Polarized light plate and preparation method

A manufacturing method and technology of polarizing plates, applied in optics, polarizing elements, nonlinear optics, etc., can solve the problems of poor adhesion of polarizing plates and aggravate different shrinkage on both sides, and achieve improved dimensional stability, excellent optical properties, and improved The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

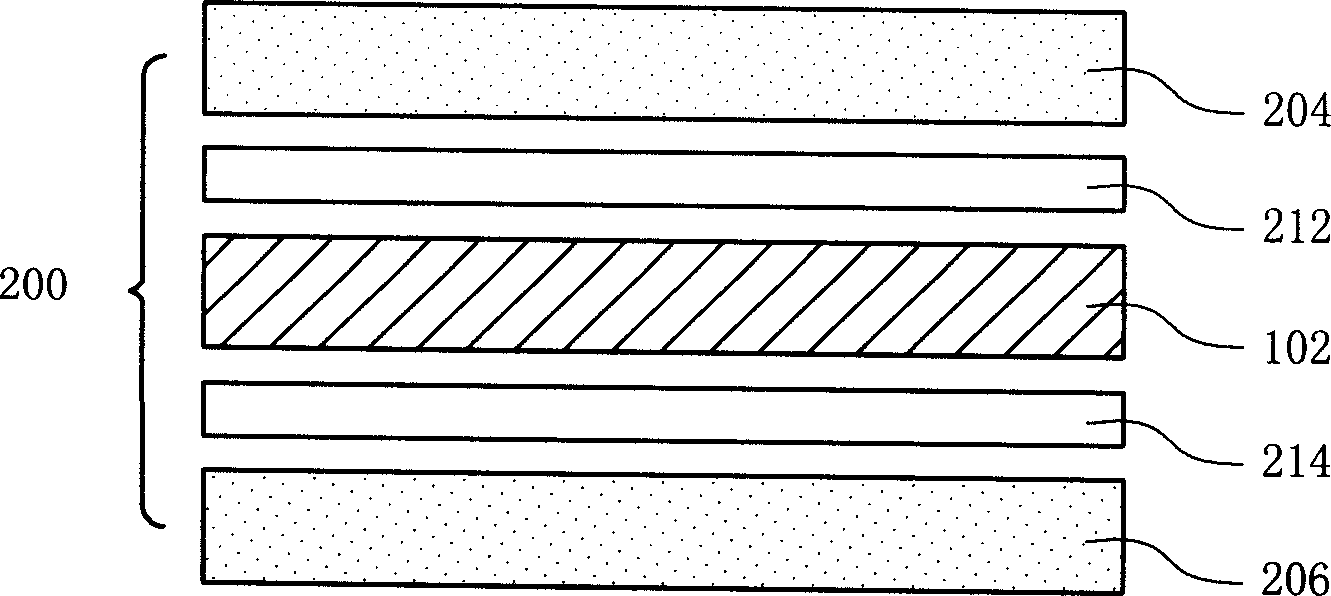

[0036] Figure 2A Shows a schematic diagram of a preferred embodiment of the present invention, and Figure 2B Illustrate Figure 2A Flow chart of the manufacturing method. First, a first protective layer 206 is provided. The material of the first protective layer 206 is selected from the group consisting of cyclic olefin copolymer (coc) and cyclic olefin polymer (cop) ( Step 222).

[0037]Cyclic olefin copolymers and cyclic olefin polymers have good moisture resistance. Moreover, since the cycloolefin copolymer and the cycloolefin polymer have high transparency and small tortuosity, they also have excellent optical properties, such as average wavelength dispersion and good optical isotropy. In addition, cycloolefin copolymers and cycloolefin polymers have low moisture absorption, low moisture permeability, and high heat resistance. In other words, the protective layer 206 can maintain a stable size even in a high-temperature and high-humidity environment.

[0038] Then, the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com