Low-temperature top-assembling type fixed ball valve

A fixed ball valve, mounted technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve the problem of poor sealing performance of the pan plug sealing ring, the sealing ring is not tightly fitted, and the overall travel tolerance is difficult, etc. problem, to achieve the effect of good sealing performance, avoiding the reduction of sealing performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

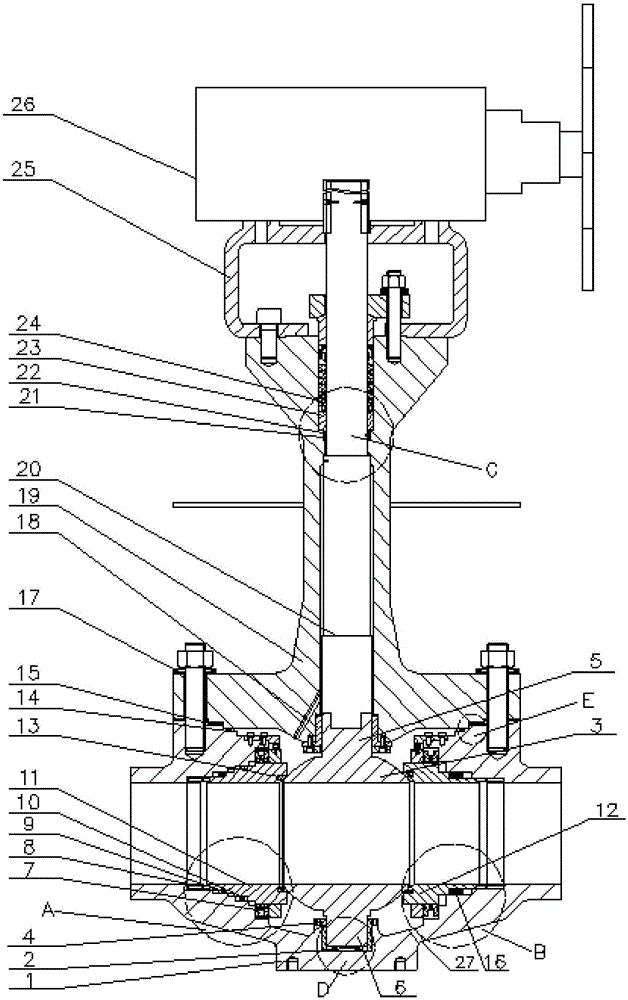

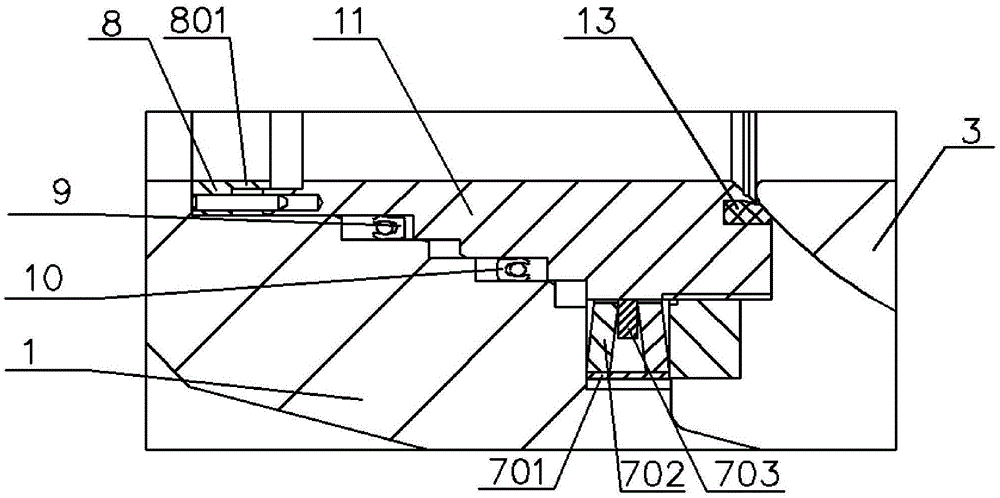

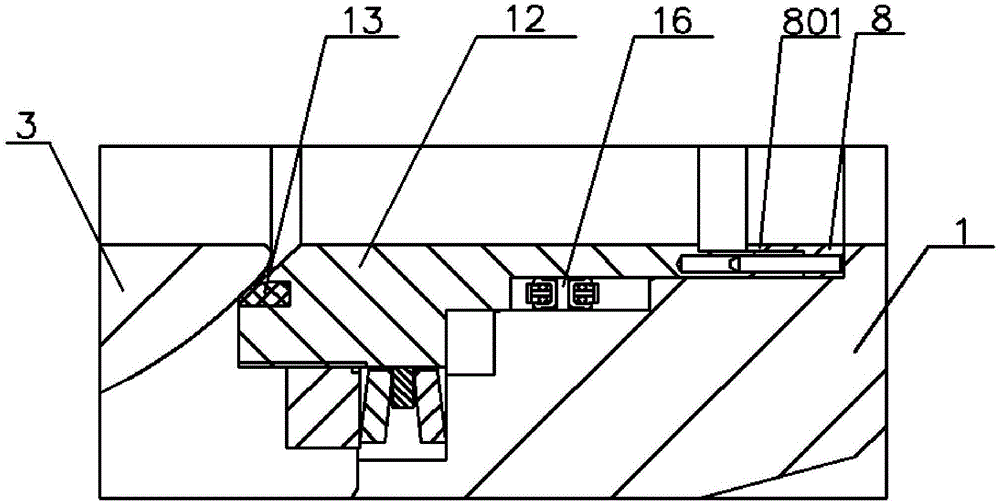

[0047] An embodiment of the present invention provides a low-temperature top entry fixed ball valve, see figure 1 and combine Figure 2 ~ Figure 6 , the cryogenic top entry fixed ball valve includes: valve body 1, ball 3, upstream valve seat 11, downstream valve seat 12, valve cover 19, valve stem 20, connecting bracket 25 and actuator 26; the ball 3 is located inside the valve body 1; The upstream valve seat 11 and the downstream valve seat 12 are located between the sphere 3 and the valve body 1 and on both sides of the sphere 3, and a valve seat fixing ring 8 is arranged between the upstream valve seat 11, the downstream valve seat 12 and the valve body 1; 1 and the valve cover 19 are connected by bolts and nuts; the actuator 26 is fixed on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com