Novel glue-free roll tail sealing device

A new type of rubber sealing technology, applied in winding strips, transportation and packaging, thin material processing, etc., can solve problems such as abnormal use, increased material costs, waste materials, etc., to achieve the effect of adjustment and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

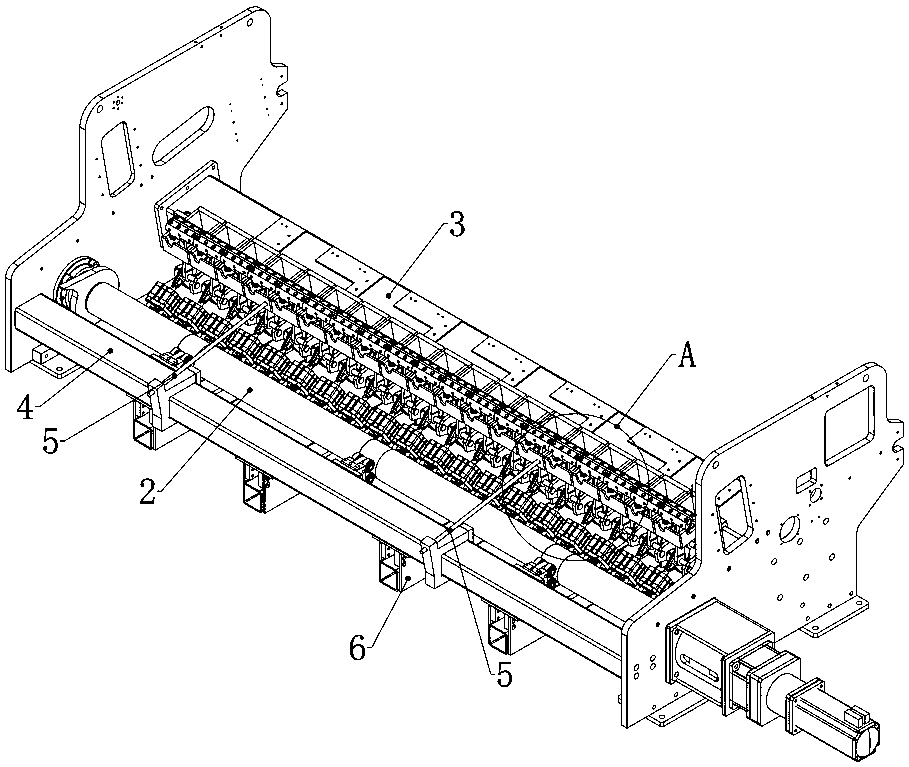

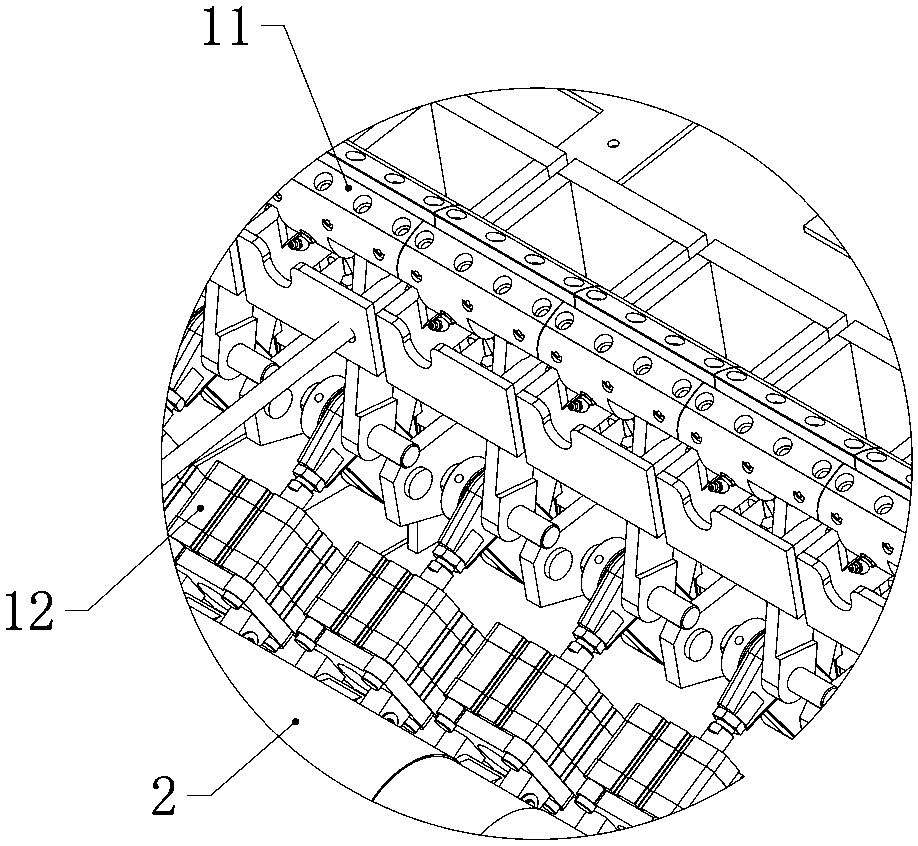

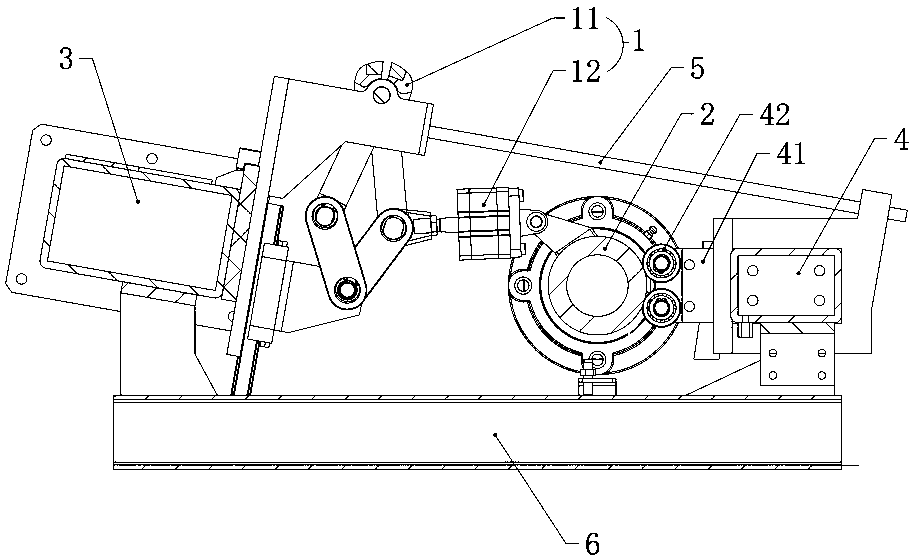

[0024] See attached figure 1 And attached figure 2 As shown, a new type of glueless sealing and winding device in this embodiment includes multiple groups of sealing mechanisms 1 and drive units 2 arranged side by side, wherein each group of sealing mechanisms 1 includes sealing clips 11 and connecting Unit 12. The driving unit 2 is driven by a rotating shaft, wherein, multiple sets of connecting units 12 of the sealing mechanism 1 are in transmission cooperation with the driving unit 2, and the driving unit 2 reciprocates to drive a plurality of connecting units 12 to swing, and with the Each of the connecting units 12 swings to drive the corresponding end sealing clip 11 to open and close; each of the connecting units 12 adjusts the clamping force of the corresponding end sealing clip 11 when closing.

[0025] See attached image 3 And attached Figure 4 As shown, in this embodiment, each end-sealing clamp 11 includes a frame 111, two mutually hinged clamp arms 112, two...

Embodiment 2

[0033] See attached Figure 6 As shown, the difference between this embodiment and the first embodiment is that each end-sealing folder 11 includes a frame 111, a movable tongs arm and a fixed tongs arm hinged to each other, and two clamping dies 114, wherein the two clamps Dies 114 are respectively arranged on the heads of the movable tongs arm and the fixed tongs arm; secondly, one end of the connecting unit 12 is hinged to the moving tongs arm, and the driving unit 2 rotates to drive the connecting unit 12 to swing, thereby connecting the connecting unit 12 to the moving tongs arm. The phase transmission between the tong arms makes the movable tong arm groove and the fixed tong arm move unilaterally, finally realizing the mutual clamping of the two clamping dies 114 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com