Check valve

A check valve, closed-stop technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve problems such as troublesome molding, increased flow resistance, and complex shapes of opening restriction parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

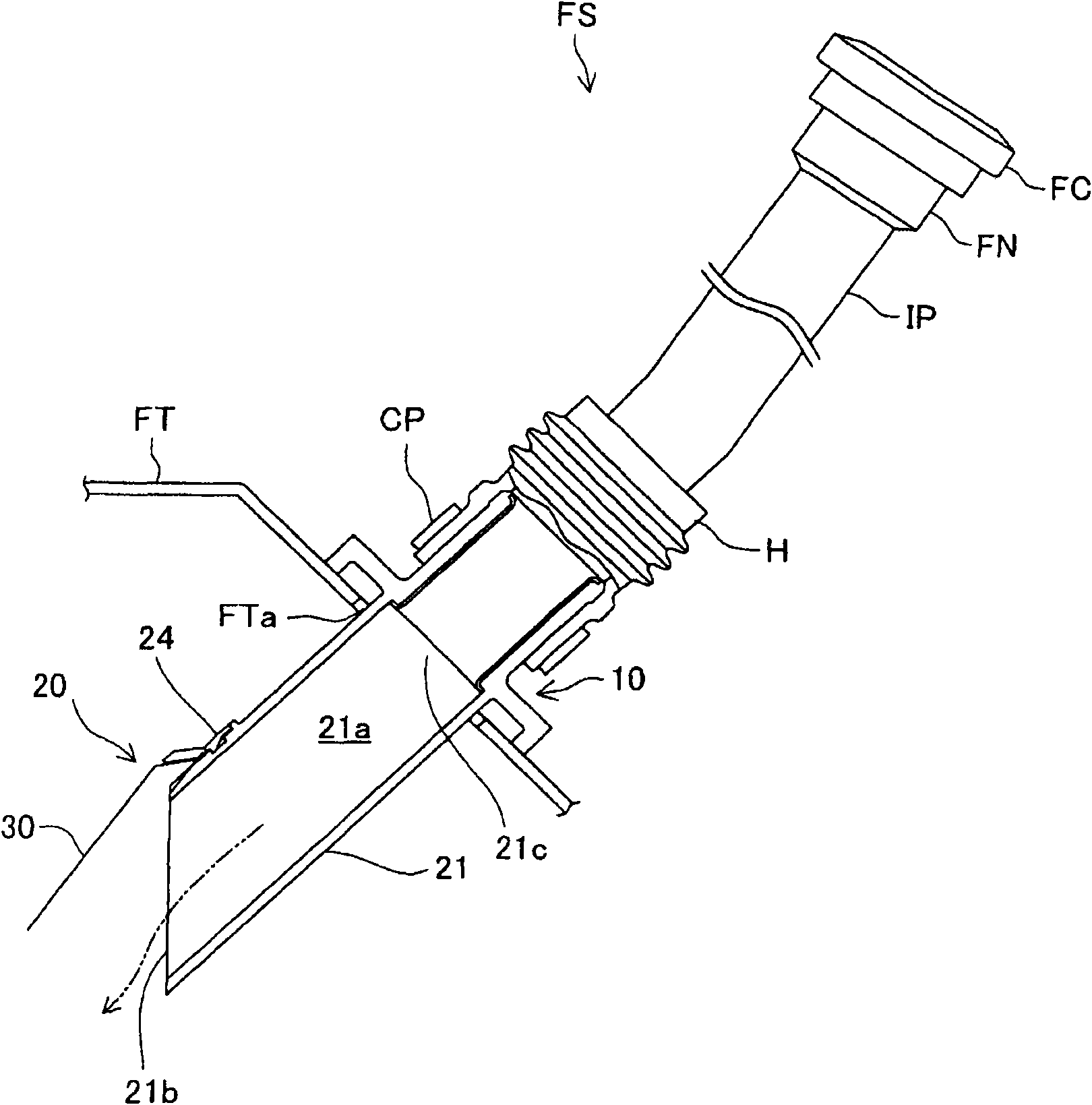

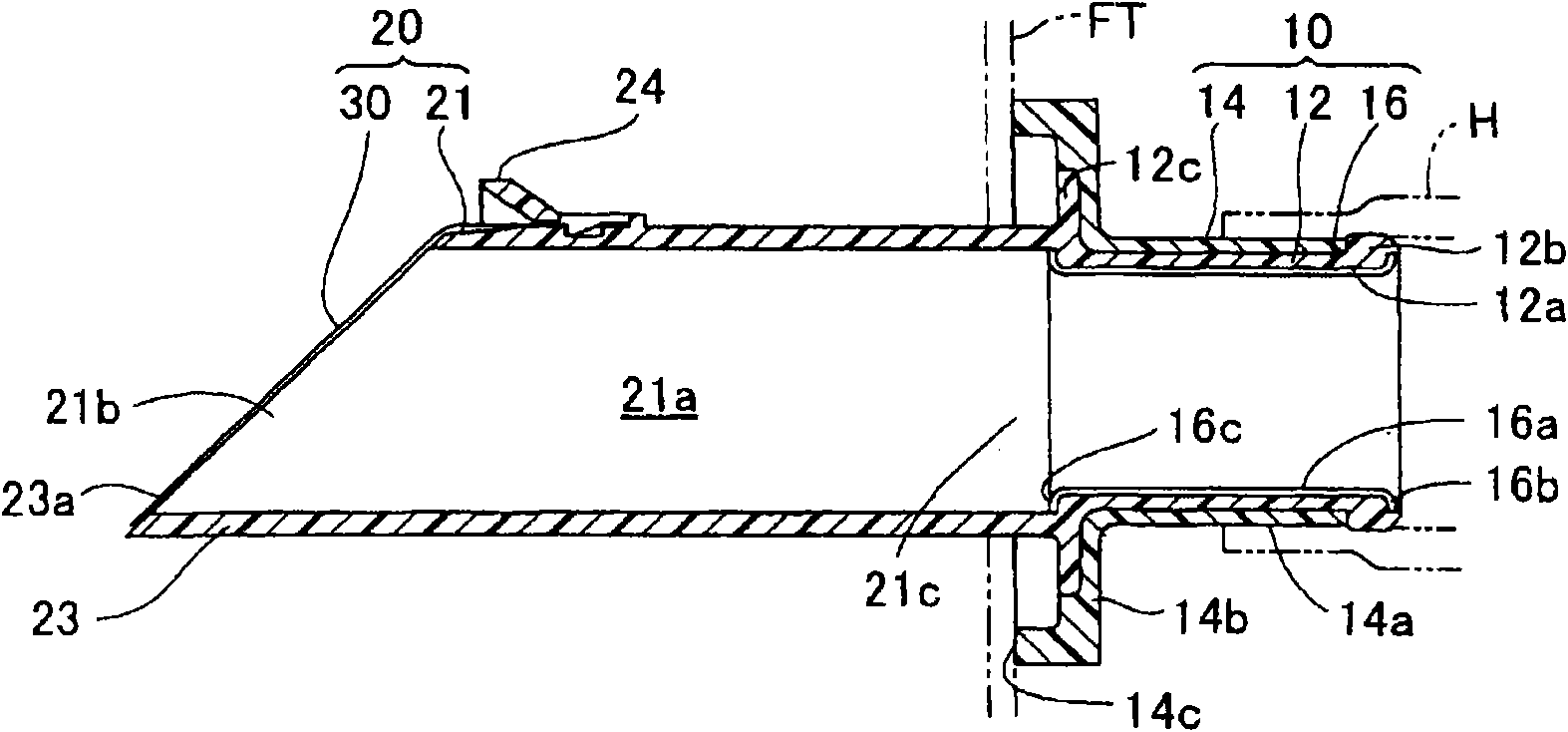

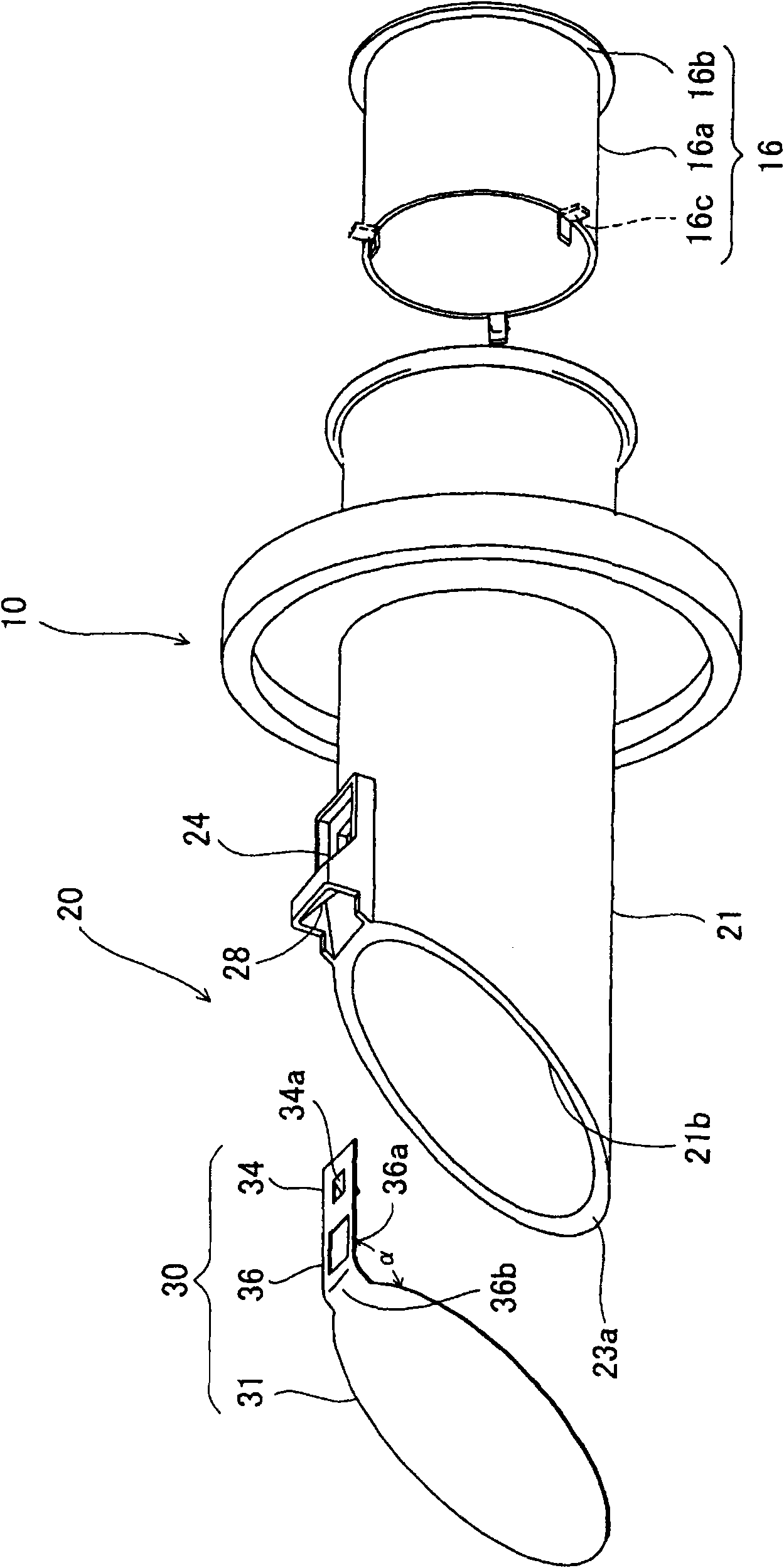

[0035] (1) Outline structure of oil supply unit FS

[0036] figure 1 It is a schematic diagram showing a fuel supply device FS for supplying fuel to a fuel tank FT of an automobile. Such as figure 1 As shown, the fuel supply device FS is connected to the fuel tank FT, and delivers the fuel supplied from the fuel supply gun (not shown) to the fuel tank FT. Inlet; metal or resin oil inlet pipe IP, which is connected to one end of the filling nozzle FN; rubber oil inlet hose H, which is connected to the oil inlet pipe IP; fuel tank pipe connector 10, which is connected to the oil inlet One end of the hose H is connected and welded to the fuel tank FT; and the check valve 20 is integrally assembled with the fuel tank pipe connection body 10 . The fuel inlet hose H is press-fitted into the fuel tank pipe connection body 10 and fastened with the clamp CP. According to the structure of the above-mentioned fuel supply device FS, if the fuel cap FC is removed during fuel supply, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com