High-transmittance flexible touch material and making method thereof

A high light transmittance, soft technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of discussing or improving the light transmittance of undecorated boards, general products and methods that do not have suitable structures and methods, processing methods of soft-touch materials, and inconvenience in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

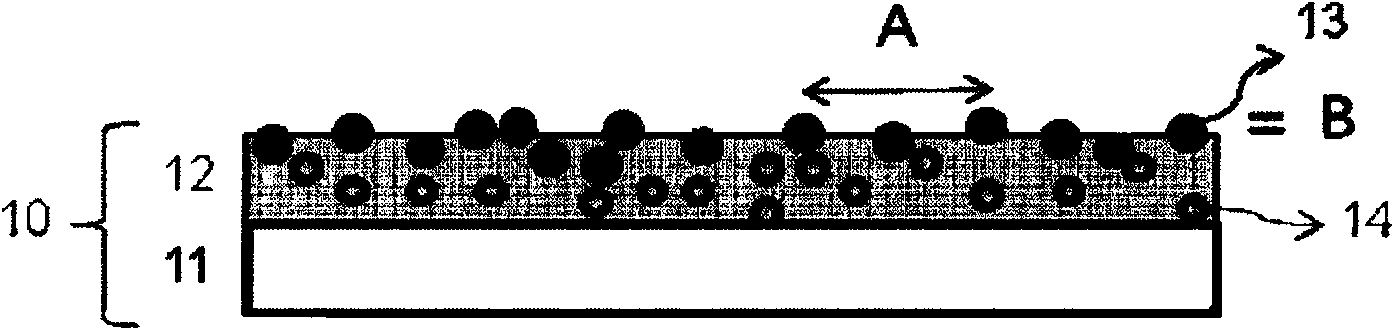

[0079] see figure 1 Shown is a schematic structural view of a high-transmittance soft-touch material according to a preferred embodiment of the present invention. 11 is a transparent plastic substrate on which a soft-touch coating 12 is coated to form a structure 10 of a high-transmittance soft-touch material. The soft touch coating 12 is made by the following method:

[0080] Polyurethane resin A

100 copies

10 copies

curing catalyst

0.5 parts

Elastic particle A

80 copies

[0081] Stir and mix the above materials to obtain a resin formula, which is the material of the soft touch coating 12 . The material is coated on a polyethylene terephthalate (polyethylene terephthalate, PET) film or plate, and after drying at 80° C. for 15 minutes, a 60-micron soft-touch decorative plate 10 (such as figure 1 shown).

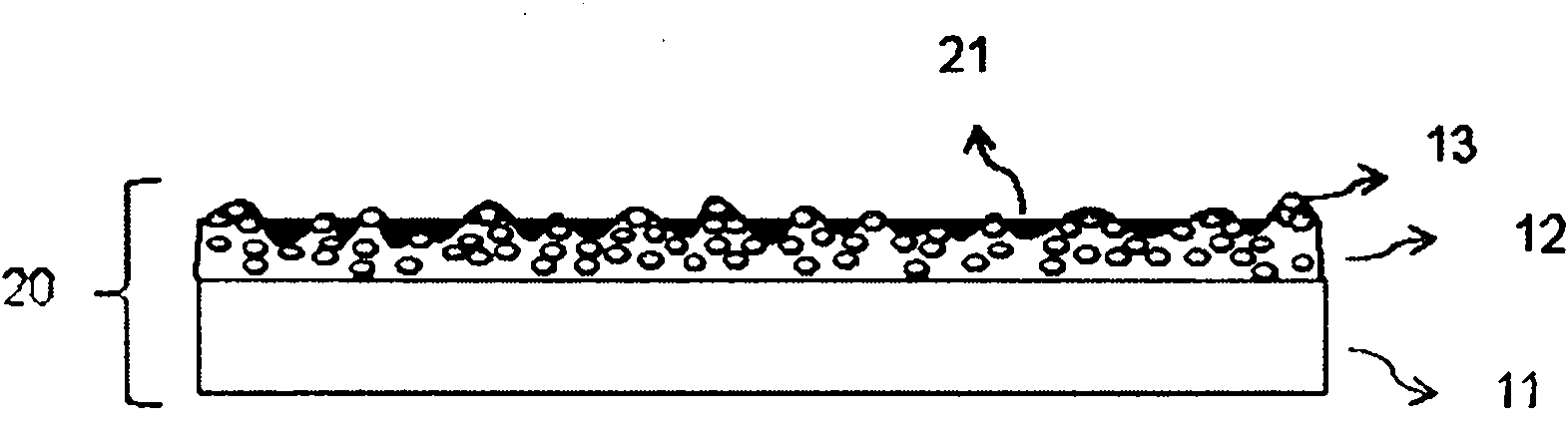

[0082] see figure 2 Shown is a schematic cross-sectional structure diagram of a high-transparency soft...

