Environment-friendly 3D printing material processing device

A 3D printing and material processing technology, applied in additive processing, metal processing equipment, 3D object support structures, etc., can solve the problems of blockage of the outlet, not being completely crushed, printing interruption, etc., to achieve swing amplitude, prevent Cooling and solidification to achieve the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

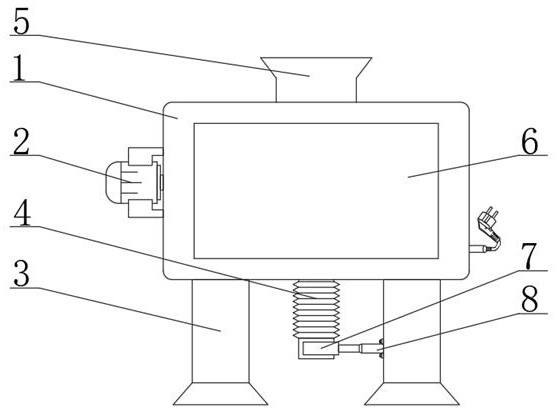

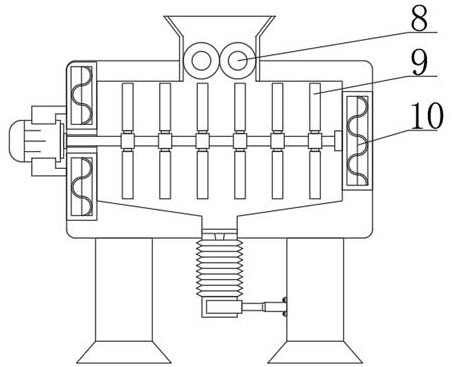

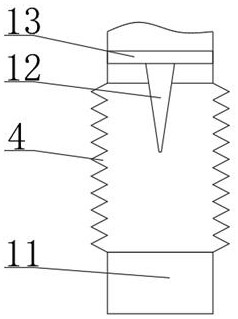

[0021] see Figure 1-5 , the present invention provides a technical solution: an environment-friendly 3D printing material processing device, comprising a storage box 1 and an outrigger 3, the outrigger 3 is rigidly connected to the bottom of the storage box 1, and the top of the storage box 1 is provided with The feed port 5 is a funnel-shaped structure, the inside of the feed port 5 is connected with a crushing mechanism, the inside of the storage box 1 is connected with a stirring mechanism, and the bottom of the storage box 1 is provided with a discharge port. An anti-clogging mechanism is provided on the feed opening, and the anti-clogging mechanism includes a swing mechanism and an adjusting mechanism.

[0022] In this embodiment, a crushing mechanism is installed inside the feed port 5 to prevent the raw material from containing particles that are not completely crushed, which will affect the uniformity of the material. A stirring mechanism is installed inside the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com