Electric vehicle thermal management system and electric vehicle

A thermal management system and technology for electric vehicles, applied in the thermal management system of electric vehicles and the field of electric vehicles, can solve the problems of consuming electric energy of the whole vehicle, reducing the driving range, and reducing the battery life, so as to ensure the discharge power and life, and prolong the battery life. Mileage, the effect of reducing the opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

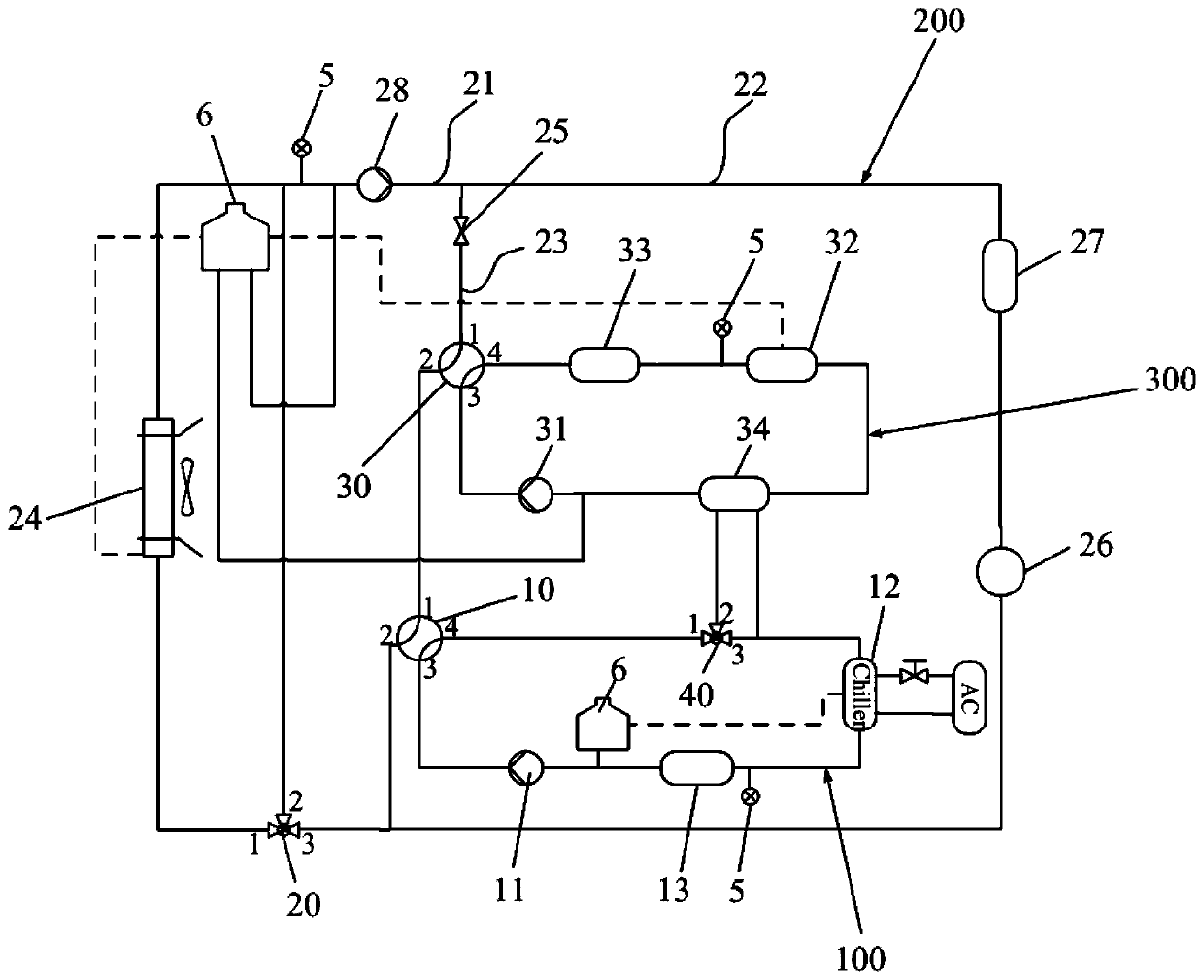

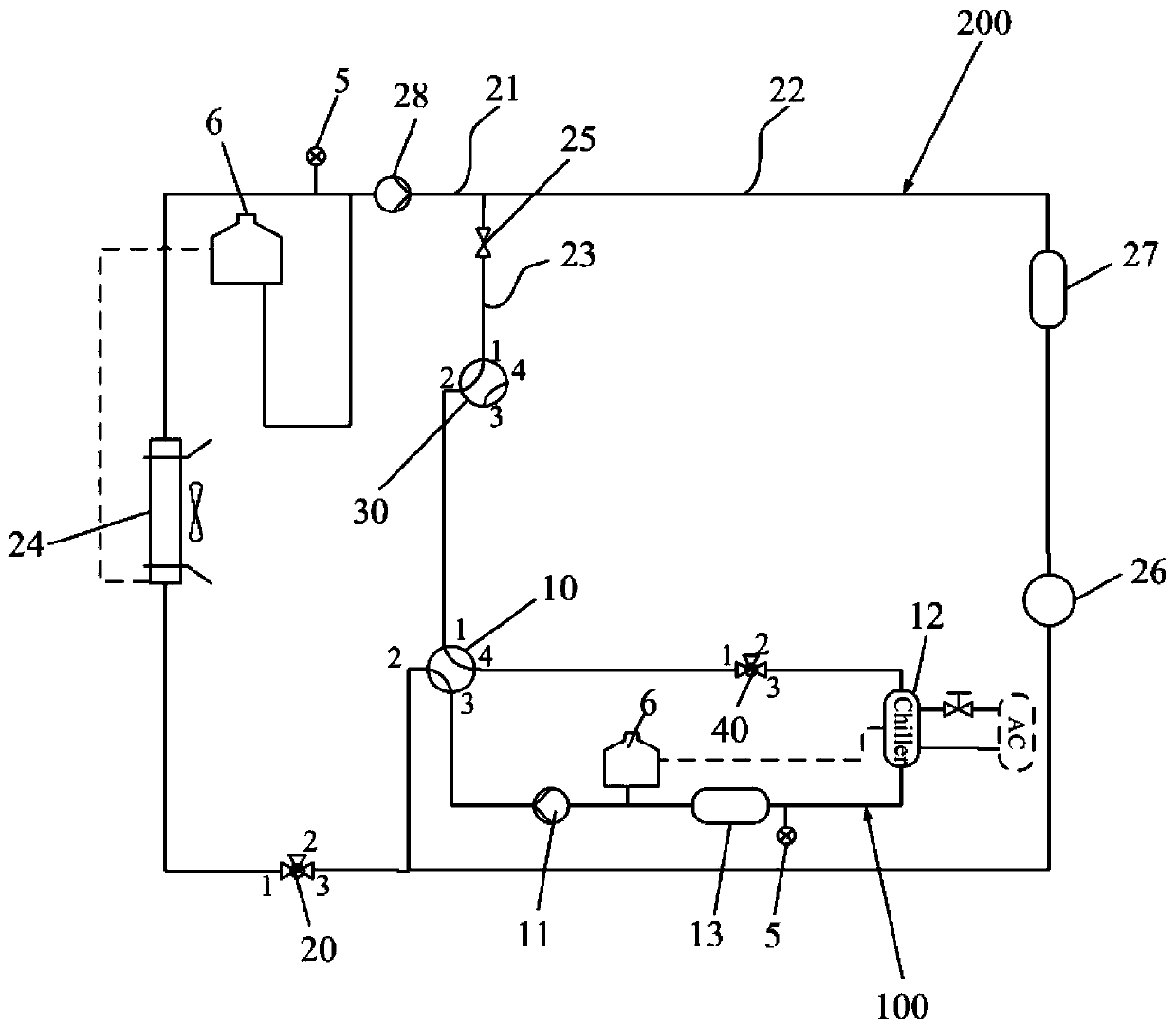

[0050] figure 1 It shows the electric vehicle thermal management system provided by this embodiment, including a battery control circuit 100 , a power train control circuit 200 and a heater control circuit 300 .

[0051]Specifically, the battery control circuit 100 is coupled to the battery pack 13 of the electric vehicle. The battery control circuit 100 is provided with a first circulating pump 11 and a cooling device 12 (Chiller). The first circulation pump 11 drives the circulation of the heat transfer fluid in the battery control circuit 100, and the heat transfer fluid exchanges heat with the battery pack 13, and controls the temperature of the battery pack 13 to be in the optimum working temperature range, ensuring the charging and discharging efficiency of the battery and the battery life of the electric vehicle ability. When the ambient temperature is high and the heat dissipation requirement of the battery is high, the cooling device 12 is activated.

[0052] The w...

