Separator for fuel battery

A fuel cell and separator technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of gasket forming groove damage, stress concentration, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

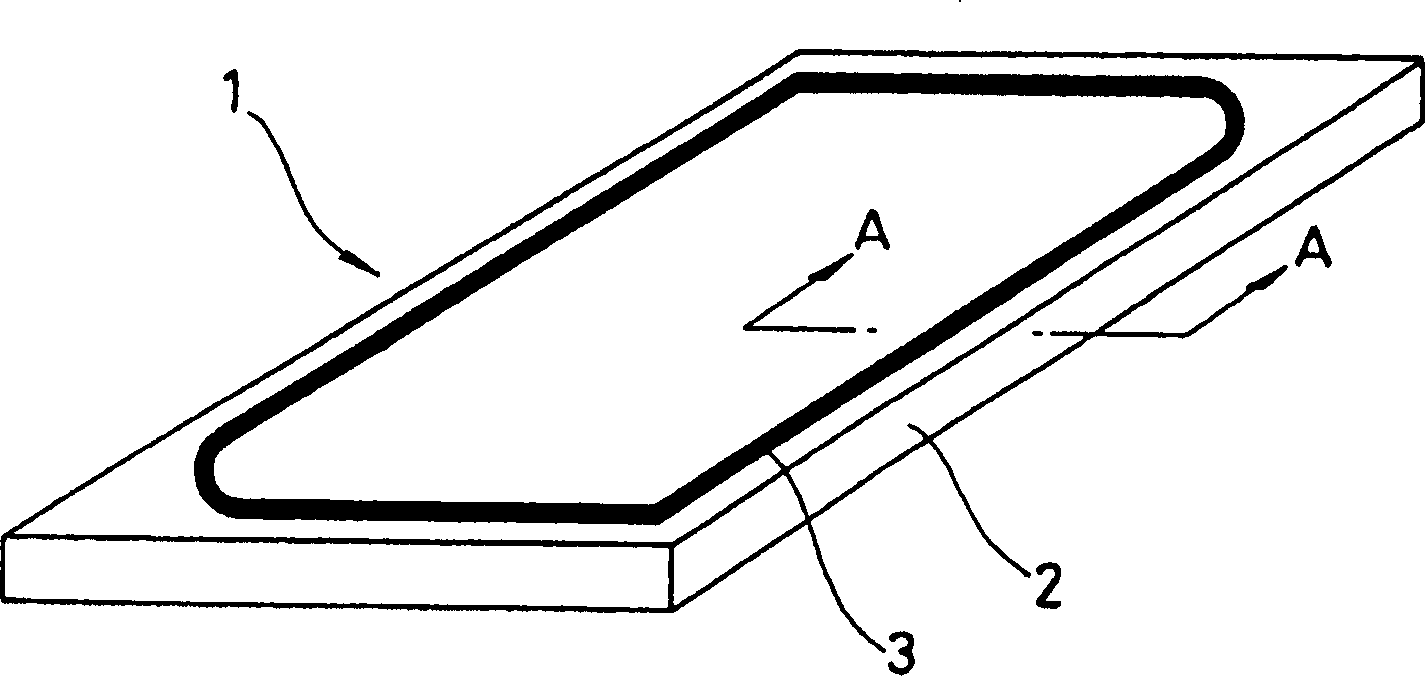

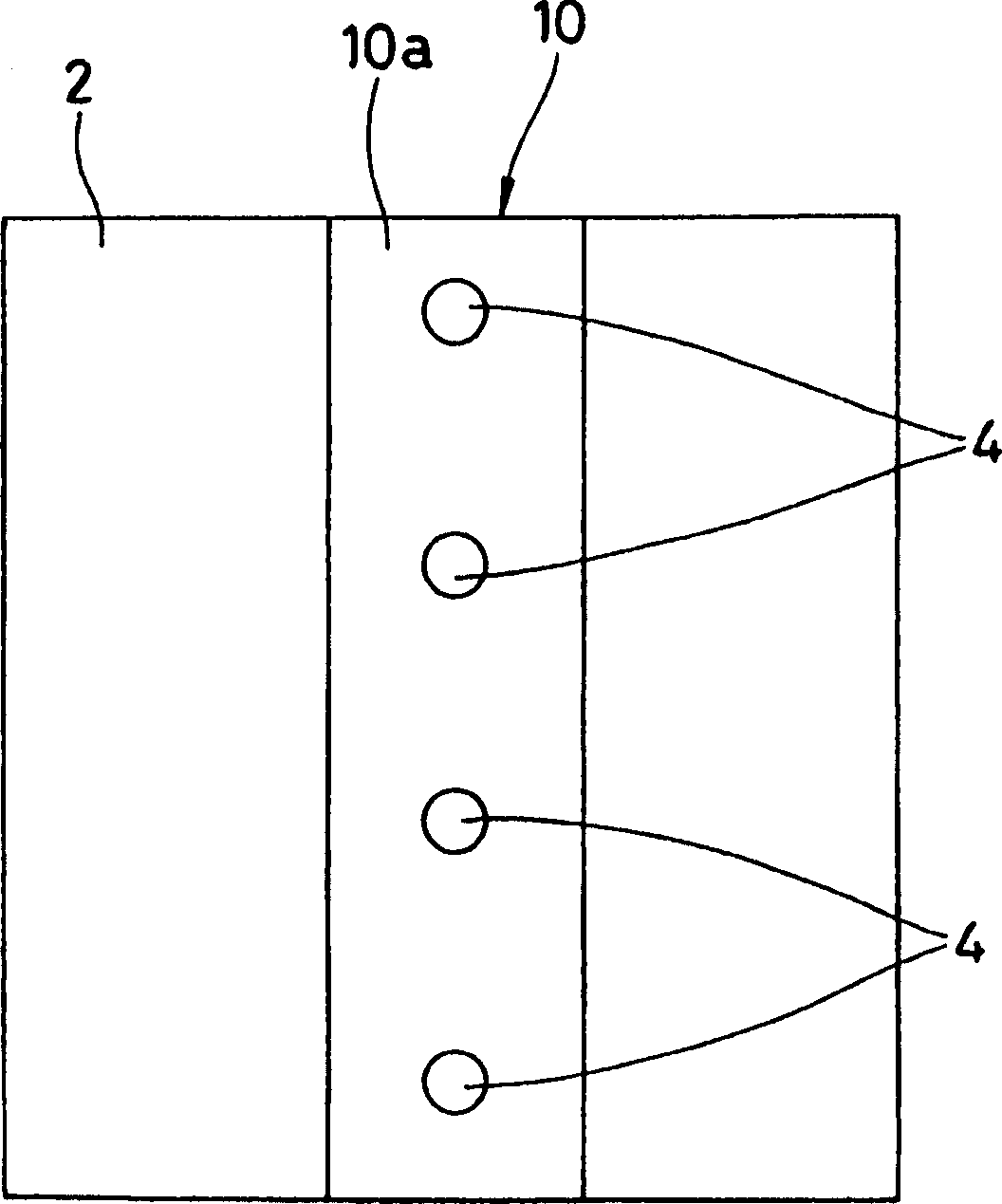

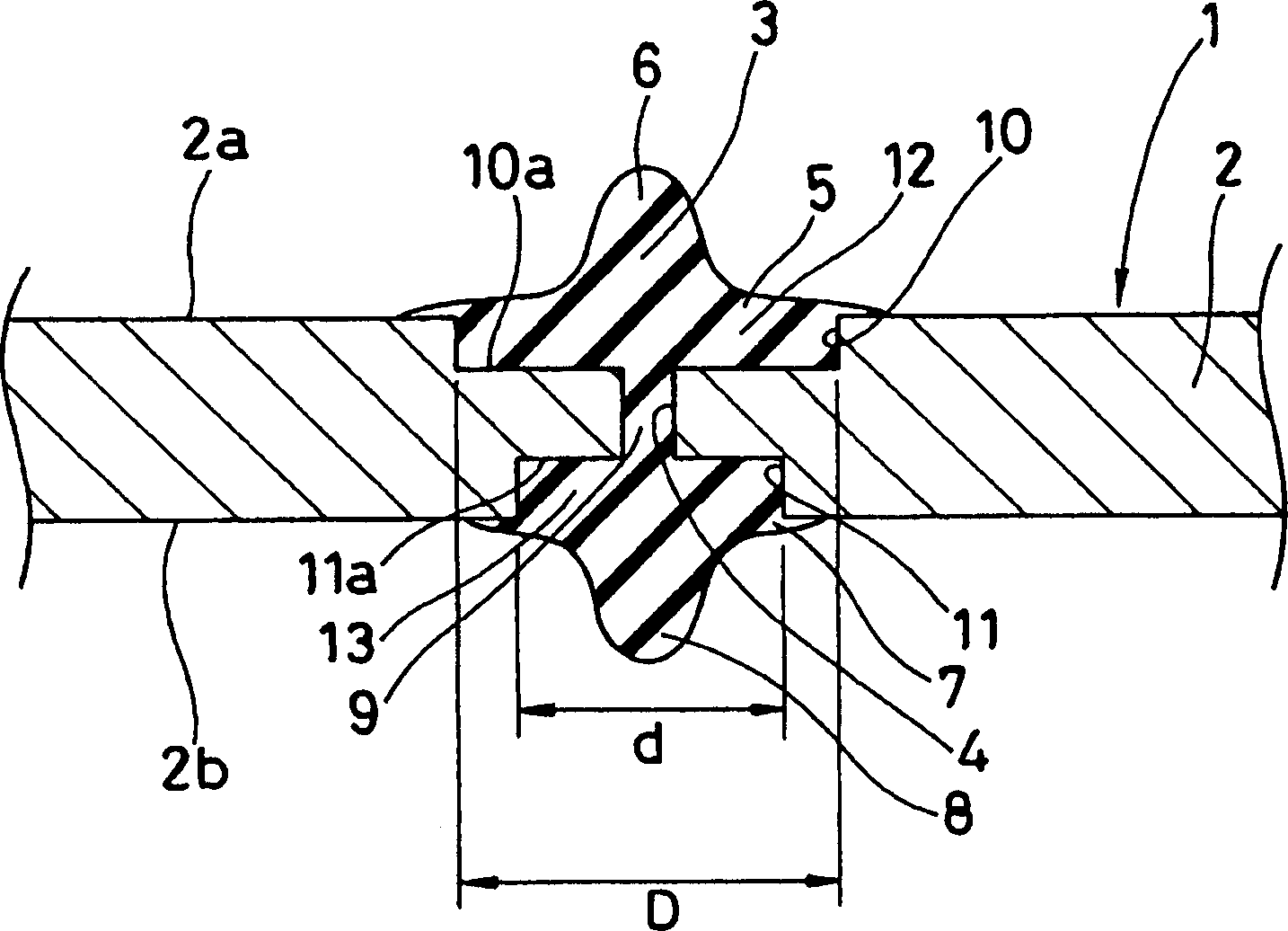

[0056] figure 1 It is a perspective view of the fuel cell separator 1 involved in the first embodiment of the present invention, figure 2 It is a plan view of a part of the separator main body 2 constituting the fuel cell separator 1, image 3 is along figure 1 Partial sectional view of line A-A in middle.

[0057] The fuel cell separator 1 used in this first embodiment, as figure 1 As shown, there are two independent constituent elements of the separator main body 2 and the gasket 3, and the composition of these two elements is as follows.

[0058] That is, first, the gasket forming groove 10 and the gasket forming groove 11, such as figure 2 As shown, each is formed along the extending direction of the gasket on both sides of the separator main body 2 which is compression-molded