Quick-clamping jig for printed boards and method of use

A technology for clamping tooling and printed boards, which is applied in the manufacture of printed circuits, printed circuits, electrical components, etc. It can solve the problems that flying probes cannot be used for testing and cannot be clamped, and it is easy to move and carry, and the tooling is compact , flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

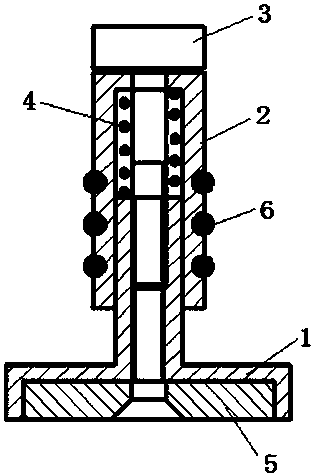

[0021] Such as Figures 1 to 7 As shown, a printed board fast clamping fixture includes a base 1 , a jacket 2 , a guide rod 3 , a spring 4 , a magnet 5 , and an O-ring 6 .

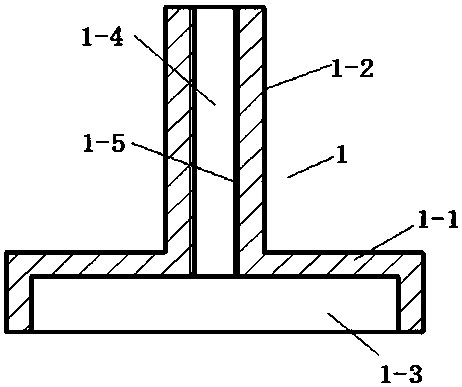

[0022] The base 1 is composed of an integral circular surface 1-1 and a circular tube 1-2, a circular groove 1-3 is provided on the circular surface 1-1, and a circular tube 1 is arranged at the center of the circular groove 1-3 inner surface. -2 are communicated through holes 1-4, and threads 1-5 are provided on the inner wall of the through holes 1-4.

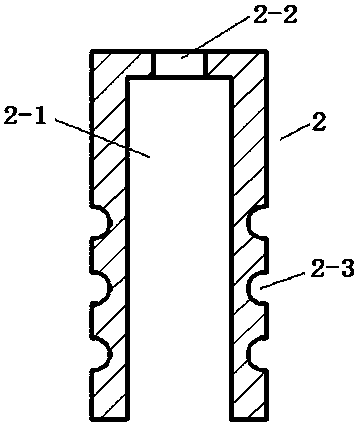

[0023] Overcoat 2 is cylindrical, is provided with circular groove 2-1 on one end face of overcoat 2, is provided with the hole 2-2 that communicates with circular groove 2-1 on the surface of overcoat 2 other end, on the surface of overcoat 2 Three semicircular grooves 2-3 are arranged at intervals on the outer wall.

[0024] Guide rod 3 is made of integral small circular surface 3-1 and cylinder 3-2, and one end of small cylinder 3-2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com