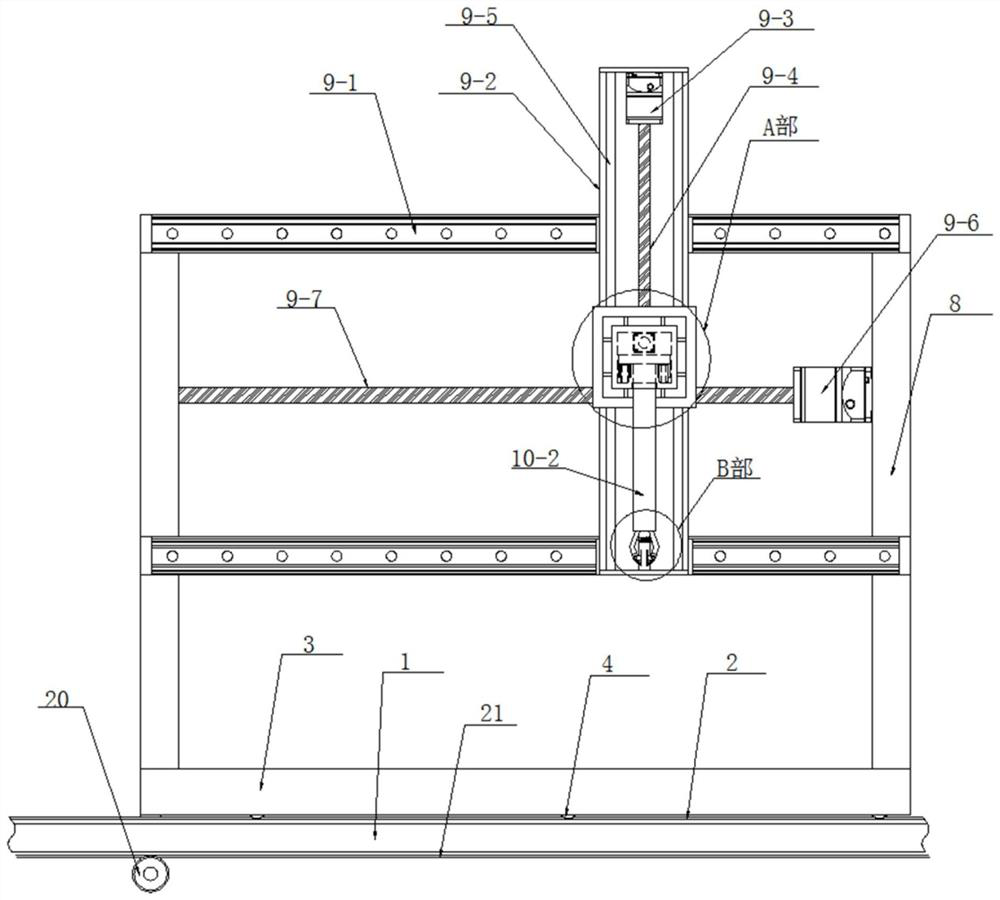

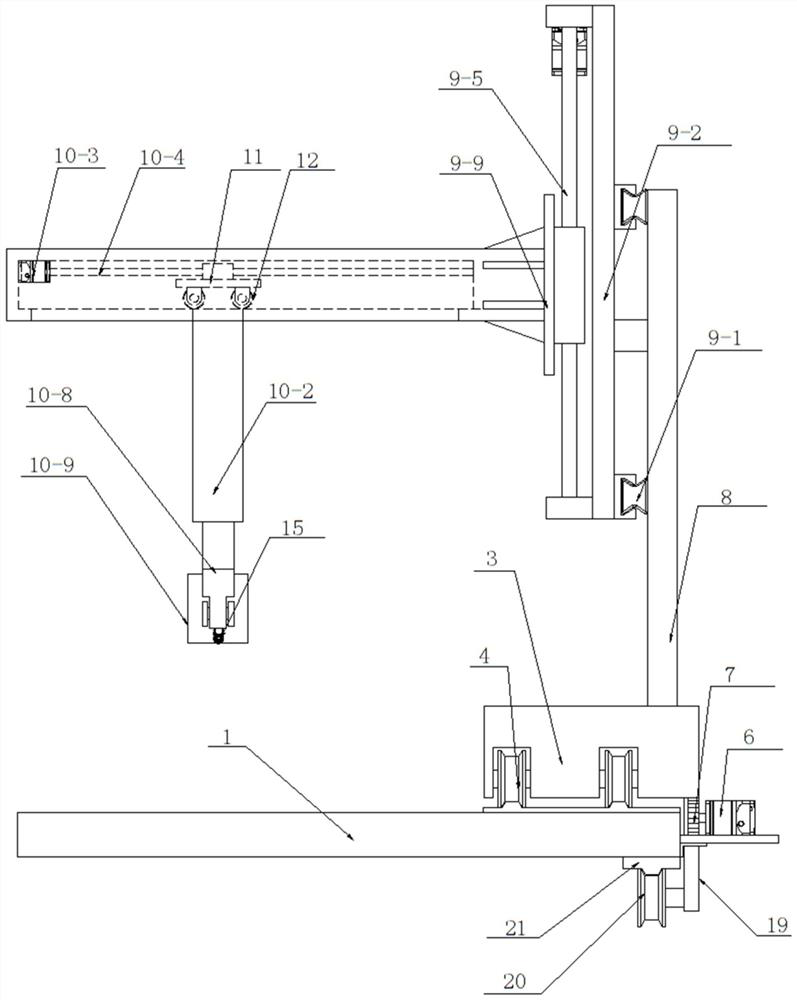

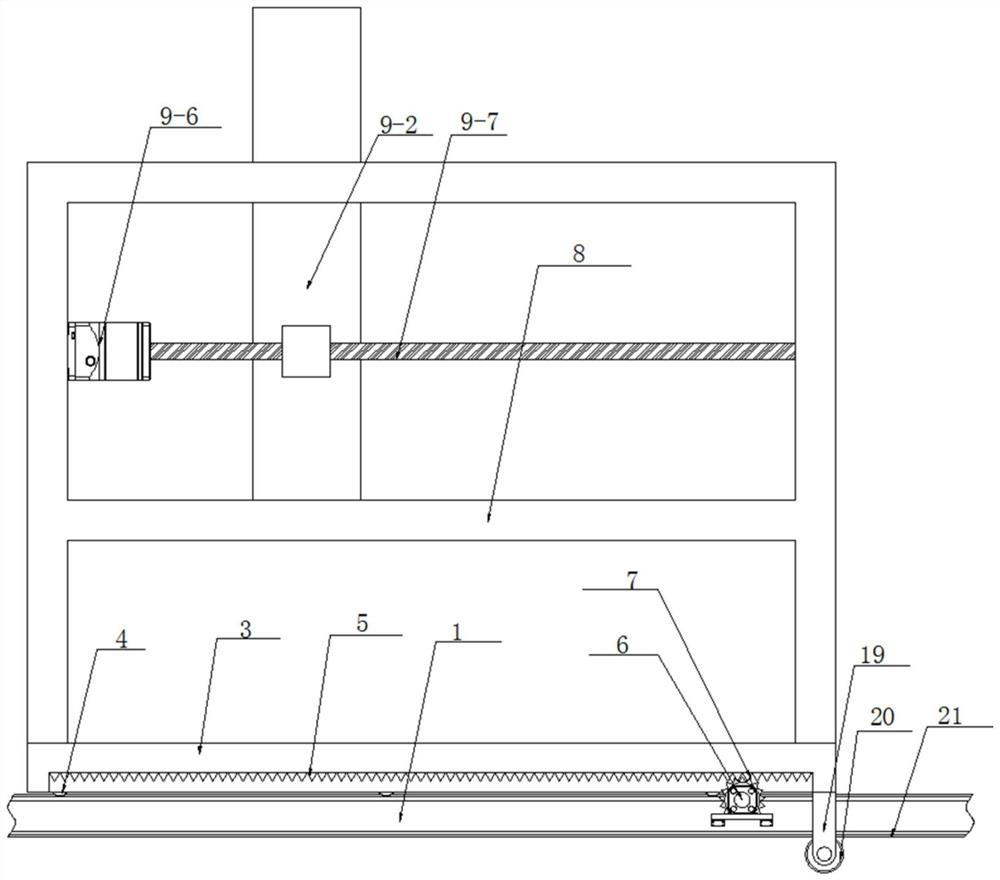

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] see as Figure 1-Figure 7 As shown, the technical solution adopted in this specific embodiment is: it includes the operating table 1, the base 3, the guide wheel 4 and the No. 1 guide rail 2, and the rear side of the operating table 1 top is fixed with the No. 1 guide rail 2 by bolts, and the No. 1 guide rail 2 is provided with a base 3, and the inside of the base 3 is embedded with several guide wheels 4 through the rotation of the wheel shaft. The several guide wheels 4 are all rolled on the corresponding No. 1 guide rail 2, and the several guide wheels 4 are arranged in two rows. It also includes No. 1 motor 6, position adjustment mechanism 9 and clamping mechanism 10; the inner top surface of the groove provided on the rear side wall of the base 3 is fixedly welded with a rack 5, and one side of the rear side wall of the console 1 A No. 1 motor 6 of 60KTYZ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com