Parallel clamping mechanism

A clamping mechanism and clamping piece technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of poor clamping effect, large occupied volume, and poor clamping mechanism accuracy, and achieve simple structure and high precision. High, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

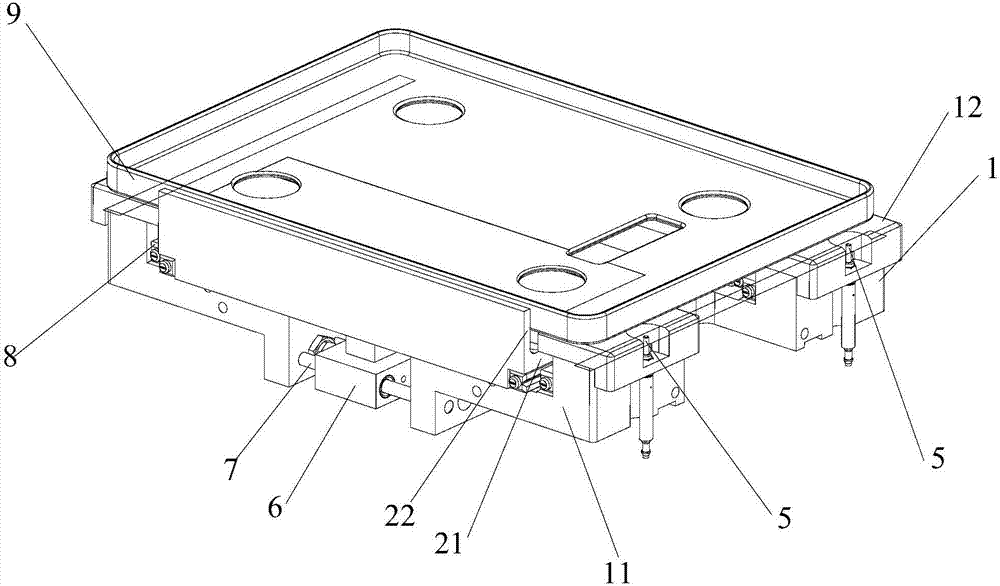

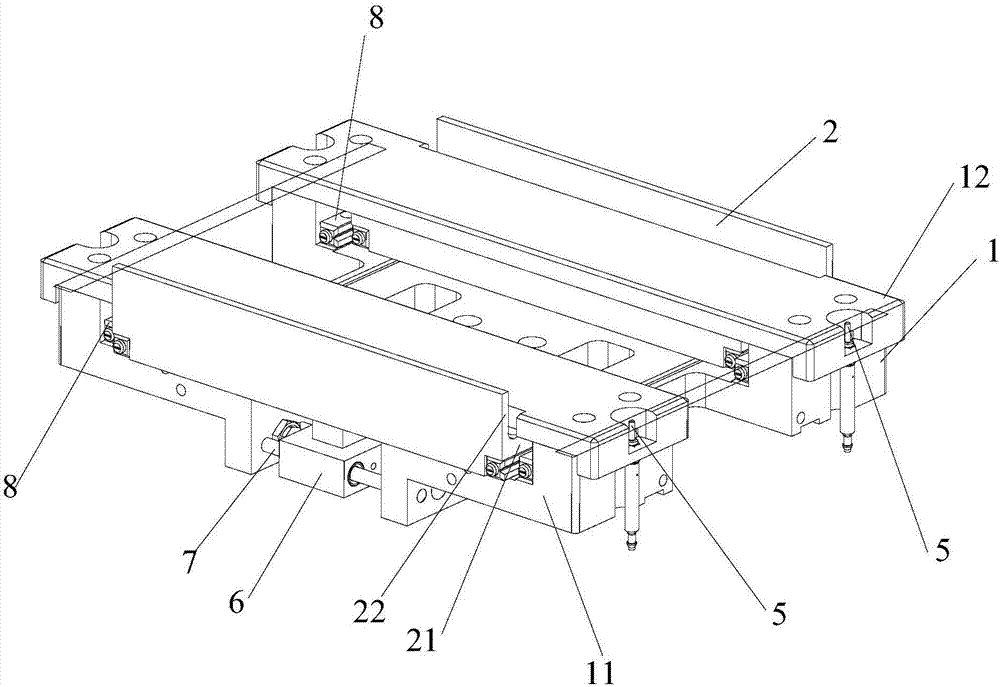

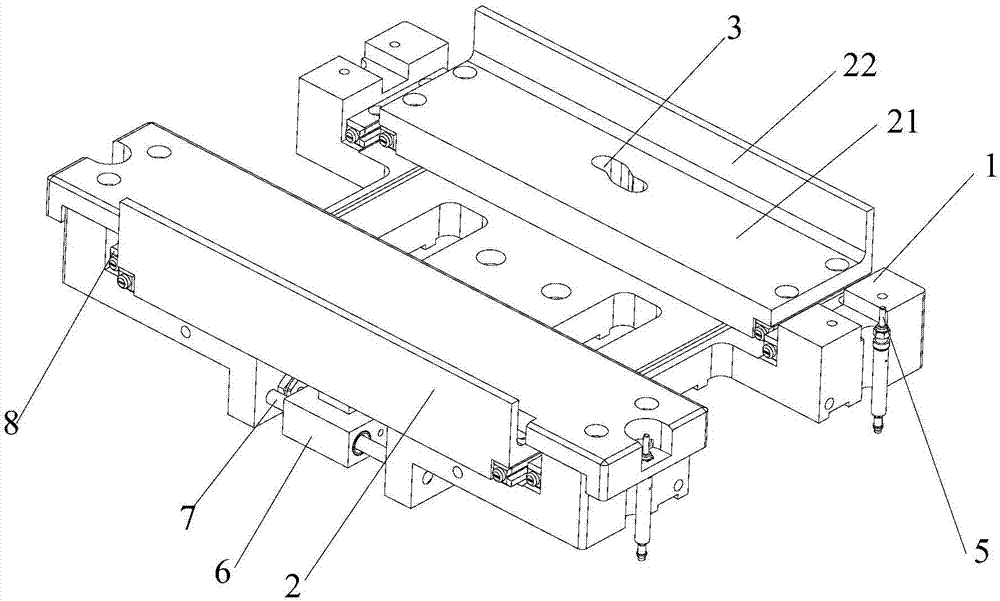

[0030] This preferred embodiment provides a parallel clamping mechanism, such as Figure 1 to Figure 4 As shown, the parallel clamping mechanism is a kind of parallel clamping mechanism, including a base 1, the base 1 includes a first side 11 and a second side 12 oppositely arranged, and the first side 11 is provided with a clamping assembly, a second An auxiliary clamping structure is provided on the two sides; the auxiliary clamping structure has the same structure as the clamping assembly; the clamping assembly includes a power device and a clamping part 2 slidingly arranged on the base 1, and the power device and the clamping part 2 One of them is provided with an arc-shaped chute 3, and the other is provided with a driving slider 4 that is slidably fitted in the arc-shaped chute 3, and the power unit can drive the driving slider 4 or the arc-shaped chute 3 arranged on the power unit Make a linear movement along the length direction of the base 1 to drive the clamping part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com