Automatic batch cutting device for stone-like insulation boards

A technology of cutting device and insulation board, which is applied in the direction of metal processing, etc., can solve the problems of large manpower consumption, large energy consumption, and inability to realize mass production, etc., achieve good pushing effect, save energy, improve stability and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

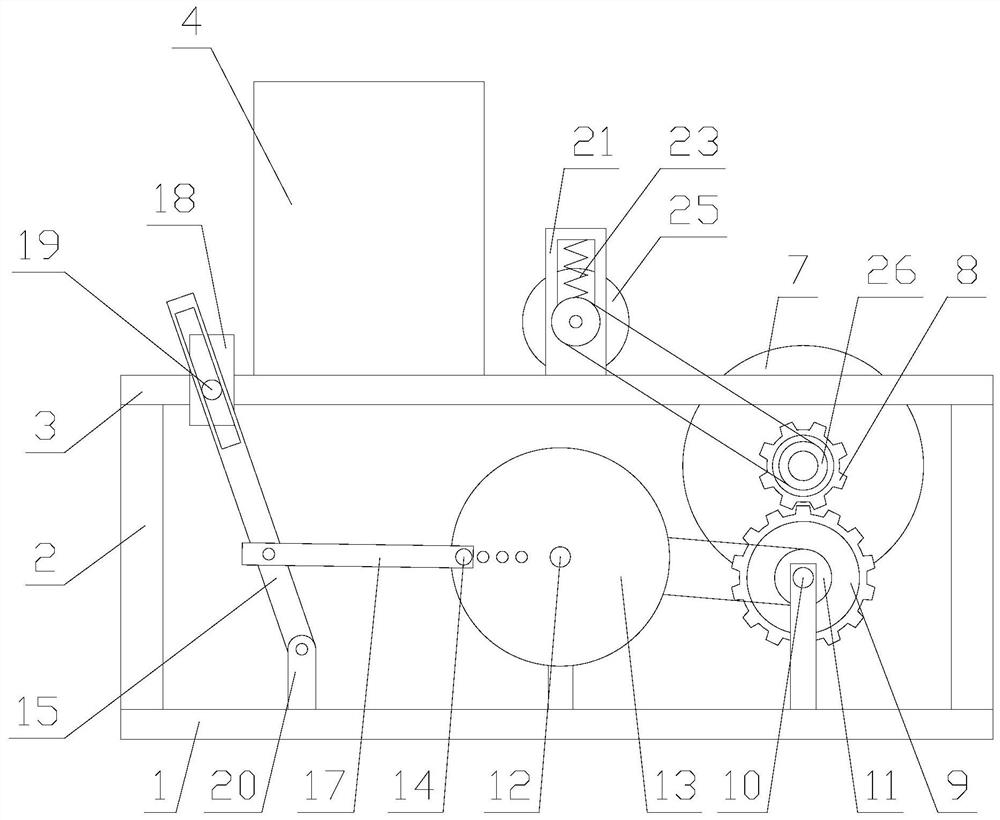

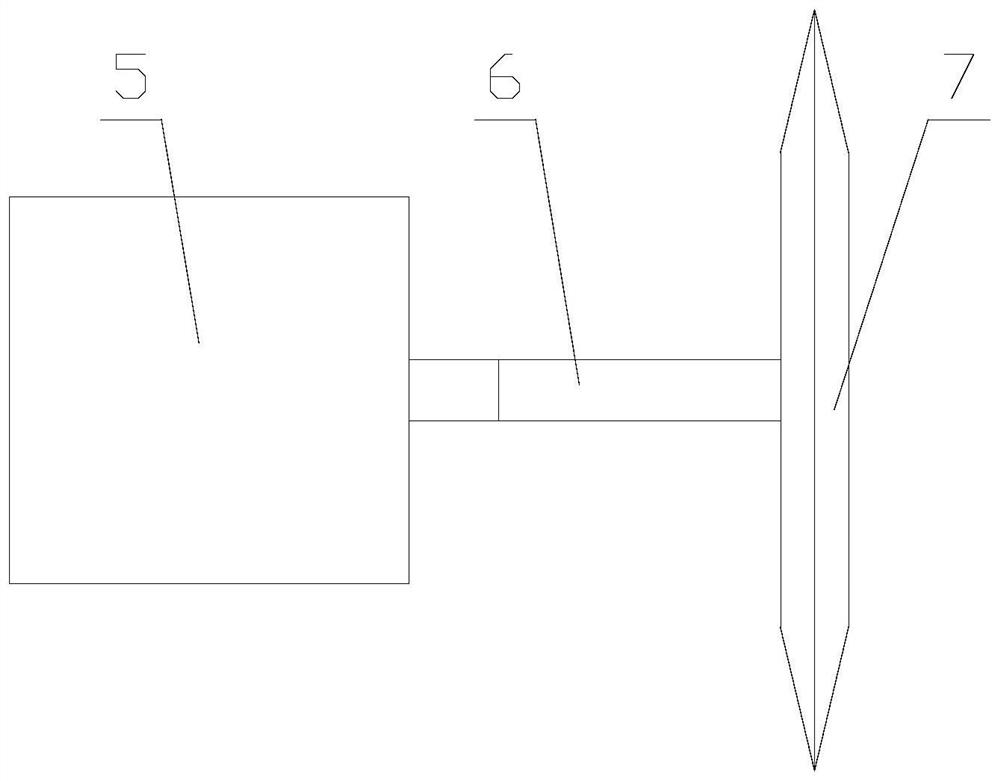

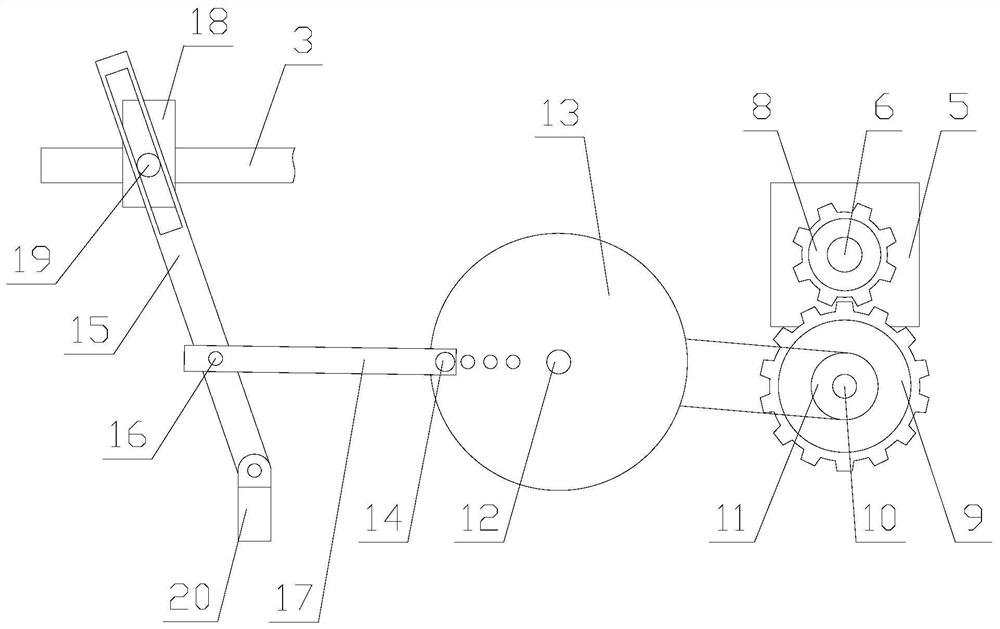

[0027]The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0028]Such asfigure 1 As shown, an automatic batch cutting device for imitation stone insulation boards includes a base 1, a supporting rod 2, a bottom plate 3, a storage box 4, a cutting mechanism, a pushing mechanism, and a clamping and conveying mechanism. The bottom plate 3 passes through a supporting rod. 2 is set above the base 1, the storage box 4 is set on the bottom plate 3, the cutting mechanism and the clamping and conveying mechanism are both set on the bottom plate 3, and the pushing mechanism is set between the base 1 and the bottom plate 3;

[0029]When the device is used, the plate is placed in the storage box 4, the plate is pushed intermittently by the pushing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com