from a mixture of carbon powder and thermosetting resin phenol, namely 2a and 2b, and is made along the two molding grooves 10 and 11. A desired number of through holes 4 communicate with t...

no. 2 example

[0061] Figure 4 It is a partial cross-sectional view of a fuel cell separator 1 according to a second embodiment of the present invention. The fuel cell separator 1 used in the second embodiment has two independent structures of a separator main body 2 and a gasket 3 components, the composition of these two components is as follows.

[0062] That is, first, the gasket forming groove 10 and the gasket forming groove 11, such as figure 2 As shown, each is formed along the extending direction of the gasket on both sides of the separator main body 2 which is compression-molded from a mixture of carbon powder and thermosetting resin phenol, namely 2a and 2b, and is made along the two molding grooves 10 and 11. A desired number of through holes 4 communicate with the bottom surfaces 10 a and 10 b of the two shaped grooves 10 and 11 . Here, if Figure 4 As shown, the groove side surfaces 16 and 17 of the molding grooves 10 and 11 formed on the two surfaces of the separator main ...

no. 3 example

[0065] Figure 5 It is a partial cross-sectional view of a fuel cell separator 1 related to the third embodiment of the present invention. The fuel cell separator 1 used in the second embodiment has two independent structures of a separator main body 2 and a gasket 3 components, the composition of these two components is as follows. That is, first, the gasket forming groove 10 and the gasket forming groove 11, such as figure 2 As shown, each is formed along the extending direction of the gasket on both sides of the separator main body 2 which is compression-molded from a mixture of carbon powder and thermosetting resin phenol, namely 2a and 2b, and is made along the two molding grooves 10 and 11. A desired number of through holes 4 communicate with the bottom surfaces 10 a and 10 b of the two shaped grooves 10 and 11 . Here, if Figure 5 As shown, the corner portions 14 of the bottom surfaces of the grooves 10 and 11 formed on the two surfaces of the separator main body 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com