Lithium battery cavity negative pressure formation method and apparatus

A chemical synthesis method and technology for lithium batteries, which are applied in secondary batteries, electrochemical generators, non-aqueous electrolyte batteries, etc., can solve the problem that the injection hole is difficult to align with the negative pressure hole, so as to reduce the opening time, save costs, The effect of isolating external environmental interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 The lithium battery cavity negative pressure formation method of the present invention comprises the following steps:

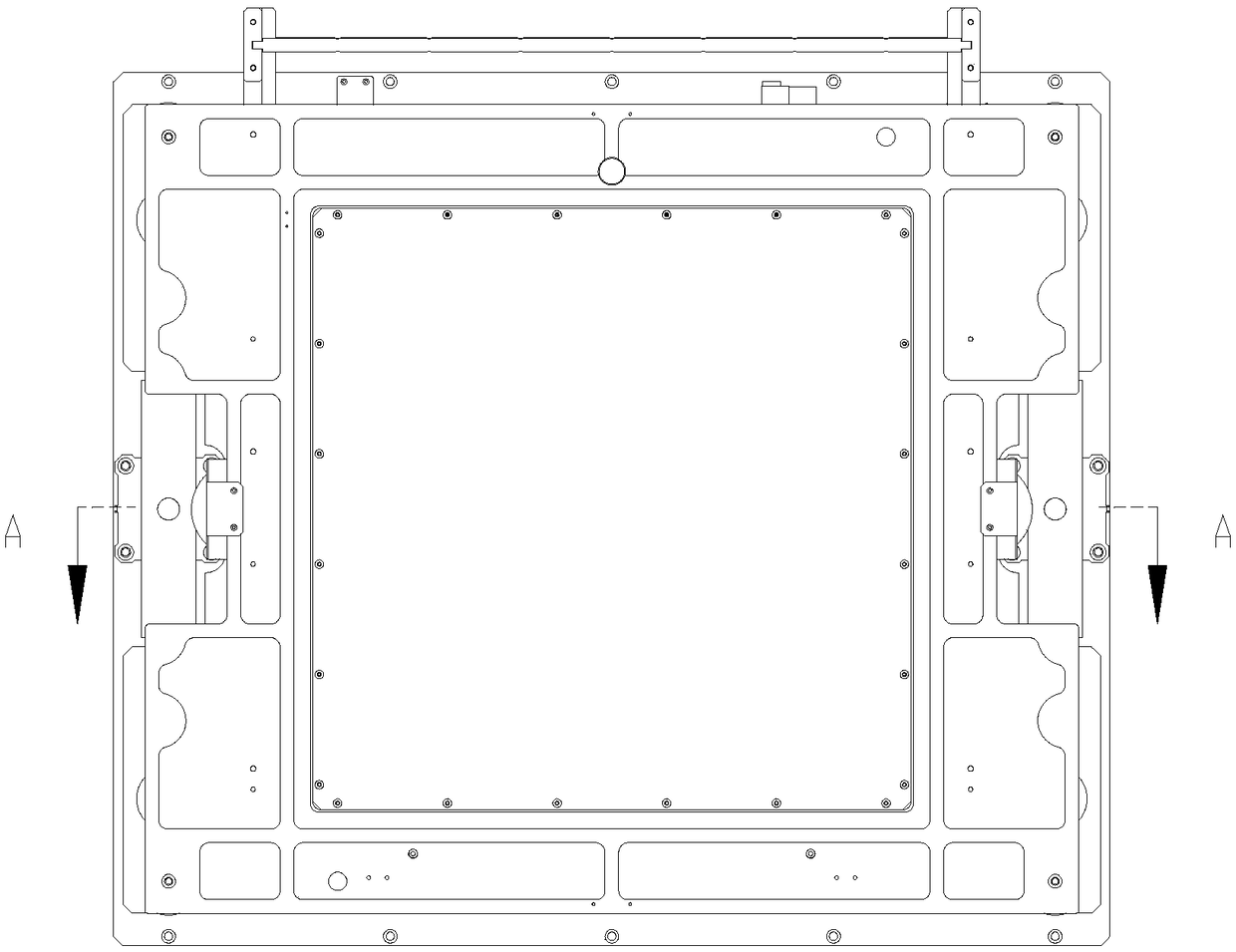

[0061] 1) Put the lithium battery that has been injected into the tray, and keep the upper and lower edges of the outer frame of the tray in sealed contact with the upper and lower needle plates; The contact part is equipped with a sealing groove, and when the cylinder is closed, it cooperates with the sealing strip at the needle plate to play a double sealing role; the removable inner village of the tray is made of corrosion-resistant materials, which is convenient for cleaning and battery specification replacement, and plays a certain role in restraint and guiding role;

