Nano function material for treating water and its application

A nano-functional, rare-earth nano-material technology, applied in water/sewage treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve complex treatment equipment, ion scaling operation cost, and cumbersome operation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

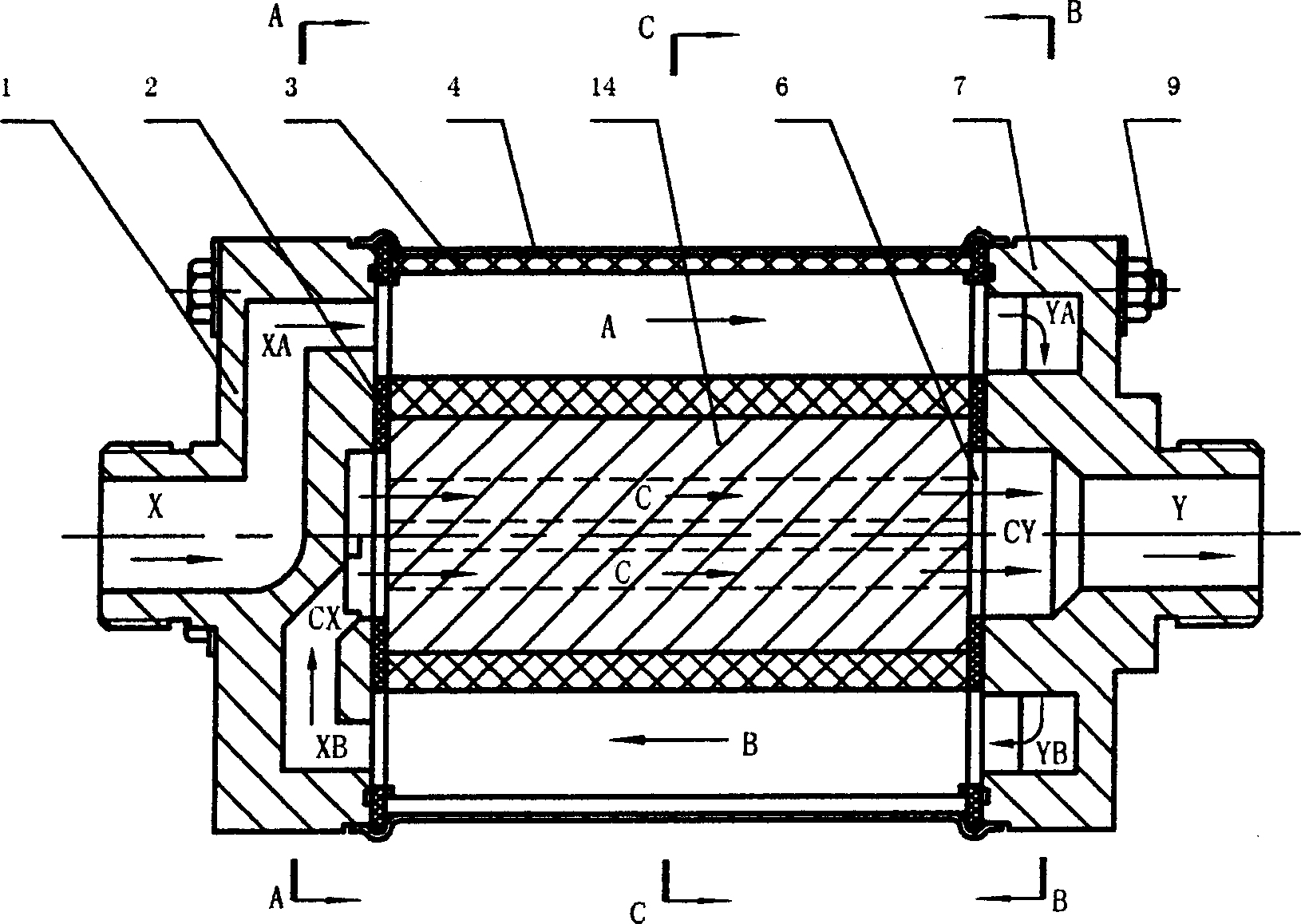

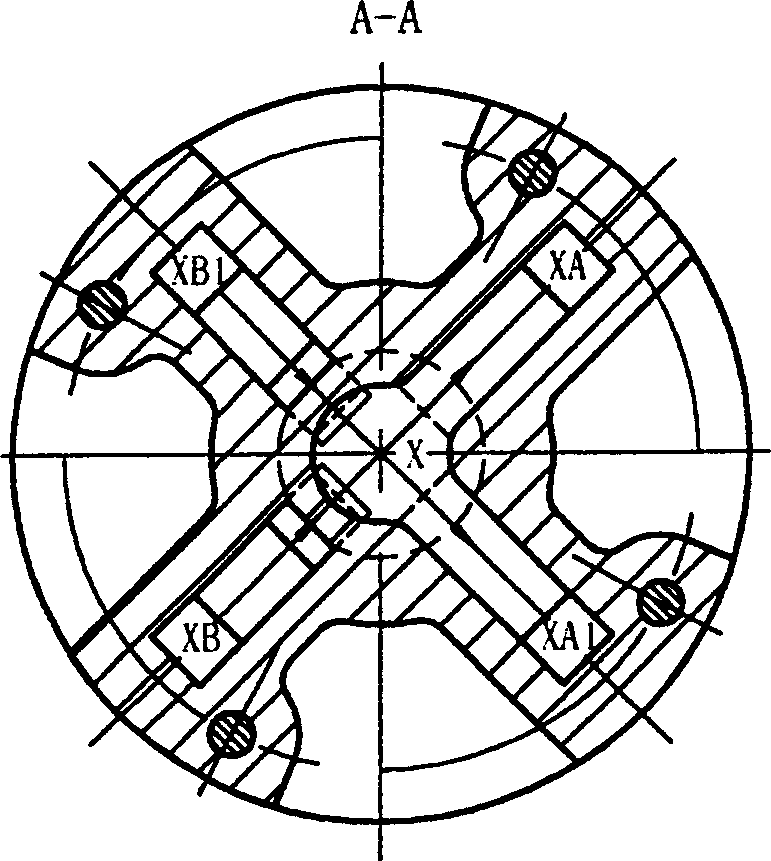

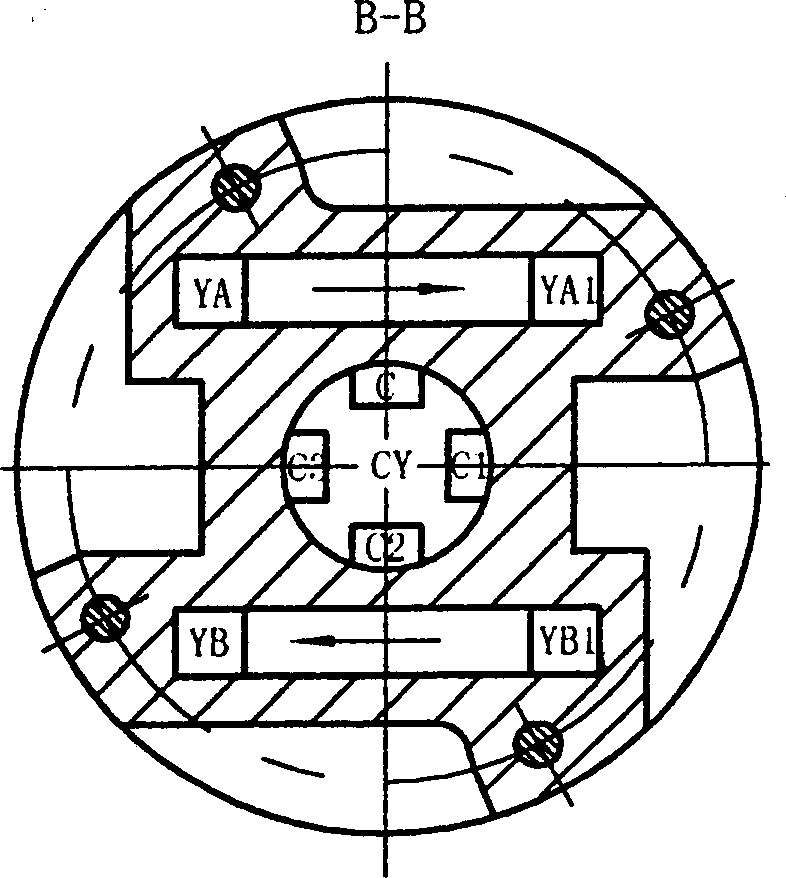

[0018] First mix 0.5Kg mineral powder and 1.5Kg metal zinc powder and ball mill for 5 hours to make BCC functional material with a particle size of about 100nm, then add 50g of RF (metal lanthanum) nano powder and ball mill for 3 hours, then put it into graphite clamp pot Into the container, 100Kg molten iron melted at 1400°C is poured into it, and finally cast into small iron pillars with a square cross-section and each with a groove, which becomes a square longitudinal channel embedded in the center of the plastic support.

Embodiment 2

[0020] First mix 1.0Kg mineral powder with 1.0Kg metal zinc powder, ball mill for 5 hours to make a BCC functional material with a particle size of about 100nm, then add 50g of RF (metal cerium) nano powder and ball mill for 3 hours, and then put it into a graphite clamp pot container 100Kg of molten iron at 1500°C is poured into it, and finally cast into a small iron column with a square cross-section and grooves on each side, which becomes a square longitudinal channel embedded in the center of the plastic support.

Embodiment 3

[0022] First mix 1.0Kg mineral powder with 1.0Kg metal zinc powder, ball mill for 5 hours to make a BCC functional material with a particle size of about 100nm, then add 50g of RF (metal neodymium) nano powder and ball mill for 3 hours, and then put it into a graphite clamp pot container 100Kg of molten iron at 1500°C is poured into it, and finally cast into a small iron column with a square cross-section and grooves on each side, which becomes a square longitudinal channel embedded in the center of the plastic support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com