Device and method for strengthening filtering of internal-pressure membrane by using pulsed electric field

A technology of pulsed electric field and internal pressure membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as increasing processing costs and operational difficulties, affecting membrane service life, and polluting water inlets. Improve the degree of concentration polarization and membrane fouling, prolong the service life of the membrane, and reduce the total hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

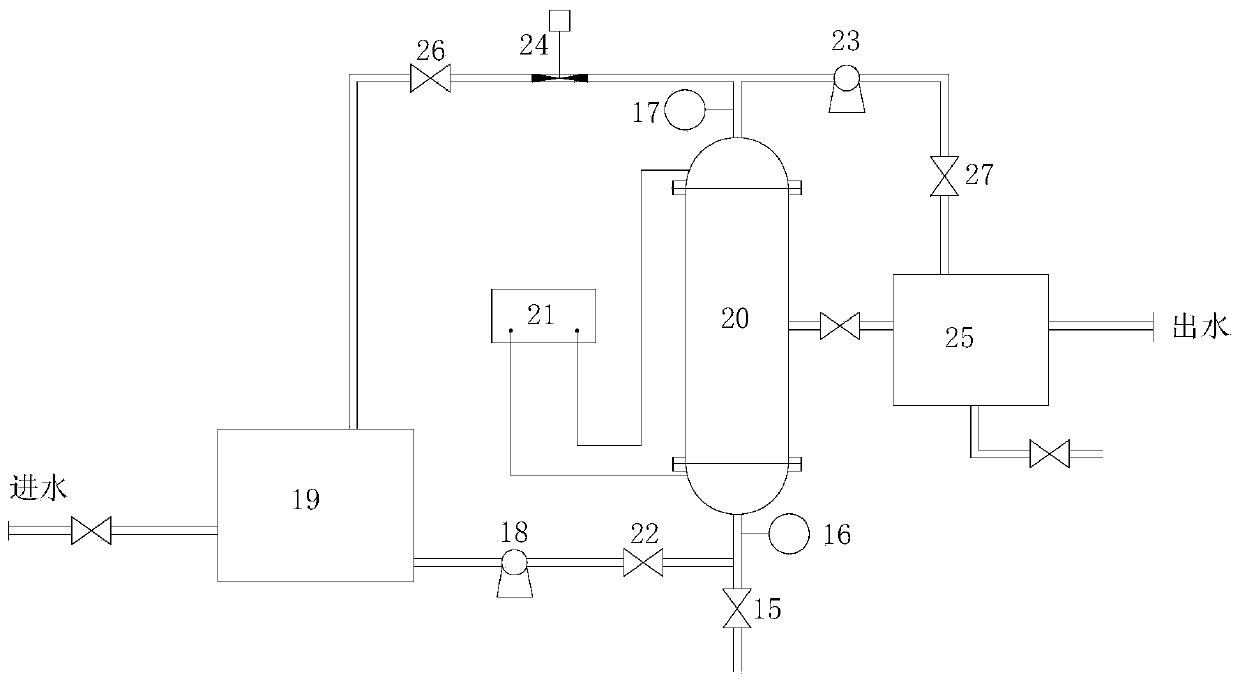

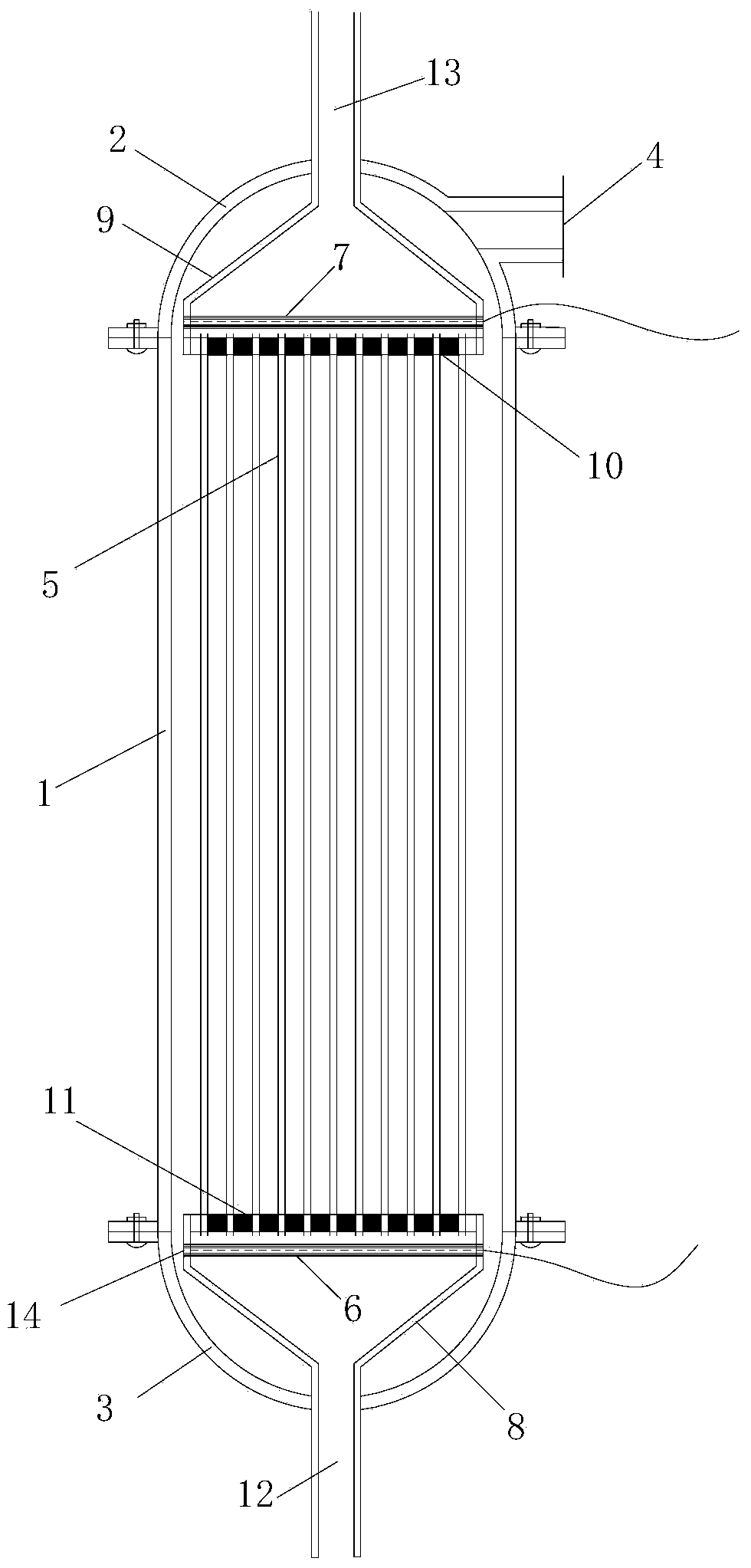

[0027] A device that utilizes a pulsed electric field to strengthen internal pressure membrane filtration, including a casing, a hollow fiber membrane module 20 and a pulse power supply 21 inside, the casing consists of an upright cylinder 1 and upper and lower heads arranged at its two ends Composed of 2 and 3, the cylinder 1 and the heads at both ends are connected into one body by flanges.

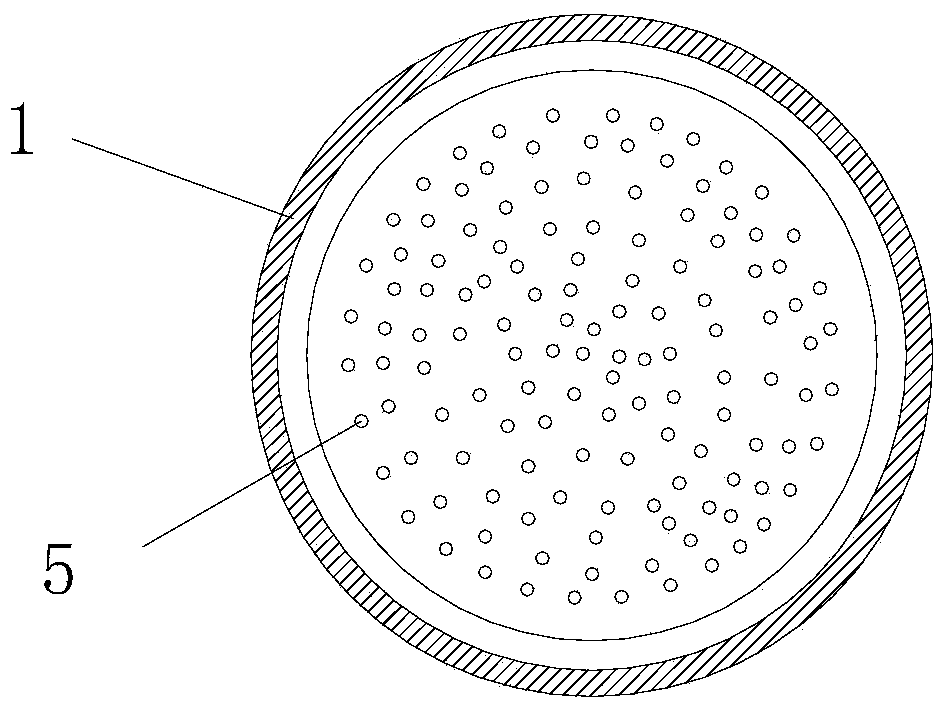

[0028] The upper head 2 is provided with a permeate outlet 4, and the hollow fiber membrane module includes a membrane filament bundle composed of several membrane filaments 5 arranged in parallel and spaced apart, a cathode electrode 6, an anode electrode 7, and inlet and outlet covers 8, 9. The membrane tow is arranged in the cylinder body 1, and its two ends are fixed by upper and lower membrane heads 10, 11, and a water inlet cover 8 is arranged between the lower membrane head 11 and the lower sealing head 3, and the upper membrane head 10 is connected with the upper sealing head. A...

Embodiment 2

[0036] The influent is humic acid feed liquid, the content of humic acid is 20mg / l, the content of potassium chloride is 0.001mol / l, the pH is 6.5, the running time is 7h, and the cleaning time is 15min. The membrane module is composed of two membrane filaments. The membrane material is PVC, the length of the membrane wire is 26.5cm, and the filtration area is 0.003m 2, the cross-flow flow rate is 5ml / min, the pulse frequency is 10Hz, and the pulse duty cycle is 70%. The initial pressure difference was 26.3kpa (experimental group) and 26.5kpa (control group), and pulsed electric field (3V) was used to strengthen the filtration. After the operation, the pressure difference was 31.3kpa (increased by 19%); the filtration process without pulsed electric field , after the operation, the differential pressure was 33.2kpa (increased by 25.3%), that is, the pulsed electric field was used, the differential pressure rise slowed down, and the degree of membrane pollution was reduced; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com