A Tail Sealing Mechanism Adaptable to Multi-diameter Specifications

A technology of specifications and end-sealing clips, applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve problems such as damage, low efficiency, and inability to form end-sealing at the end of the reel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

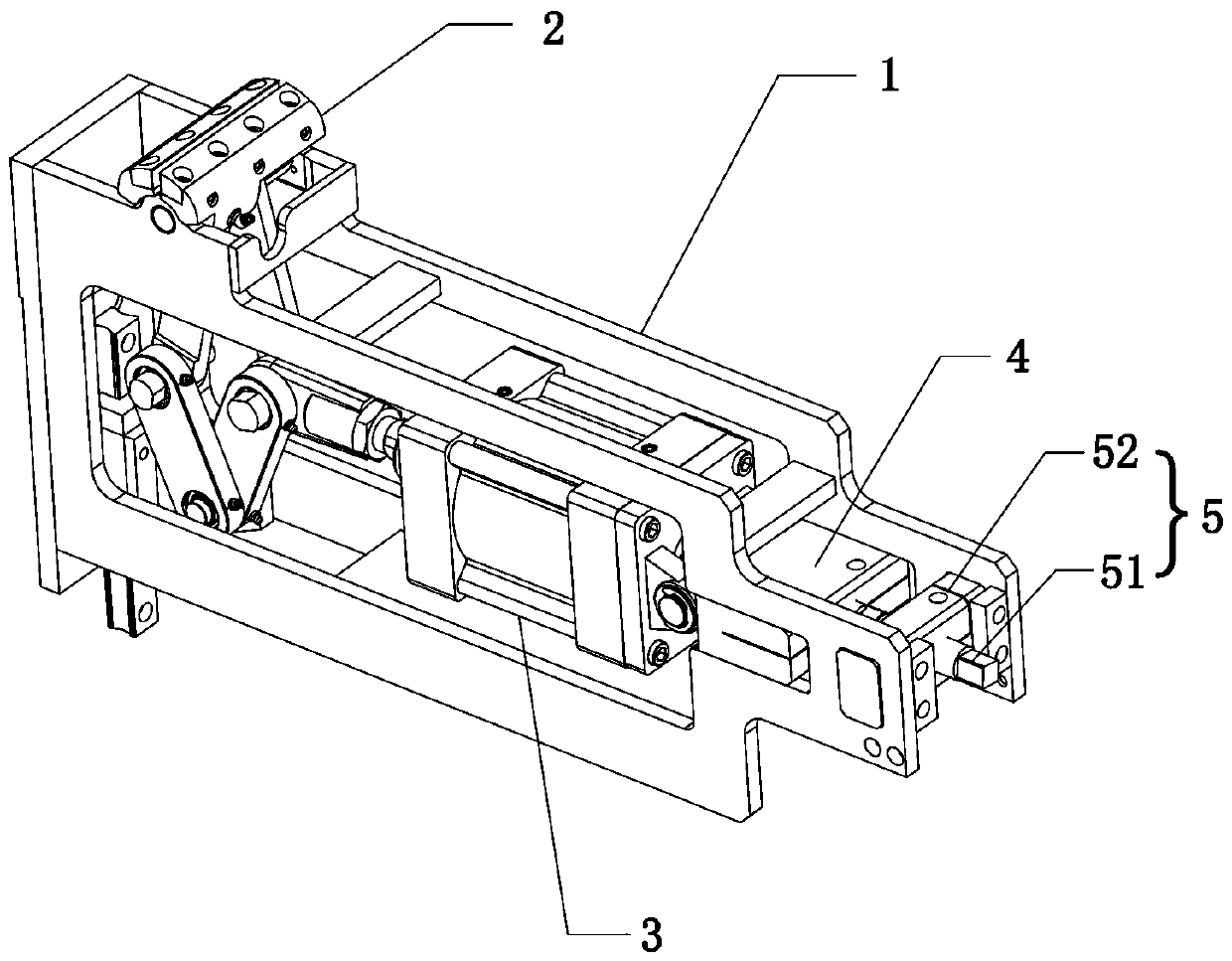

[0025] See attached figure 1 As shown, an end-sealing mechanism adaptable to multi-diameter specifications in this embodiment includes a frame 1, a end-sealing clip 2, and a telescopic drive unit 3 for driving the end-sealing clip 2 to open and close.

