Automatic stacking fixture

A stacking and automatic technology, applied in the field of automatic palletizing jigs, can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity, reducing production costs, and ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

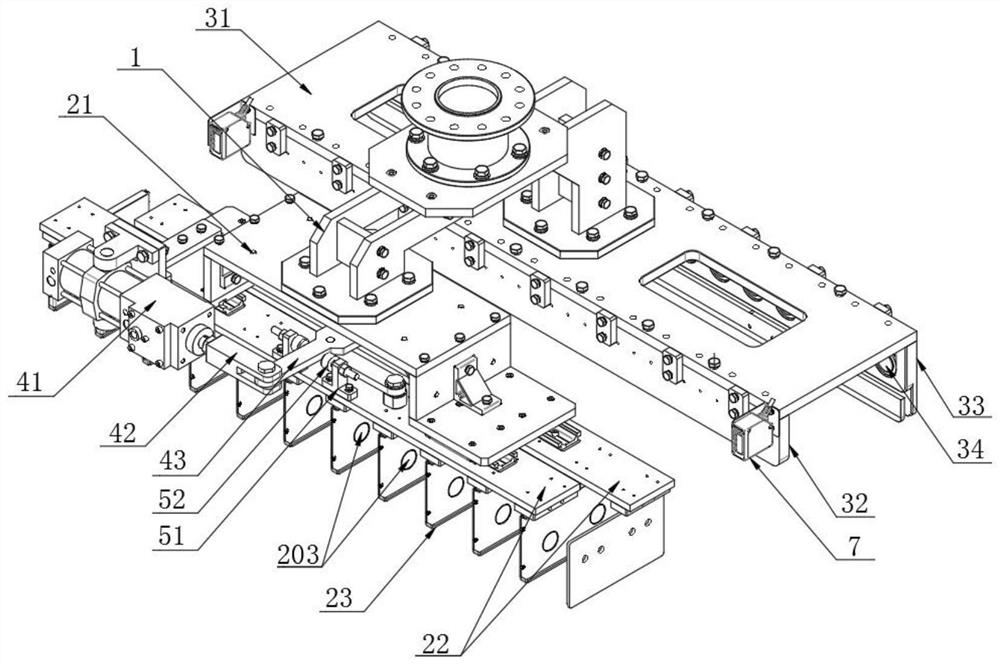

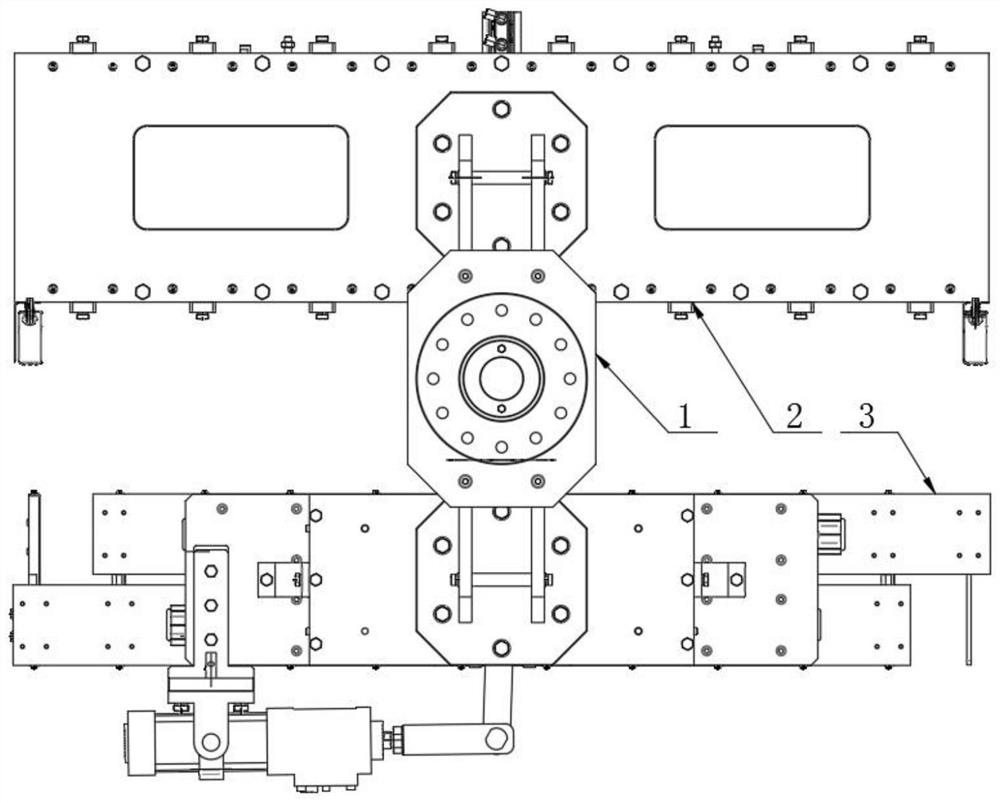

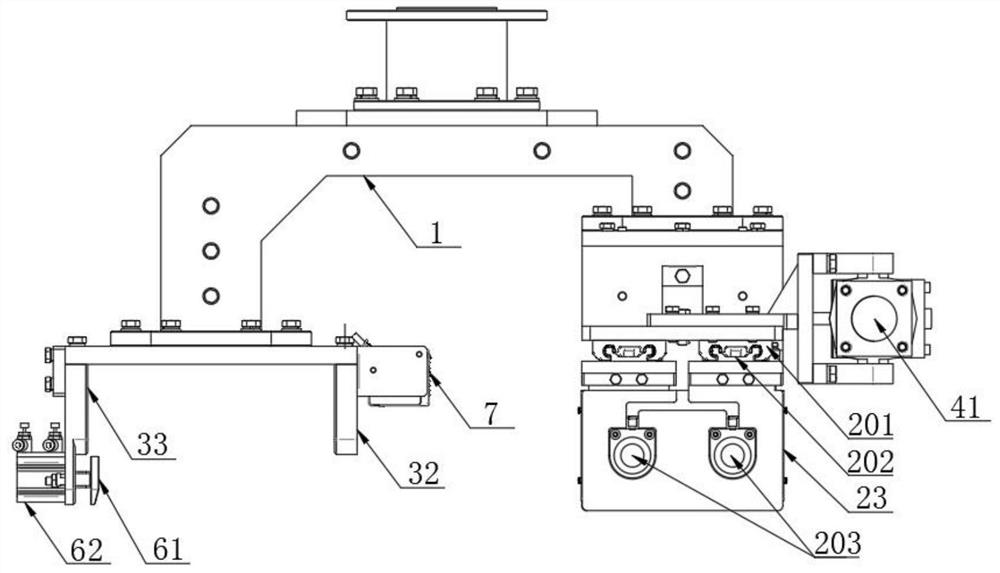

[0030] refer to figure 1 , figure 2 , image 3 and Figure 4, the automatic palletizing jig of the present invention comprises a robot and a connecting plate 1, and the robot is connected to the middle part of the connecting plate 1; one end of the connecting plate 1 is provided with a coding mechanism 2, and the other end is provided with a song unloading mechanism 3; The mechanism 3 includes a base 21 and two mutually parallel slide plates 22 slidably connected to the bottom of the base. The bottom of the slide plates is evenly provided with splints 23 parallel to each other. The distance between adjacent splints matches the width of the curved block; the base 21 is provided with a drive The power mechanism that slide plate 22 moves; Described code song mechanism 2 comprises base plate 31 and the side plate that is arranged on both sides of base plate, the distance between two side plates is matched with the length of curved block, and any side plate is provided with for ...

Embodiment 2

[0040] refer to figure 1 and image 3 , on the basis of Embodiment 1, this embodiment is provided with a damping mechanism for buffering the fall of the curved block on the side plate; the side plate includes a long plate 33 and a short plate 32, and the long plate 33 matches the height of the curved block, Short plate 32 height is less than long plate 33 heights; Described damping mechanism comprises the push plate 61 that is arranged on long plate 33 bottoms and is parallel with short plate 32 and drives the second cylinder 62 that pushes plate telescopic toward short plate; The fixing of second cylinder The end is fixedly connected with the long plate 33, and the movable end of the second cylinder is connected with the push plate 61.

[0041] Working principle: When the unloading mechanism transports the curved block to the pallet, the first floating clamping mechanism releases the curved block, and the curved block naturally falls to the lower pallet under the action of g...

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the structure of the second floating clamping mechanism 203 is different. The second floating clamping mechanism 203 of this embodiment is an airbag, and the airbag is connected to the compressor through the air pipe. The airbag has elasticity, and when the curved piece needs to be clamped, air is ventilated into the airbag, and the airbag bulges to clamp the curved piece; the airbag meets the clamping of the curved piece in this scheme, and it is flexibly connected with the curved piece to protect the curved piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com