Anti-glare and anti-static light radiation curing coating composition

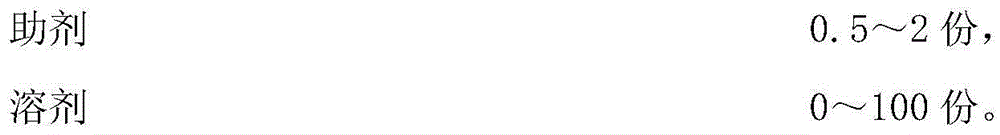

A technology of radiation curing and composition, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of difficult to wipe clean, easy to adhere to dust, high energy consumption, etc., and achieve synergistic effect of anti-glare function Strong, wide coating method, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

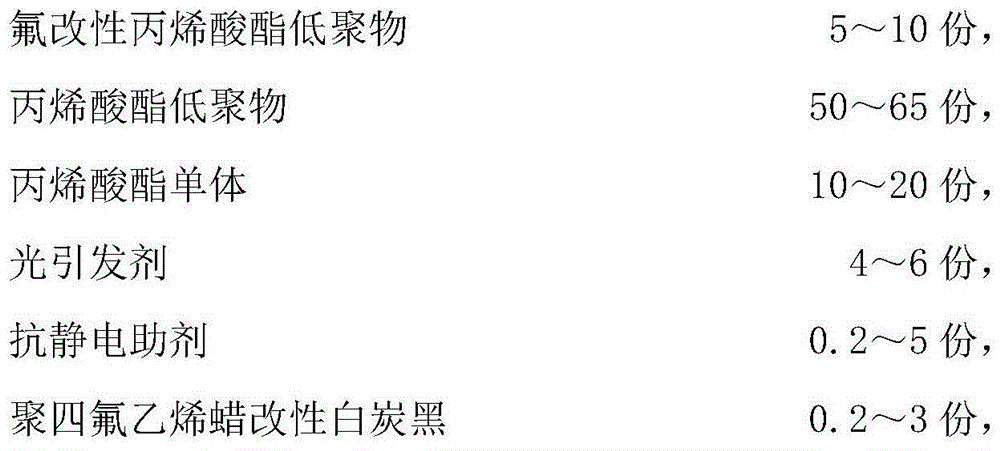

[0025] This embodiment relates to an antistatic, anti-glare radiation curing coating, including the components in parts by weight shown in Table 1; each component is taken in parts by weight, and then the components are uniformly mixed to obtain coating composition.

[0026] Table 1

[0027]

[0028]

[0029] Implementation Effect:

[0030] Mix the coating prepared above with an organic solvent (a mixed solution of butyl acetate, n-butanol, and m-trifluorotoluene in a mass ratio of 0.5:1:2) according to a mass ratio of 1:1.5, and spray on an acrylic plate , baked at 45 degrees Celsius for 4 minutes, and then UV cured to obtain a plate with a curing energy of 900mJ / cm 2 , the test results of the radiation cured coating of this formulation are as follows:

[0031] 1. The surface resistance of the coating is 3.7*10^9. After rubbing back and forth with a dust-free cloth for 5 times, paper scraps of 1cm*1cm (length*width) are covered on the board of A4 size. After picking ...

Embodiment 2

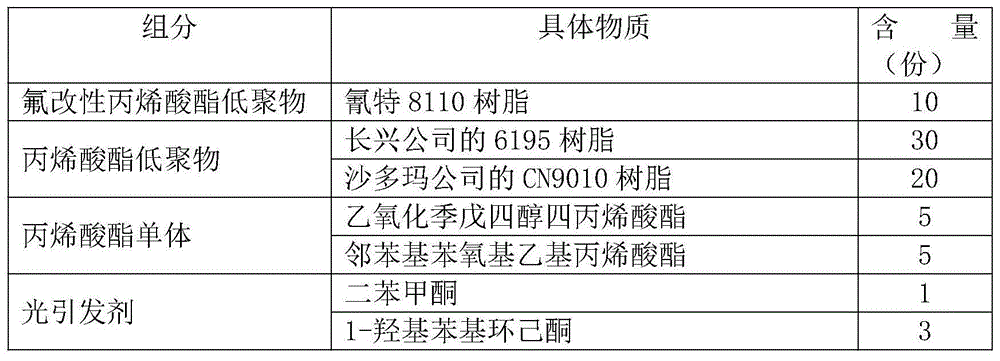

[0039] This embodiment relates to an antistatic, anti-glare radiation curing coating composition, including the components in parts by weight shown in Table 2; take each component in parts by weight, and then mix the components uniformly, then A coating composition is prepared.

[0040] Table 2

[0041]

[0042] Implementation Effect:

[0043] The paint prepared above was mixed with an organic solvent (a mixed solution of butyl acetate, n-butanol, and m-trifluorotoluene in a mass ratio of 0.5:1:2) according to a mass ratio of 1:1.5, and was sprayed on an acrylic plate. Coating, baking at 45 degrees Celsius for 4 minutes, and then UV curing, the curing energy is 800-1000mJ / cm 2 , the test results of the radiation cured coating of this formula are as follows:

[0044] 1. The surface resistance of the coating is 7.5*10^9. After rubbing back and forth with a dust-free cloth for 5 times, 1cm*1cm (length*width) paper scraps are covered on the A4-sized board. After picking up t...

Embodiment 3

[0051] This embodiment relates to an antistatic, anti-glare radiation curing coating composition, including each component in parts by weight shown in Table 3; take each component in parts by weight, and then mix the components uniformly A coating composition is prepared.

[0052] table 3

[0053]

[0054] Implementation Effect:

[0055] The coating prepared above is mixed with an organic solvent (a mixed solution of butyl acetate, n-butanol, and m-ditrifluorotoluene in a mass ratio of 0.5: 1: 2) according to a mass ratio of 1: 1.5, and coated on a PMMA / PC composite board The PMMA surface is sprayed, baked at 45 degrees Celsius for 4 minutes, and then cured by UV light with a curing energy of 1000mJ / cm 2 , the test results of the radiation cured coating of this formula are as follows:

[0056] 1. The surface resistance of the coating is 6.0*10^9. After rubbing back and forth with a dust-free cloth for 5 times, 1cm*1cm (length*width) paper scraps are covered on the A4 siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com