[0062] 2) Form a sealed environment, airtight test:

[0063] The outer frame of the tray and the upper and lower needle boards are pressed and sealed under the drive of the driving cylinder, so that the entire tray forms a sealed cavity, and the battery contacts the pr...

Embodiment 2

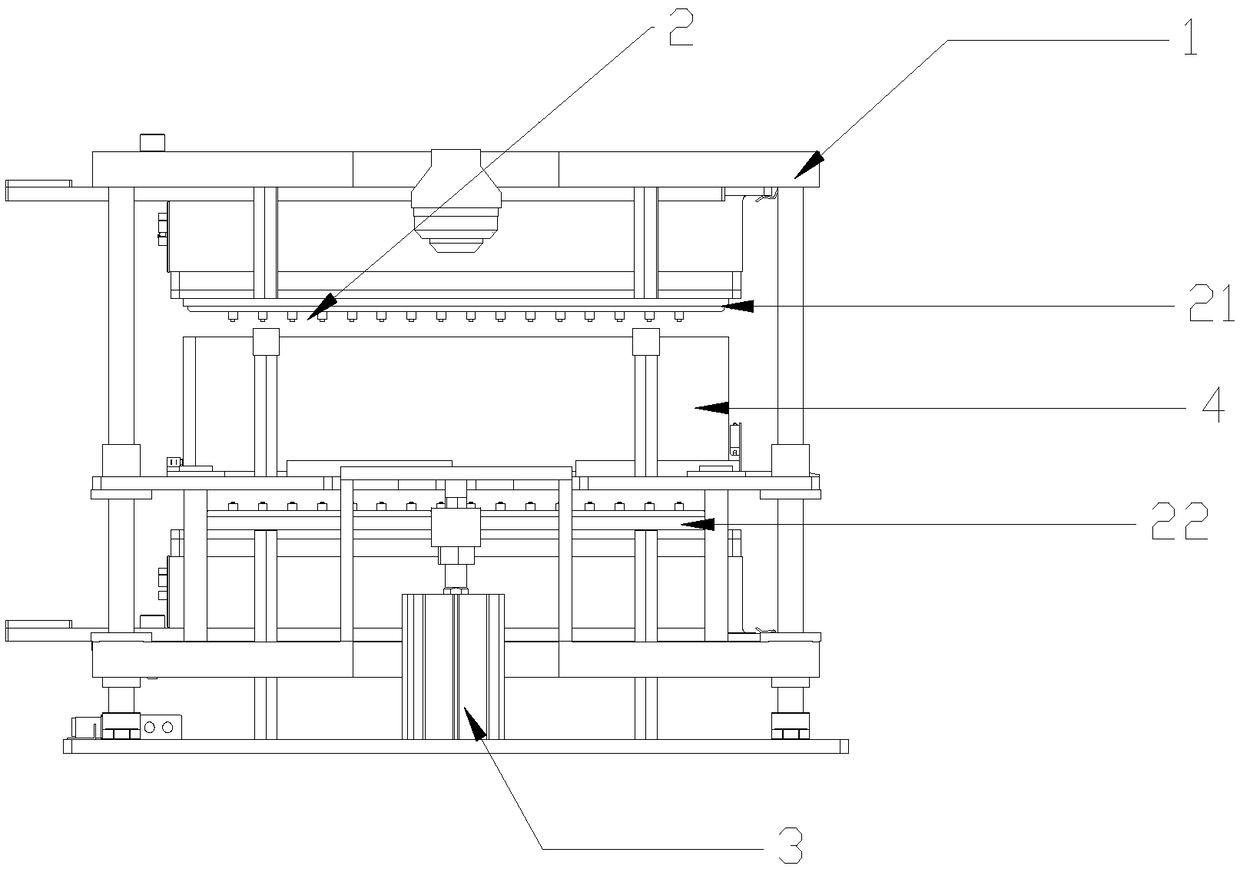

[0076] Embodiment 2 The device constructed according to the lithium battery cavity negative pressure forming method described in Embodiment 1 includes a support device 1, a needle plate assembly 2, a driving cylinder 3, a tray 4 and a control device,

