Sealing chain

A technology of annular sealing and inner chain link, applied in the field of sealing chain, can solve the problems of shortened sealing life of sealing parts, reduced sealing effect, leakage of lubricating oil, etc., and achieve the effect of improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

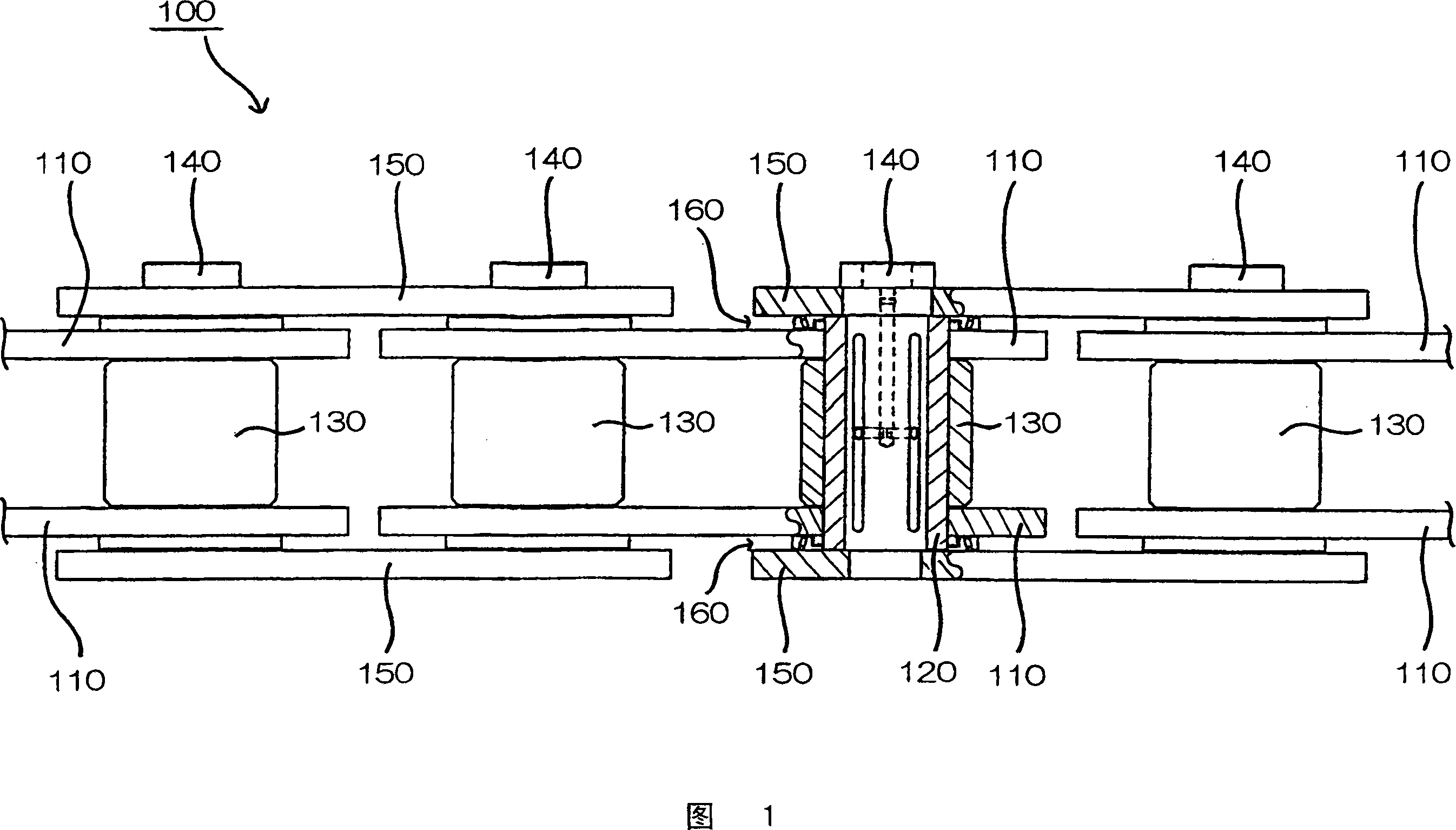

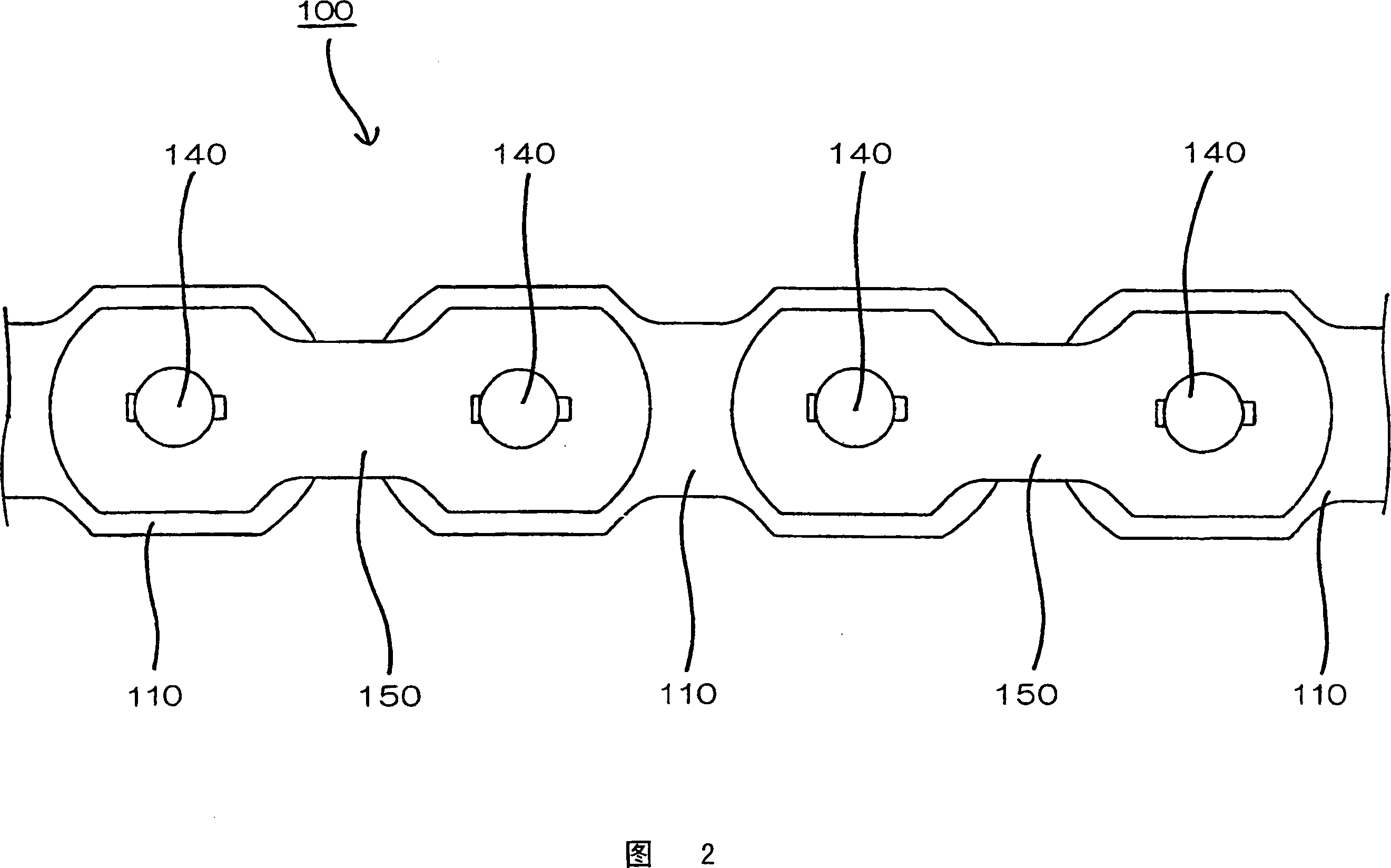

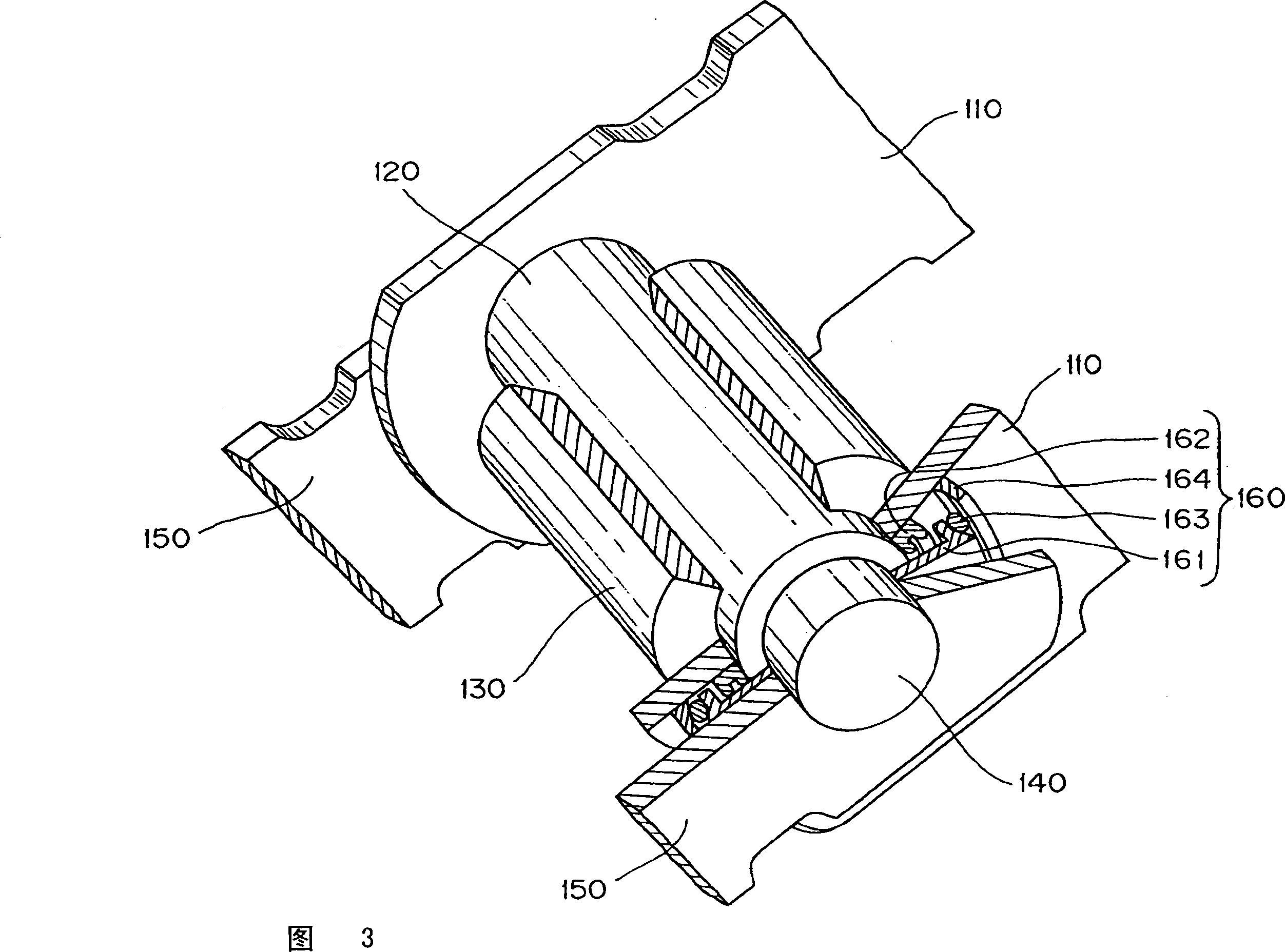

[0032] Next, the sealing chain 100 as an embodiment of the present invention will be described with reference to the accompanying drawings.

[0033] Here, FIG. 1 is an overall schematic diagram of a partial section of the sealing chain according to the first embodiment of the present invention, FIG. 2 is a partial sectioned side view of the sealing chain shown in FIG. 1 , and FIG. 4 is an explanatory view of a part of the sealing chain shown in FIG. 1, and FIG. 5 is an explanatory view of the sealing mechanism used in the sealing chain shown in FIG. 1.

[0034] First of all, the seal chain 100 of the first embodiment of the present invention is a seal chain used as a bucket chain in a continuous unloader for unloading iron ore, coal, etc., as shown in Figures 1 to 4, has: A pair of separate inner link plates 110, 110 are press-fitted into a pair of front and rear sleeves 120, 120 fitted in the sleeve press-in holes 111 of the inner link plate 110, and are rotatably fitted outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com