A multi-line delivery system and method for a multi-stage pumping station slurry pipeline

A technology for pipeline transportation and pumping stations, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of low utilization rate, high cost and large environment of the slurry pipeline transportation system, and improve the transportation efficiency and economic benefits, improve utilization, and improve the effect of conveying output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

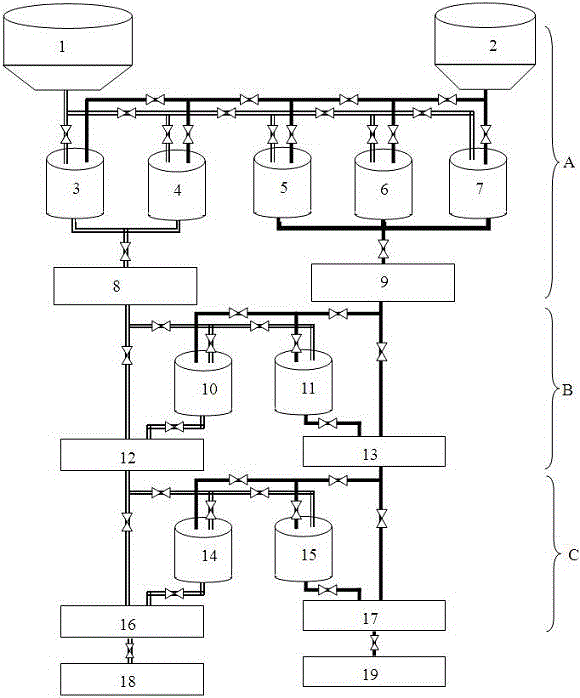

[0024] combined with figure 1As shown, the multi-stage pumping station slurry pipeline multi-line delivery system of the present invention is preferably a double-pipeline delivery system based on a three-stage pumping station, including a first-stage pumping station A, a second-stage pumping station B, and a third-stage pumping station. Pumping station C, the first-level pumping station A is used as a concentrated treatment pumping station for different grades of ore produced by the upper-level dressing plant, including a first pipeline delivery unit and a second pipeline delivery unit, wherein the first pipeline delivery unit includes the first Thickening tank 1, stirring tank 3 and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com