Embodiment 2

[0085] Stir and mix the above materials to obtain a resin formula, which is the material of the soft touch coating 12 . The material is coated on a polymethacrylic acid (PMMA) film or plate, and after drying at 80° C. for 5 minutes, a 100 micron thick soft-touch decorative plate 10 (such as figure 1 shown).

[0086] see figure 2 Shown is a schematic cross-sectional structure diagram of a high-transparency soft-touch decorative panel according to another preferred embodiment of the present invention. in such as figure 1 The surface of the soft-touch decorative board 10 shown is covered with polyurethane resin B as the transparent resin coating 21 on the surface of the soft-touch coating 12. This coating is about 1 to 2 microns thick to form a high-transparency soft-touch decoration Plate 20 with 40% light transmission.

Embodiment 3

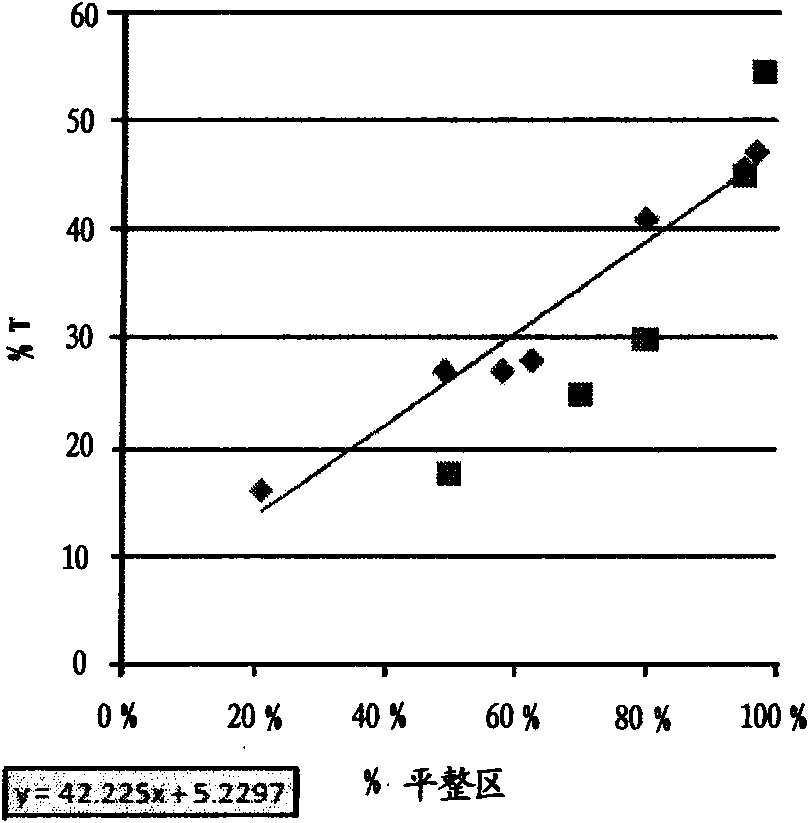

[0088] After mixing the main agent (polyurethane resin L60H150 from Xinzhengfeng Company) and hardener (aliphatic isocyanate H79 from Xinzhengfeng Company) in proportion, after stirring evenly at room temperature, coat the translucent resin on a surface of 180 μm On a polycarbonate transparent substrate, the coating thickness is between 70 μm. The coating was dried at 80°C for 5 minutes to give samples A, B and C. Cover the surface of A with a layer of transparent resin about 1 to 2 microns thick to obtain A1; cover the surface of B with a layer of transparent resin about 2 to 4 microns thick to obtain B1; cover the surface of B with a layer of about 1 to 2 microns thick transparent resin 2 micron thick clear resin, yielding B2. The features of its surface are magnified 50 to 100 times under an optical microscope, and its photos are as follows Figure 6 Shown are the schematic diagrams of the observation photos A, B, C, A1, B1, B2 and E of the optical microscope of the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com