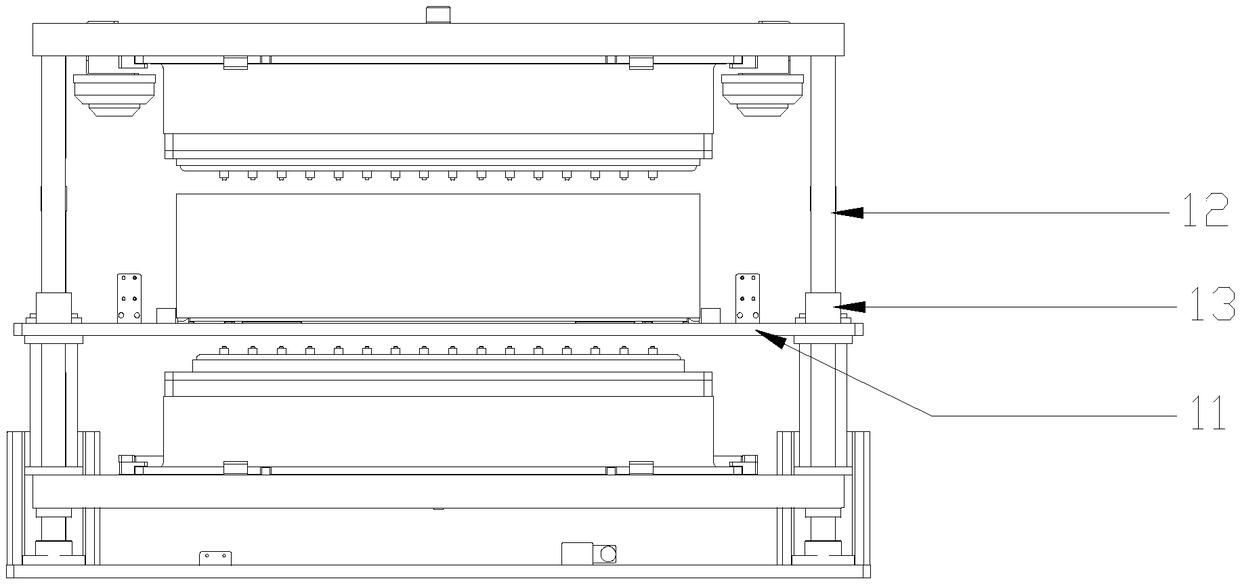

[0077] The support device 1 includes a support plate 11, a support guide rod 12 and a slide block 13, the support plate 11 is provided with holes for the probes to pass through to contact the electrodes of the battery 5, and a plurality of rods and electrodes are installed on the support plate 11. The supporting guide rod 12 that is vertical to the supporting plate and is rotatably connected with it; the supporting guide rod 12 is screwed with a slide block 13, and the sliding block 13 is fixed on the supporting plate 12, and can be moved along the supporting guide rod under the drive of the driving cylinder 3. The rod 12 moves up and down axially to adjust the distance between the needle plate assemblies;

[0078] The needle pl...

Embodiment 3

[0089] Embodiment 3 In terms of negative pressure control, adopt Figure 5 The control unit used. Its negative pressure control process:

[0090] 1) According to the negative pressure process, issue the negative pressure value. When the negative pressure is greater than the set value of 10kps, close the negative pressure valve; when the negative pressure is less than the set value of 10kps, open the negative pressure valve, and the negative pressure will value rises slowly;

[0091] 2) Change the negative pressure value according to the average voltage of the battery; because the type and volume of gas produced by the battery cell are different in different stages of formation; the state of the stage of formation is evaluated by the collected average voltage of the pallet cell, so as to automatically adjust Set value for the corresponding negative pressure;

[0092] 3) Set the negative pressure according to the process time; set the negative pressure value in different time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com