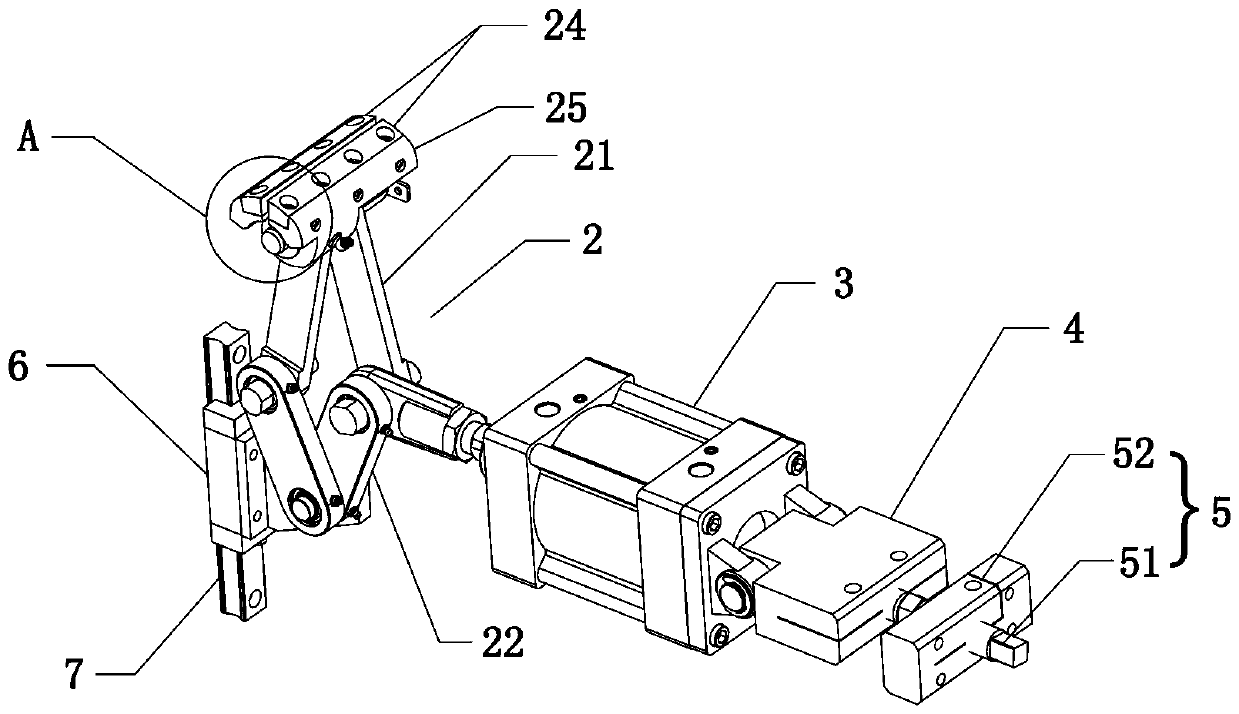

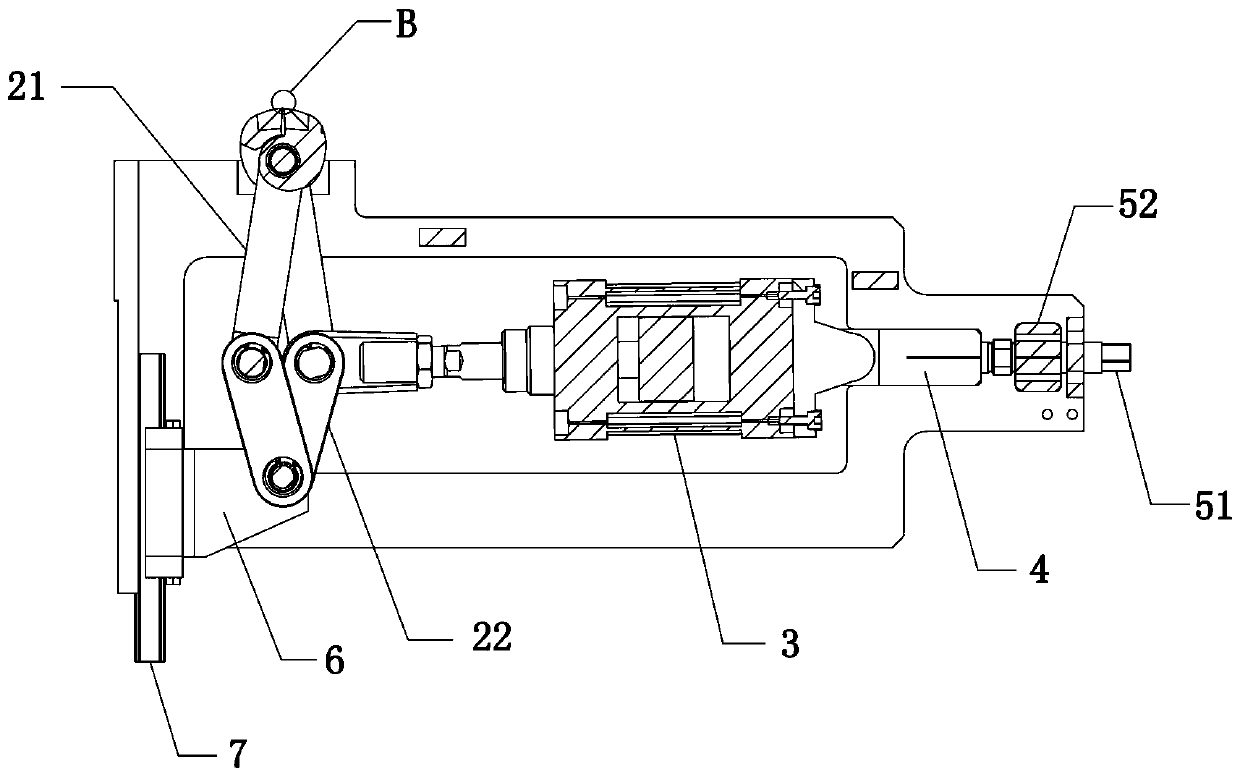

[0026] see figure 2 with image 3 As shown, wherein, the end sealing clamp 2 includes two mutually hinged pincer arms 21, two connecting rods 22 respectively hinged to the rear ends of the two pincer arms 21, and the pin shaft 23 fixed on the frame 1 is passed between the two pincer arms 21 Hinged to each other, the two connecting rods 22 are hinged to each other, and the lifting slider 6 is also hinged on the hinge point of the two connecting rods 22, and the lifting slider 6 is slidably connected by the guide rail 7 arranged on the frame 1 .

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com