Embodiment 2

[0078] The difference between this embodiment and embodiment one is:

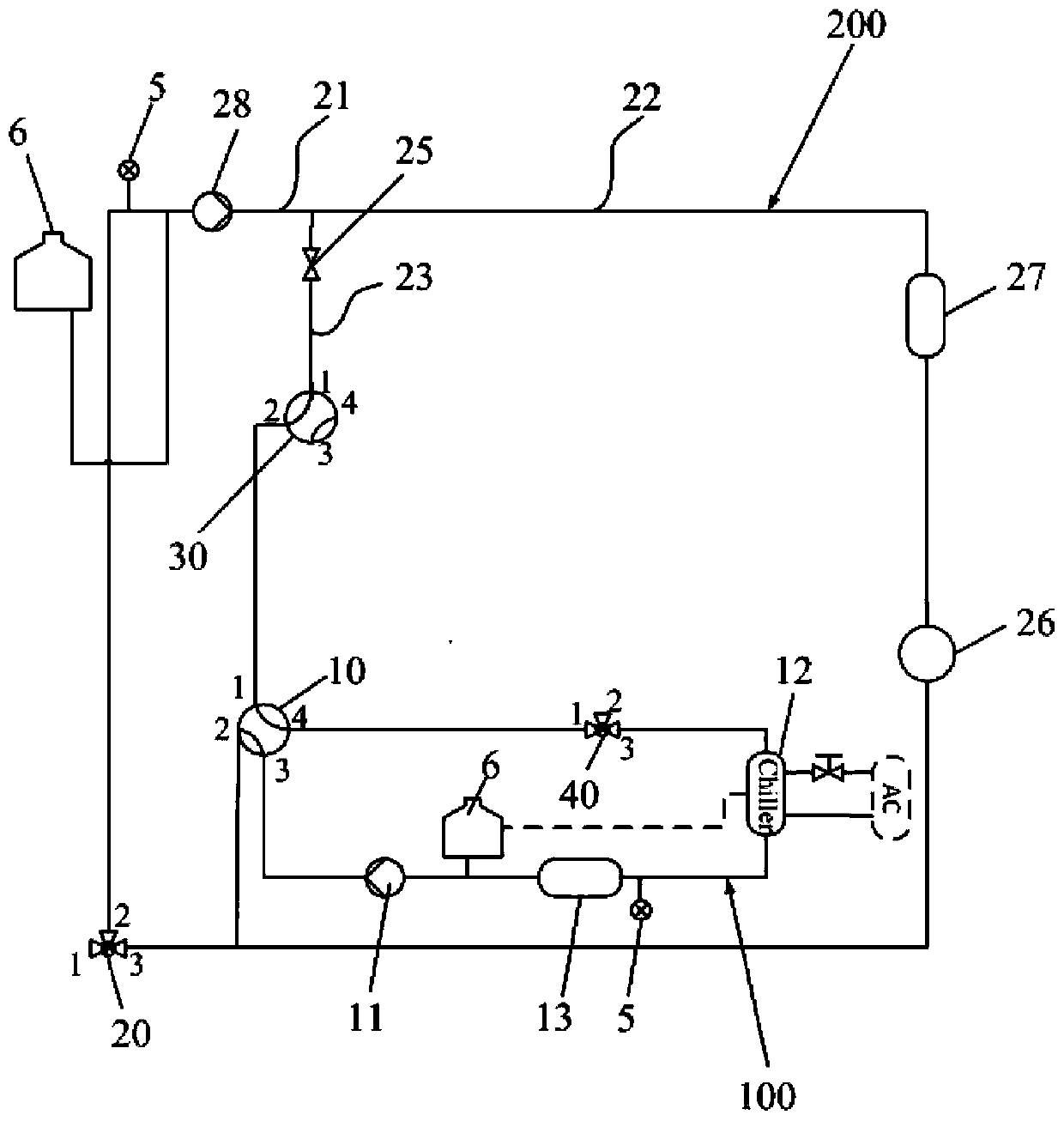

[0079] Such as Figure 8 As shown, for the first valve assembly 10, the scheme of using two first three-way valves instead of one first four-way valve can still realize the parallel connection of the powertrain control circuit 200 and the battery control circuit 100; for the third The valve assembly 30 adopts the form of two second three-way valves instead of a second four-way valve, which can still realize the parallel connection of the power train control circuit 200 and the heating air control circuit 300; for the second valve assembly 20, a first The form of a two-way valve replaces the above-mentioned second valve assembly 20 , which can still realize the connection or disconnection between the radiator 24 and the main circuit 21 . Obviously, for the fourth valve assembly 40, three second two-way valves can also be used instead of the fourth three-way valve, and the heat exchanger 34 in the warm air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com